Patents

Literature

82results about How to "Reduce maintenance man-hours" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

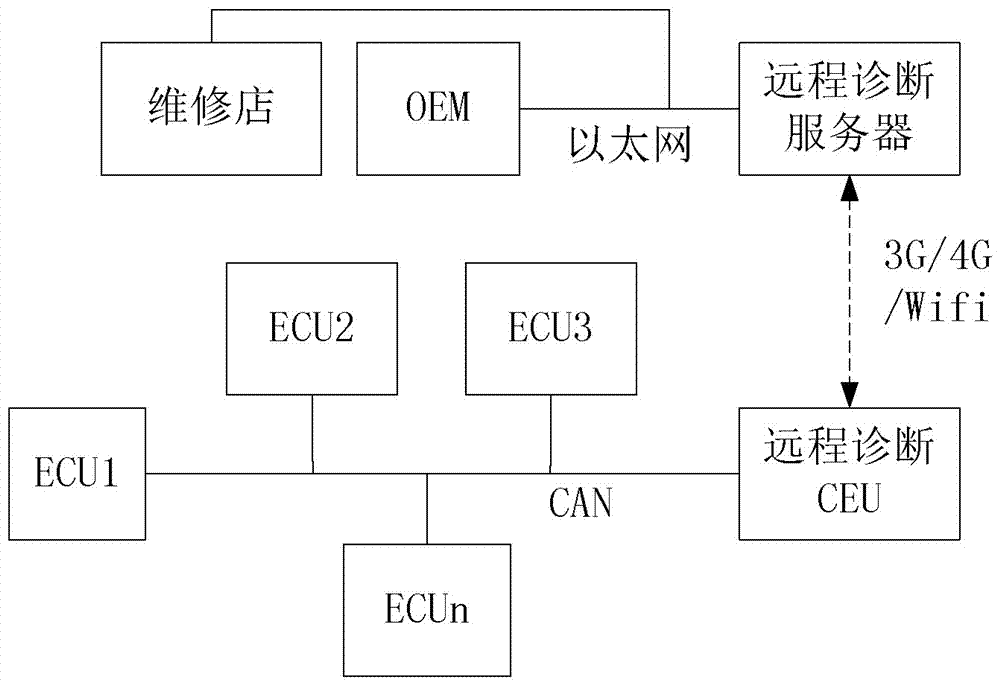

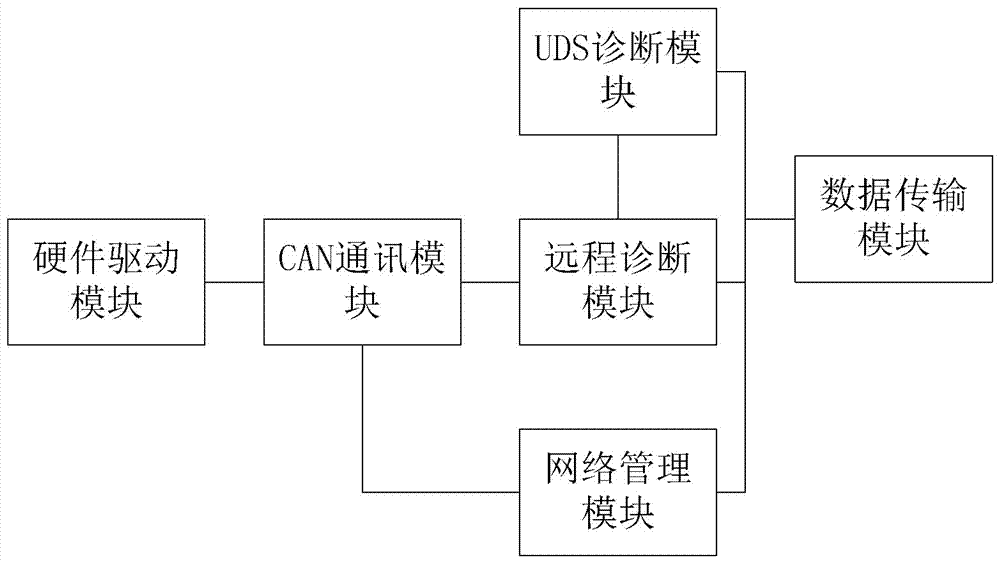

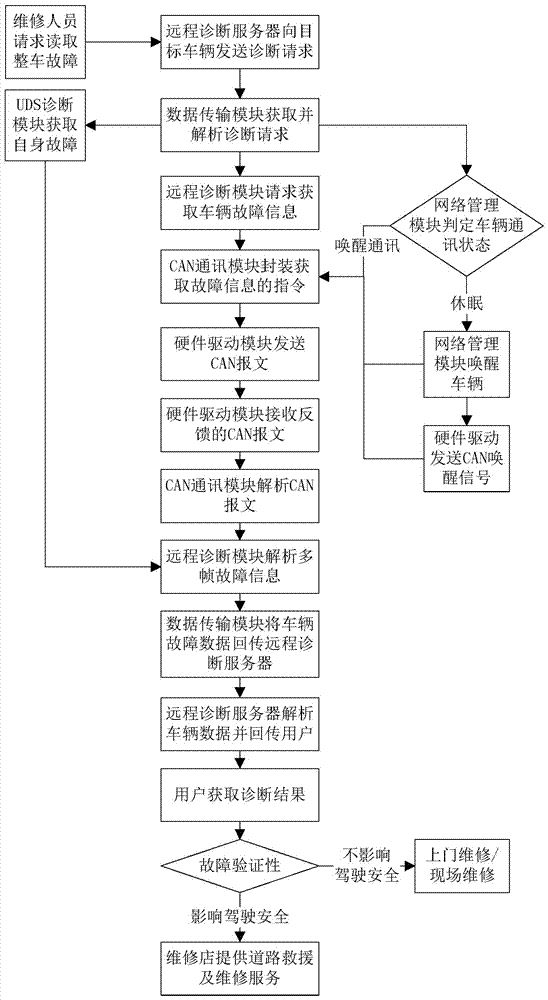

Vehicle fault remote diagnosis system and method

InactiveCN107272649AImprove maintenance efficiencyEnsure safetyElectric testing/monitoringTime informationEngineering

The invention provides a vehicle fault remote diagnosis system, which includes a remote diagnosis ECU and a remote diagnosis server. The remote diagnosis ECU is connected with a CAN bus of a vehicle. The remote ECU collects fault information stored in ECUs on the vehicle and collects real-time dynamic information of the vehicle according to the needs of a user. Meanwhile, the remote diagnosis ECU executes the real-time information interaction between the vehicle and the remote diagnosis server. The ECUs on the vehicle refer to all the other ECUs on the vehicle except the remote diagnosis ECU. The remote diagnosis server stores an ECU diagnosis database, the vehicle model and the vehicle VIN code information, sends the collected diagnosis request of the user to the remote diagnosis ECU, and converts fault data returned by the remote diagnosis ECU into a diagnosis result which is sent to the user. According to the invention, a faulty vehicle can be remotely diagnosed in real time, the influence of the remote diagnosis on the normal running of the vehicle is eliminated, and the vehicle driving safety is ensured.

Owner:SOUEAST

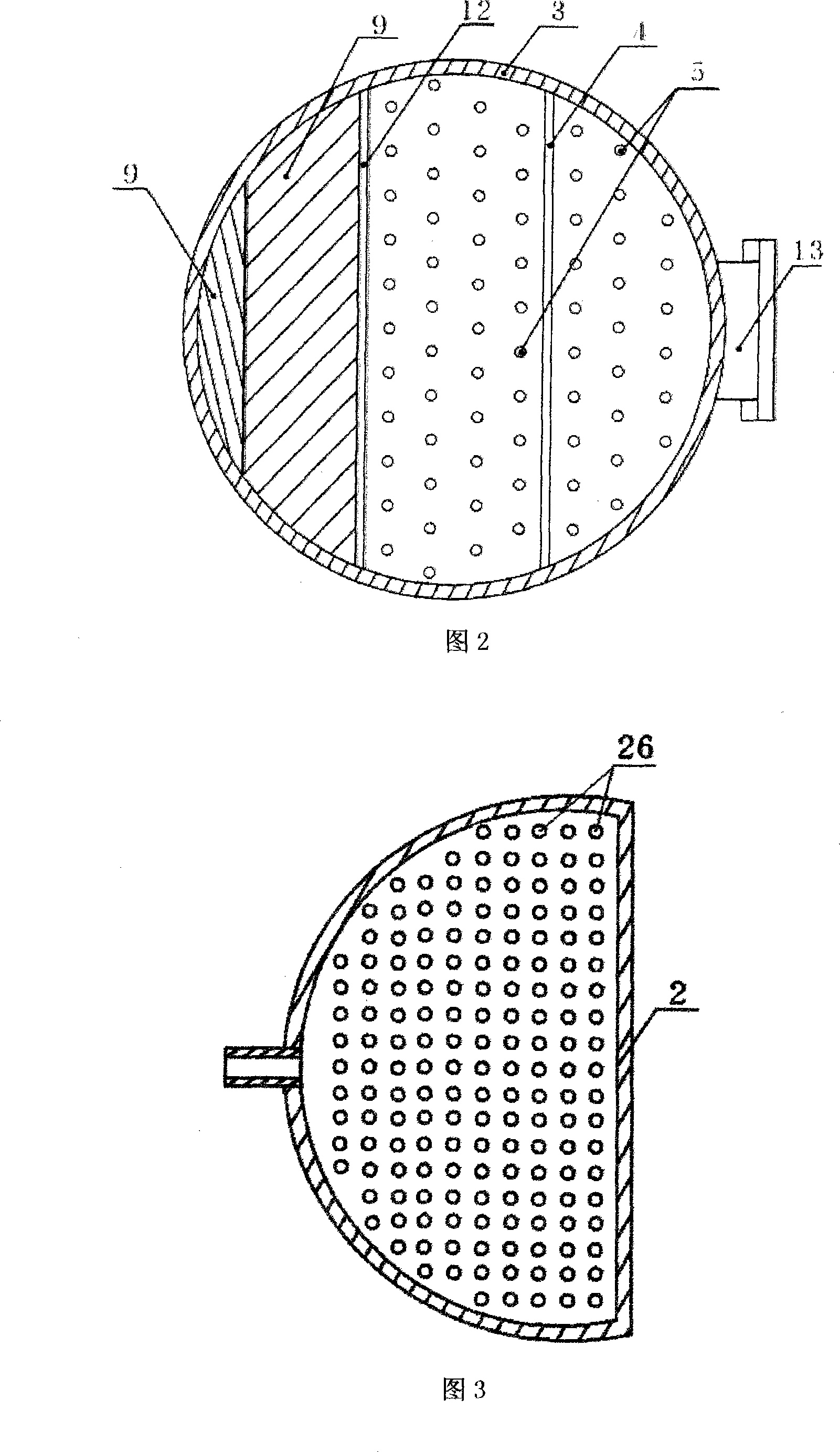

Efficient simplified wheat flour milling technology and efficient simplified wheat flour milling device

InactiveCN103894260ADoes not destroy nutrientsKeep the scentGrain treatmentsProcess engineeringIndustrial engineering

The invention relates to an efficient simplified wheat flour milling technology comprising the working procedures of shelling, residue grinding, core grinding, tailing grinding and flour clearing, and an efficient simplified wheat flour milling device. In the shelling working procedure, an extrusion cutting grinder with a superior stripping and scraping function is used for replacing the existing tooth roller flour mill and is taken as a main residue making device; in the core grinding working procedure, an efficient impact flour mill is used for replacing a smooth roll flour mill and is taken as a main flour making device, and the grinding function of the efficient impact flour mill is more than twice as high as that of the prior art; two wraps are wetted by water, residue grinding is carried out for three times, and germ extraction is carried out during residue grinding; after the core 1 and the core 2 are slightly ground by a roller mill, the aim of rapidly and efficiently producing the high-quality flour at low temperature with low consumption can be achieved by virtue of a strong impact method of a water cooling efficient impact grinder and the like. The wheat flour milling production line extrusion process designed by the invention is simple in process, low in civil engineering equipment investment, high in production efficiency, simple in operation and management and low in energy consumption; the produced high precision flour is large in proportion; the produced flour is good in edible quality and food production performance; the produced flour has the advantages that the original fragrance of the wheat is maintained by the flour, and the like.

Owner:王洪福

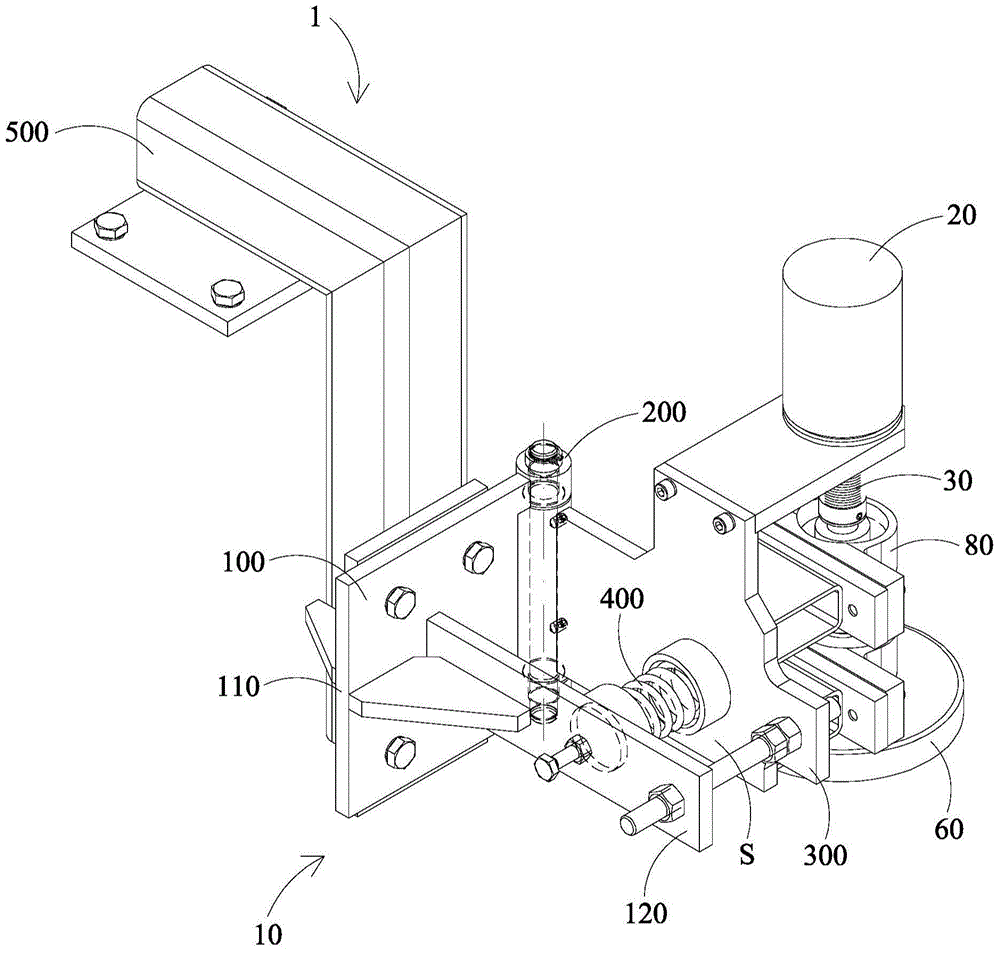

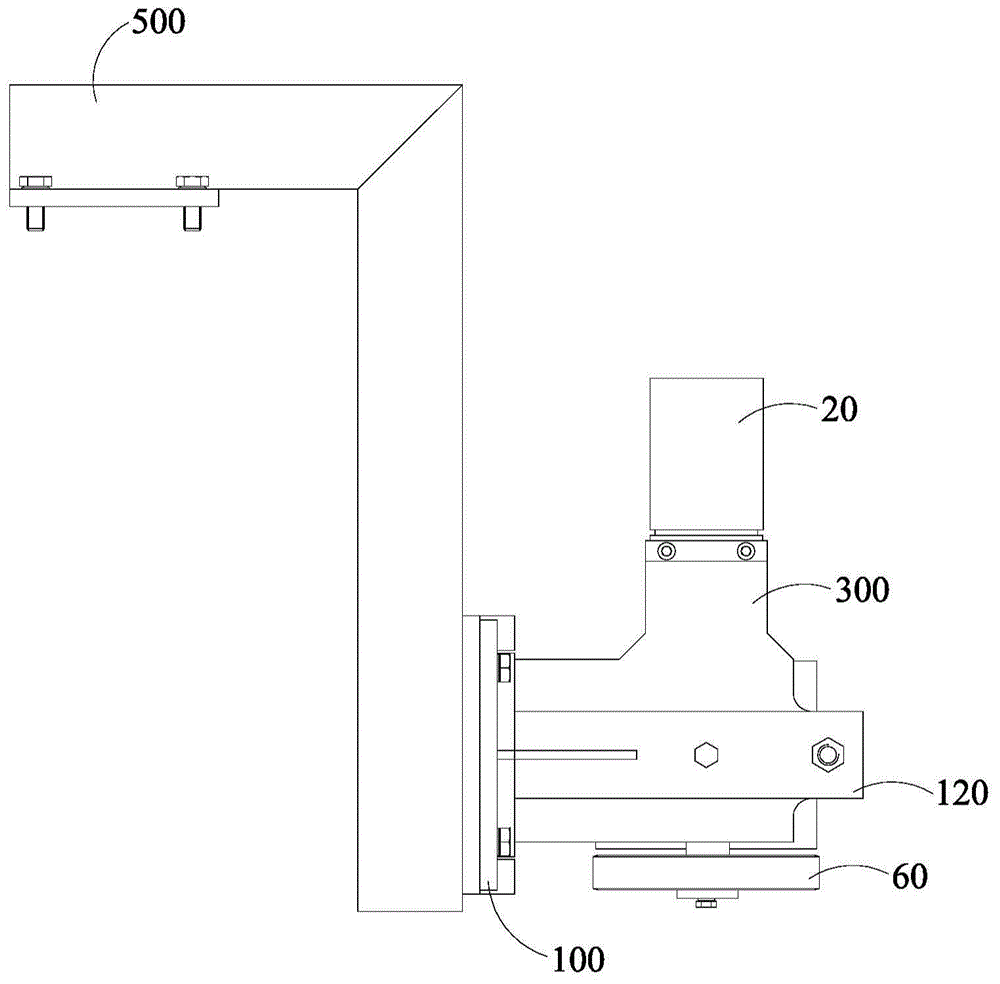

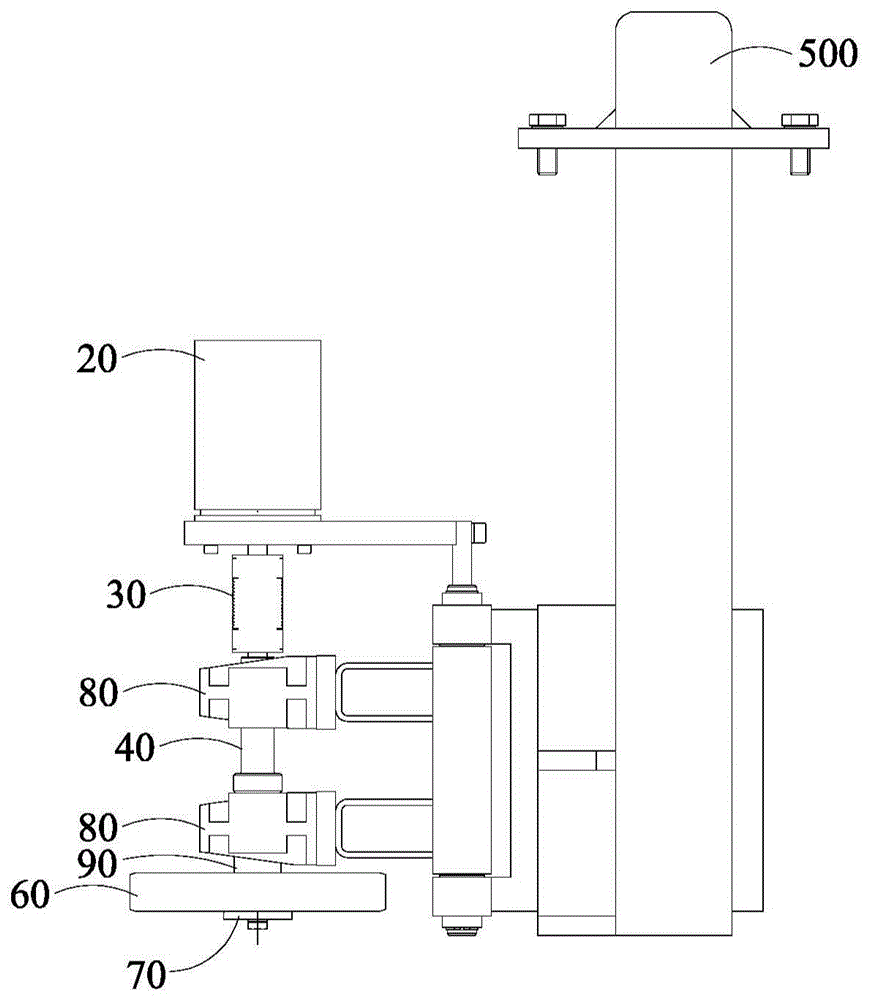

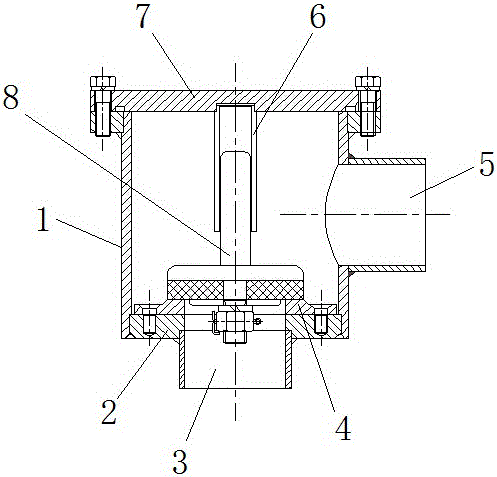

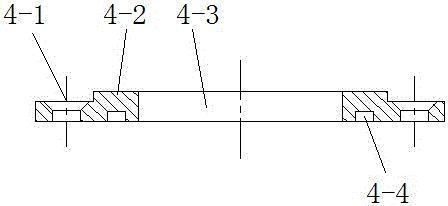

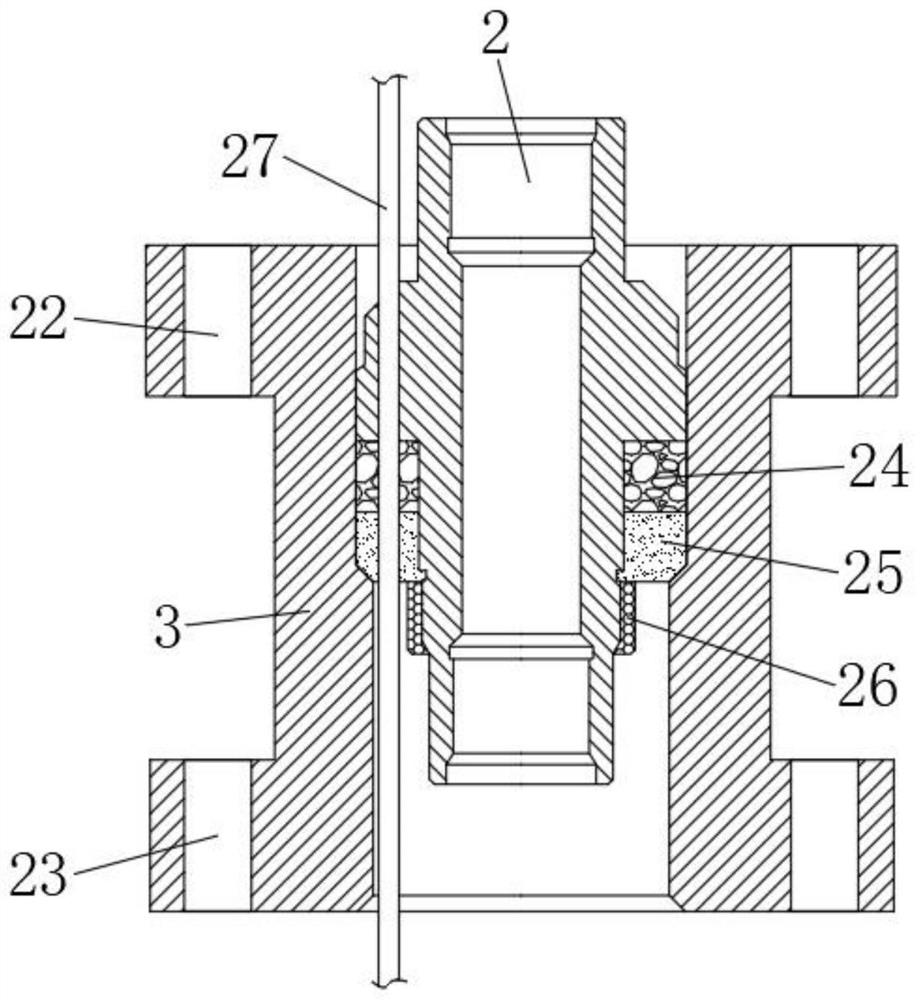

Detecting device capable of adjusting transmission gap and transmission gap adjusting mechanism

ActiveCN104457661AAvoid Accumulation Errors in ReadingsGuaranteed meshingMeasurement devicesGearing detailsScrew threadRack and pinion

The invention discloses a detecting device capable of adjusting a transmission gap and a transmission gap adjusting mechanism. The detecting device capable of adjusting the transmission gap comprises the transmission gap adjusting mechanism and a displacement detection mechanism. The transmission gap adjusting mechanism comprises a first support, a rotating assembly, a second support and an elastic assembly, wherein the first support is provided with a first plate and a second plate perpendicular to the first plate, the first plate is fixed to a rack, the second plate is provided with at least two threaded holes, the rotating assembly comprises a rotating shaft, the side edge of the first plate of the first support is fixed to the rotating assembly, the second support is fixed to the rotating assembly and is parallel to the second plate of the first support, and the elastic assembly is arranged in containing space. According to the detection device capable of adjusting the transmission gap, by keeping meshing of a gear and a rack, accumulated errors of reading of a jumping gear and an encoder due to long-term meshing abrasion can be effectively avoided, the maintenance labor is reduced, and the equipment cost is reduced.

Owner:TAIZHONG TIANJIN BINHAI HEAVY MACHINERY

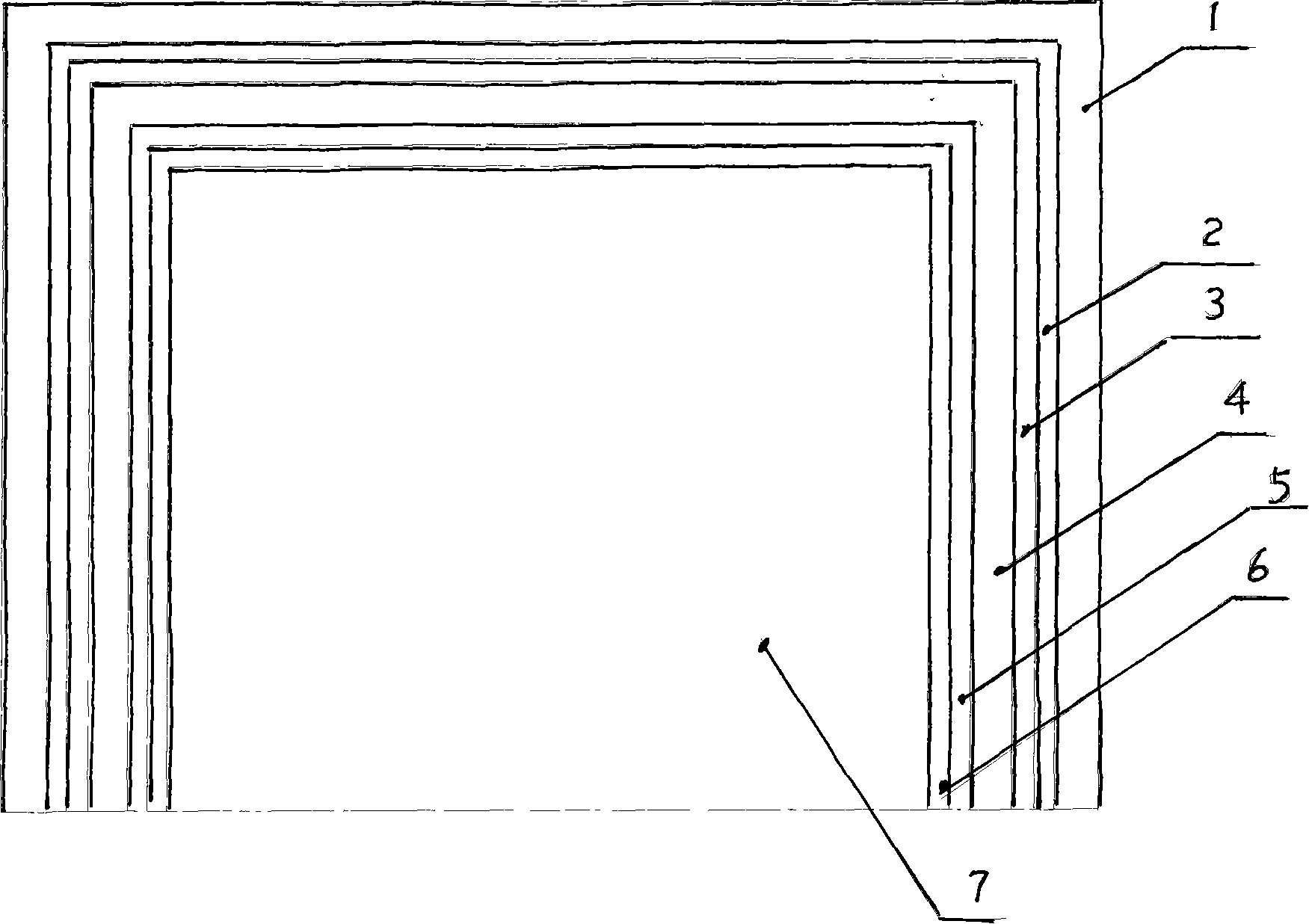

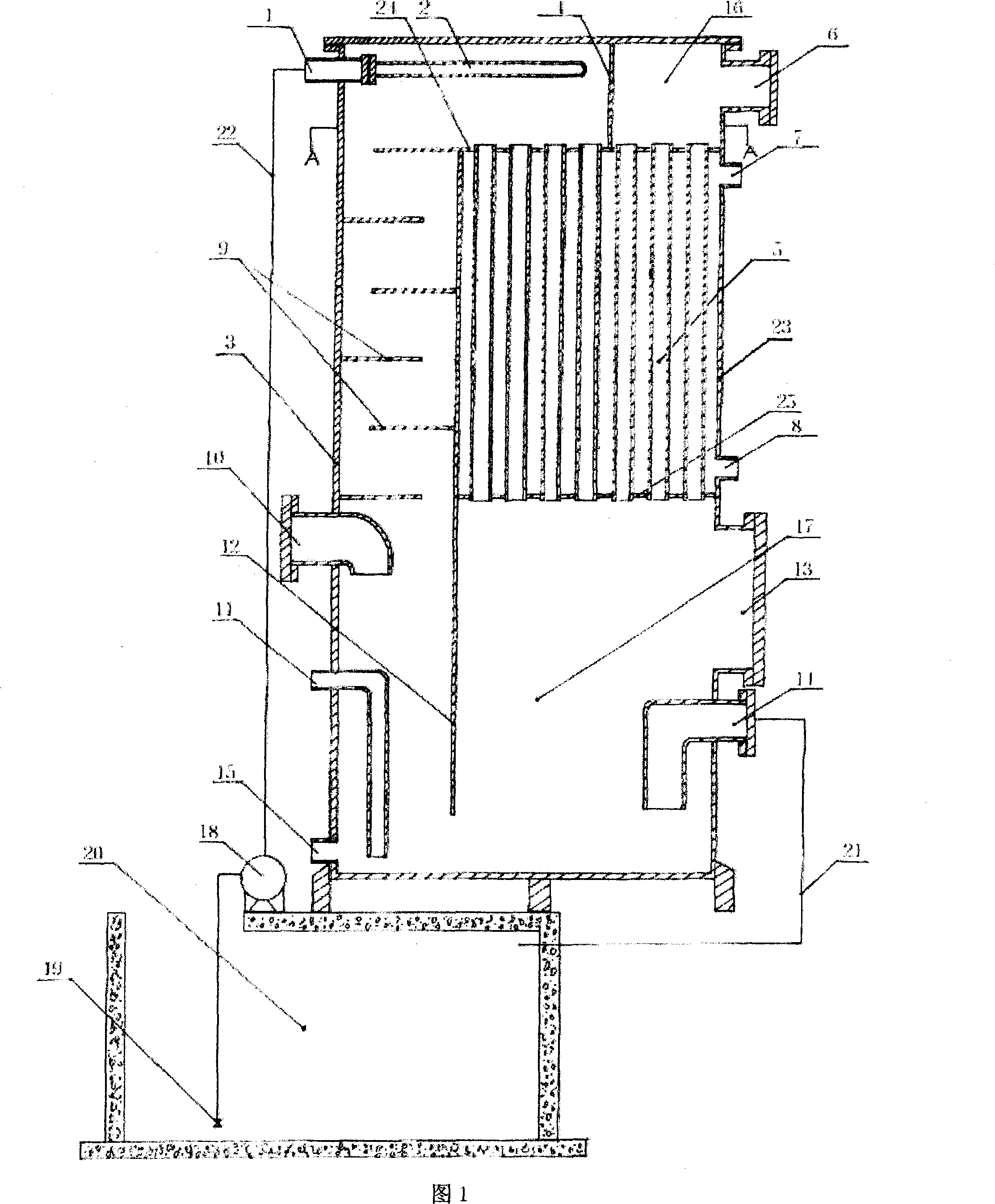

Preparation method of industrial furnace

InactiveCN101140142AHigh temperature resistantLow thermal conductivityLinings repairFiberHeat conducting

The invention relates to a manufacture method for an industrial kiln. The inner surface of the manufactured kiln body is orderly provided with a fiber bonding additive layer, a refractory fiber bonder layer, a refractory fiber block layer, a high-temperature infrared bonding additive layer and a high-temperature infrared composite liquid emulsified material layer; the refractory fiber bonder can be a high-temperature binder or a high-temperature refractory fiber bonder; the refractory fiber block can be a refractory ceramic fiber block, a aluminum silicate cotton block for heat insulation or a polycrystalline mullite fiber block; the high-temperature infrared composite liquid emulsified material can be a high-temperature infrared coating, a high-temperature infrared radiation coating or a high-temperature infrared energy-saving coating. The working temperature of the industrial kiln manufactured by the invention is 800 to 1600 degrees Celsius; the invention has the advantages of the high temperature resistance, the low heat conducting coefficient, the small heat loss, the small environmental pollution, the complete combustion, the fast temperature rise speed, the low energy consumption, the good heat shock resistance, the antioxidation, the corrosion resistance, no cracking, no peeling, the light weight, the long service life, the less maintenance time and the high labor productivity.

Owner:高晓吾

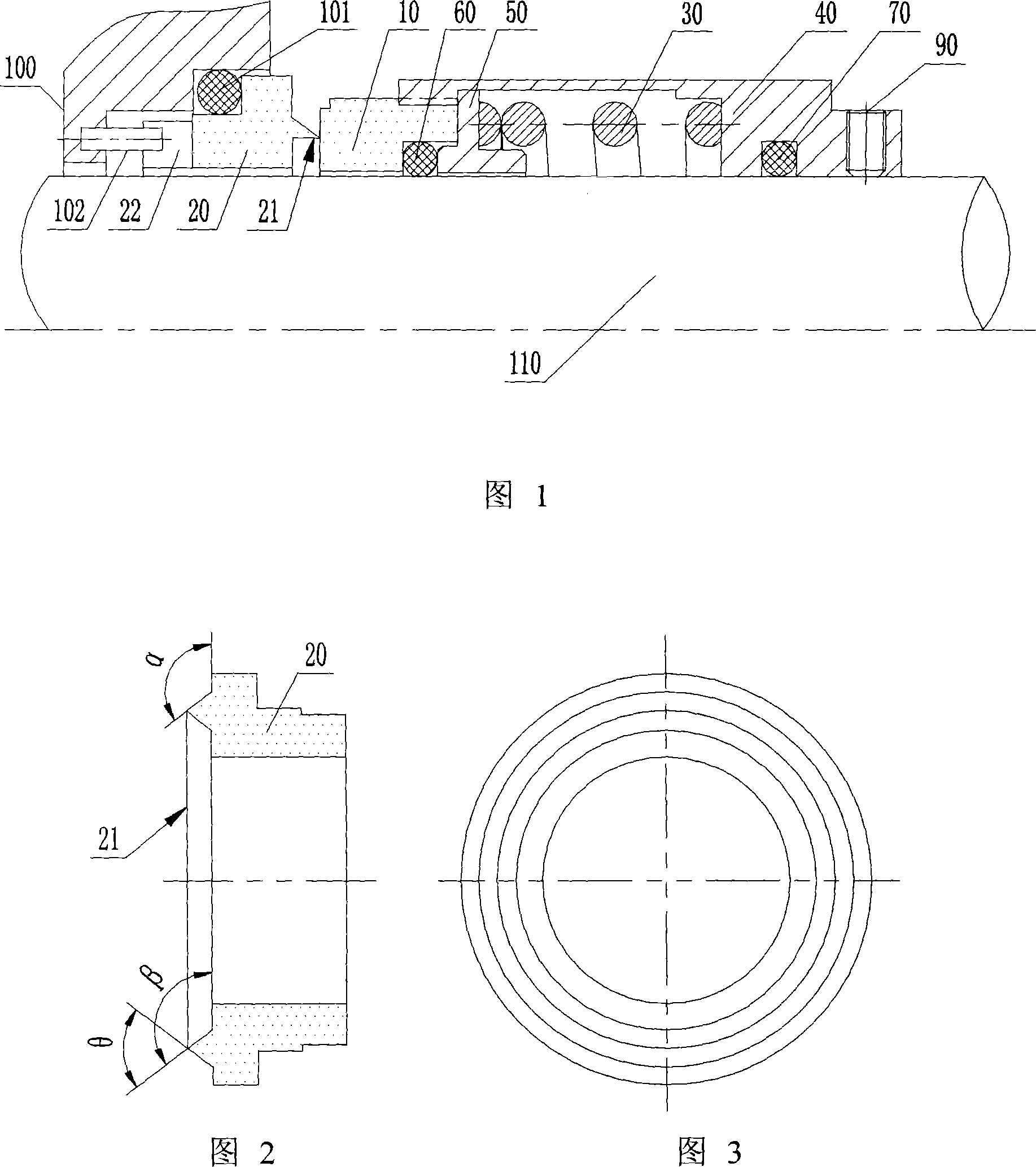

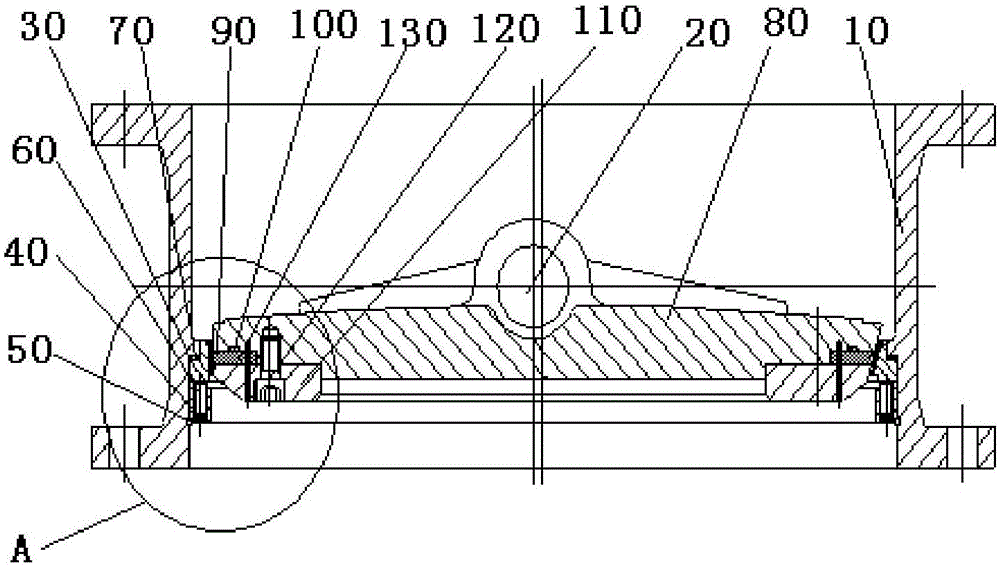

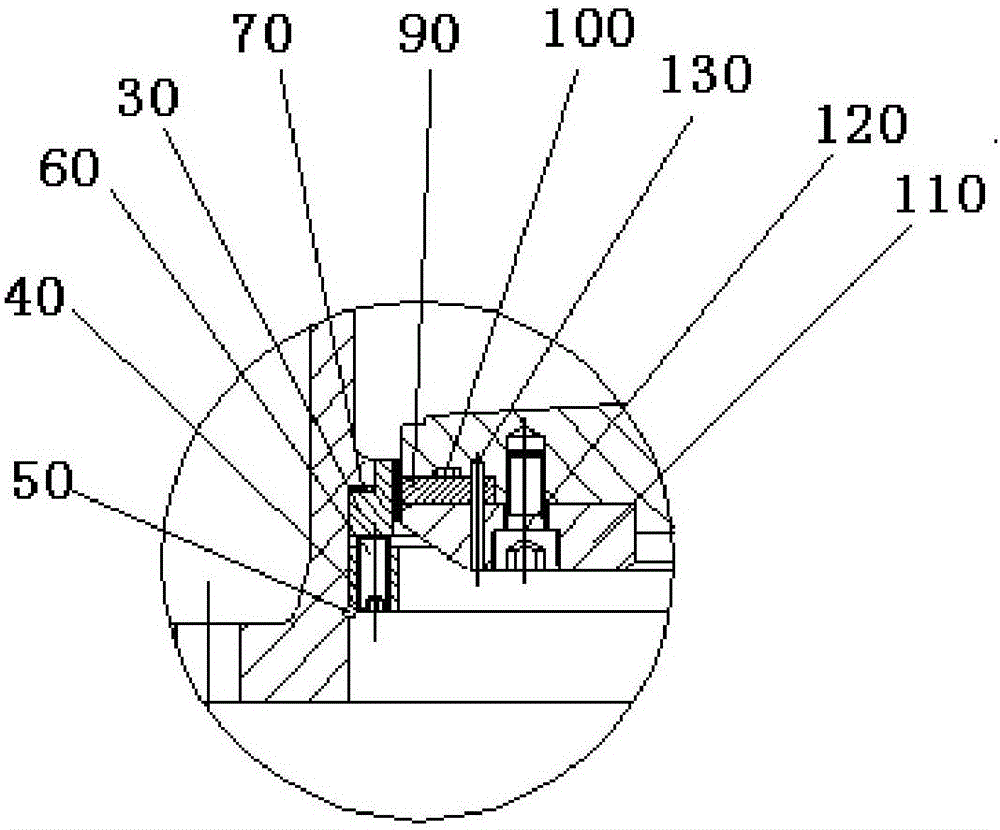

Mechanical sealing device for high-viscosity medium

InactiveCN101021270AExtended service lifeImprove operating conditionsEngine sealsEngineeringHigh pressure

The present invention relates to a rotating shaft end face sealing device for hydraulic machine containing various high-viscosity fluids and impurities. It is characterized by that one of moving ring and static ring is made into the form with cutting edge, and between the moving ring and static ring a seal-fit of end face and cutting edge is formed, so that it can make the mechanical sealing end face produced large end face specific pressure, a high-pressure can be formed on the sealing end face, therefore its sealing operation condition can be improved.

Owner:合肥华升泵阀股份有限公司

Process method for carrying out integral soldering on armature

InactiveCN102837094AImprove solder qualityImprove adhesionSoldering apparatusTinningTemperature control

The invention relates to a process method for carrying out integral soldering on an armature. Before the armature is subjected to integral soldering, a commutator pre-tinning process is added; a spiral wound gasket is used for replacing an asbestos cord; the spiral wound gasket is placed between a tin pan and the armature; the tin pan is made of titanium alloy; and a PID (Proportion Integration Differentiation) intelligent control instrument is adopted to carry out temperature control and maintenance. The commutator pre-tinning process is designed from the economy, the practicality and the manufacturability and takes an important effect in the process method for carrying out integral soldering on the armature. After the pre-tinning is carried out, the reliability of the integral soldering of the armature is improved, the pseudo soldering and the missing soldering are avoided, the repair rate of the armature is reduced and the motor quality is fundamentally improved. According to the method, the armature soldering efficiency is improved for dozens of times; the temperature control and constant temperature effects are good; the liquidity of molten tin, the welding strength and the welding reliability are improved; and the integral soldering quality of the armature is improved.

Owner:JIANGLU MACHINERY & ELECTRONICS GROUP

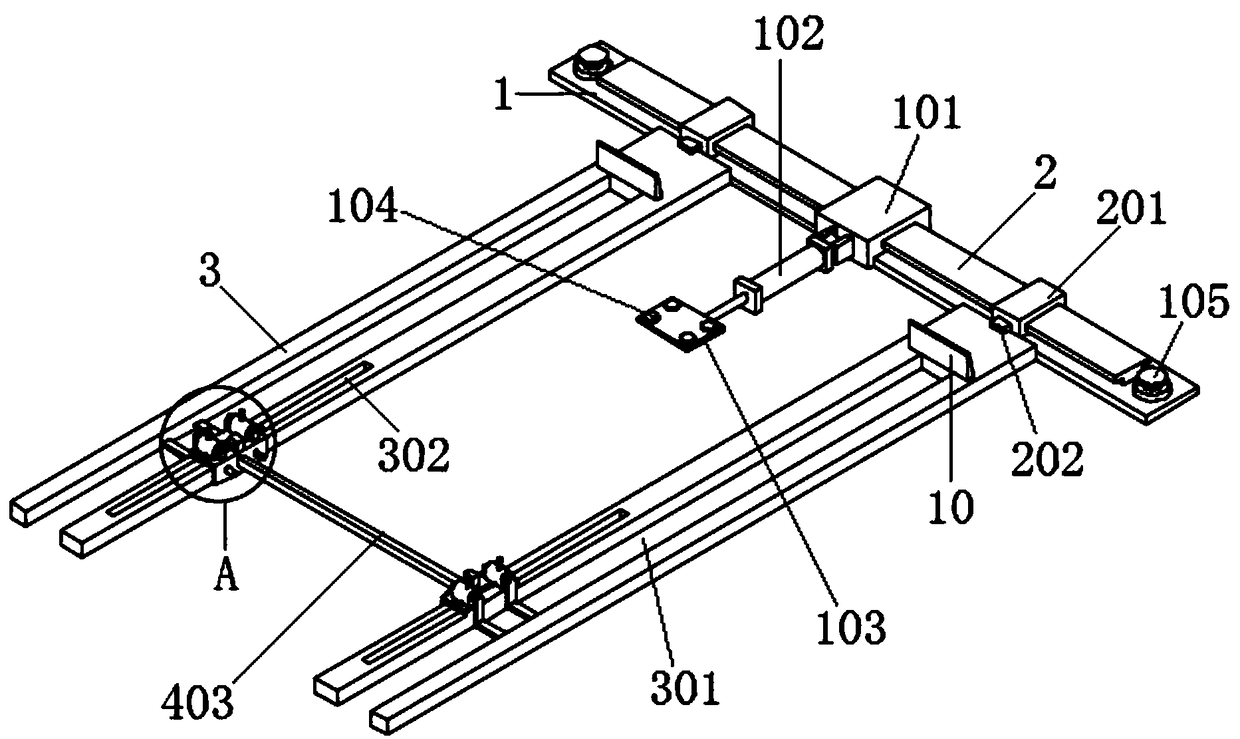

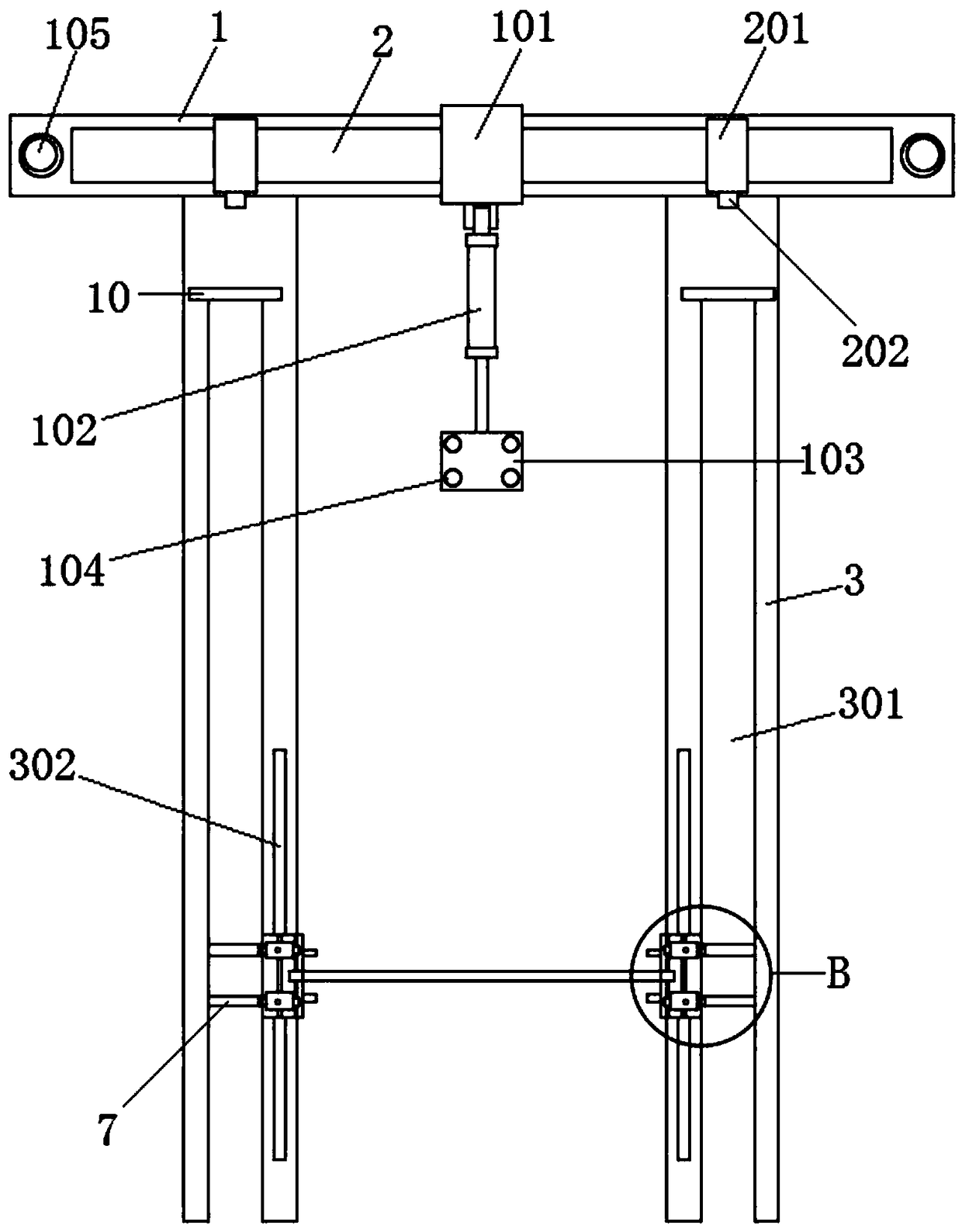

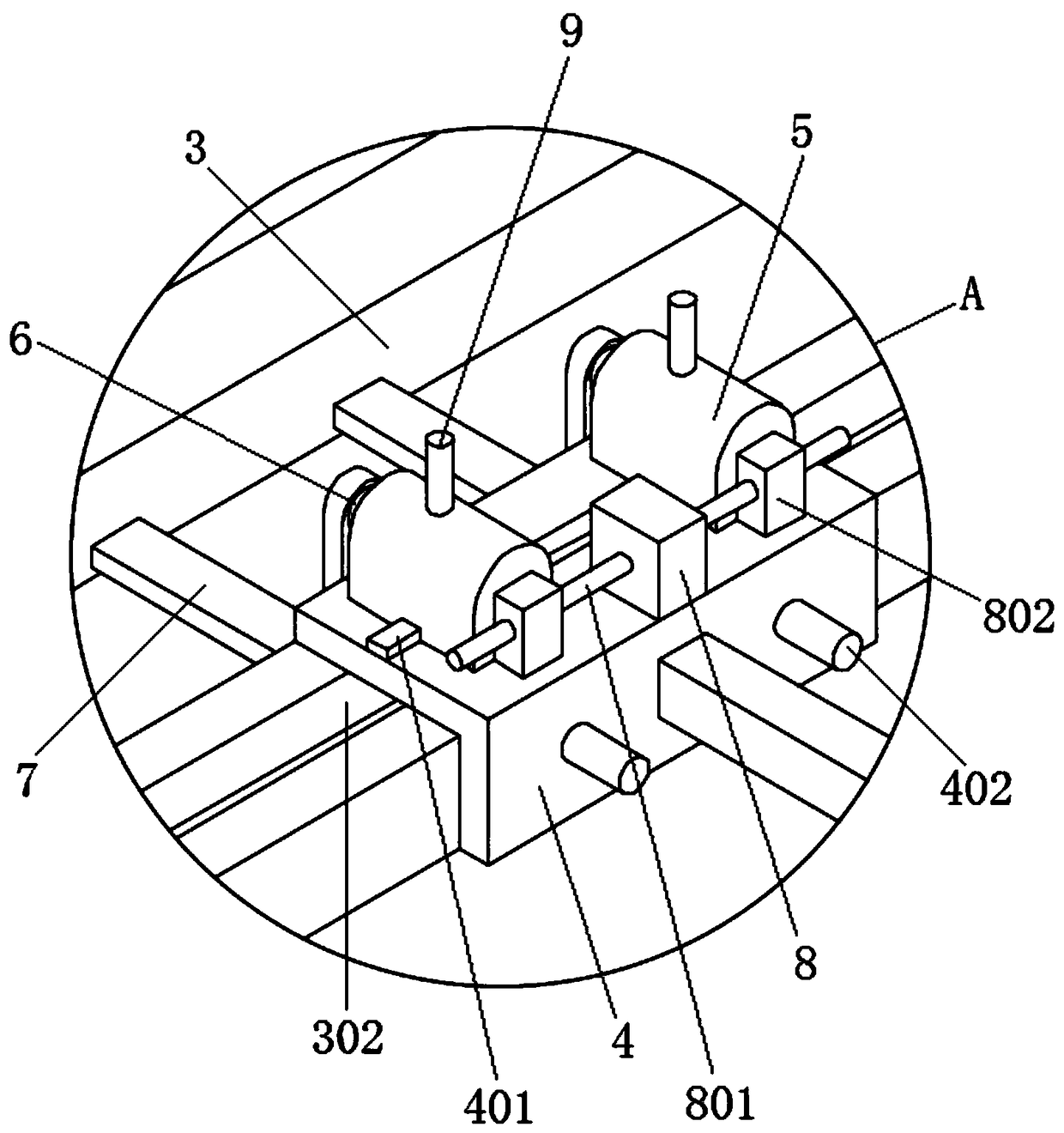

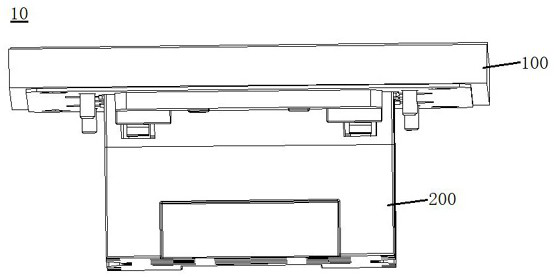

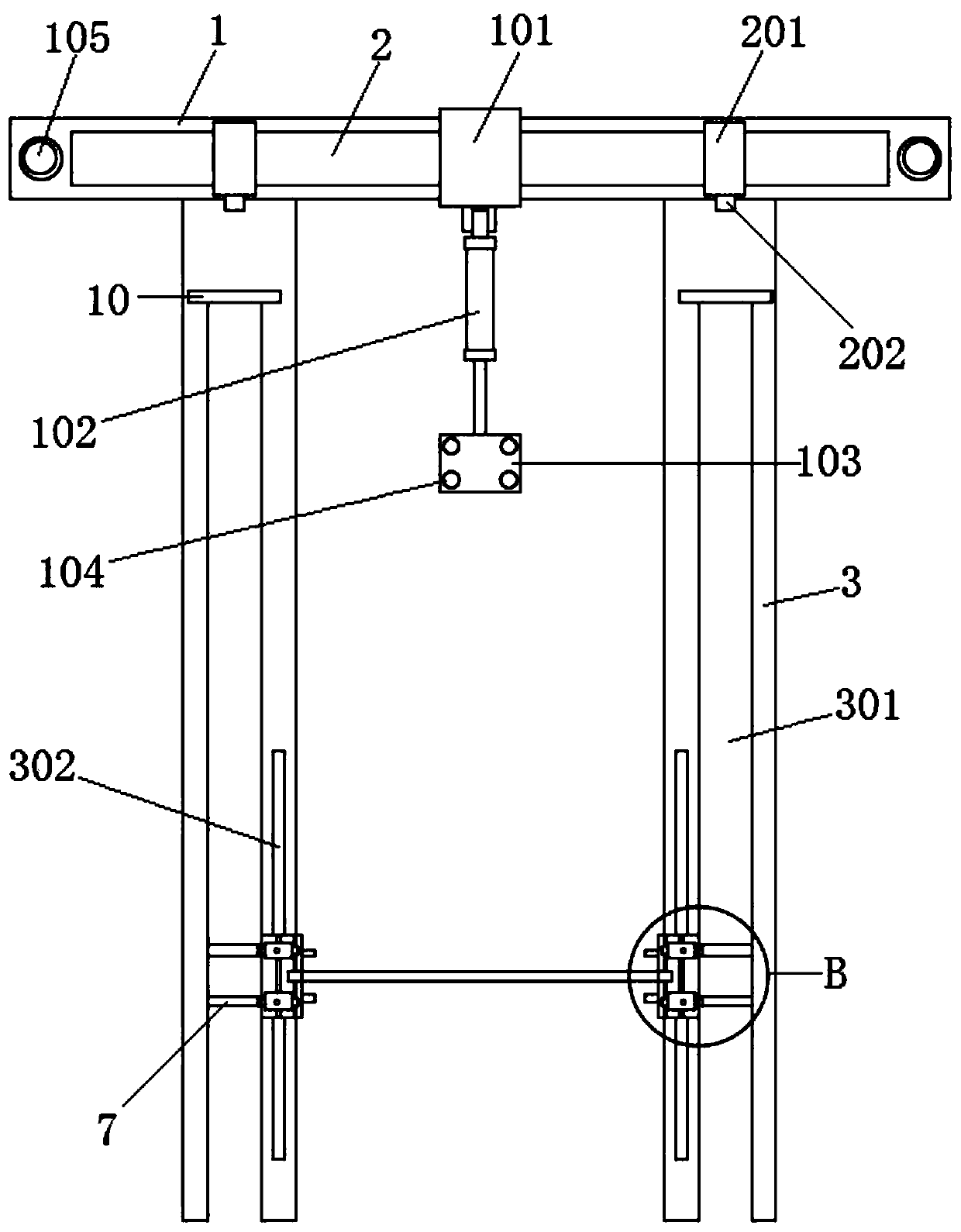

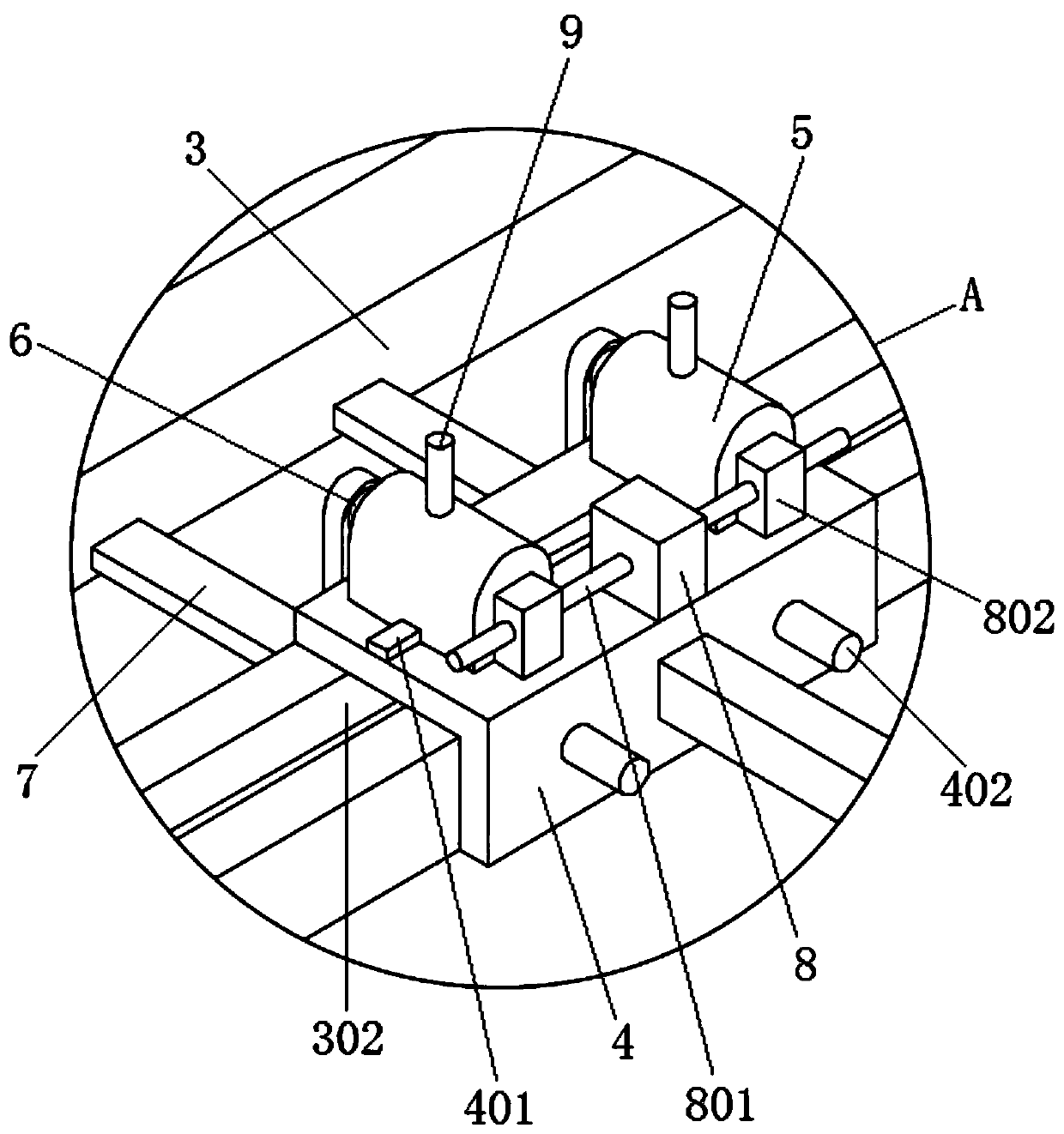

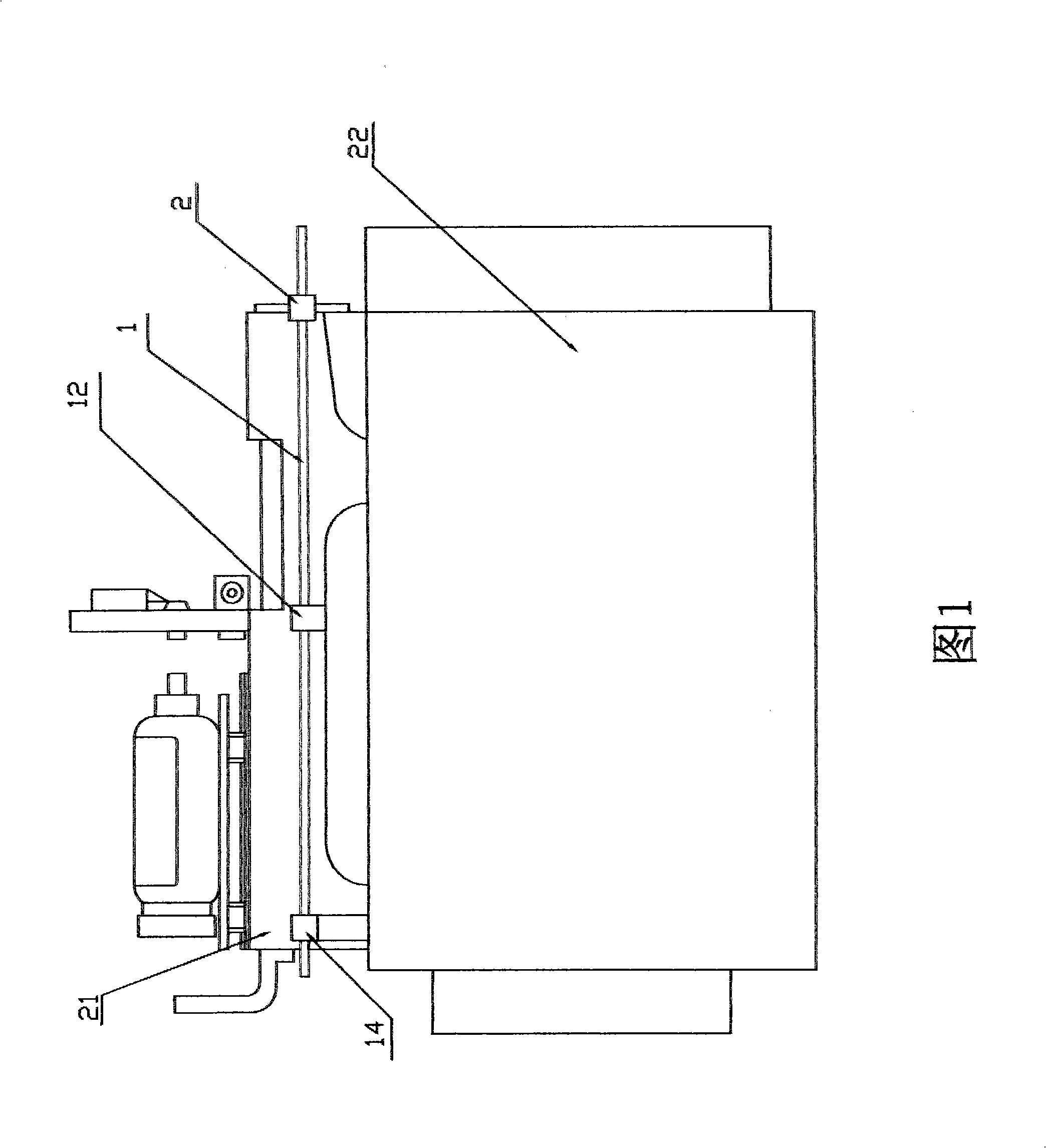

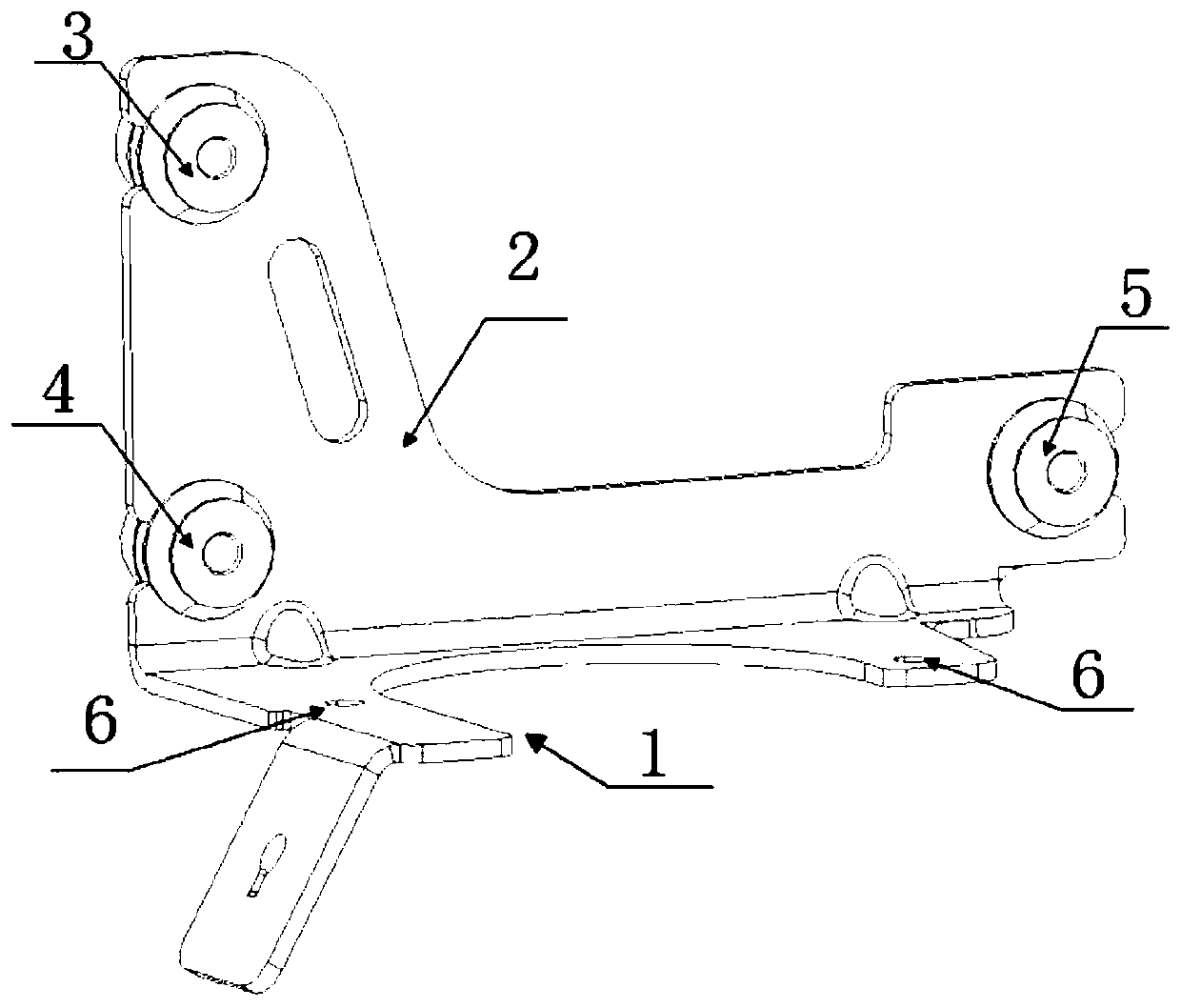

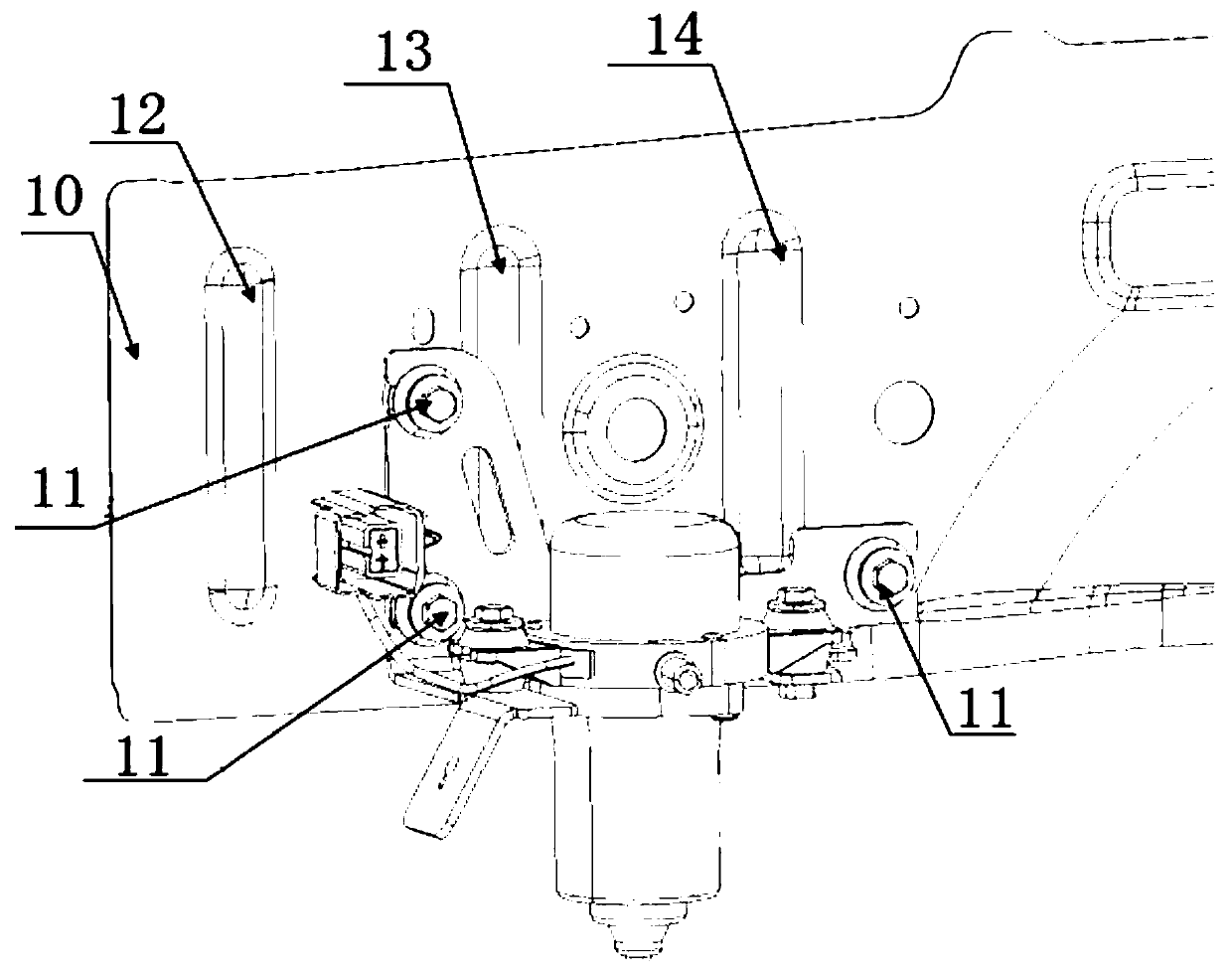

Single-sided slight-lifting lifting device for automobile maintenance

ActiveCN108726435AReduce maintenance man-hoursMeet the limit requirementsLifting framesSlide plateEngineering

The invention discloses a single-sided slight-lifting lifting device for automobile maintenance, and relates to the technical field of lifting machine equipment. The single-sided slight-lifting lifting device comprises a substrate; a first fixed block is fixed in the middle of the upper surface of the substrate, and first guide rails are fixed on one opposite side of the first fixed block; the twofirst guide rails are in sliding connection with sliding blocks, one surface of each sliding block is fixed with a supporting plate through a connecting block, and a vehicle travelling groove channeland a guiding groove are formed in the upper surface of each supporting plate; each guiding groove is internally connected with a sliding plate in a sliding mode through a guiding block, and positioning seats are mounted on the upper surfaces of the sliding plates side by side through a second guide rail; and the two positioning seats are internally matched with rotating shafts rotatably, and oneend of each rotating shaft is fixedly connected to a limiting frame. According to the single-sided slight-lifting lifting device, the movement of the front or rear wheels of a car is limited by usingthe adjustable limiting frames, the rear or front part of the car is slightly lifted by using power telescopic rods, the time-consuming and labor-intensive problems caused by the traditional whole car lifting are solved, and the higher market promoting value is achieved.

Owner:鲁首佳(山东)工业设计有限公司

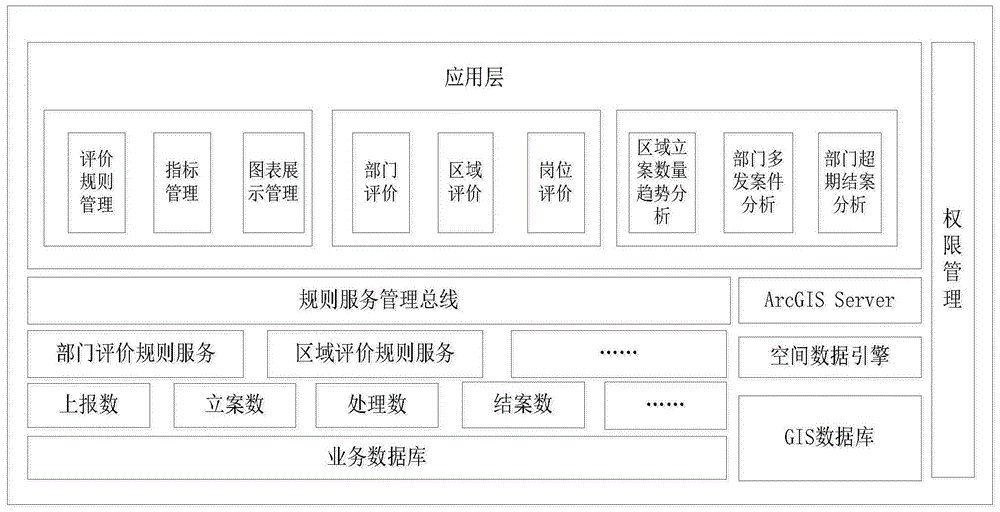

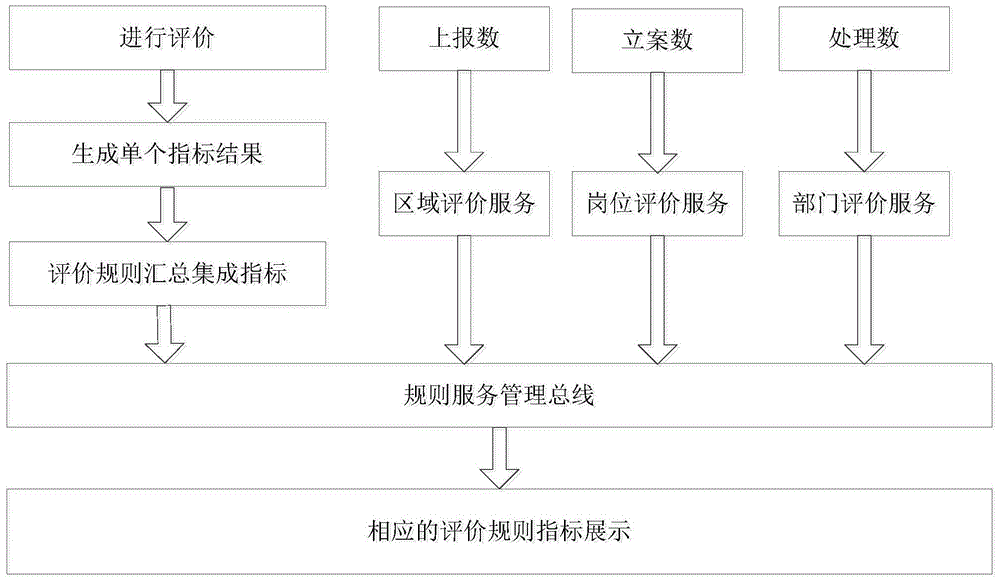

Comprehensive analyzing subsystem of digital city monitoring center and working method thereof

InactiveCN105046387AImprove intelligenceEnhanced interactionResourcesSpecific program execution arrangementsUser needsComputer module

The invention discloses a comprehensive analyzing subsystem of a digital city monitoring center and a working method thereof. The system has a subsystem which is provided with: an application layer, a service layer, a storage layer, a geological information system platform, an authority management module and a space data engine; the application layer is used for providing business processing and interactive service for users, and for performing interface dynamic configuration of indexes, analyzing rules and analyzing results of the comprehensive analysis, and for generating corresponding assessment service via invoking and analyzing assessment rules. The subsystem and working method have the beneficial effects that: the analyzing rules are managed in an integral manner, the analyzing indexes are managed in a plug-in type manner, and the analysis and calculation of the analyzing indexes are all operated by T-SQL, thus a comprehensive analyzing system is formed and features in higher intelligence and excellent interaction. When the users need to view the indexes of a certain analysis, the users can directly invoke services of the rules to obtain the index information as required. Therefore, a comprehensive assessing system which is fast in development, unified in maintenance, and has a high level in resources integration is established.

Owner:TAIHUA WISDOM IND GRP CO LTD

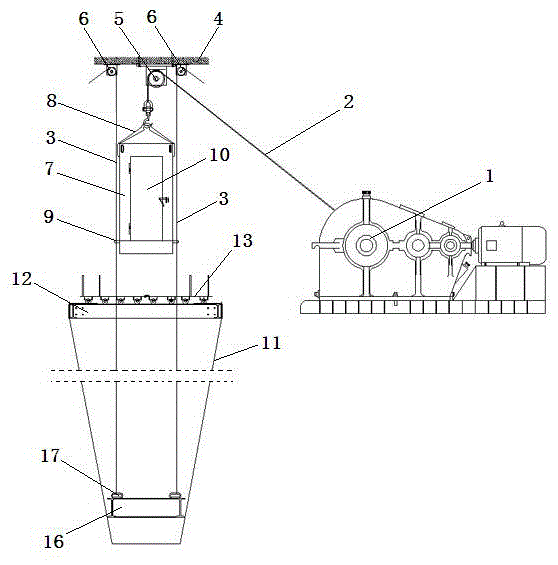

Coal bunker maintenance device

InactiveCN105565129AProbability of avoiding accidental injuryPractical and convenientMine liftsEngineeringCoal

The invention relates to a coal bunker maintenance device. The device comprises a traction mechanism, a head sheave suspension mechanism, a cage mechanism, a sealing disc mechanism, a static rope base mechanism, a traction rope and two static ropes. The device solves the technical problem of no special complete maintenance equipment in damage maintenance or daily maintenance of traditional underground coal bunker, is practical and convenient, saves a lot of labor costs for maintenance of the underground coal bunker, shortens the maintenance time, is high in safety, and prevents the probability of accidental injury caused by up-down climbing of constructors in the coal bunker maintenance or daily maintenance.

Owner:陕西彬长大佛寺矿业有限公司

Method for preventing oil leakage of worm gear reducer

The invention relates to a method for preventing the oil leakage of a worm gear reducer, which comprises the following steps: arranging spiral seals on in-shaft covers at both ends of a worm screw to serve as first seals, respectively arranging second seals composed of high temperature resistant stuffing outside the two spiral seals, and arranging bidirectional dynamic oil seals composed of high temperature resistant and wear resistant materials to serve as third seals. The method for preventing the oil leakage of the worm gear reducer combines the spiral seals of non-contact type seal with contact type seals, and enables the reducer to be well sealed in both dynamic and static modes.

Owner:DAXIN MANGANESE MINE BRANCH OF CITIC DAMENG MINING IND

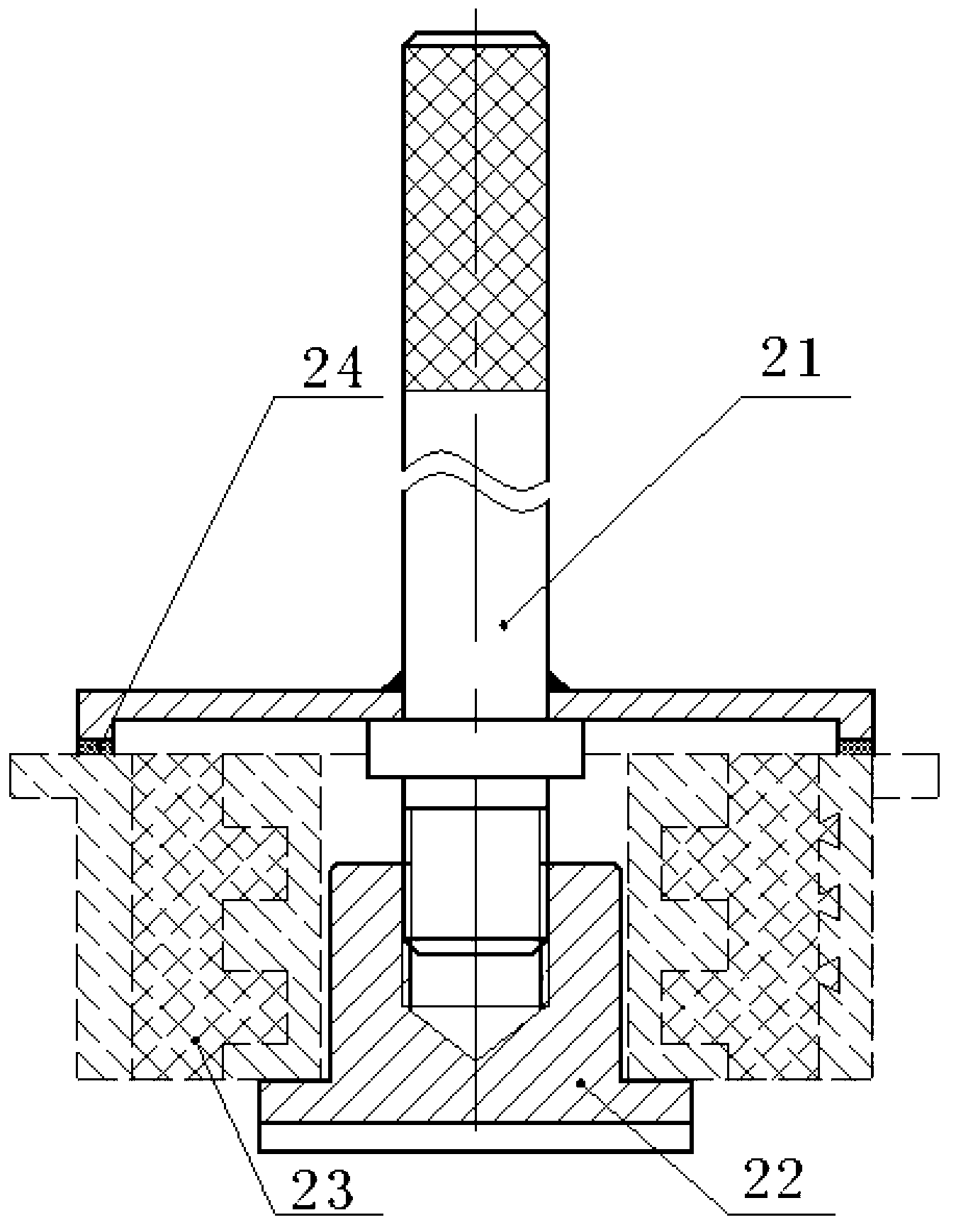

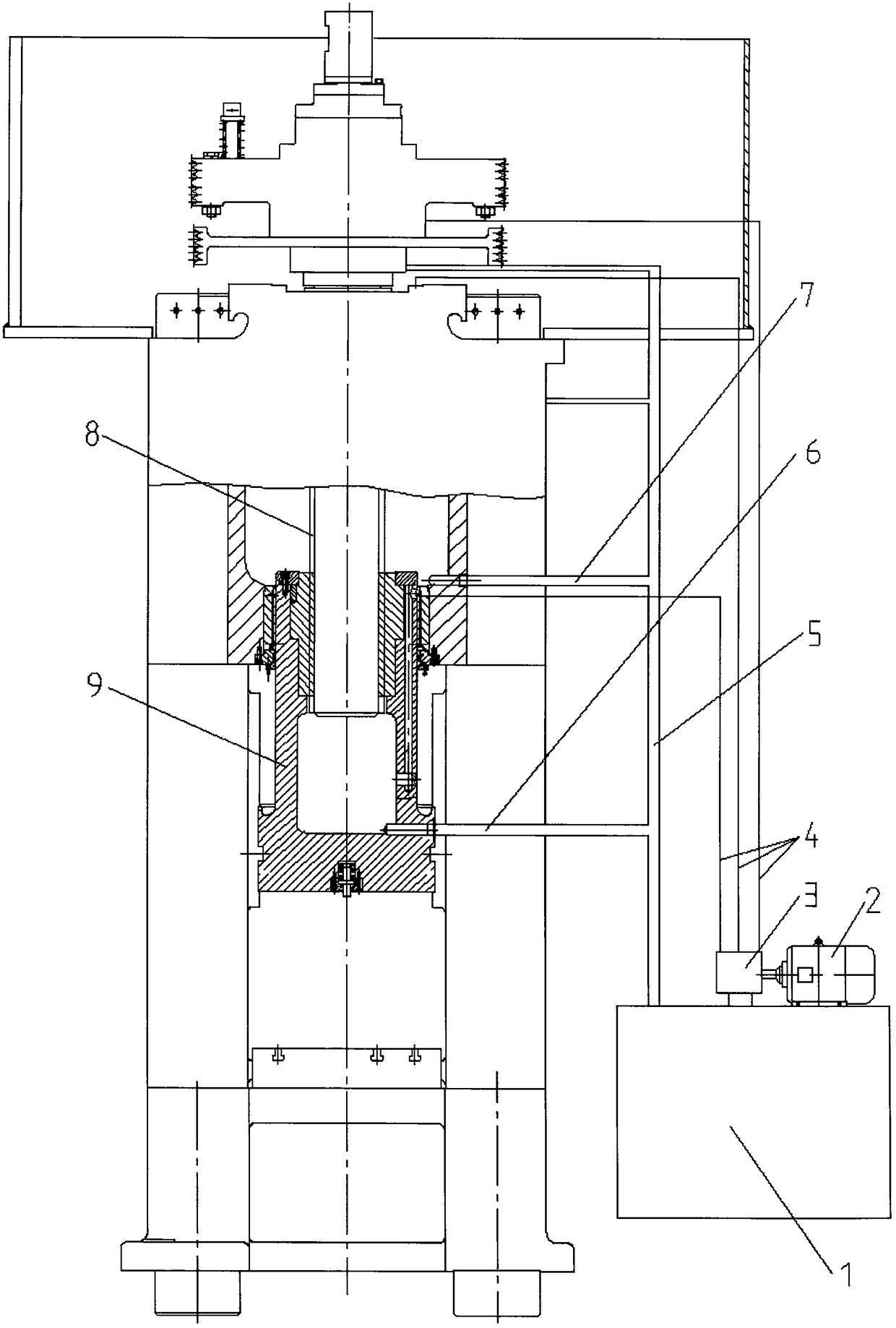

Automatic centralized circulating lubrication system for screw press

The invention discloses an automatic centralized circulating lubrication system for a screw press. The automatic centralized circulating lubrication system for the screw press comprises an oil tank, ahydraulic motor oil pump, a multi-lubricating-oil-passage distributor, multi-passage oil injecting branch pipes, a main oil returning pipe, a lower oil returning branch pipe and an upper oil returning branch pipe, wherein the hydraulic motor oil pump is installed on the oil tank, the multi-lubricating-oil-passage distributor is connected with the hydraulic motor oil pump, the multi-passage oil injecting branch pipes are connected between the multi-lubricating-oil-passage distributor and a plurality of lubricating points, the main oil returning pipe is connected with the oil tank, the lower oil returning branch pipe which is used for collecting dripping lubricating oil is connected between the bottom of a lower cavity of a sliding block and the main oil returning pipe, and the upper oil returning branch pipe for collecting the dripping lubricating oil is connected between the bottom of an upper cavity of the sliding block and the main oil returning pipe. According to the automatic centralized circulating lubrication system for the screw press, automatic centralized lubrication is achieved, recycling is achieved, the energy is saved, the consumption is reduced, oil pollution does not exist, clean environment and environmental protection are achieved, the abrasion of moving parts is reduced, the operation of equipment is reliable, the service life of the equipment is long, the production cost is reduced, the maintenance time is reduced, fully lubrication is achieved, the operation cost is reduced, cooling is achieved, the operation of the equipment is safe, sealing is used for preventing corrosion and rusting, damping and cushioning are achieved, and the automatic centralized circulating lubrication system for the screw press is widely used in the lubrication of the screwpress.

Owner:青岛浩源益友锻压机械有限公司

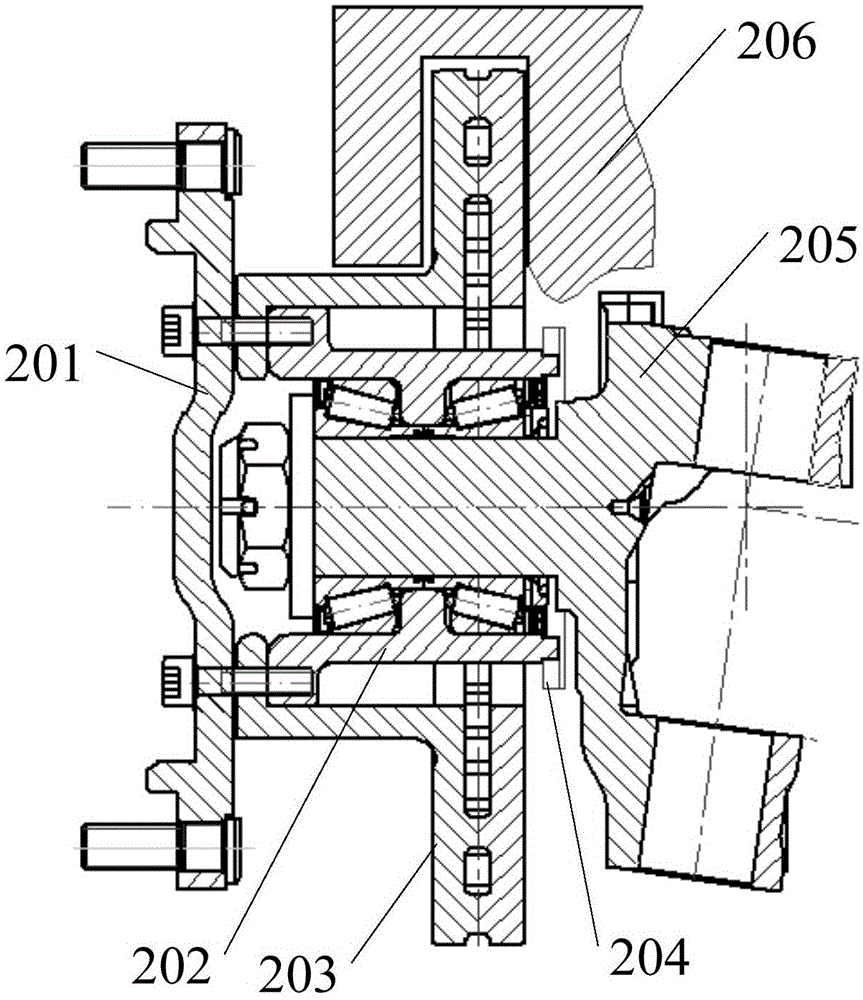

Front axle wheel end structure and automobile

The invention belongs to the technical field of automobile components, and provides a front axle wheel end structure and an automobile. The front axle wheel end structure comprises a hub and a brake disc. The brake disc is provided with a hub hole. The hub is a stepped shaft which is provided with an axially-through bearing hole. The large shaft end of the stepped shaft is inserted in the hub hole and locked to the brake disc through a locking mechanism. A disc body of the brake disc is located at the small shaft end of the stepped shaft. A knuckle is rotationally installed in the bearing hole through a bearing. According to the front axle wheel end structure, due to the fact that the hub hole is formed in the brake disc and the hub is inserted into the hub hole and locked by the locking mechanism, when the brake disc becomes invalid and needs to be replaced, the brake disc can be disassembled only by disassembling a tire at first, then disassembling a brake caliper and loosening the locking mechanism; the disassembly and assembly technology is simple, maintenance time is shortened, maintenance efficiency is improved, and the brake disc placement cost is reduced; due to the fact that an ABS gear ring and the bearing do not need to be disassembled, the ABS gear ring and the bearing are protected, normal stress of the bearing is ensured, and the service life of the bearing is prolonged.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

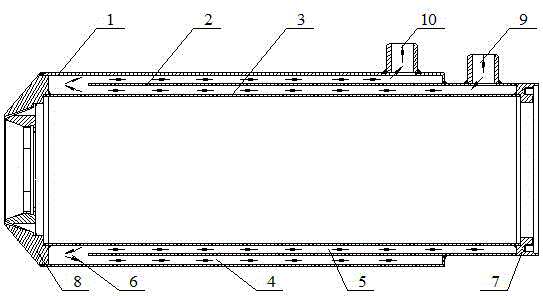

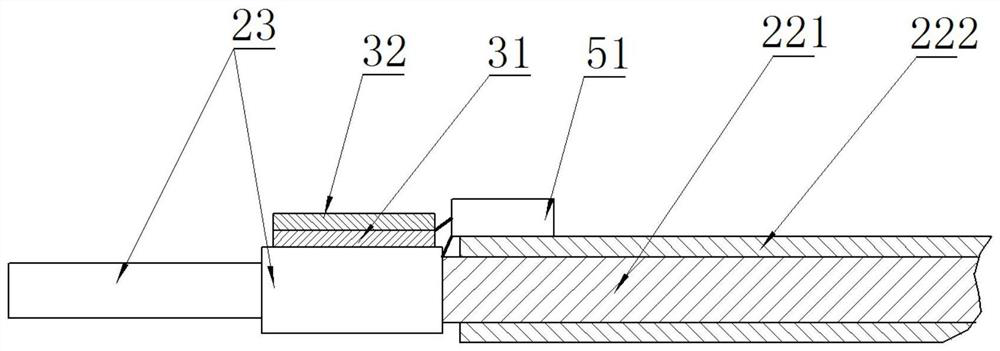

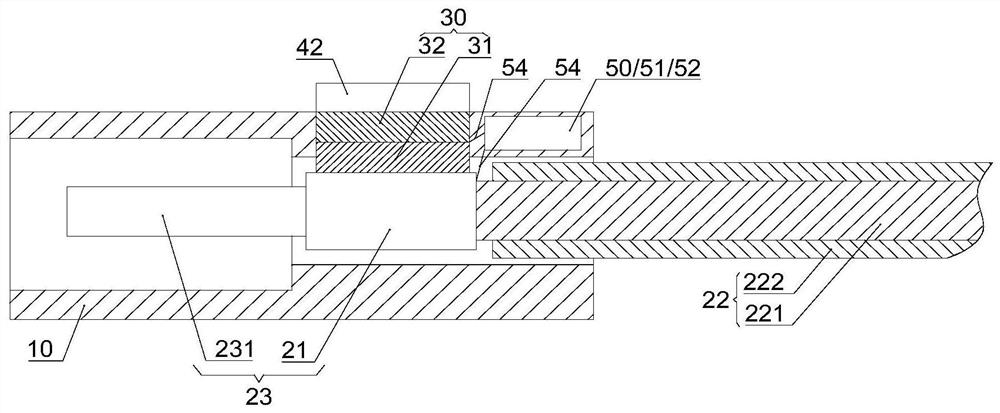

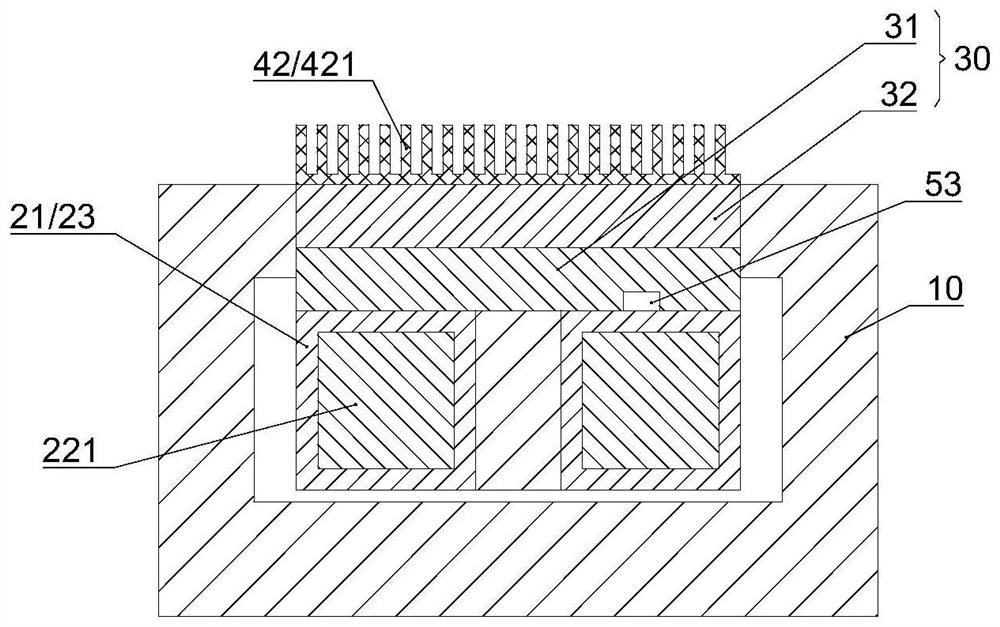

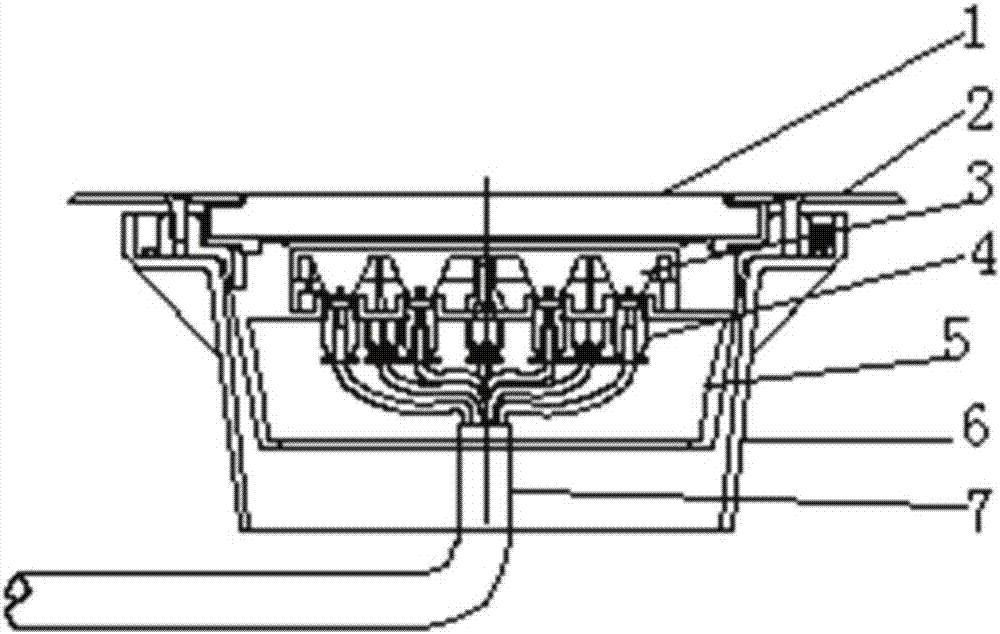

Cooling water circulation system of water cooling protection sleeve of camera in high-temperature environment

InactiveCN104360563AReduce maintenance man-hoursReduce maintenance costsTelevision system detailsColor television detailsCamera lensControl engineering

The invention relates to a cooling water circulation system of a water cooling protection sleeve of a camera in a high-temperature environment. The system comprises a water cooling outer sleeve and a water cooling inner sleeve, wherein a water separation sleeve is arranged between the water cooling outer sleeve and the water cooling inner sleeve so as to form an outer sandwiched layer and an inner sandwiched layer; a circulation channel is reserved at the front end of the water separation sleeve; the rear end of the water separation sleeve is fixed on a rear flange; the front end of the water cooling outer sleeve is fixed on a front flange; the rear end of the water cooling outer sleeve is fixed on the rear part of the water separation sleeve; the front end and the rear end of the water cooling inner sleeve are fixed on the front flange and the rear flange, respectively; the rear end surface of the water separation sleeve is provided with a water inlet; the rear end surface of the water cooling sleeve is provided with a water outlet. According to the invention, the problem that a camera and a camera lens are damaged frequently because the circulation of cooling water is not smooth, a circulation dead corner occurs at the front end of the water cooling protection sleeve, cooling water at the front end of the water cooling protection sleeve cannot be circulated, and the water cooling protection sleeve is burned to be leaked because of local overheating is solved, so that the device maintenance working time is shortened, and the device maintenance cost is lowered. The system has the advantages of reasonable structure design, processing simplicity, low cost and the like.

Owner:TIANJIN TELEVISION TECH INST

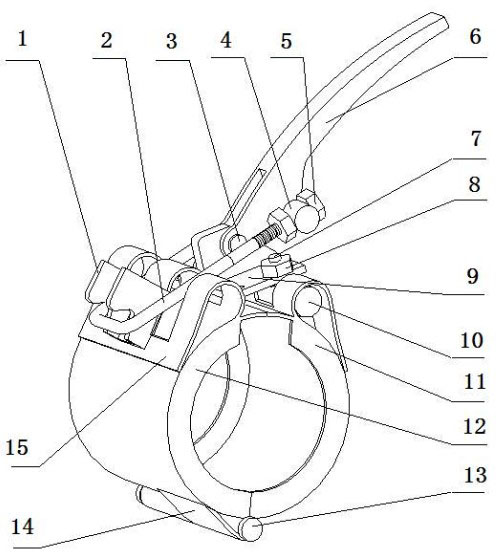

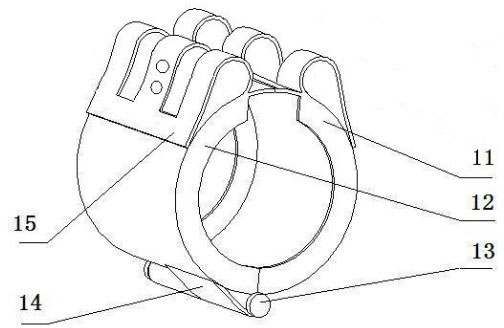

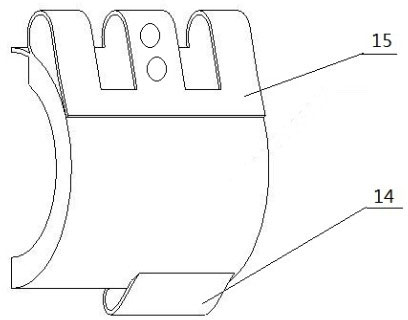

Quick plugging kit for clamping-type pipeline

InactiveCN102135220APlugging is convenientReduce maintenance man-hoursPipe elementsLeft halfEngineering

The invention relates to a quick plugging kit for a clamping-type pipeline, belonging to the field of mechanical engineering. The kit consists of a closed ring and a locking device; and the locking device is fixed on the closed ring by bolts and nuts. The closed ring consists of a left half ring, a right half ring and a main pin shaft, wherein the left half ring and the right half ring are embedded and connected with each other by the main pin shaft. The locking device consists of a base fixing pin shaft, a handle base, rivets, a handle, a handle pin shaft, a U-shaped elastic pulling rod, a clamping hook, an adjusting nut, a fixed bolt and a nut, wherein the base fixing pin shaft is connected with the handle base; the handle is connected with the handle base by the handle pin shaft; the handle is connected with the handle base by the rivets; the clamping hook is fixed on a reversely-coiled lug sheet of the left half ring; the handle pin shaft passes through the handle; and the U-shaped opening end of the U-shaped elastic pulling rod passes through holes at two ends of the handle pin shaft respectively. The quick plugging kit can be used for quickly plugging various leaked pipelines without stopping water or gas; and compared with a traditional pipeline plugging method, the quick plugging kit can be operated conveniently and quickly, saves effort and time, and has a good effect.

Owner:FUQING BRANCH OF FUJIAN NORMAL UNIV

Water curtain sprinkling purifier

ActiveCN101235323AIncrease volumeTo achieve the purpose of separation and purificationGas purification by non-gaseous materials condensationExtracorporeal circulationTar

The invention relates to a gas cleaning device, the structure of a cleaner is modified from internal circulation of a normal cleaner to be extracorporeal circulation and from a spray head of a normal cleaner to be a dousing tank, which is equipped with a water-curtain wall baffle plate, gas is forced to reversely pass through the water-curtain wall, and water consumption of spraying and pool volume of spraying are enlarged, spraying water which is used gets into the spraying pool, coke tar and impurity substance are condensed, coke tar floats on water surface, which is put into a coke tar pool to store and sale after gathering. Impurity substance is settled at the bottom of the pool, which is cleaned and stored when changing water, and is returned to field with plant ash.

Owner:辽宁中农承天环境科技有限公司

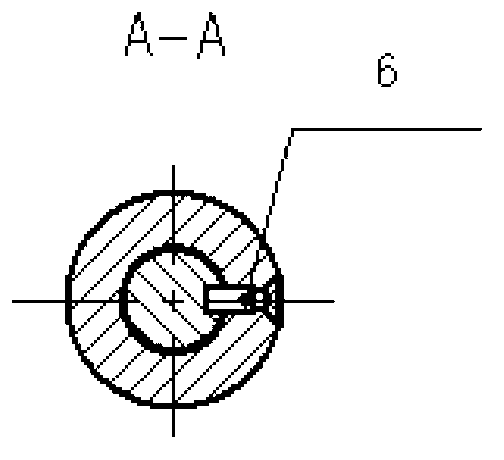

One-way valve assembly used in sludge pump

PendingCN105697798AEasy to assemble and disassembleEasy to replaceCheck valvesLift valveSludgeVALVE PORT

The invention relates to a one-way valve assembly used in a sludge pump, and belongs to the technical field of valves. The one-way valve assembly comprises an assembly shell and a valve element arranged in the assembly shell. The assembly shell is composed of an inlet end, an outlet end, a bottom plate and a valve deck. The included angle of 90 degrees is formed by the inlet end and the outlet end. A valve ring is arranged above the bottom plate. The valve deck is fixed to the portion above the assembly shell. A sliding groove is formed in the bottom face of the valve deck, and a valve rod of the valve element slides and acts on the interior of the sliding groove. A sealing pad at the bottom of the valve element acts on the upper surface of the valve ring in an opening and closing manner. The one-way valve assembly is simple in structure, and the work principle is clear. Compared with a traditional valve element structure, the one-way valve assembly is more convenient to dismount, mount and replace. By means of the design of a boss, the sealing performance of the sealing pad of the valve element and the boss is increased, and the service life is prolonged; and the valve ring and the assembly bottom plate are connected through bolts, non-welding connection is achieved, and fractures generated after stress concentration at the position of a weld line are avoided. According to the one-way valve assembly, only the assembly bottom plate needs to be replaced, the manufacturing cost is saved, and the maintaining work hours are reduced.

Owner:YANGZHOU SIQI ENVIRONMENTAL PROTECTION EQUIP CO LTD

Magnetic type intelligent switch

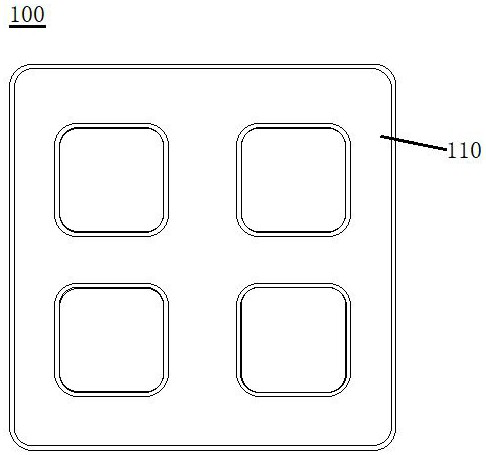

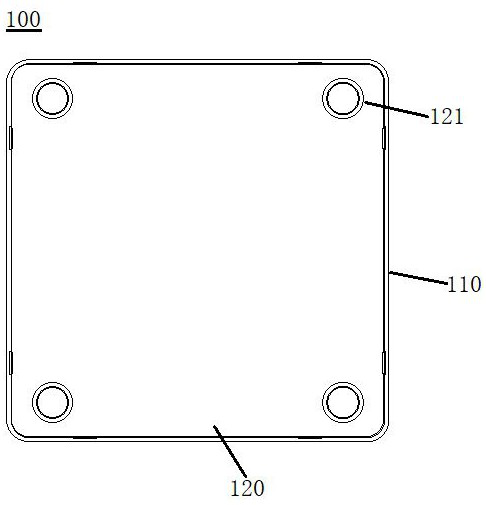

PendingCN113921303ANot easy to damageEasy maintenancePermanent magnetsElectric switchesInterior spaceSmart switch

The invention discloses a magnetic type intelligent switch, and relates to the technical field of intelligent switches. The magnetic type intelligent switch comprises a switch panel and a bottom box; the switch panel comprises a switch upper shell, a switch lower shell and a plurality of magnets; the switch upper shell and the switch lower shell are fixedly connected in a clamping manner and define an internal space of the switch panel, and the plurality of magnets are at least partially fixed in the internal space; the bottom box comprises a bottom box body and a connecting frame plate, the connecting frame plate is perpendicular to the depth direction of the bottom box body and fixedly connected with the bottom box body, and the connecting frame plate is made of magnetic materials; and the switch panel is fixedly connected with the connecting frame plate of the bottom box through the magnetic attraction force of the plurality of magnets. According to the invention, the maintenance and secondary installation of the intelligent switch are facilitated, and the panel structure and the internal flat cable structure are not easy to damage when the intelligent switch is disassembled, assembled and maintained.

Owner:ZHEJIANG YASHA DECORATION

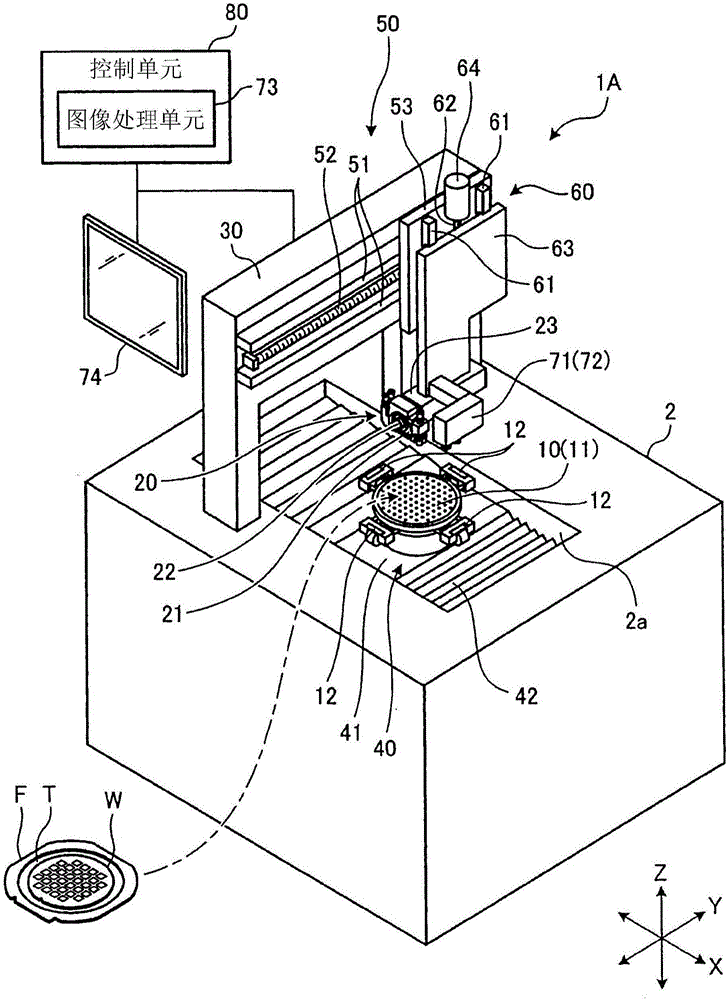

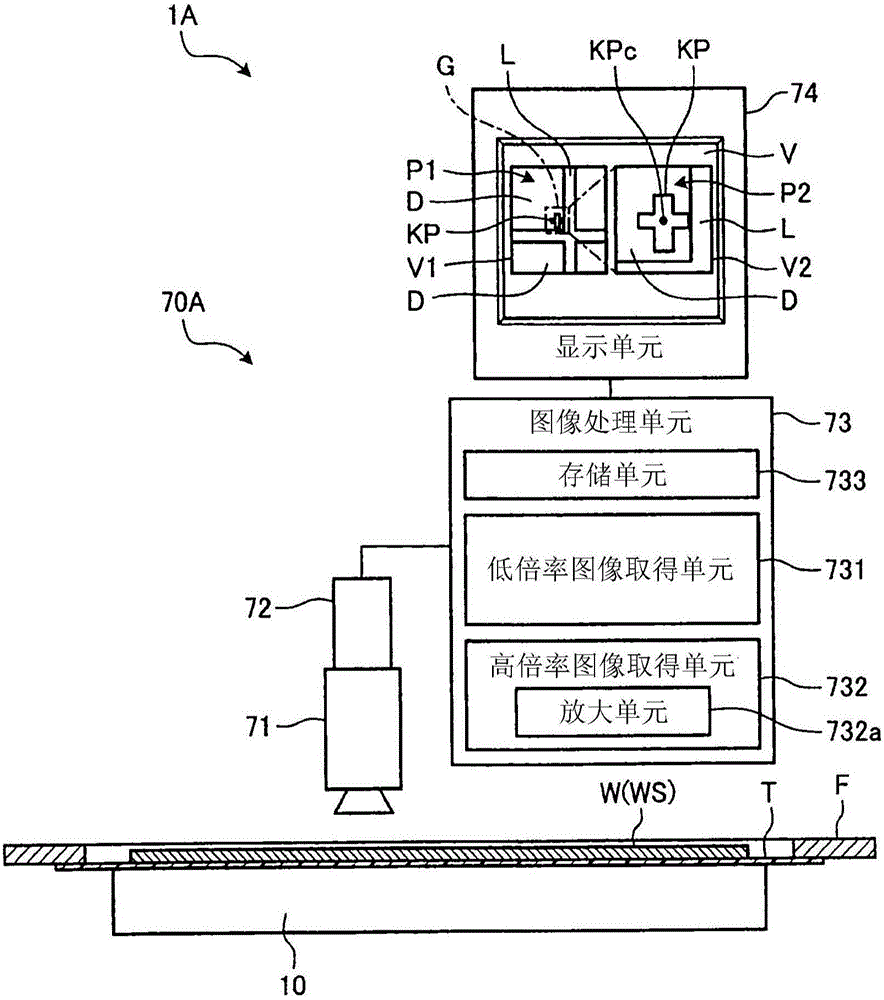

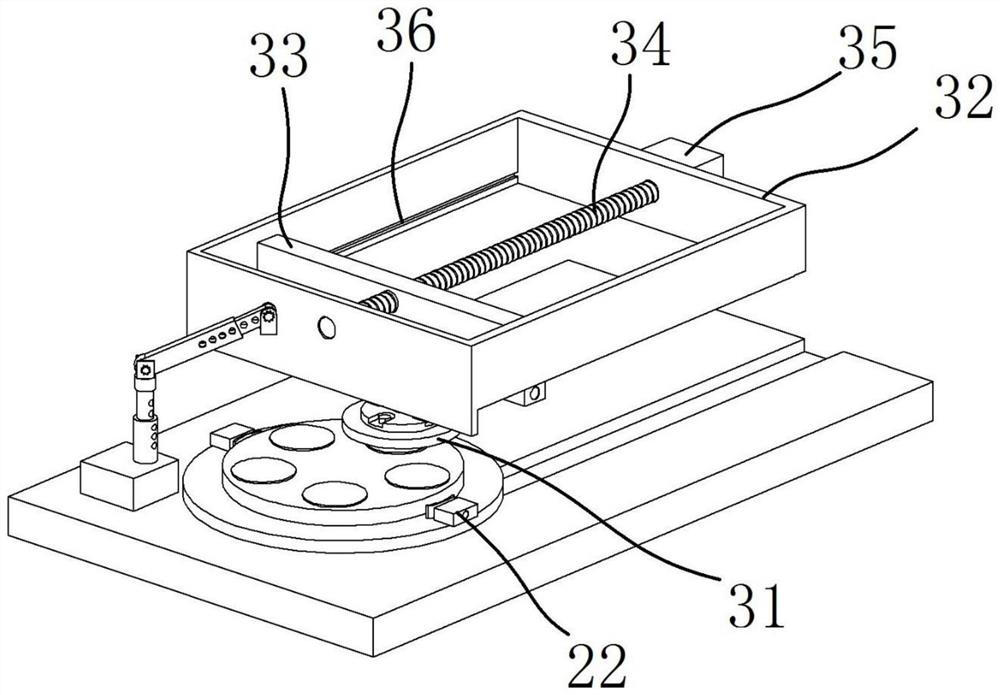

Processing apparatus

InactiveCN105914174AReduce maintenance man-hoursReduce axis actionSemiconductor/solid-state device manufacturingHigh magnificationComputer science

The invention provides a processing apparatus which simplifies the structure of a calibration device. The processing apparatus processes an image which is photographed by one optical system (71) and an image photographing unit (72), thereby obtaining a low-magnification image (P1) and a high-magnification image (P2). Therefore, in acquiring the low-magnification image (P1) and the low-magnification image (P2), arrangement of an optical system (71) and an image photographing unit (72) for high magnificiation and an optical system (71) and an image photographing unit (72) for low magnification are not required, thereby reducing cost of the optical system (71) and the image photographing unit (72) and reducing maintenance cost of the optical system (71) and the image photographing unit (72). Furthermore, in acquiring the low-magnification image (P1) and the high-magnification image (P2), positioning for shaft motion of the optical system (71) can be finished through one-time operation, thereby reduucing number of shaft motions.

Owner:DISCO CORP

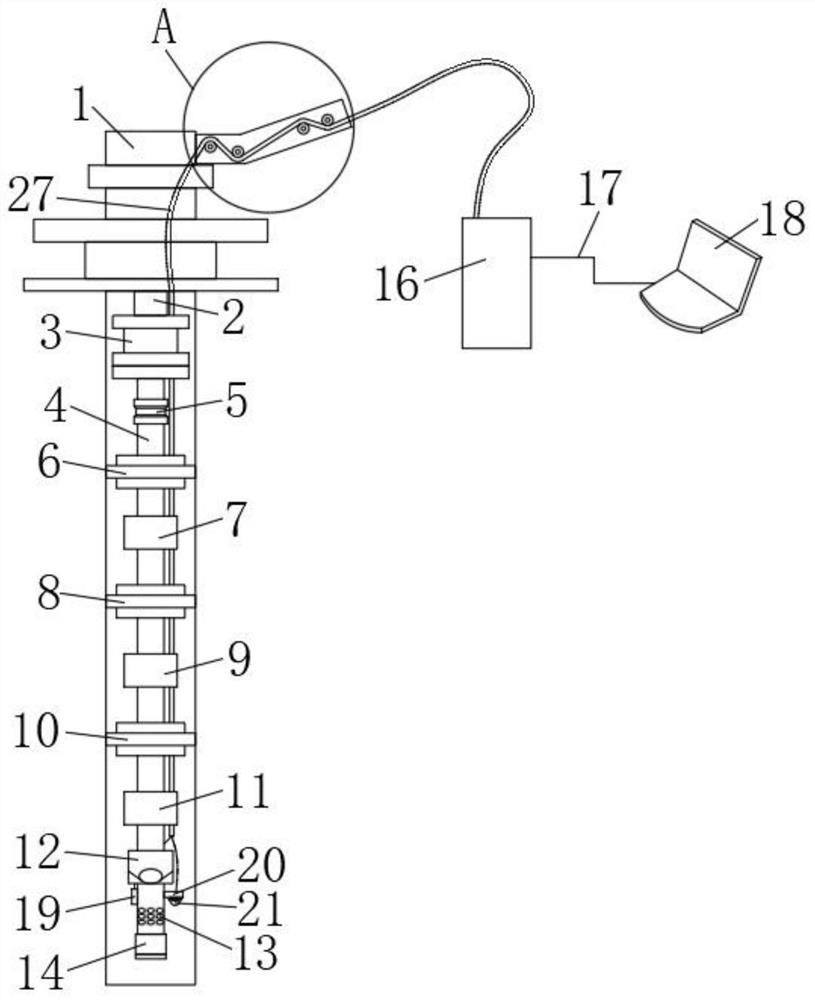

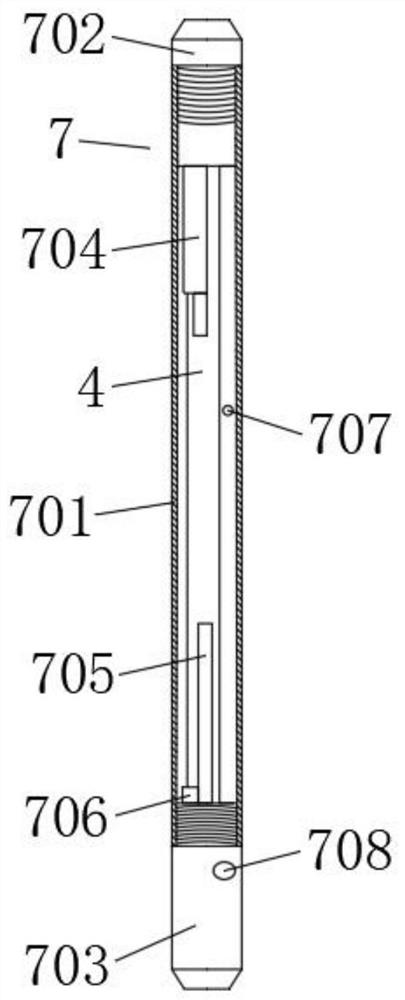

Cabled intelligent separate injection system capable of being monitored in real time and using method thereof

PendingCN113818850AAvoid damage or even crushingCompact structureSurveyConstructionsControl engineeringSurveillance camera

The invention discloses a cabled intelligent separate injection system capable of being monitored in real time and a using method thereof. The cabled intelligent separate injection system comprises a water injection well opening, a cable pressure prevention mechanism is arranged on the outer side of the water injection well opening, a hanger is fixedly connected to the bottom of the water injection well opening, a lifting short section is fixedly connected to the outer side of the hanger, a pipe column is fixedly connected with the bottom of the lifting short section, and the position, located below the lifting short section, of the outer side of the pipe column is fixedly connected with a depth correction short section. The cabled intelligent separate injection system is compact in structure, simple and convenient top operate and high in practicability, an electricity-approaching alarm and a monitoring camera are arranged at the well bottom and connected with a ground control cabinet and a central control computer, and therefore, the condition at the well bottom can be monitored and controlled in real time; and meanwhile, a cabled pressure-proof mechanism is arranged at the water injection well opening, so that a signal cable can be prevented from being damaged or even broken by extrusion when an oil pipe is pulled out of the cabled intelligent separate injection system, the maintenance time is greatly shortened, the cost is saved, and practical application is facilitated.

Owner:XIAN LUOKE ELECTRONICS SCI & TECH

Connector with semiconductor cooling device and automobile

PendingCN113490397AReduce burnoutFast chargingElectric vehicle charging technologyVehicular energy storageThermodynamicsEngineering

The invention provides a connector with a semiconductor cooling device and an automobile. The connector comprises a lead wire, a terminal and a semiconductor cooling device, wherein the terminal is configured such that one end thereof is connected to the lead wire and the other end thereof is connected to an external electrical structure, ; and the semiconductor cooling device is provided with a cooling part and a heat dissipation part, and the cooling part absorbs heat of the terminal. According to the connector, the technical problem that a connection point of the lead wire and the terminal is large in heat productivity and prone to burn out is solved.

Owner:CHANGCHUN JETTY AUTOMOTIVE PARTS CORP

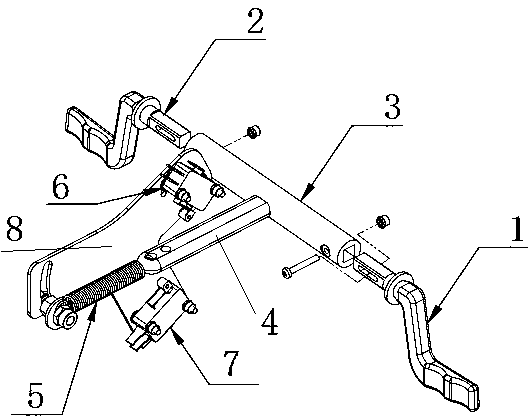

Forwards and backwards moving control handle device

The invention relates to a forwards and backwards moving control handle device which is mainly used for a non-driven scrubber capable of moving forwards and backwards. A left control handle (1), a right control handle (2) and a middle connecting rod (3) are connected, an extension rod (4) is arranged in the middle of the middle connecting rod, one end of a reset spring (5) is connected with an installing plate (8), the other end of the reset spring is connected with the extension rod (4), and an upper microswitch (6) and a lower microswitch (7) are installed on an installing plate and located on the two sides of the extension rod respectively. The forwards and backwards moving control handle device has the advantages of reducing the occupied space, saving machining cost, reducing mounting, demounting and maintenance labor hours and the like.

Owner:NANJING TVX CLEANING EQUIP

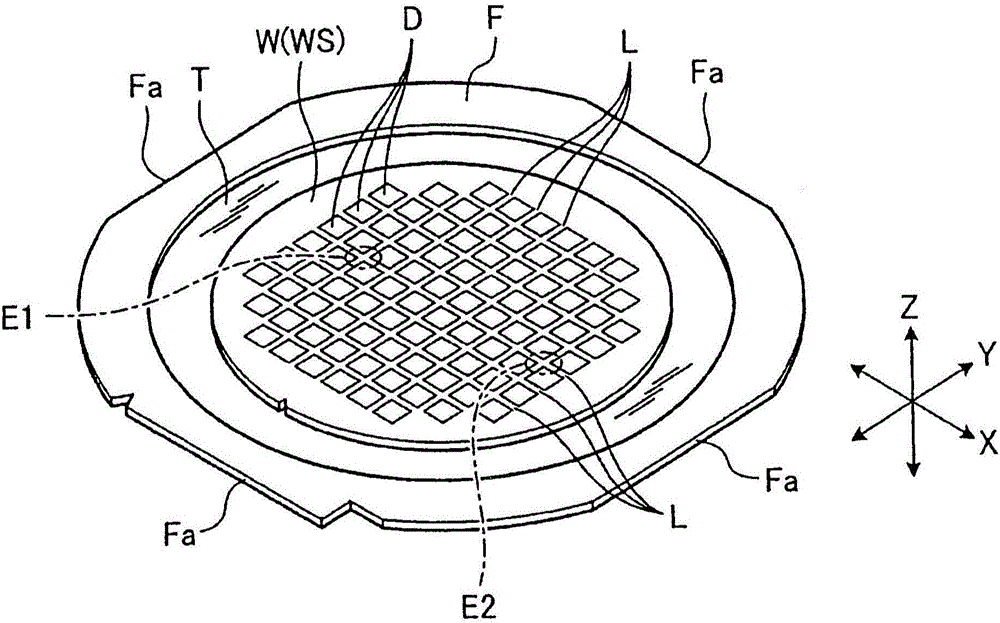

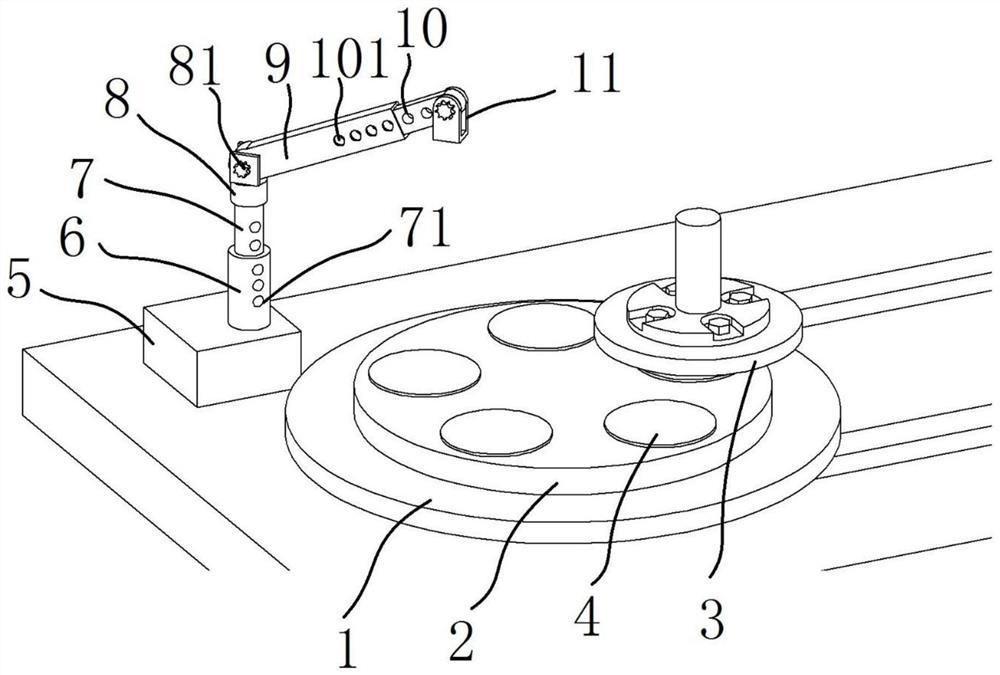

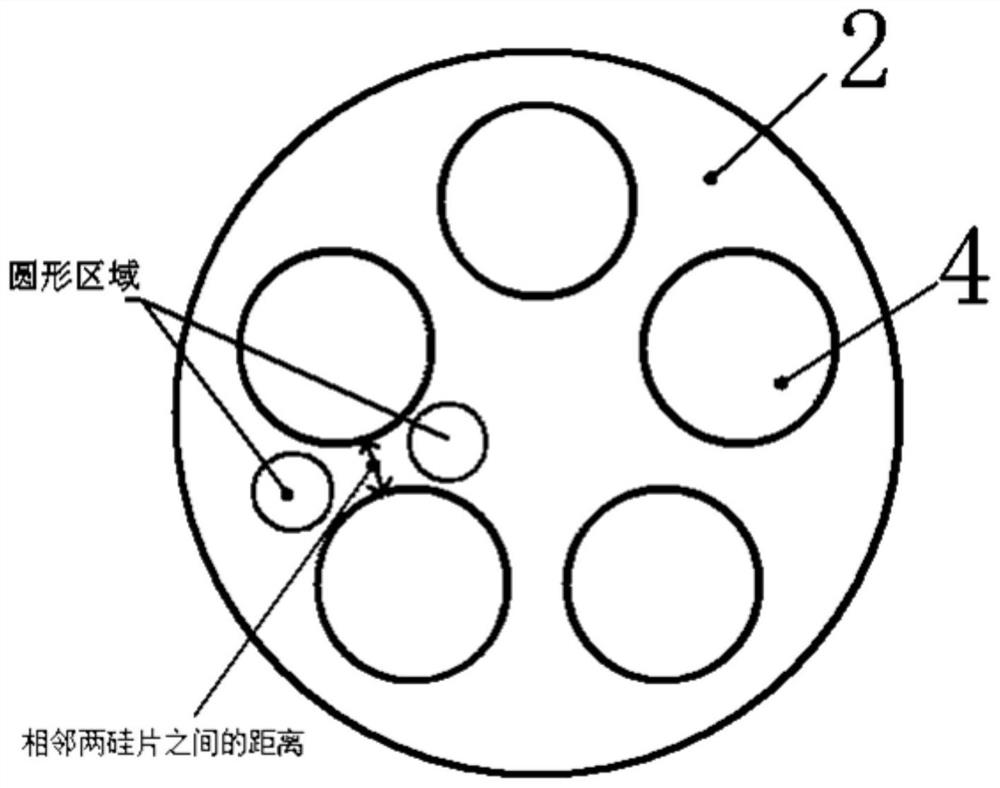

Chip mounter anti-chip-floating detection device and method

PendingCN113267125AIncrease detection functionAvoid chippingUsing optical meansComputer hardwareImaging processing

The invention provides a chip mounter anti-chip-floating detection device and method. The device comprises a ceramic disc, a chip mounter and an image acquisition unit. The upper surface of the ceramic disc forms a placement area for placing silicon chips, and the chip mounter is arranged above the ceramic disc and is used for placing the silicon chips on the ceramic disc; the image acquisition unit comprises a camera and an image processing system, the camera is arranged above the ceramic plate, and the camera is connected with the image processing system. The device and method have the advantages that the chip fluttering prevention detection function of the chip mounter is added, and the chip mounter chip fluttering prevention detection device and method are easy to manufacture, low in failure rate, safe, reliable and convenient to operate; according to the actual use effect of a workshop site, the system can effectively avoid silicon wafer fragmentation and damage to parts such as a polishing pad, a ceramic disc, a center guide wheel, a side guide wheel and a polishing machine large disc caused by chip fluttering of the chip mounter, avoids huge economic loss and reduces maintenance man hours.

Owner:ZHONGHUAN ADVANCED SEMICON MATERIALS CO LTD +1

A single-side micro-lift lifting device for vehicle maintenance

ActiveCN108726435BReduce maintenance man-hoursMeet the limit requirementsLifting framesSlide plateMachine

The invention discloses a single-sided slight-lifting lifting device for automobile maintenance, and relates to the technical field of lifting machine equipment. The single-sided slight-lifting lifting device comprises a substrate; a first fixed block is fixed in the middle of the upper surface of the substrate, and first guide rails are fixed on one opposite side of the first fixed block; the twofirst guide rails are in sliding connection with sliding blocks, one surface of each sliding block is fixed with a supporting plate through a connecting block, and a vehicle travelling groove channeland a guiding groove are formed in the upper surface of each supporting plate; each guiding groove is internally connected with a sliding plate in a sliding mode through a guiding block, and positioning seats are mounted on the upper surfaces of the sliding plates side by side through a second guide rail; and the two positioning seats are internally matched with rotating shafts rotatably, and oneend of each rotating shaft is fixedly connected to a limiting frame. According to the single-sided slight-lifting lifting device, the movement of the front or rear wheels of a car is limited by usingthe adjustable limiting frames, the rear or front part of the car is slightly lifted by using power telescopic rods, the time-consuming and labor-intensive problems caused by the traditional whole car lifting are solved, and the higher market promoting value is achieved.

Owner:鲁首佳(山东)工业设计有限公司

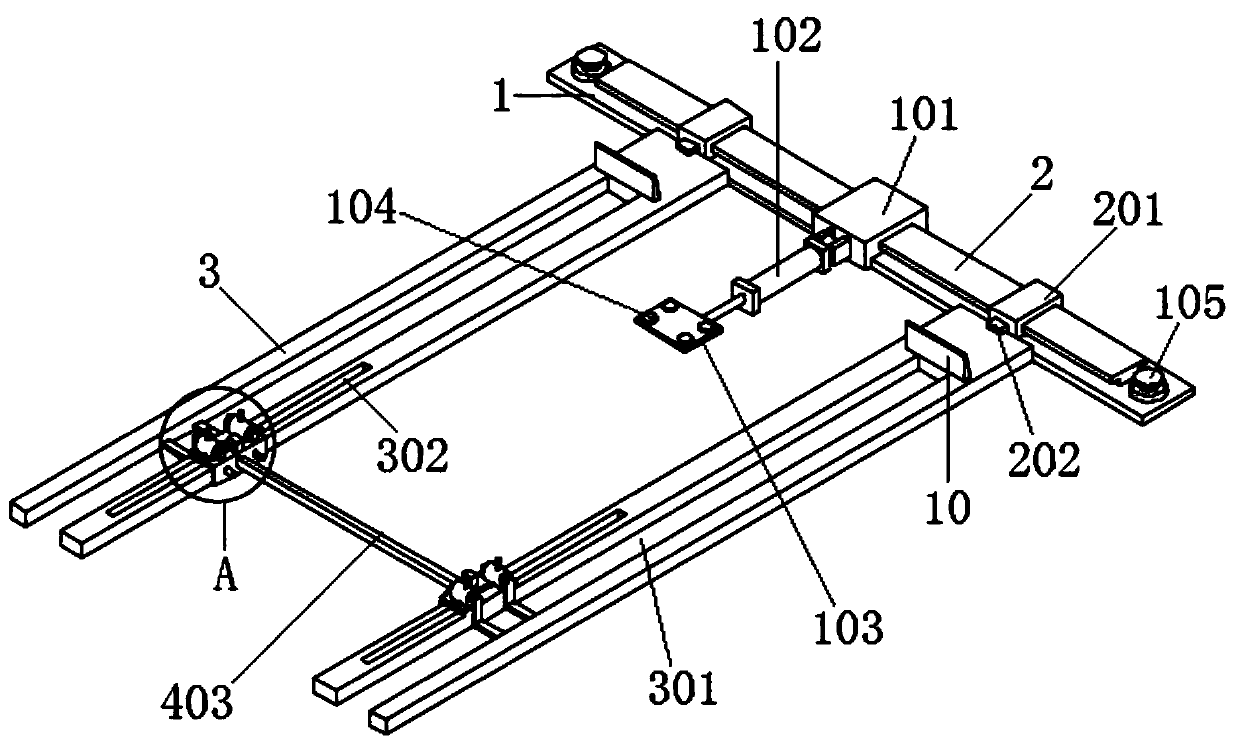

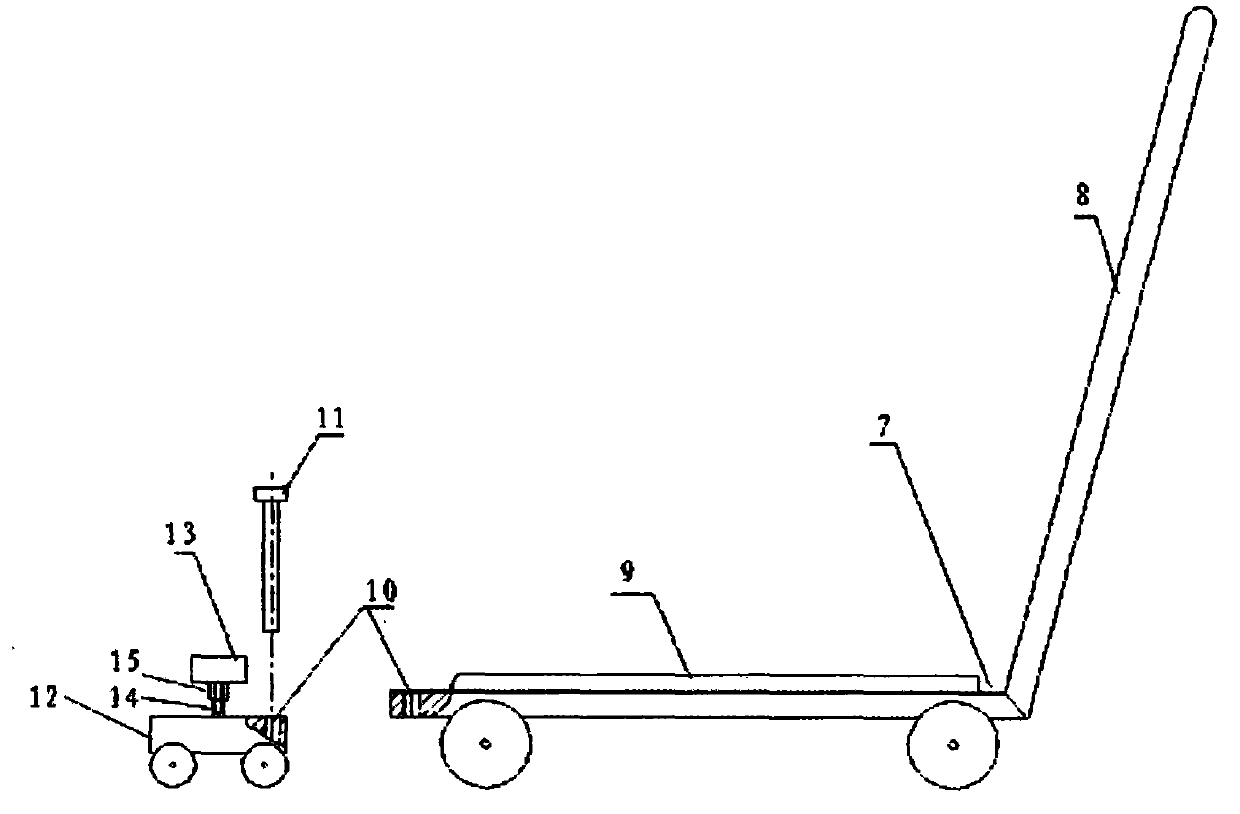

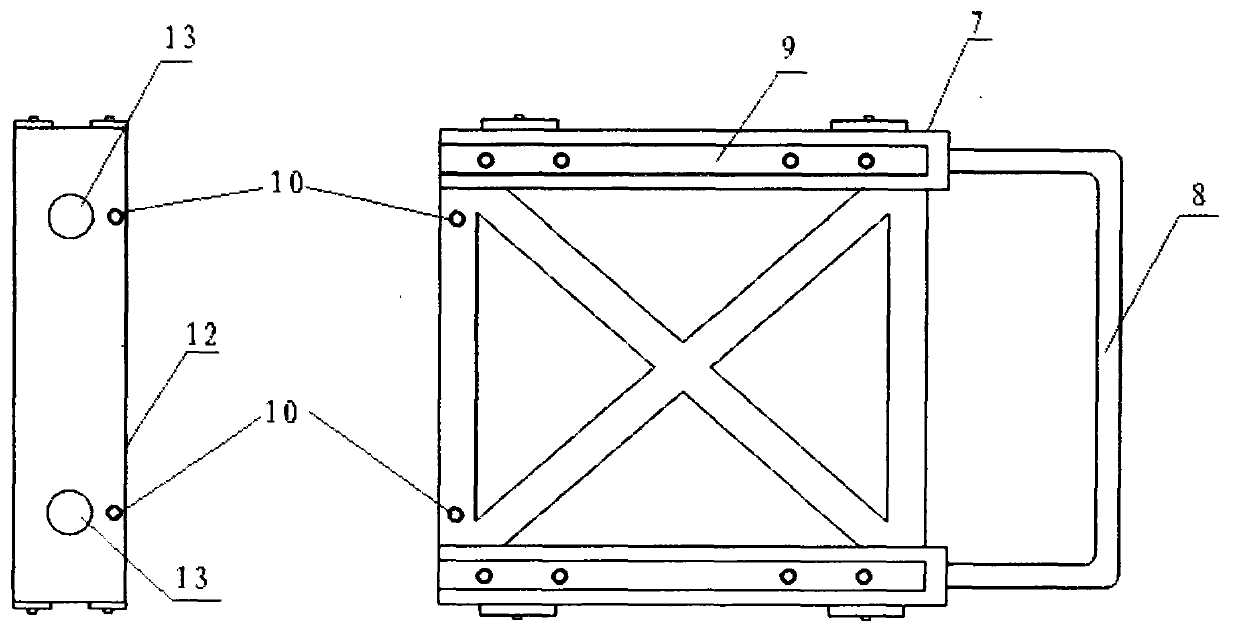

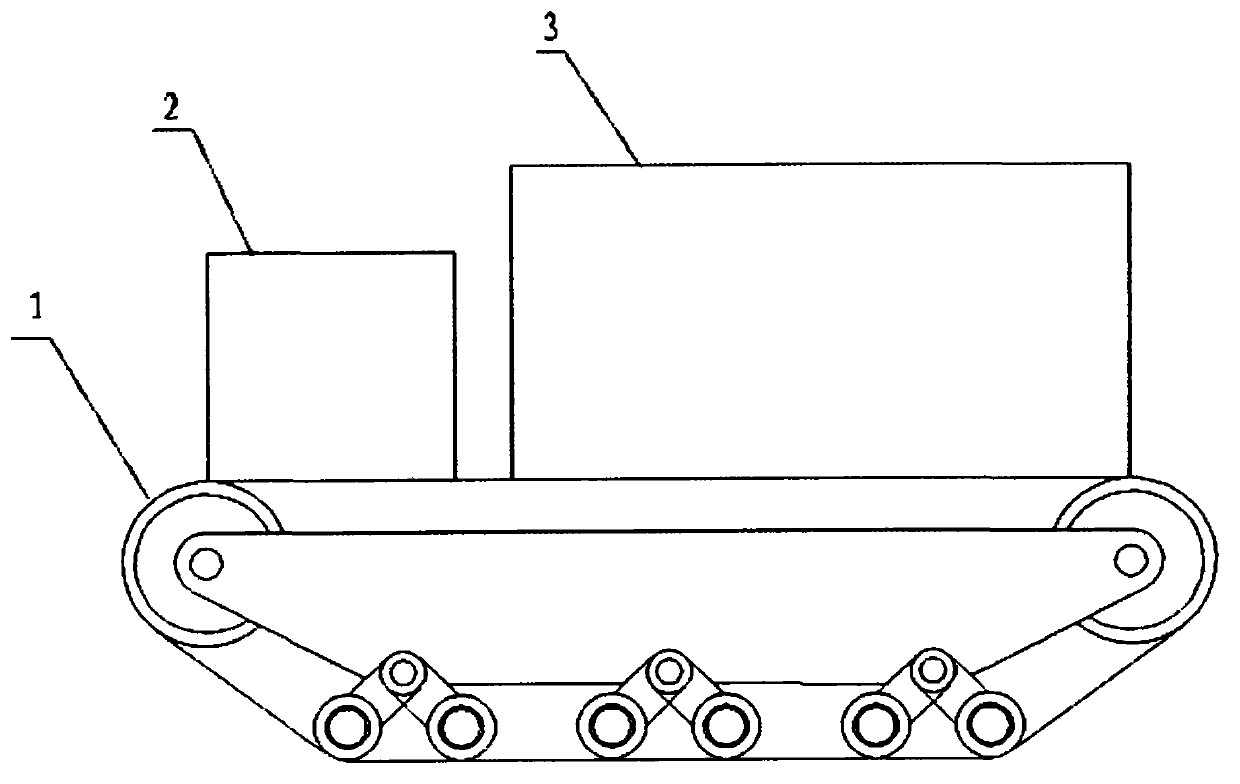

Device for rapidly reloading plurality of operating modules by combining vehicle chassis

InactiveCN103460842APromote repairImprove dressing efficiencyAgricultural undercarriagesComputer moduleAgricultural machinery

The invention belongs to the technical field of operating machines, and discloses a device for rapidly reloading a plurality of operating modules by combining a vehicle chassis. The device for rapidly reloading the operating modules by combining the vehicle chassis comprises a moving platform with a sliding rail and a movable load-bearing transfer platform connected with the moving platform, wherein a load-bearing seat is arranged on the movable load-bearing transfer platform. According to the device, the operating modules of an agricultural machine or an engineering machine with a plurality of functional operating modules can be rapidly and safely reloaded or conveniently and rapidly maintained, so that the reloading efficiency of the operating module can be remarkably improved, labor hours for maintenance can be remarkably reduced, and positive effects on the promotion of rapid development of an operating machine with a plurality of functional modules are ensured.

Owner:杨挺

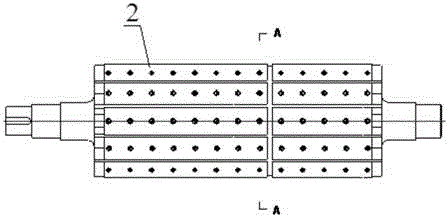

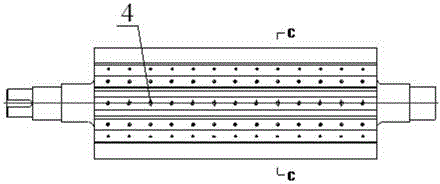

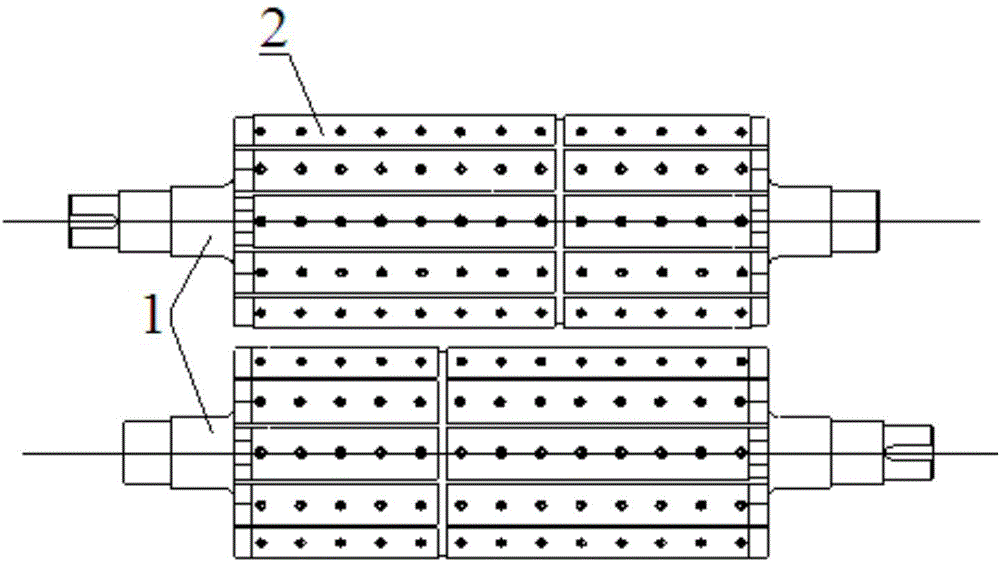

Rolling-type crusher pressure roller with double-metal pressure strips

InactiveCN104128226AReduce consumptionSimple manufacturing processGrain treatmentsWear resistantCrusher

The invention discloses a rolling-type crusher pressure roller with double-metal pressure strips. The rolling-type crusher pressure roller comprises multiple roller shafts rotatingly installed in a crusher housing, the multiple roller shafts are arranged side by side, outer cylindrical surfaces of the multiple roller shafts are provided respectively with multiple axial grooves along a circumferential direction, strip-shaped bosses are inset respectively in the axial grooves, pressure strips are integrally connected to the upper surfaces of the strip-shaped bosses, and the strip-shaped bosses are prepared from a metal material different from a metal material for preparation of the pressure strips. The pressure strips are inset in the surfaces of the roller shafts so that a manufacturing process is simplified and a manufacturing cost is saved. Maintenance time is greatly reduced by insertion installation. Through use of the double-metal pressure strips, energy and precious metals consumed by surfacing of a wear-resistant layer on the roller surfaces are saved, processes are simplified and labor and time are saved.

Owner:盛金平

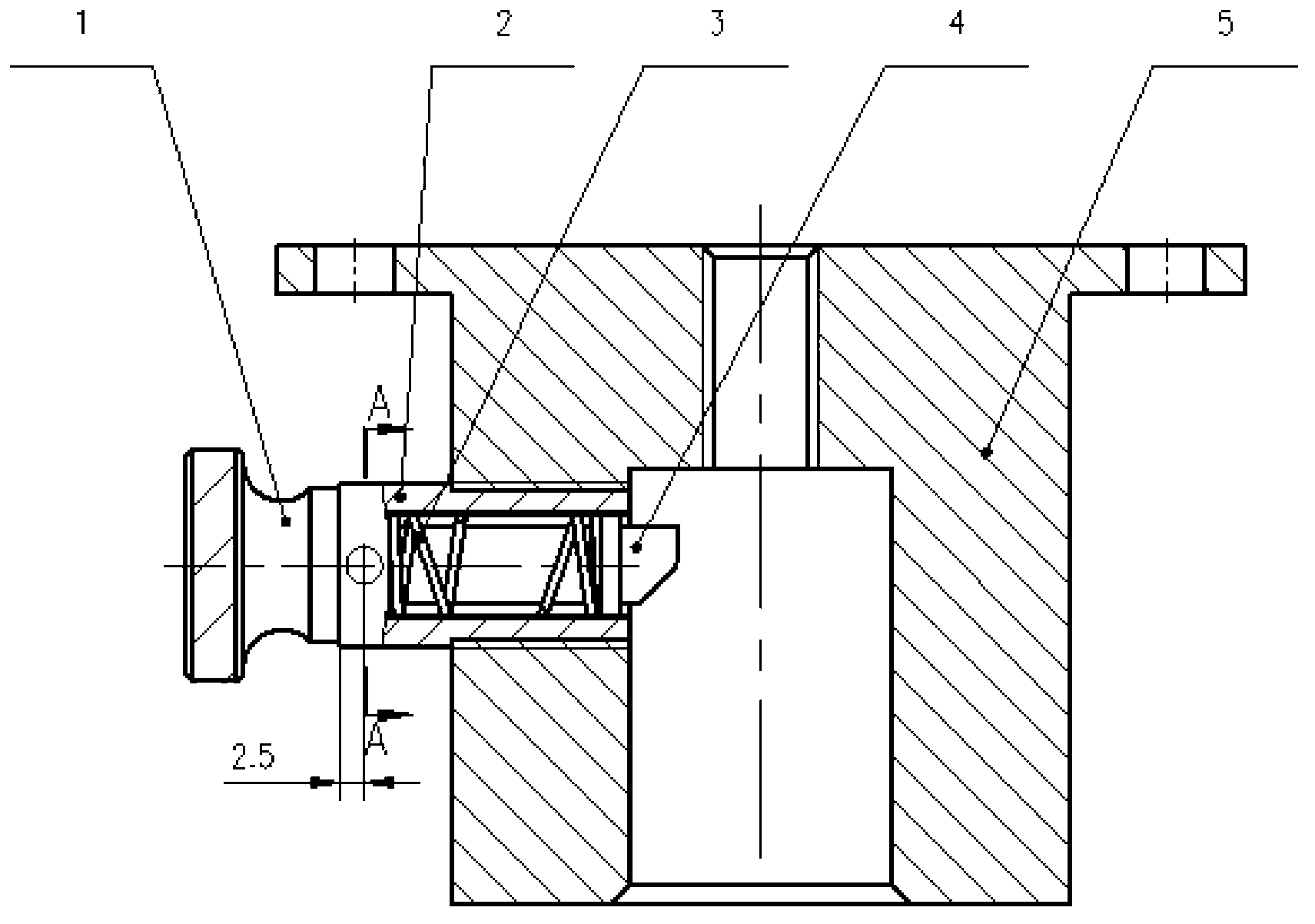

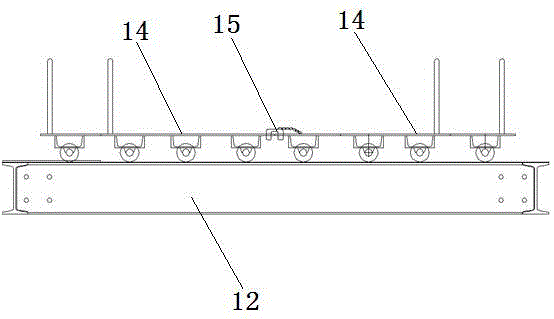

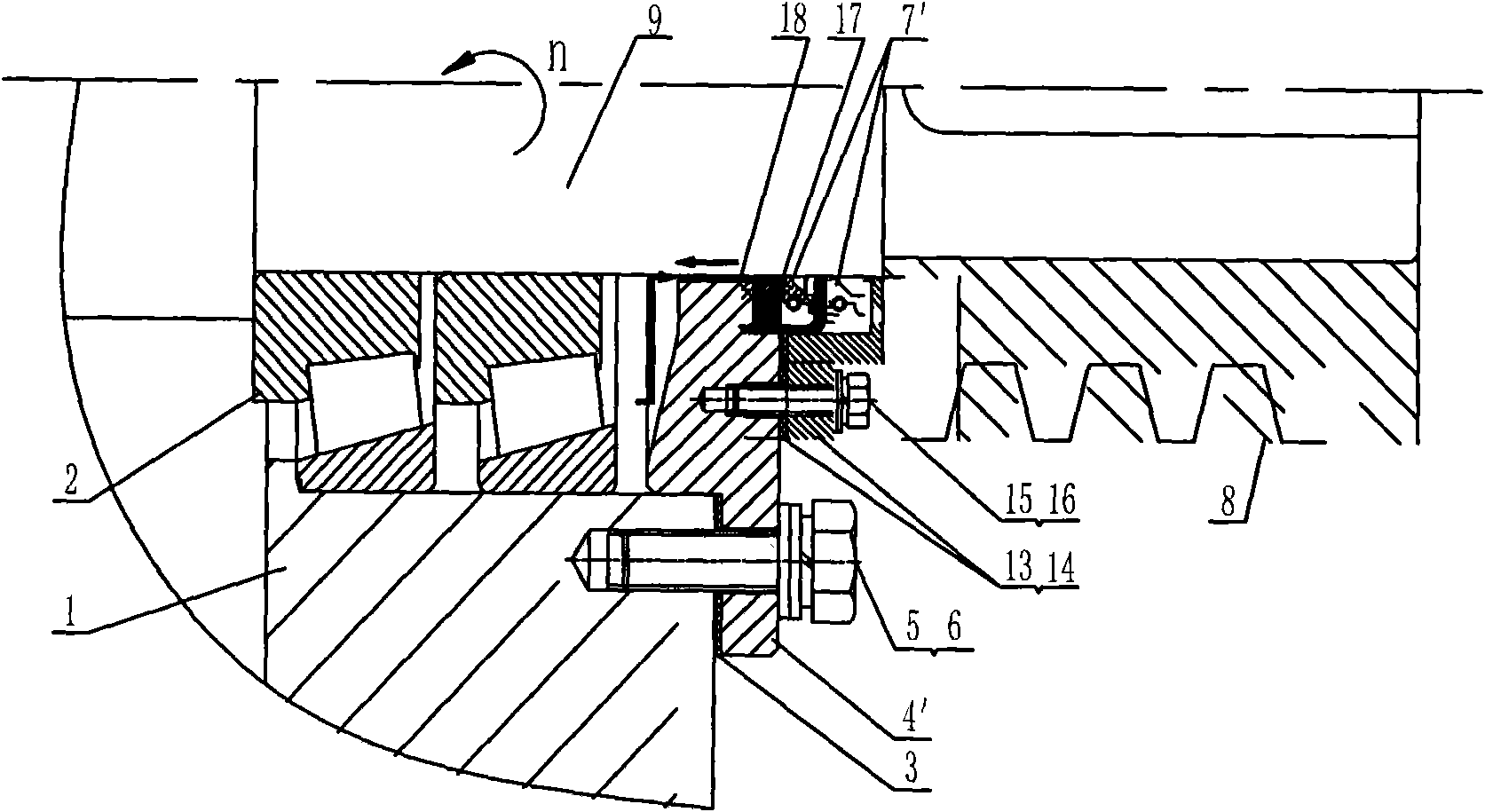

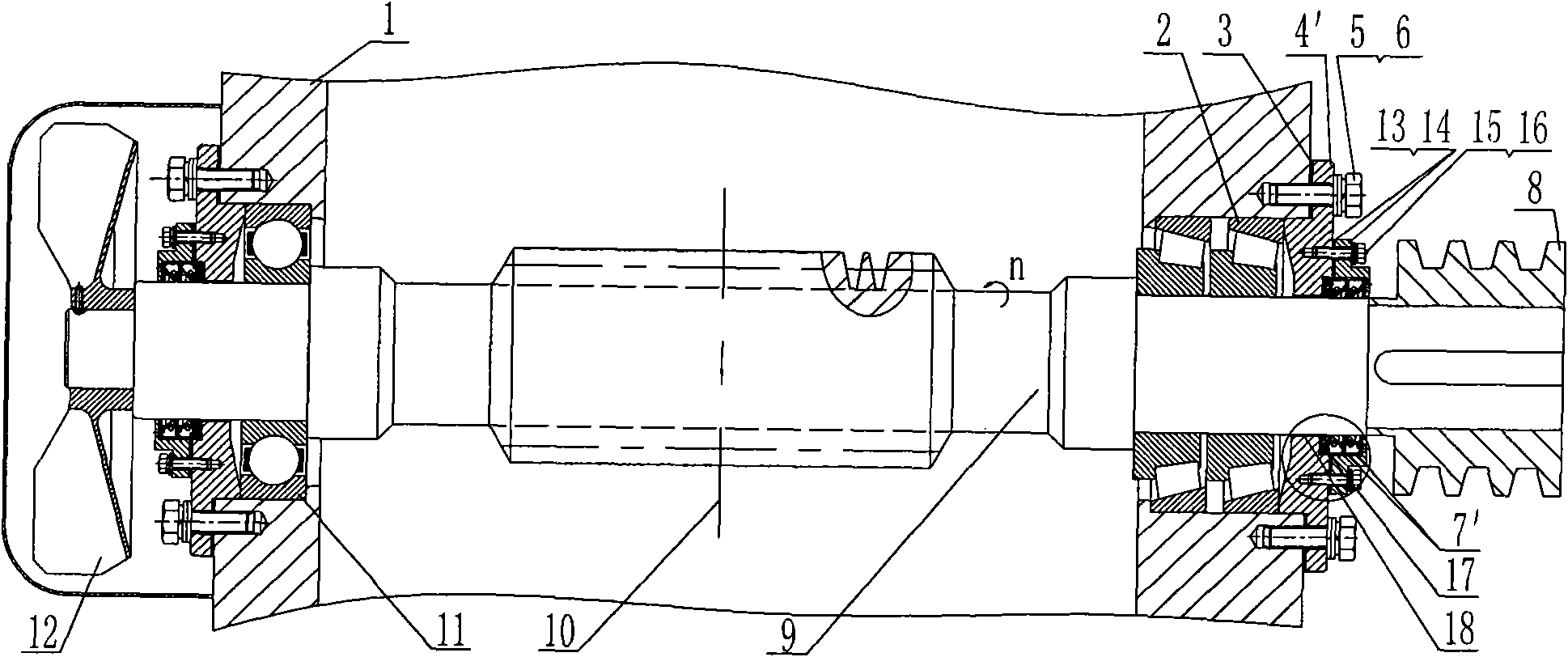

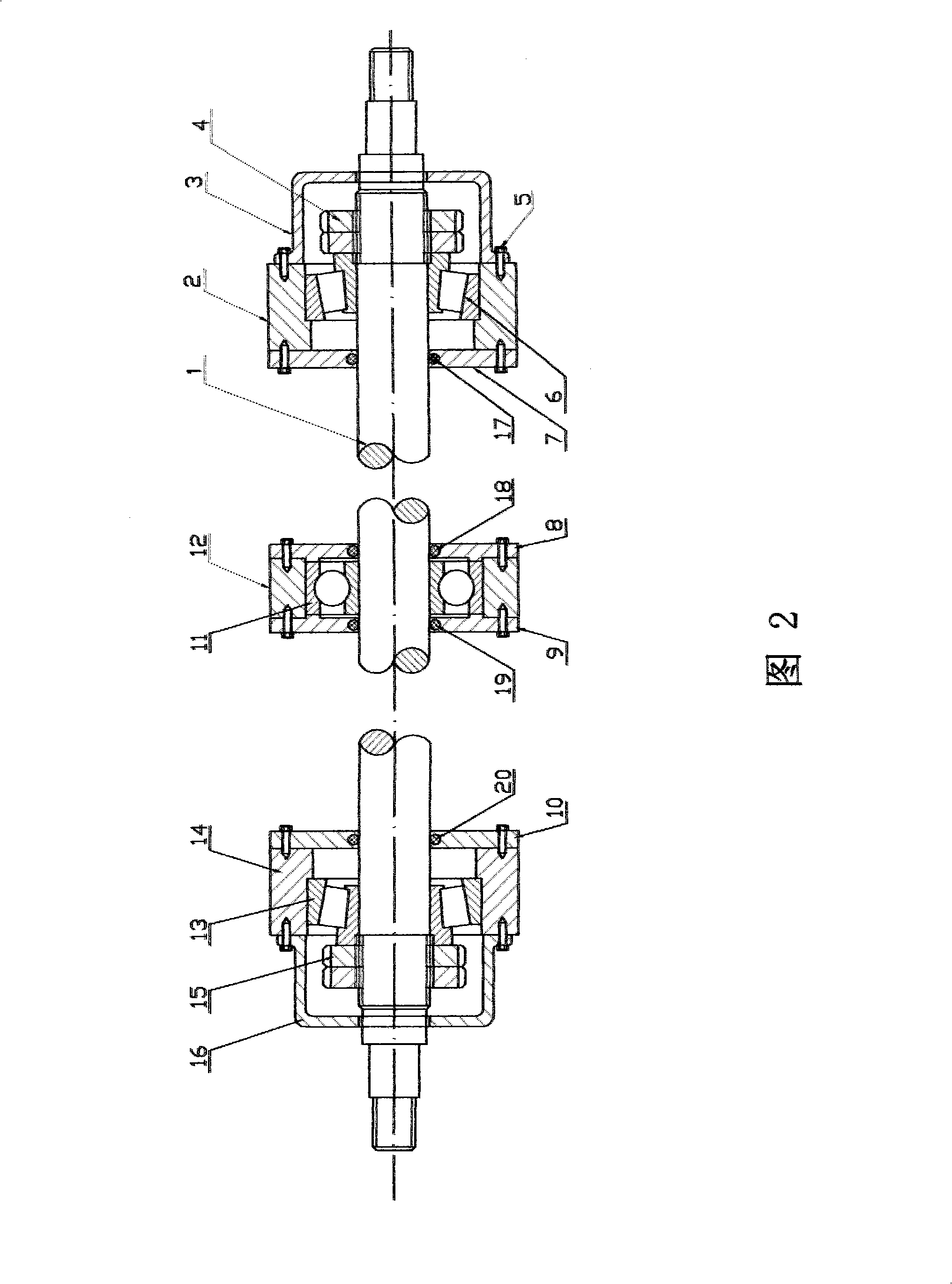

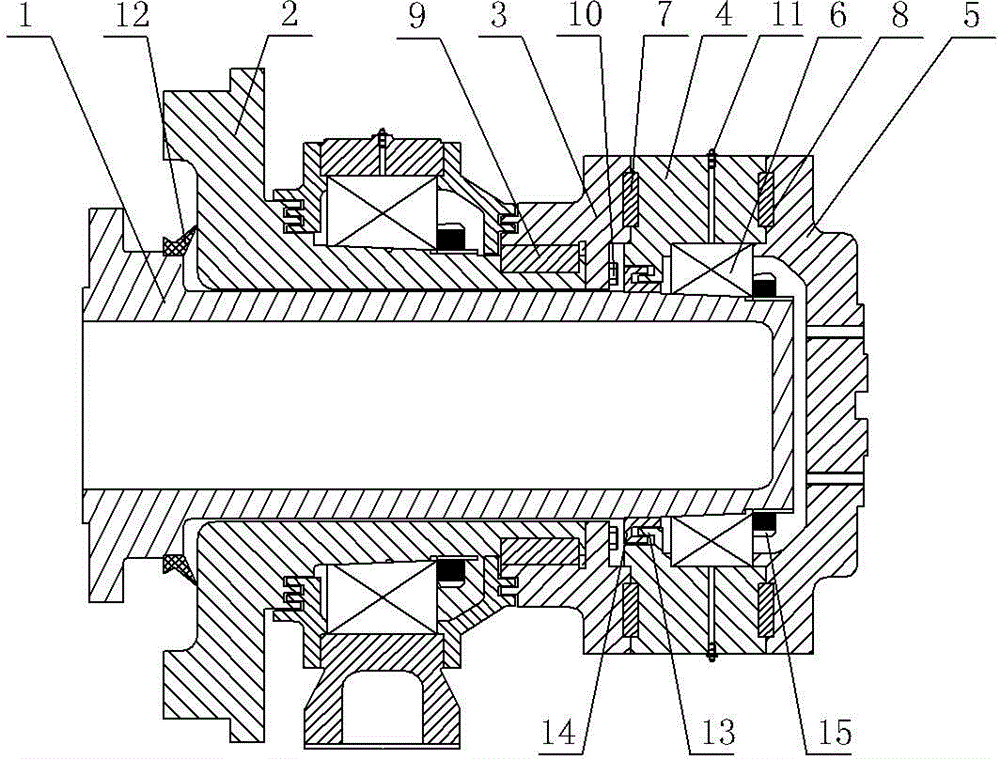

Transmission gear for control spindle of cam automatic lathe

InactiveCN101407028AExtend the lifespanImprove cutting accuracyAutomatic/semiautomatic turning machinesFeeding apparatusEngineeringCam

The invention provides a transmission device for a distributing shaft of a cam automatic lathe. A bearing 6, a bearing 11 and a bearing 13 are arranged between the distributing shaft 1 and distributing shaft brackets 2, 12 and 14, so as to improve the cutting precision of the lathe, prolong the service life of the distributing shaft, and reduce wasted working hours due to maintenance. The transmission device is characterized in that the bearing 6, the bearing 11 and the bearing 13 are arranged in holes formed by the distributing shaft 1 and the distributing shaft brackets 2, 12 and 14.

Owner:刘军

High-performance metal hard sealing butterfly valve

The invention discloses a high-performance metal hard sealing butterfly valve which comprises a valve body, a butterfly plate assembly, a valve rod, a valve seat, a valve seat pressure plate and a retainer ring; the valve seat is fixed onto the inner wall of the valve body through the valve seat pressure plate and an inner hexagonal flat-end fastening bolt; a metal gasket is arranged between the valve seat and the plane adjacent to the valve body; the butterfly plate assembly comprises a butterfly plate, a metal sealing ring, a sealing ring gasket, a pressure plate, an inner hexagonal screw and a dowel pin; a groove is formed in the end surface on one side of the butterfly plate; the sealing ring gasket is arranged in the groove; the metal sealing ring is arranged between the butterfly plate and the pressure plate; and the pressure plate is used for fixing the metal sealing ring through the inner hexagonal screw. According to the high-performance metal hard sealing butterfly valve disclosed by the invention, the butterfly plate metal sealing ring and the butterfly plate are independent, and the valve body and the valve seat are also independent, so that two-way sealing is realized, the butterfly valve is not limited by a flow direction, and application of the butterfly valve is expanded; and moreover, the metal sealing ring on the butterfly plate and the valve seat can be independently replaced, and the valve is not needed to be integrally replaced, so that economic benefits are improved.

Owner:SHANGHAI KAIGONG VALVE CO LTD

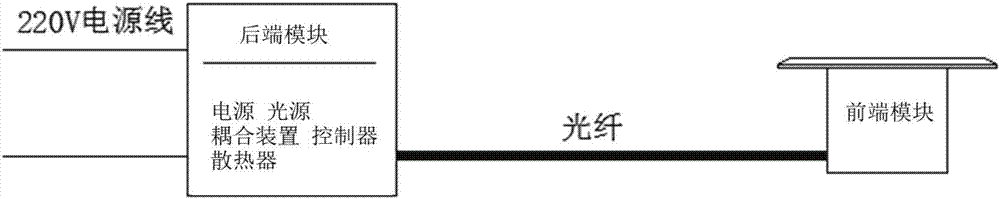

Optical fiber underground lamp

PendingCN107023801AAvoid the risk of electric shockReduce volumeMechanical apparatusElectric circuit arrangementsEngineeringLighting system

The invention provides an optical fiber underground lamp which is characterized by comprising a back end module and a front end module, the back end module is connected with the front end module by using an optical fiber, wherein the front end module comprises an optical fiber lock, an optical fiber, an optical device, a surface cover, toughened glass, an embedded part and a lamp body, wherein the optical fiber is fixedly arranged on the lamp body by the optical fiber lock, the optical device is fixedly arranged on the lamp body, the surface cover and the toughened glass are fixedly arranged on the lamp body by using screws, and the lamp body is connected with the embedded part in a rotational torsion or buckling way. A lighting system of the optical fiber underground lamp is developed for overcoming hidden dangers including electrification, electric shock and electric leakage at a user side, which cannot be solved by lamps in traditional occasions such as a marketplace, a parking lot, a green belt, a park tourist attraction, a residence community, an urban sculpture, a walk street and a building step, and electric shock danger is stopped.

Owner:CHONGQING GLORYCARE TECH CO LTD

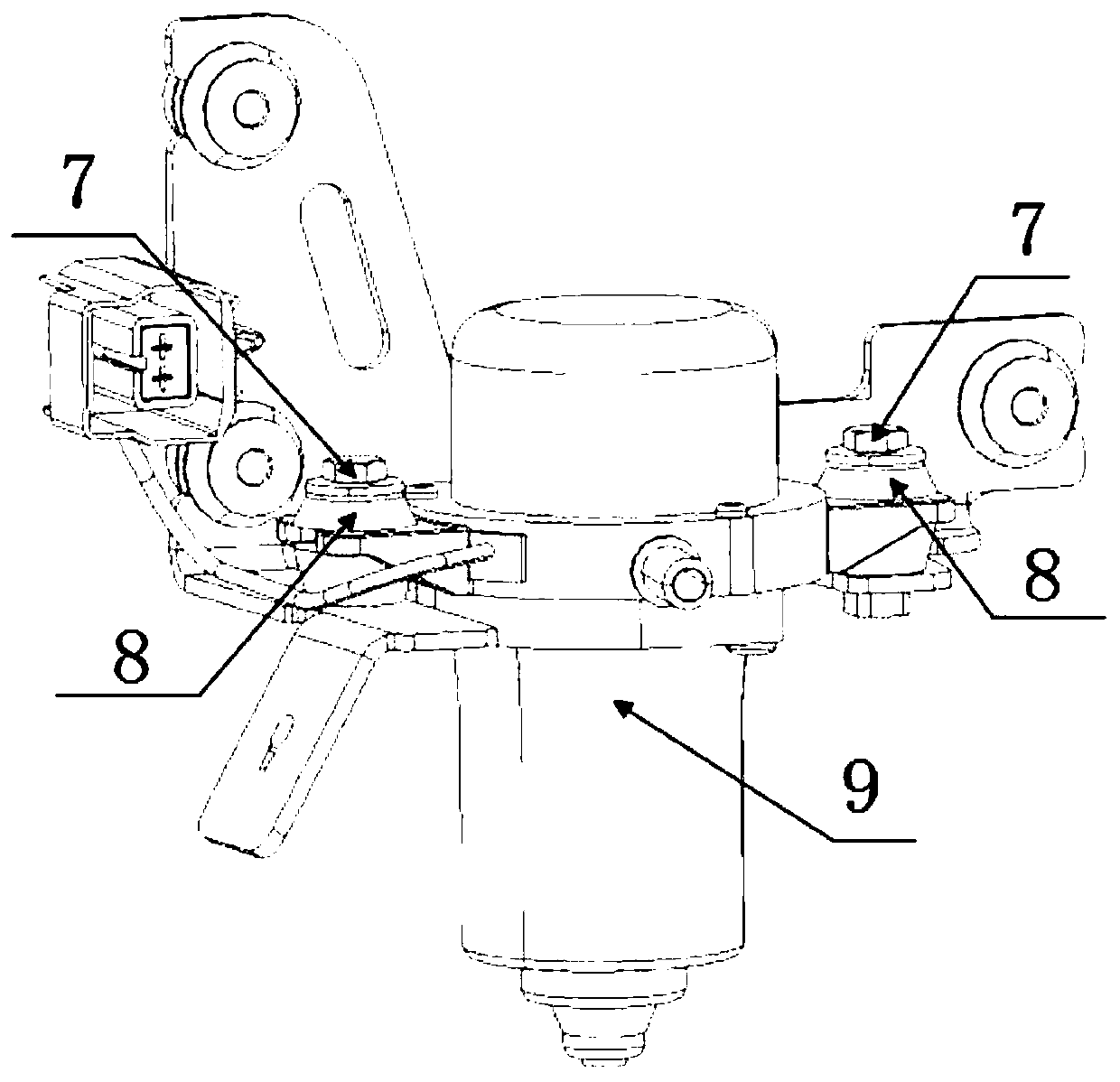

Noise reduction installation support of vacuum booster pump assembly

ActiveCN110103929AReduce vibration noiseReduce electromagnetic noisePump/compressor arrangementsCushioningEngineering

The invention discloses a noise reduction installation support of a vacuum booster pump assembly. The noise reduction installation support comprises a support body. The support body comprises a transverse frame and a longitudinal frame which are connected. The longitudinal frame is provided with a flexible cushioning structure used for reducing noise. An installation structure for installing a vacuum booster pump is reserved on the transverse frame. Vibration and electromagnetic noise of the vacuum booster pump are effectively reduced, and the quiet space in a vehicle is enlarged.

Owner:CHERY COMML VEHICLE ANHUI

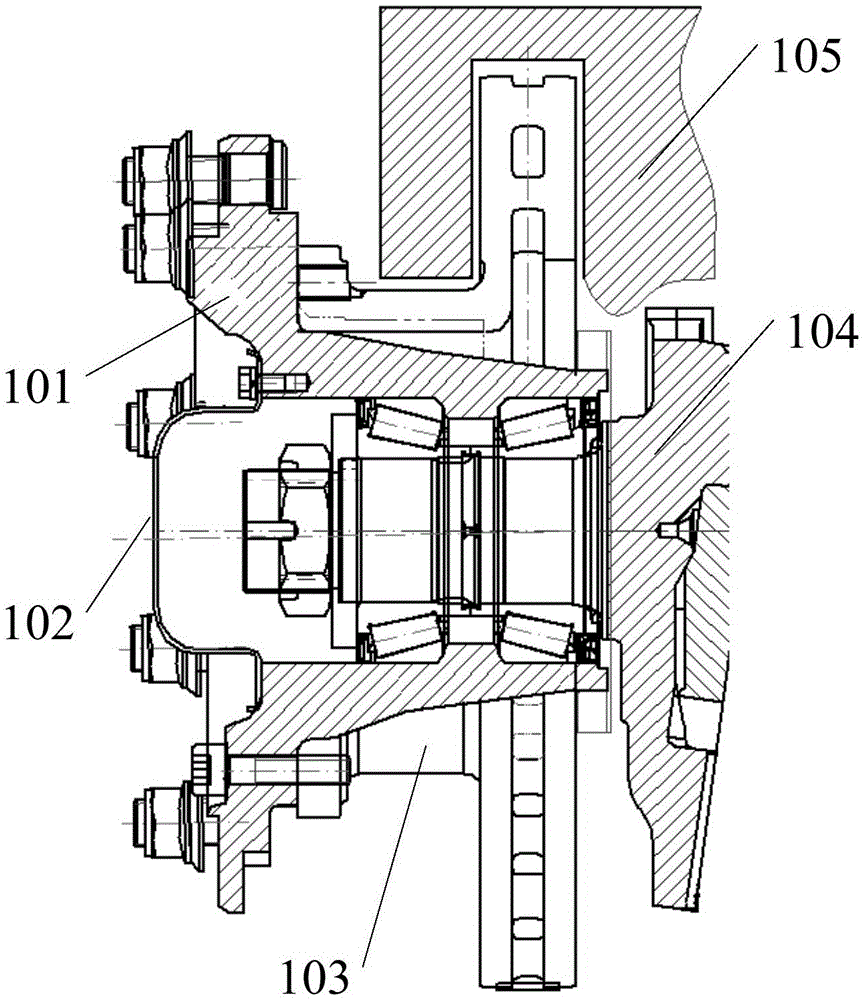

Supporting structure of vacuum box of suction couch roll

InactiveCN105463913AEasy to disassemble and maintainPrevent oil spillsEngine sealsPress sectionEngineeringRegular Production

The invention provides a supporting structure of a vacuum box of a suction couch roll. According to the supporting structure of the vacuum box of the suction couch roll, the structure is simple, the repair is convenient and is short in time consuming, and the adverse effect on regular production can be effectively lowered. The supporting structure comprises a driving side vacuum box head and a journal, wherein the journal sleeves the driving side vacuum box head. The supporting structure is characterized in that the axial length of the driving side vacuum box head is greater than that of the journal, the driving side vacuum box head is located at the outer side of the journal, a bearing seat is arranged on the driving side vacuum box head, and an inner bearing cover of the bearing seat is fixedly connected with the journal.

Owner:WUXI HONGCHENG PAPER MAKING MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com