Forwards and backwards moving control handle device

A joystick, forward and backward technology, applied in machine parts and other directions, can solve the problems of large occupied space, unsatisfactory structure, installation and maintenance, unsatisfactory disassembly and operation, and deviation of the machine, so as to reduce the occupied space and shorten the loading and unloading. and maintenance man-hours, the effect of saving processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

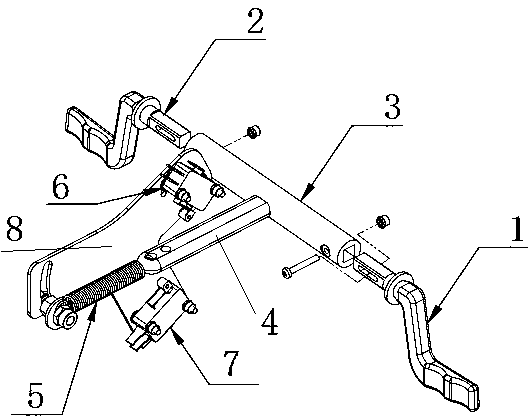

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

[0017] A forward and backward joystick device, mainly used on non-driving type washing machines with forward and backward movement, characterized in that it includes a left joystick 1, a right joystick 2, an intermediate link 3, an extension rod 4, Return spring 5, upper micro switch 6, lower micro switch 7, mounting plate 8, wherein the left joystick 1, the right joystick 2 and the middle connecting rod 3 are connected, and the middle part of the middle connecting rod is provided with an extension rod 4, One end of back-moving spring 5 links to each other with mounting plate 8, and one end links to each other with extending rod 4, and last microswitch 6, following microswitch 7 are installed on the mounting plate, are respectively positioned at the both sides of extending rod.

[0018] The basic principles, main features and advantages of the present invention have be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com