Connector with semiconductor cooling device and automobile

A technology for cooling devices and connectors, which is applied in the direction of cooling/ventilation/heating modification, modification through conduction and heat transfer, etc. It can solve the problems of large heat generation at connection points, blown connection points, and large heat generation, so as to reduce the number of connections Point burnout, avoid vibration and noise, long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

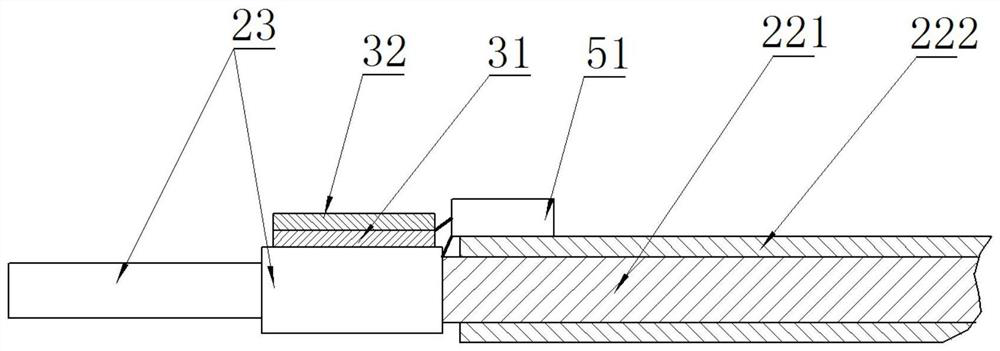

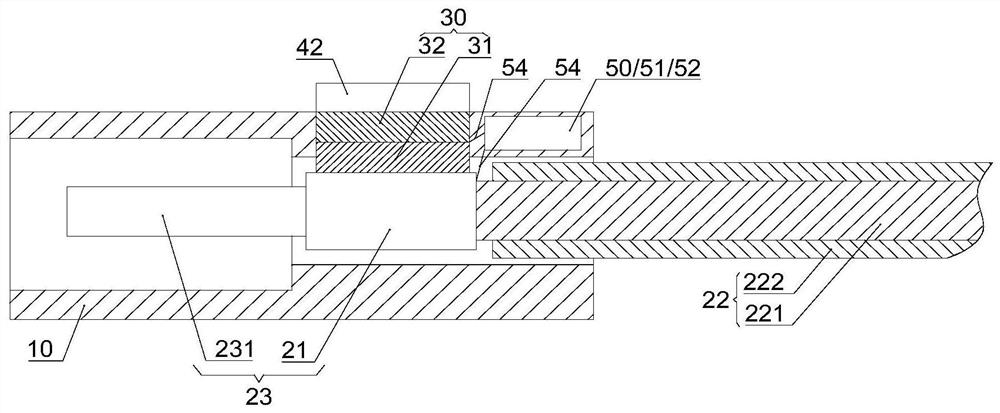

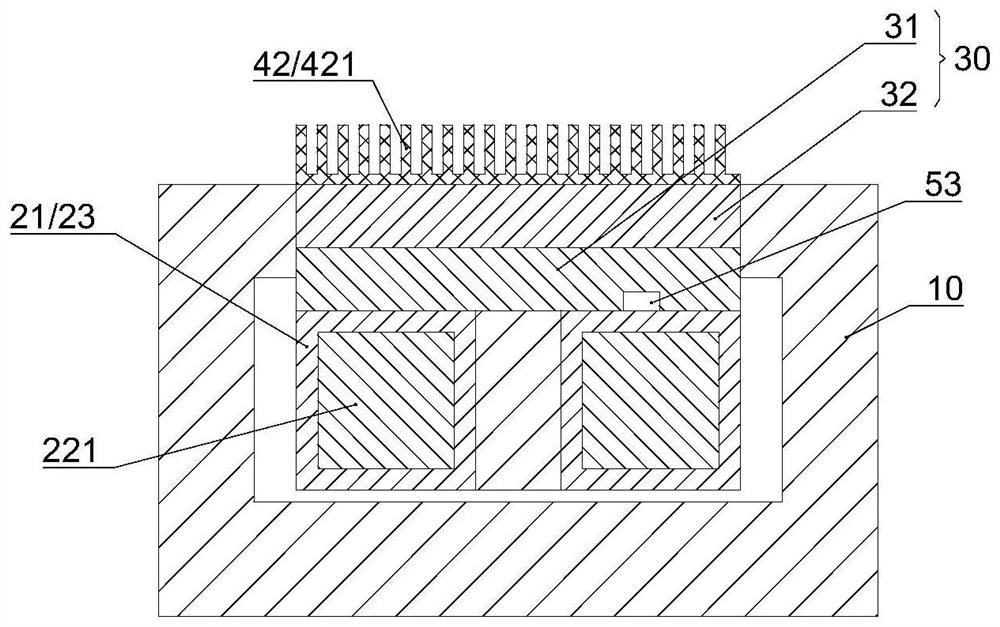

[0054] The present invention provides a connector with a semiconductor cooling device, such as figure 1As shown, the connector includes: a wire 22, a terminal 23 and a semiconductor cooling device 30, the wire 22 is connected to the terminal 23, and the terminal 23 is configured to be connected to an external electrical structure; the semiconductor cooling device 30 has a cooling part 31 and a heat dissipation part 32 , the cooling unit 31 absorbs the heat of the terminal 23 ; and the semiconductor cooling device 30 is electrically connected to the wire 22 .

[0055] In detail, in principle, the semiconductor cooling device 30 is a tool for heat transfer. When a current flows through a thermocouple pair formed by connecting an N-type semiconductor material and a P-type semiconductor material, heat transfer will occur between the two ends, and the heat will be transferred from one end to the other end, thereby generating a temperature difference to form cold and heat. end. In...

Embodiment 2

[0100] The present invention provides an automobile, including the above-mentioned connector with a semiconductor cooling device. The connector in the automobile has the above-mentioned structure, function and beneficial effect, which will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com