One-way valve assembly used in sludge pump

A one-way valve and sludge pump technology, applied in the field of one-way valve components and one-way valve components in sludge pumps, can solve the problems of lack of working strength of the component shell, waste of maintenance man-hours, and high manufacturing costs, and achieve convenient The effect of inspection and maintenance, prolonging service life and saving maintenance man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

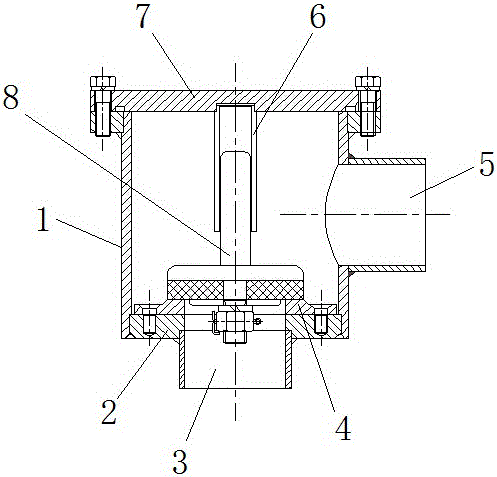

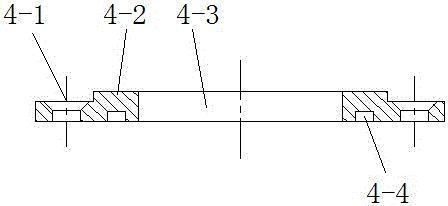

[0022] Such as Figure 1-2 As shown, the one-way valve assembly used in the sludge pump includes an assembly housing 1 and a valve core 8 set in the assembly housing 1; the assembly housing 1 consists of an inlet port 3, an outlet port 5, a bottom plate 2 and a valve The inlet port 3 and the outlet port 5 form an included angle of 90° with each other. A valve ring 4 is arranged above the bottom plate 2. The valve cover 7 is fixed above the component housing 1. The bottom surface of the valve cover 7 is provided with a chute 6. The valve The valve stem of the core 8 slides and acts on the chute 6 , and the sealing pad at the bottom of the valve core 8 acts on the upper surface of the valve ring 4 .

[0023] Such as Figure 1-2 As shown, for the one-way valve assembly used in the sludge pump, the inlet port 3 and the outlet port 5 are provided with flanges that can be conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com