Processing apparatus

A technology for processing devices and processed objects, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as time-consuming, and achieve the effect of reducing axis movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

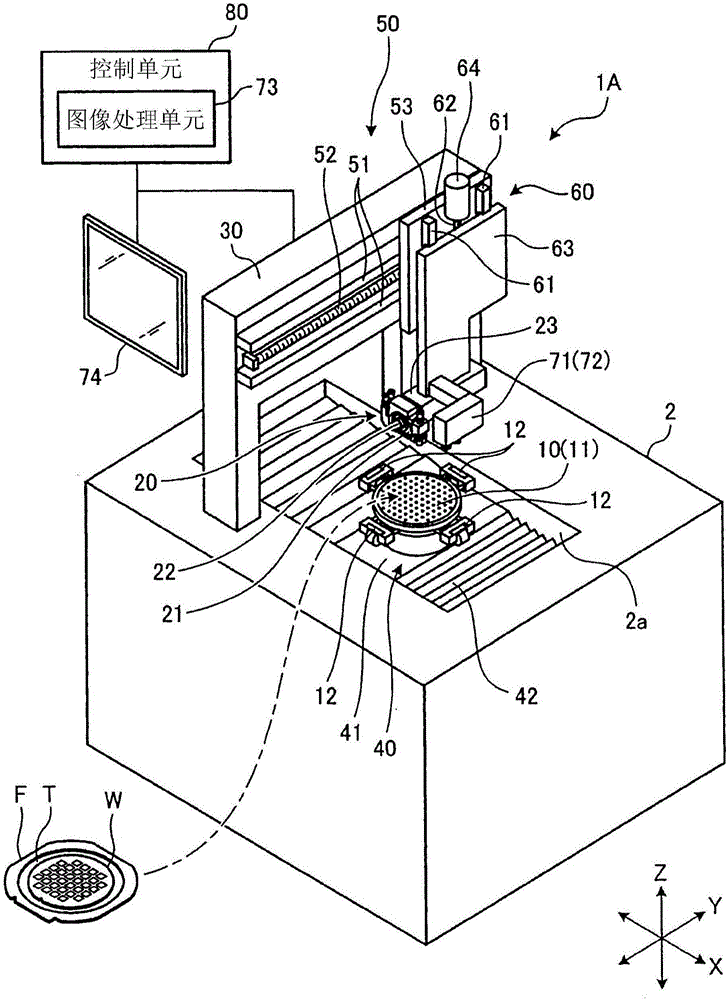

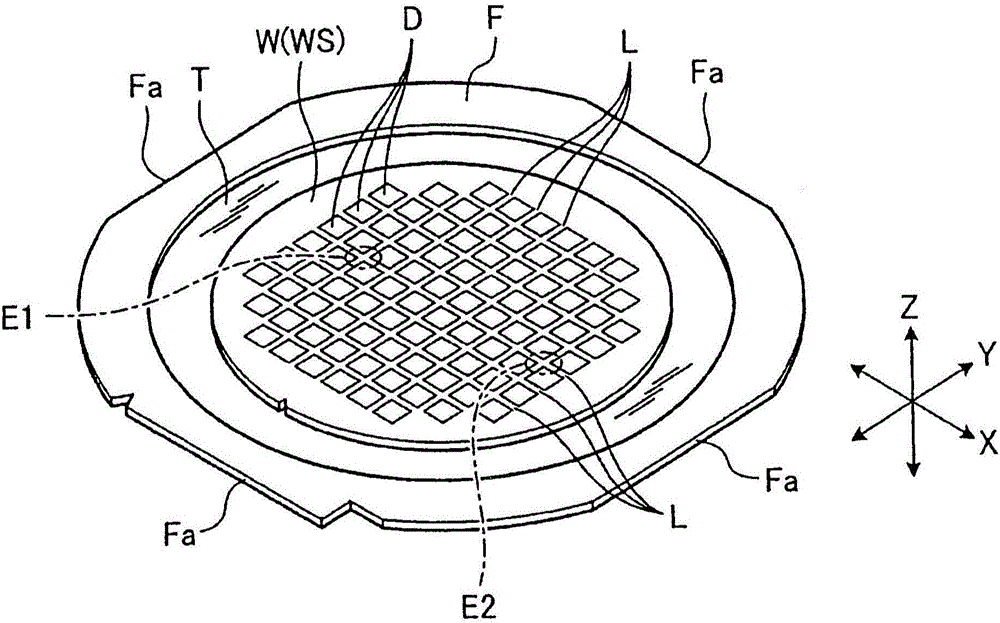

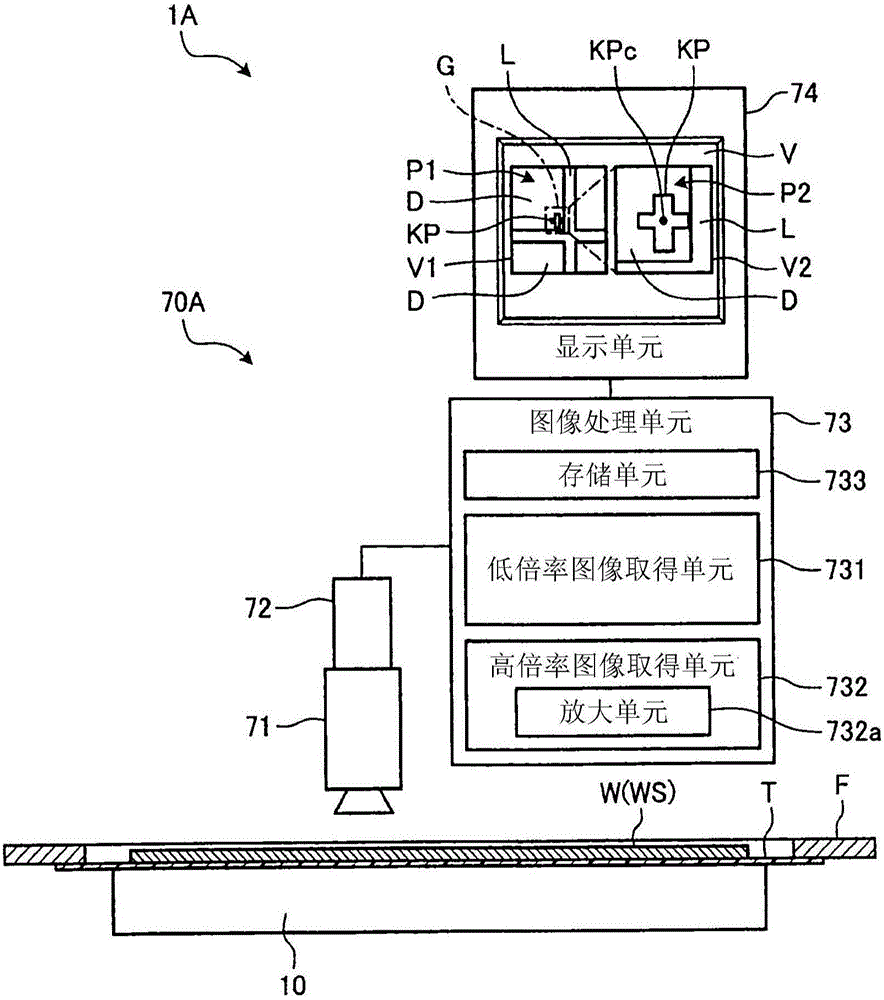

[0023] Next, a configuration example of the processing device according to the first embodiment will be described. figure 1 It is a perspective view which shows the structural example of the processing apparatus of 1st Embodiment. figure 2 It is a perspective view showing the imaging area of the wafer according to the first embodiment. image 3 It is a block diagram showing a configuration example of the calibration unit of the first embodiment.

[0024] The processing apparatus 1A is used to cut the wafer W. As shown in FIG. The processing device 1A has a chuck table 10 , a processing unit 20 , a portal frame 30 , a processing feed unit 40 , an index feed unit 50 , a plunging feed unit 60 , a calibration unit 70A, and a control unit 80 .

[0025] The wafer W is various workpieces such as semiconductor wafers and optical device wafers formed with semiconductor devices and optical devices, inorganic material substrates, ductile resin material substrates, ceramic substrates...

no. 2 Embodiment approach

[0049] Next, a processing device according to a second embodiment will be described. Figure 5 It is a block diagram showing a configuration example of the calibration unit of the second embodiment. Figure 5 The illustrated calibration unit 70B differs from the calibration unit 70A of the first embodiment in that the low-magnification image acquisition unit 731 includes an image compression unit 731 a.

[0050] The image compression unit 731a compresses the low-magnification image data, for example, using methods such as JPEG (Joint Photograph Experts Group: Joint Photographic Experts Group) or GIF (Graphics Interchange Format: Graphics Interchange Format) to compress the low-magnification image data to about a fraction .

[0051] Next, an example of the operation of the calibration unit 70B will be described. Figure 6 It is a flowchart showing an operation example of the calibration unit of the second embodiment. In this example, as a premise of the description, the notc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com