Transmission gear for control spindle of cam automatic lathe

A technology of automatic lathes and transmission devices, which is applied in the direction of automatic lathes/semi-automatic lathes, feeding devices, turning equipment, etc., and can solve the problems of reduced precision of distribution shafts, difficulty in ensuring the precision of processed parts, and large fit gaps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0006] specific implementation plan

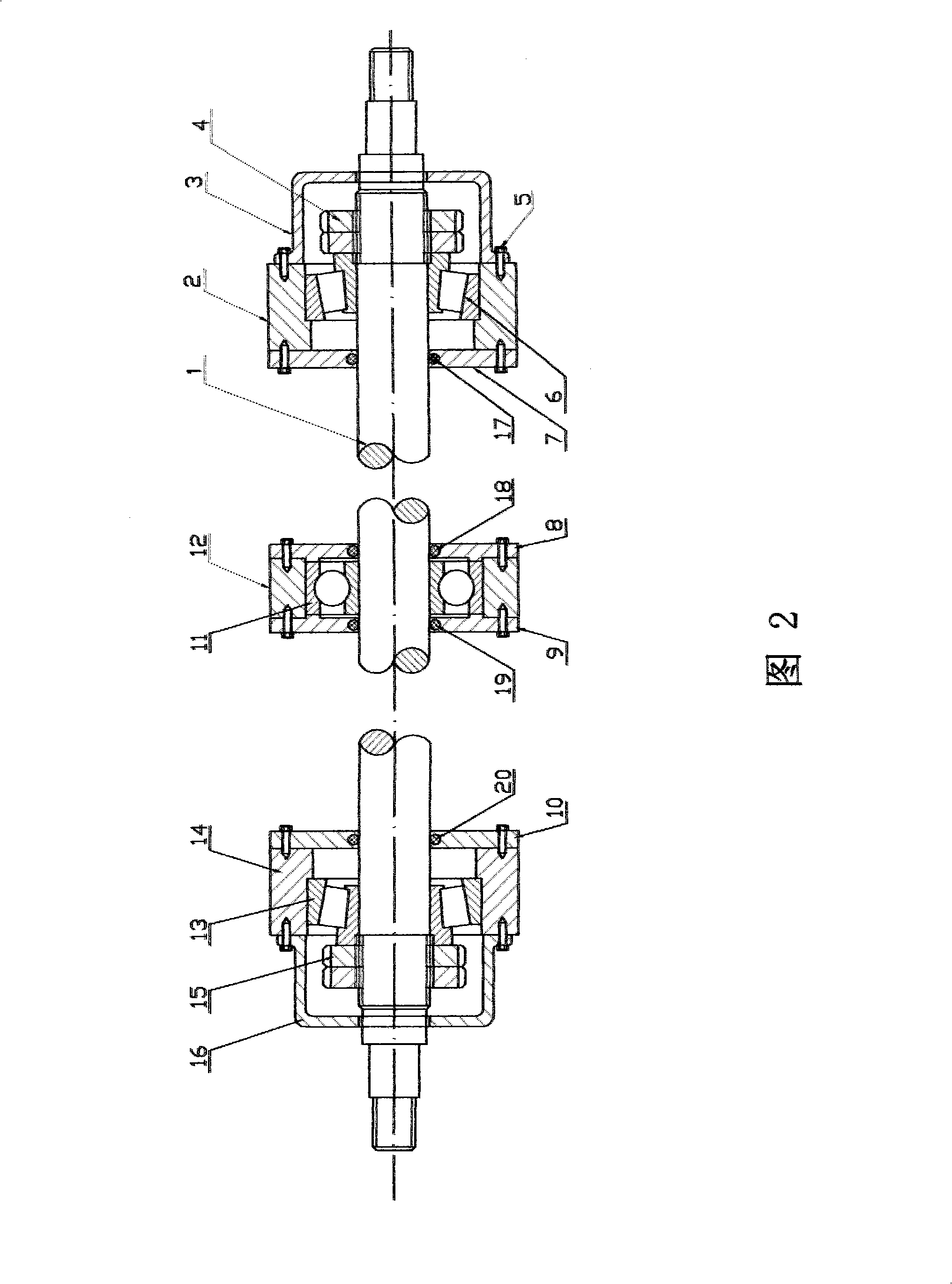

[0007] 1. The current utilization method is: refer to Figure 2, according to the design requirements of the drawing of the distribution shaft 1, A. After quenching and tempering the round steel, use the lathe to make the size, B. Mill the keyway, C. Heat treatment, D. Grinding outer diameter.

[0008] 2. The current utilization method is, referring to Fig. 2, according to the drawing design requirements of distribution shaft brackets 2, 12, 14, A, making the appearance with cast iron casting, milling, and wire cutting, B, using a lathe, boring machine, and wire cutting The processing is used for the holes of device bearings 6,11,13.

[0009] 3. The method currently utilized is, referring to Fig. 2, according to the design requirements of the drawings of the dust cover 3, 16, A, using metal materials, car-making its external shape and inner hole cavity, B, drilling and distributing shaft frame 2 , 12, 14, the screw hole of connection, C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com