Supporting structure of vacuum box of suction couch roll

A technology of vacuum couch roll and support structure, applied in the field of rolls of paper machines, can solve the problems of reduced production efficiency, complicated maintenance operations, long working hours, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

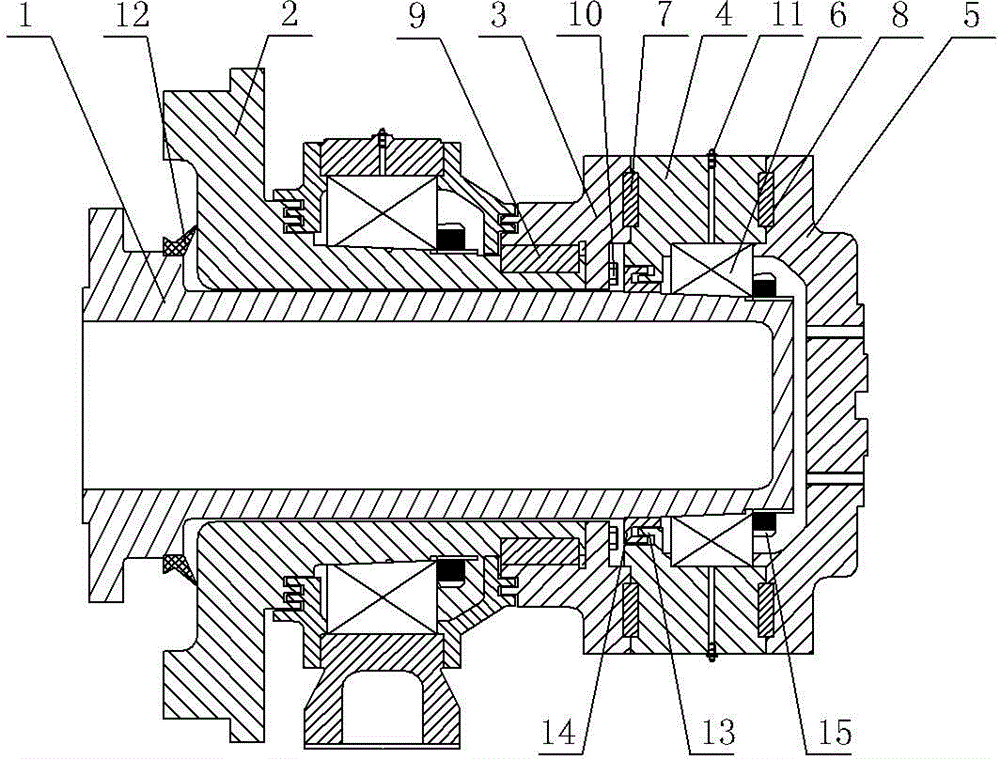

[0015] Such as figure 1 As shown, the supporting structure of the vacuum box of the vacuum couch roll includes the transmission side vacuum box head 1 and the journal 2, the journal 2 is set on the transmission side vacuum box head 1, and the axial length of the transmission side vacuum box head 1 is larger than the journal The axial length of 2 is located on the outside of the journal 2. There is a bearing seat on the transmission side vacuum box head 1. The bearing seat includes the inner bearing cover 3, the outer bearing cover 5, the bearing shell 4 and the bearing 6. The bearing seat is set on the transmission side. The vacuum box head 1 is located outside the journal 2, the bearing is arranged in the installation groove of the bearing seat, and is matched with the transmission side vacuum box head 1, and the inner bearing cover 3 and the outer bearing cover 5 are respectively arranged in the inner bearing shell 4 , the outer two sides, and are connected by flat keys 7 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com