Rolling-type crusher pressure roller with double-metal pressure strips

A crusher and roller press technology, which is applied in the field of roller press rollers of roller press crushers, can solve problems such as roller surface wear and surfacing repair, and achieve the effects of saving manufacturing costs, saving maintenance man-hours, saving energy and precious metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

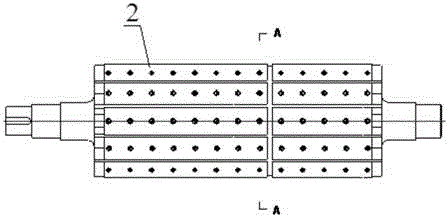

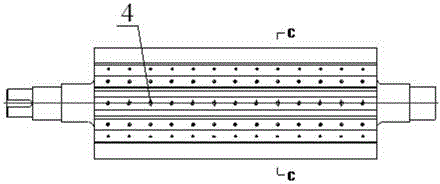

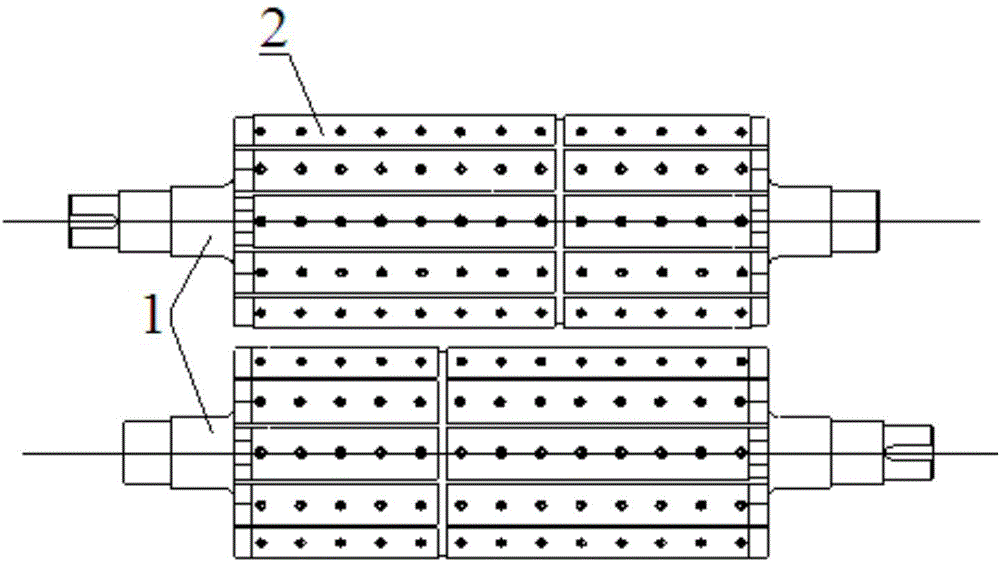

[0022] Referring to the accompanying drawings, a roller crusher roller with a bimetal bead includes a plurality of roller shafts 1 that are rotatably installed in the crusher housing. The plurality of roller shafts 1 are arranged side by side, and the plurality of roller shafts 1 A plurality of axial grooves 3 are respectively arranged on the outer surface of the outer circle along the circumferential direction, and strip-shaped bosses 7 are respectively embedded in the plurality of axial grooves 3, and the upper surface of the strip-shaped boss 7 is integrally connected with a bead 2 , the metal material of the strip boss 7 and the bead 2 are different.

[0023] In the present invention, two of the plurality of roller shafts 1 form a group; the outer circular surface of the plurality of roller shafts 1 is respectively provided with a plurality of threaded holes 4 along the axial direction at the bottom of each axial groove; The table 7 and the bead 2 are respectively provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com