Method for preventing oil leakage of worm gear reducer

A technology of worm gear and reducer, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc. It can solve the problems of poor sealing effect, affecting site sanitation, wear and aggravation of skeleton oil seal, and achieve maintenance and replacement of packing and skeleton The oil seal is convenient, reducing maintenance man-hours and reducing the effect of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

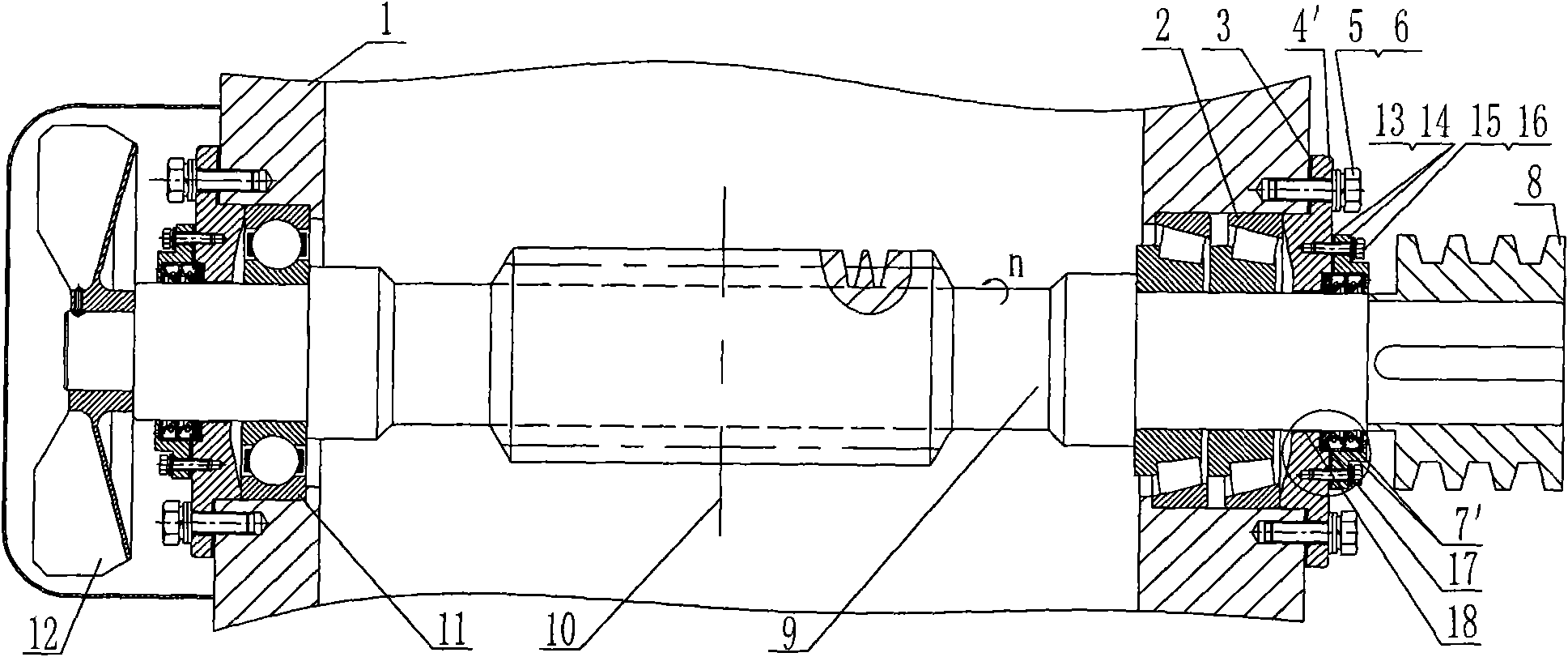

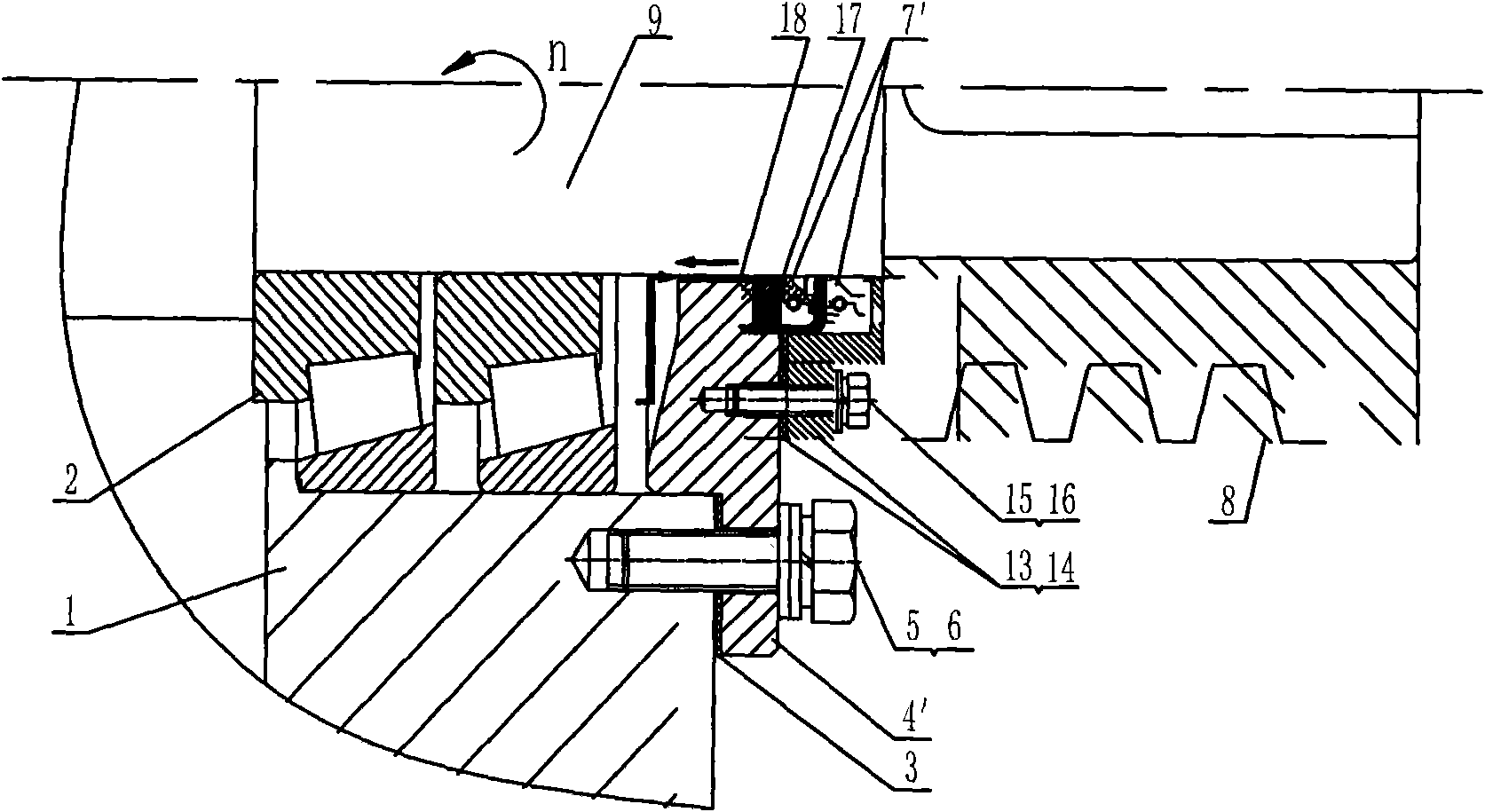

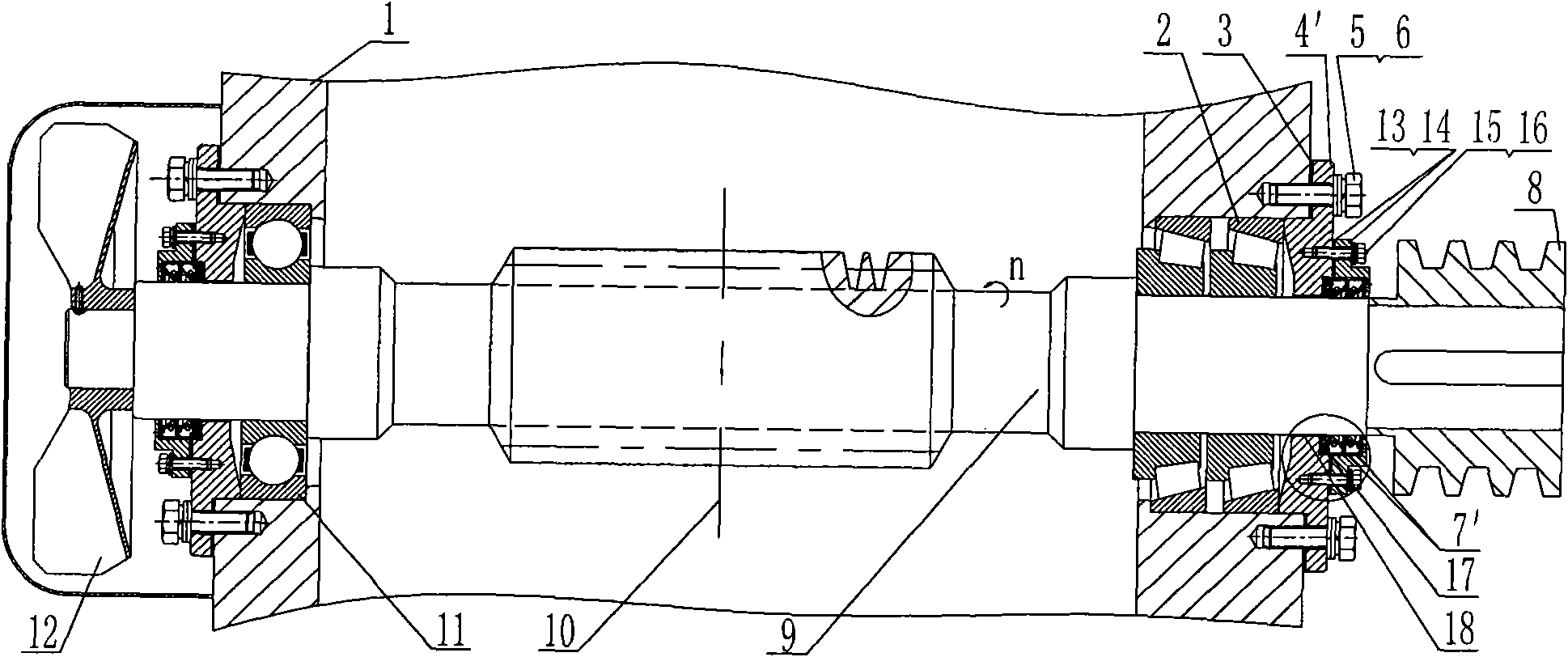

[0016] The main purpose of the present invention is to solve the problem of severe oil leakage at both ends of the worm gear of a worm gear reducer operating at a high temperature and at a medium speed. The question of service life. Because the method of the invention effectively realizes plugging, the productivity is greatly improved, the waste of a large amount of oil is avoided, the maintenance workload of the equipment is reduced, and the on-site sanitation of the reducer is improved.

[0017] The oil leakage of the reducer can be roughly analyzed as oil leakage in two situations: dynamic and static. Dynamic means that the reducer is in operation, and static refers to the state of the reducer after it stops. The method for preventing oil leakage of the present invention adopts the combined scheme of three seals to solve the oil leakage in two different situations. The first seal mainly solves the oil leakage when the reducer is in dynamic state, and the second and third ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com