Patents

Literature

81results about How to "Simplify production management" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

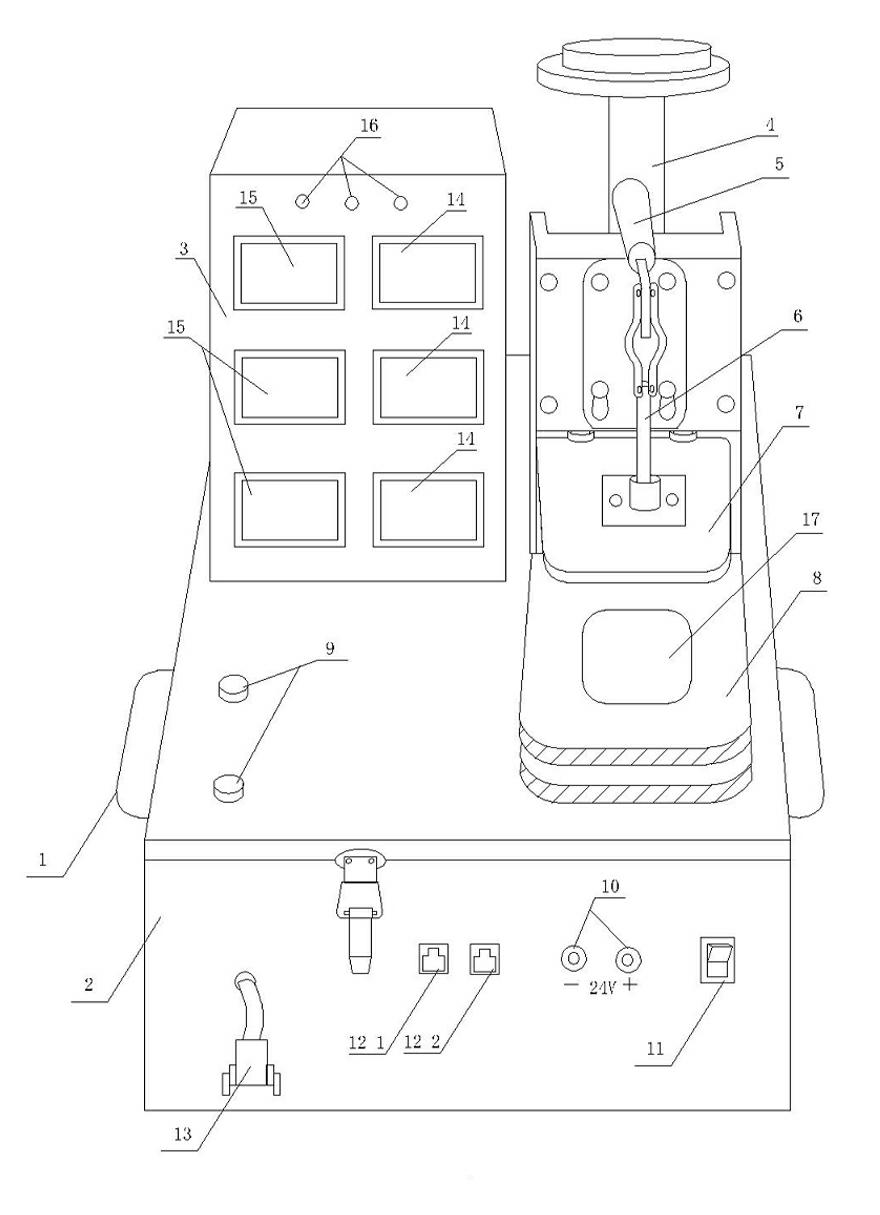

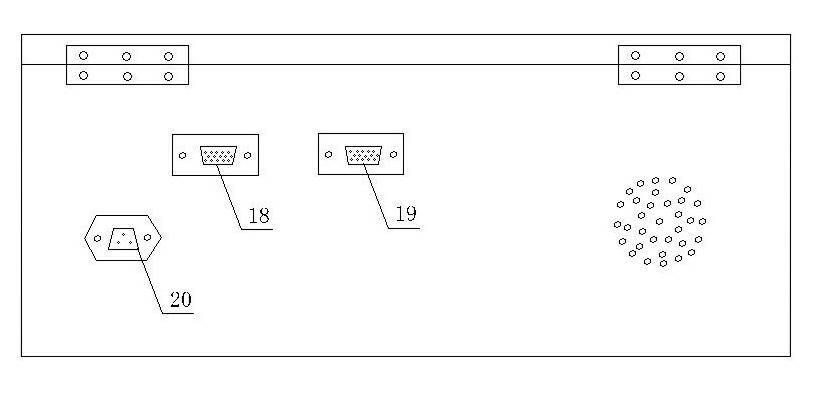

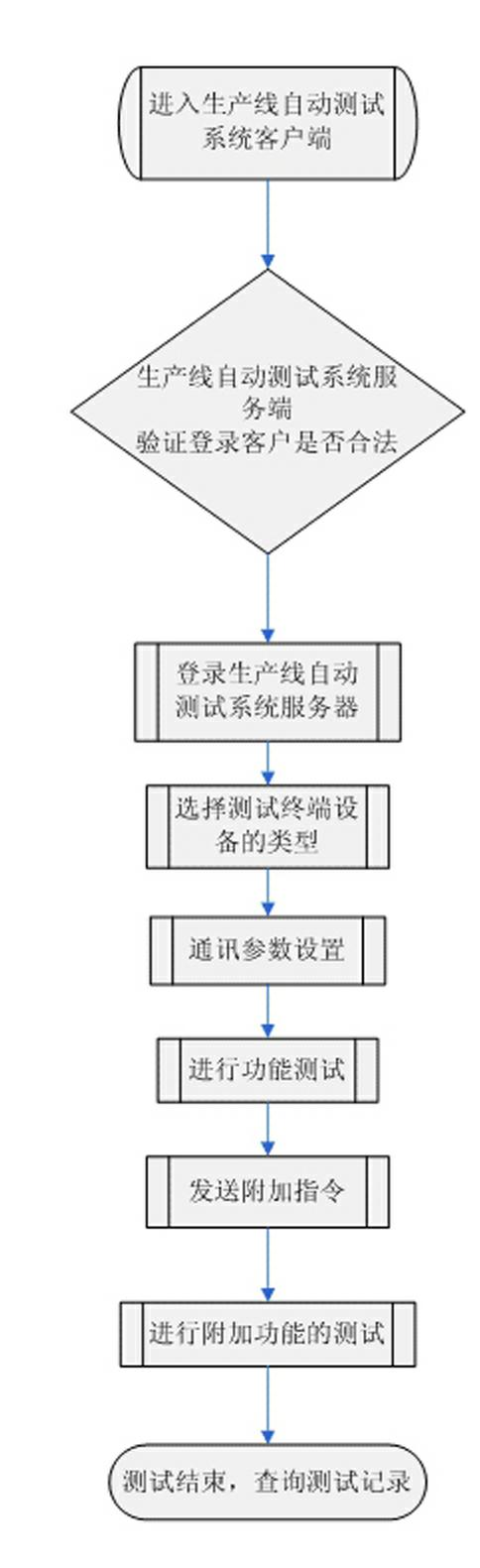

Automatic testing system of production line of vehicle information terminal and testing method of system

ActiveCN102095448AEasy for production managementSimplify production managementMeasurement devicesTransmission systemsTest fixtureFunctional module

The invention relates to an automatic testing system of the production line of a vehicle information terminal and a testing method of the system. By adopting the system and the method, the state of the test terminal can be obtained according to the test record of the automatic testing system of the production line of the vehicle information terminal, the use condition of each functional module can be analyzed and counted and the reference information can be provided for the enterprises to select the functional modules. The automatic testing system comprises a client of the automatic testing system of the production line, a server of the automatic testing system of the production line, a central database of the system, auxiliary equipment for the automatic testing system of the production line, a test fixture of the automatic testing system of the production line and a computer. The testing method comprises the following steps: 1) entering into the client of the automatic testing system of the production line and selecting the type of the test terminal equipment according to the interface prompt of the terminal testing program before testing the equipment; 2) setting the communication parameters; 3) carrying out functional test; 4) sending extra instructions; 5) testing the extra functions; and 6) inquiring the test record.

Owner:TIANZE INFORMATION IND

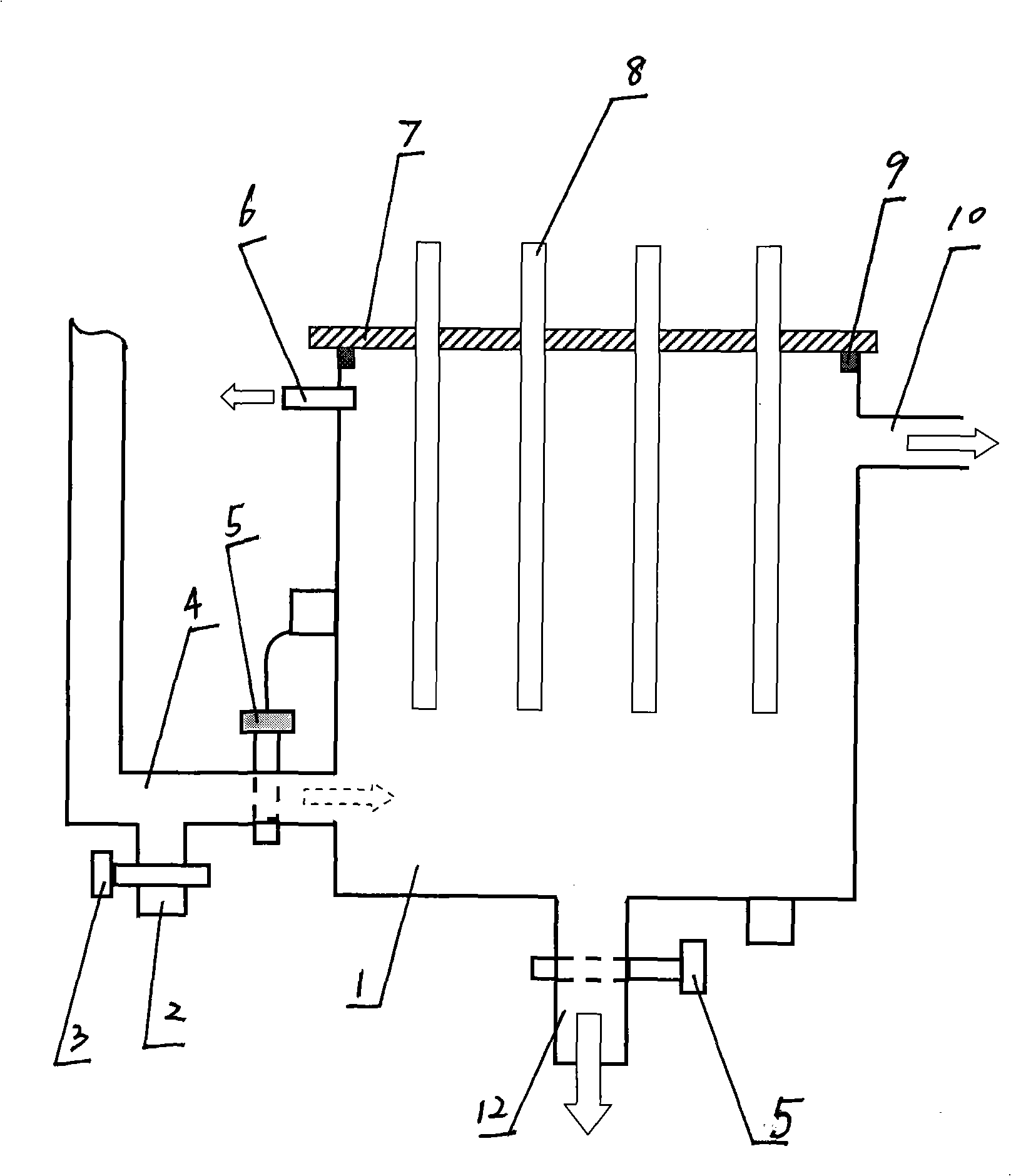

Water sample automatic sampler for monitoring cultivation water quality on-line in sea water factory

InactiveCN101329325AFast samplingAccurate water sampleWithdrawing sample devicesTesting waterWater qualityEngineering

The invention provides a water sample automatic sampler used for the online water-quality monitoring of seawater factory cultivation, which is characterized in that the water sample automatic sampler comprises a water quality detecting box which is provided with a cover plate; the lower part of the water quality detecting box is provided with a water sample inlet pipe which is connected with a plurality of sampling pipes; the upper part of the water quality detecting box is respectively provided with an overflow pipe and a water sample drainage pipe; the water quality detecting box is internally provided with a plurality of water quality sensors with the upper parts extending out of the box body; the bottom of the water quality detecting box is provided with a drainage pipe; the water sample inlet pipe, the sampling pipe and the drainage pipe are all provided with an electronic valve element. The water sample automatic sampler can realize the detection of multi-point water quality, and has low manufacture cost, good practicability and convenient operation and management.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI +1

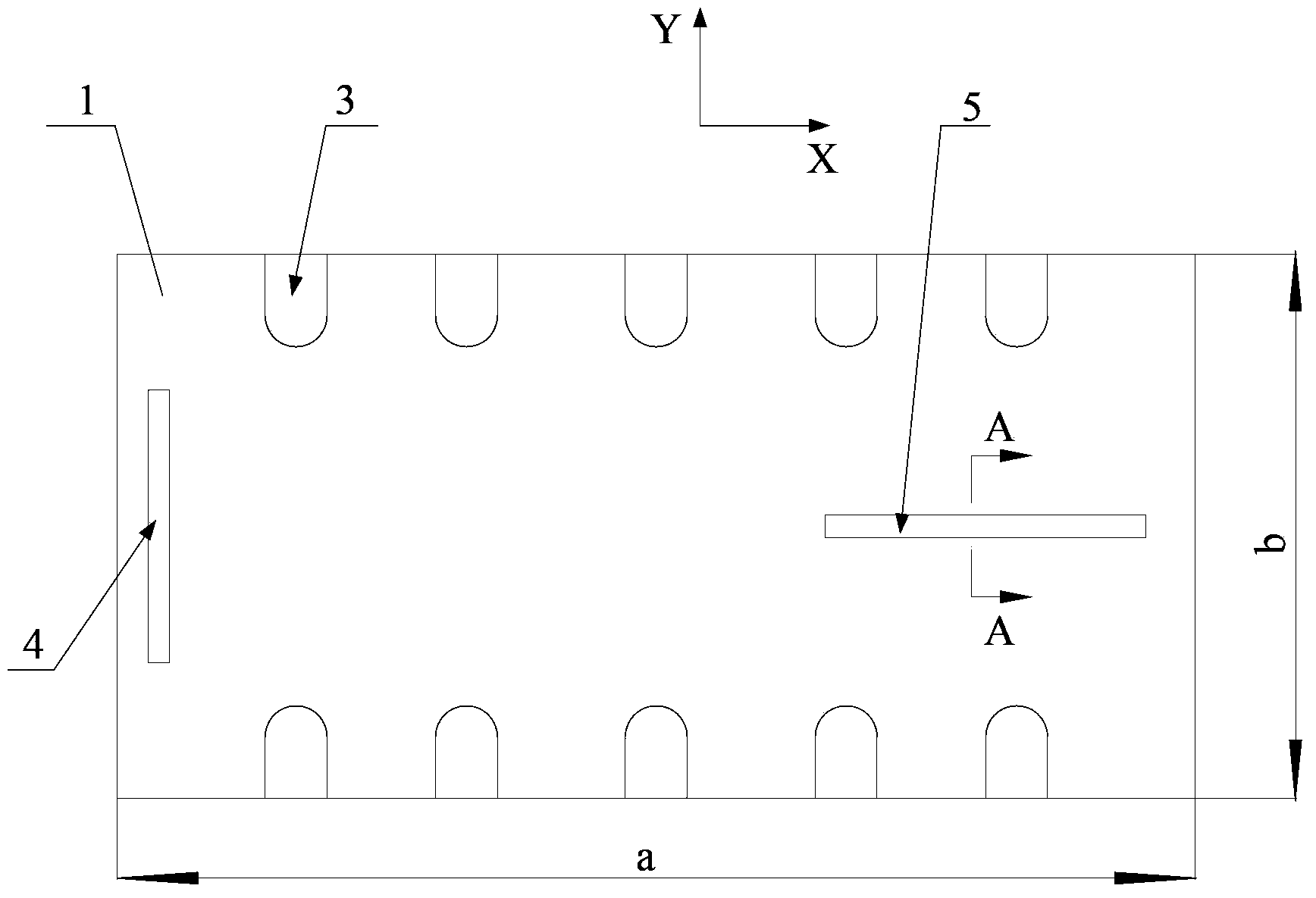

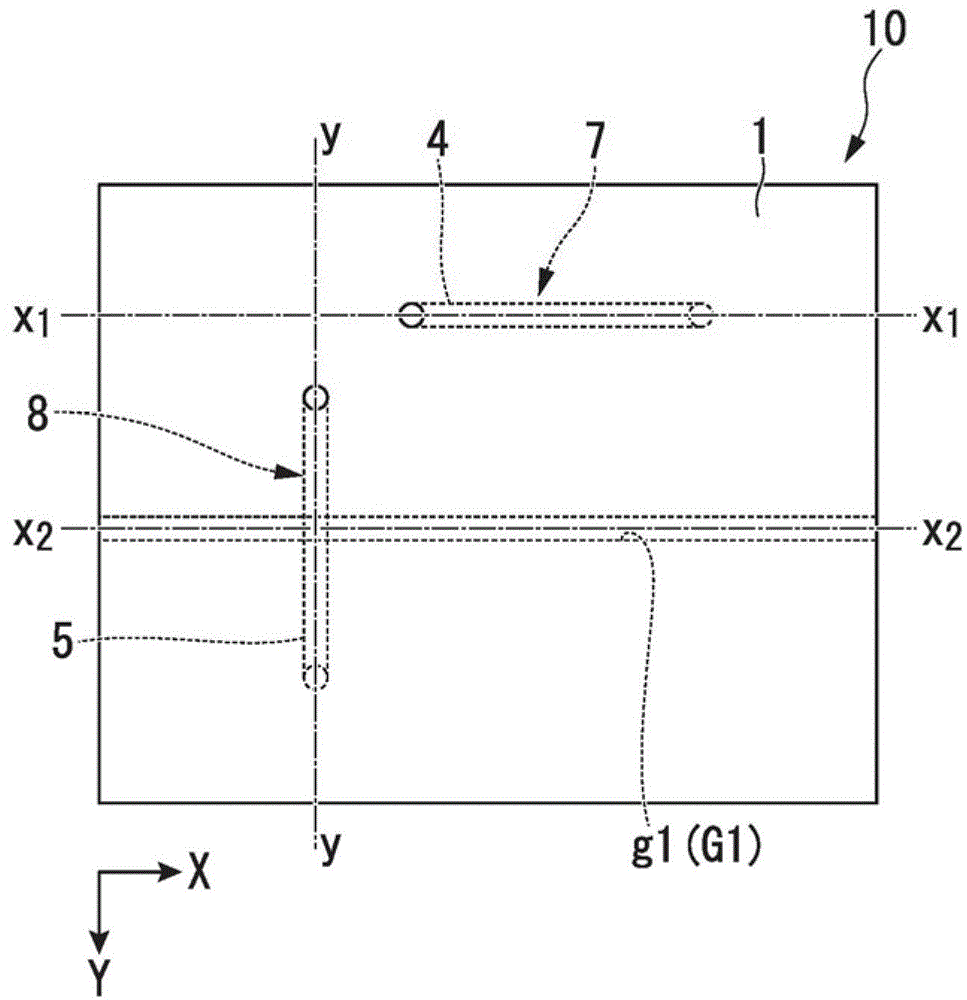

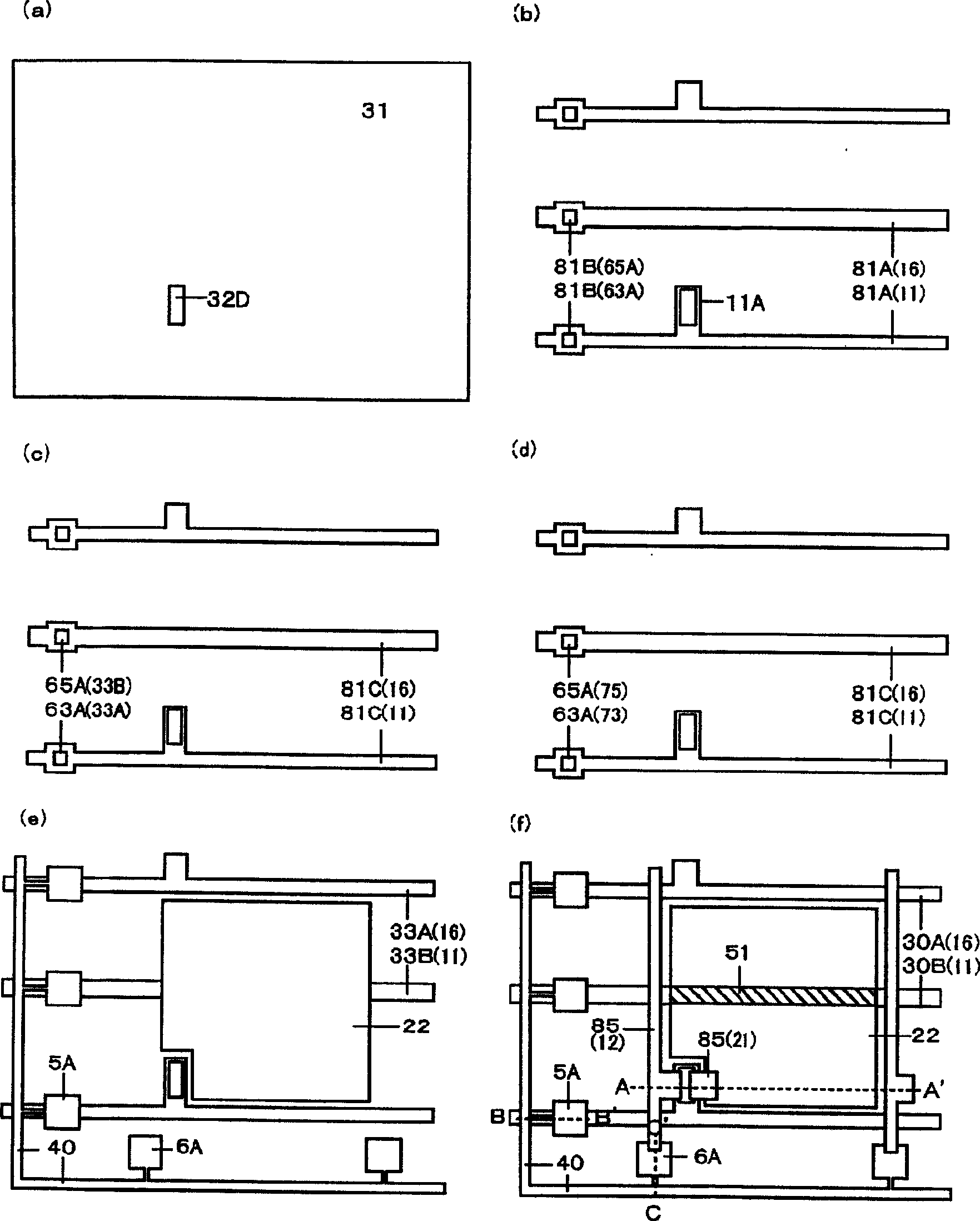

Riveting and positioning fixture, PCB riveting method, manufacturing method for PCB and PCB

InactiveCN103847097AReduce pulling forceReduce misalignmentWork holdersPrinted circuit manufacturePull forceEngineering

The invention provides a riveting and positioning fixture. The riveting and positioning fixture comprises a fixture body; two opposite sides of the fixture body are respectively provided with a plurality of rivet installation holes; one of the other two opposite sides of the fixture body is provided with a first positioning slide groove extending along a Y-axis direction, and the other of the other two opposite sides of the fixture body is provided with a second positioning slide groove extending along an X-axis direction; and a pin can slide in the first positioning slide groove and the second positioning slide groove and can be fixed at a designated position. The invention also provides a PCB riveting method, a manufacturing method for a PCB and the PCB. According to PCB riveting technology provided by the invention, riveting requirements of all standard jointed board products can be met only by manufacturing one riveting and positioning fixture, so production management is simplified; a pulling force generated in the riveting process can be effectively reduced, thereby avoiding scraping caused by dislocation and improving product yield; after pressing, rivets are drilled out through drilling, so the problems of board separation and delamination at positions where the rivets are located in later processing are overcome.

Owner:PEKING UNIV FOUNDER GRP CO LTD +1

Efficient simplified wheat flour milling technology and efficient simplified wheat flour milling device

InactiveCN103894260ADoes not destroy nutrientsKeep the scentGrain treatmentsProcess engineeringIndustrial engineering

The invention relates to an efficient simplified wheat flour milling technology comprising the working procedures of shelling, residue grinding, core grinding, tailing grinding and flour clearing, and an efficient simplified wheat flour milling device. In the shelling working procedure, an extrusion cutting grinder with a superior stripping and scraping function is used for replacing the existing tooth roller flour mill and is taken as a main residue making device; in the core grinding working procedure, an efficient impact flour mill is used for replacing a smooth roll flour mill and is taken as a main flour making device, and the grinding function of the efficient impact flour mill is more than twice as high as that of the prior art; two wraps are wetted by water, residue grinding is carried out for three times, and germ extraction is carried out during residue grinding; after the core 1 and the core 2 are slightly ground by a roller mill, the aim of rapidly and efficiently producing the high-quality flour at low temperature with low consumption can be achieved by virtue of a strong impact method of a water cooling efficient impact grinder and the like. The wheat flour milling production line extrusion process designed by the invention is simple in process, low in civil engineering equipment investment, high in production efficiency, simple in operation and management and low in energy consumption; the produced high precision flour is large in proportion; the produced flour is good in edible quality and food production performance; the produced flour has the advantages that the original fragrance of the wheat is maintained by the flour, and the like.

Owner:王洪福

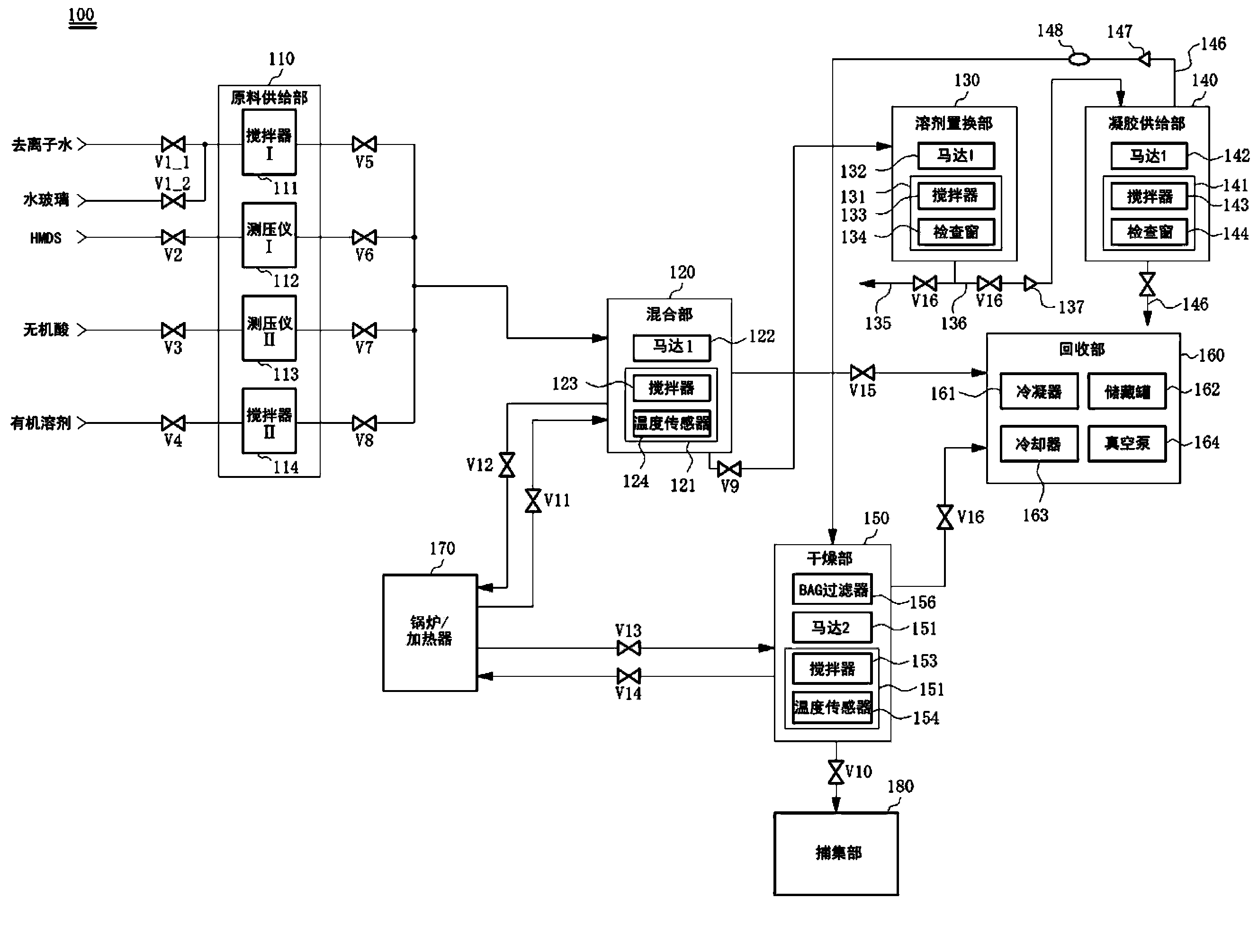

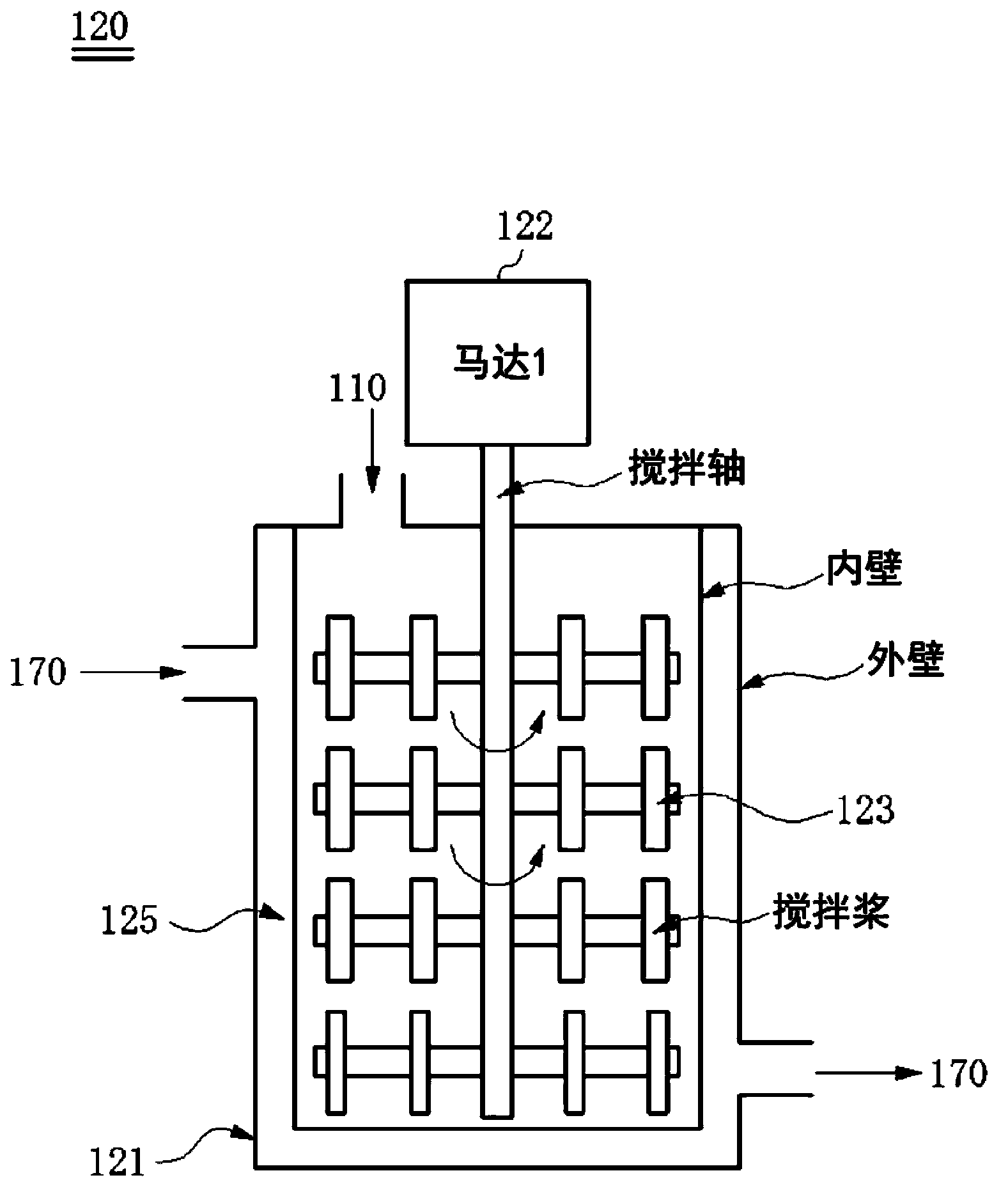

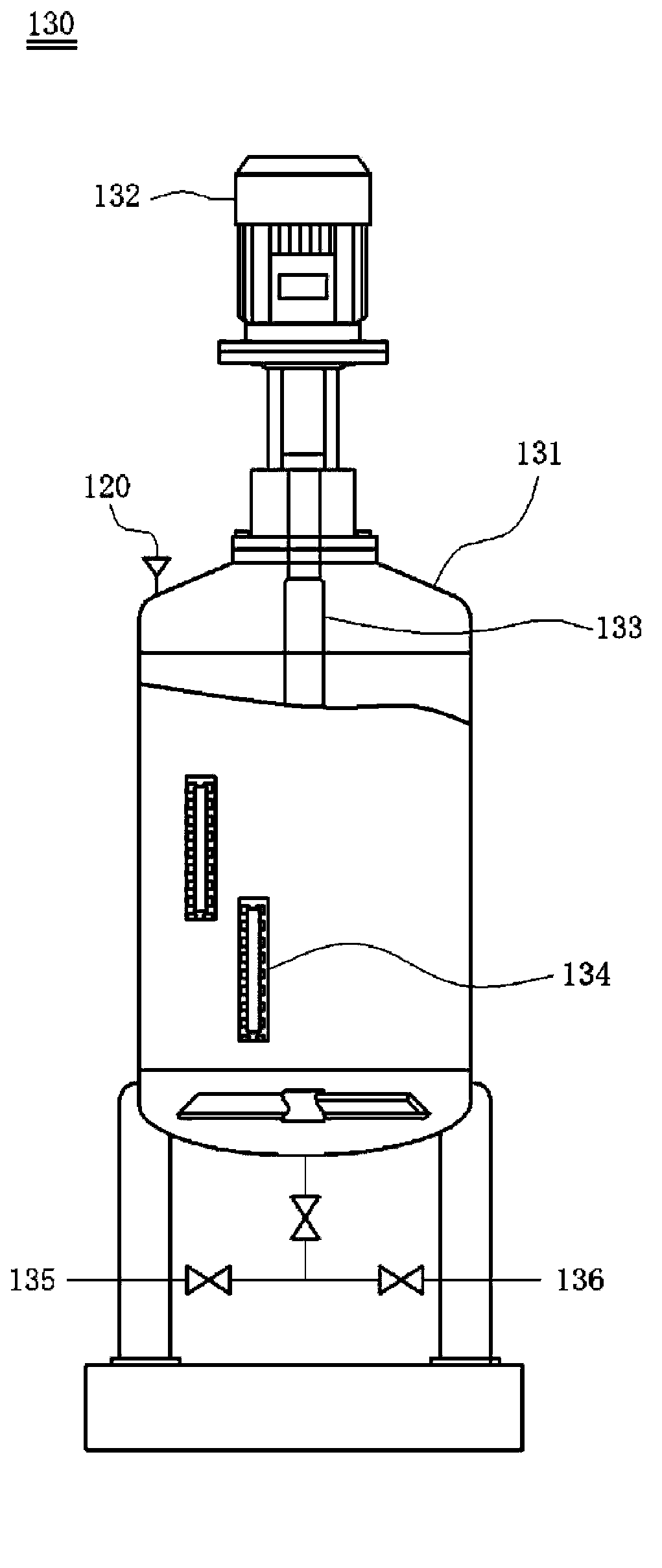

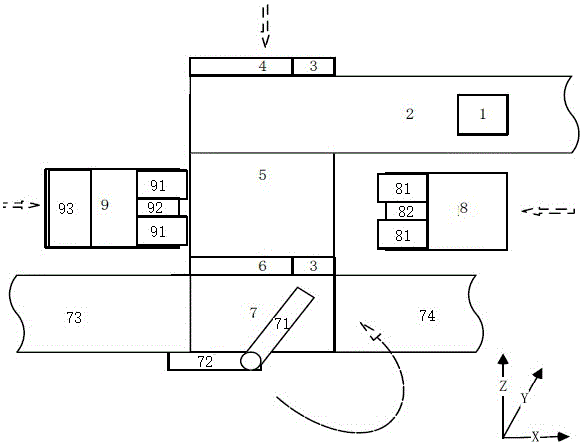

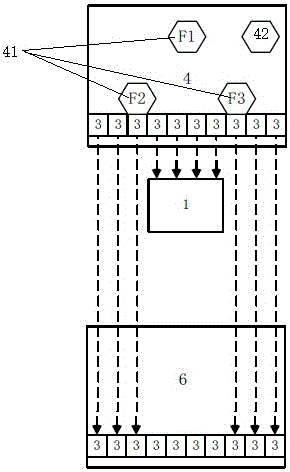

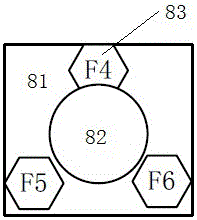

Silica aerogel power manufacturing system and manufacturing method using the same

ActiveCN103771428ASolve process imbalanceSave raw materialsSilicaChemical/physical/physico-chemical stationary reactorsIonSolvent

Provided is a silica aerogel powder manufacturing system and a method of manufacturing silica aerogel powder by using de-ionized water, water glass, an organosilane compound, an inorganic acid, and an organic solvent as raw materials, and by constructing the system by establishing a manufacturing process including supplying of raw materials, a gelling process, a solvent substitution process, a gel storage and supply process, a drying process, and a collection process, a large quantity of silica aerogel powder may be continuously produced, a dramatic increase in productivity may be achieved, and production management of a silica aerogel powder manufacturing process may be simplified.

Owner:JIOS AEROGEL LTD

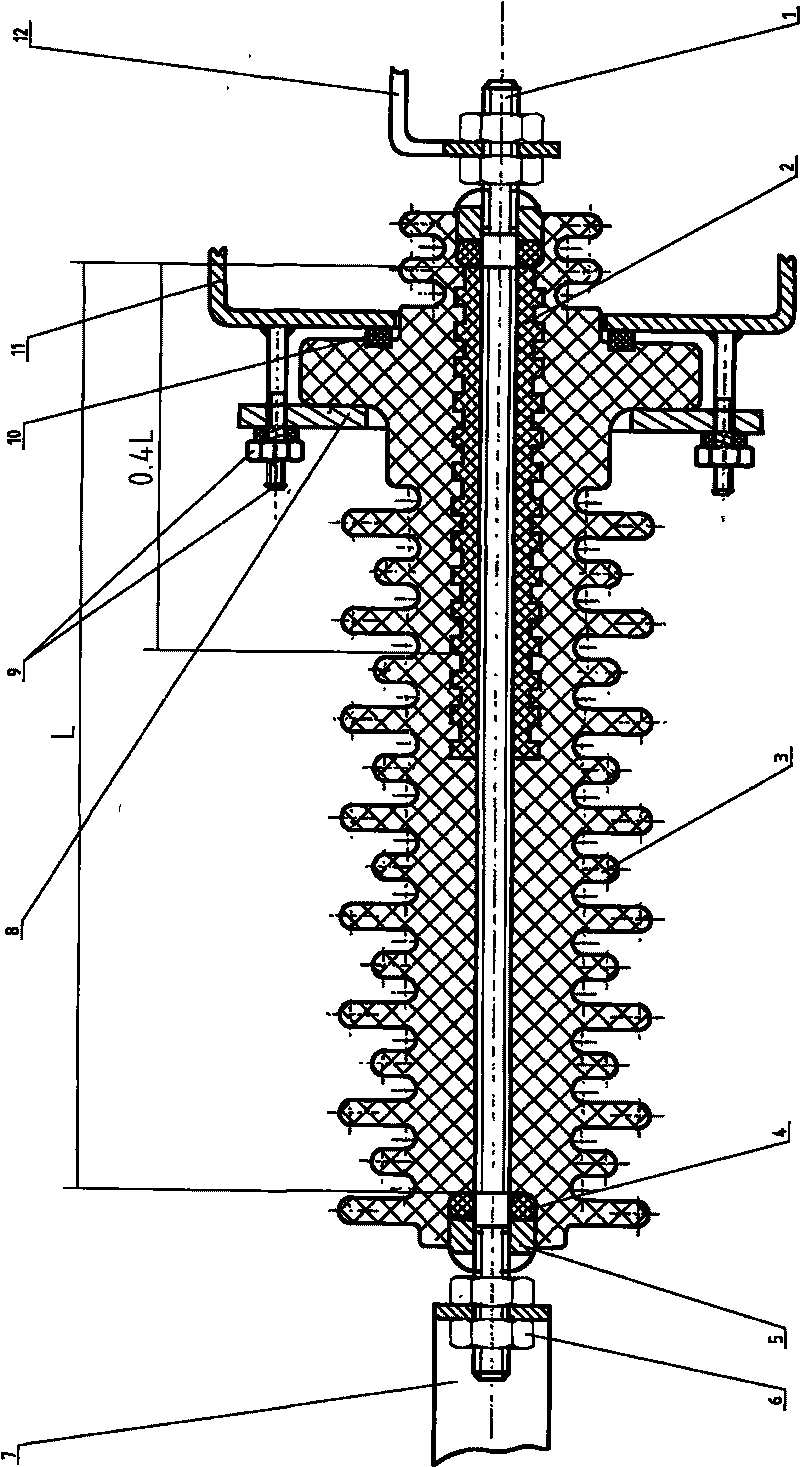

Composite insulated sleeve

InactiveCN101740177AModerate priceReduce lossInsulating bodiesLead-in/lead-through insulatorsTransformerEngineering

The invention discloses a composite insulated sleeve, which comprises a conductive rod, an insulated core, an insulated umbrella, a sealing ring, an equalizing sleeve and a wiring nut, and is characterized in that: continuous annular grooves are formed on outside diameter surface of the conductive rod with in a length L covered by the insulated umbrella; and the insulated core is looped on at least a section with a length of more than or equal to 0.4 L and the insulated umbrella is compounded outside the insulated core. The method for manufacturing the composite insulated sleeve mainly comprises the following technical steps: 1, processing the conductive rod and performing the antioxidative processing of the conductive rod; 2, manufacturing a composite member in which the insulated core is looped on the conductive rod; 3, drying the composite member; 4, plasticizing the insulated umbrella; and 5, assembling the composite insulated sleeve. The composite insulated sleeve is applicable to American box transformers and is particularly applicable to external cables of wind power generation American box transformers.

Owner:戴海永

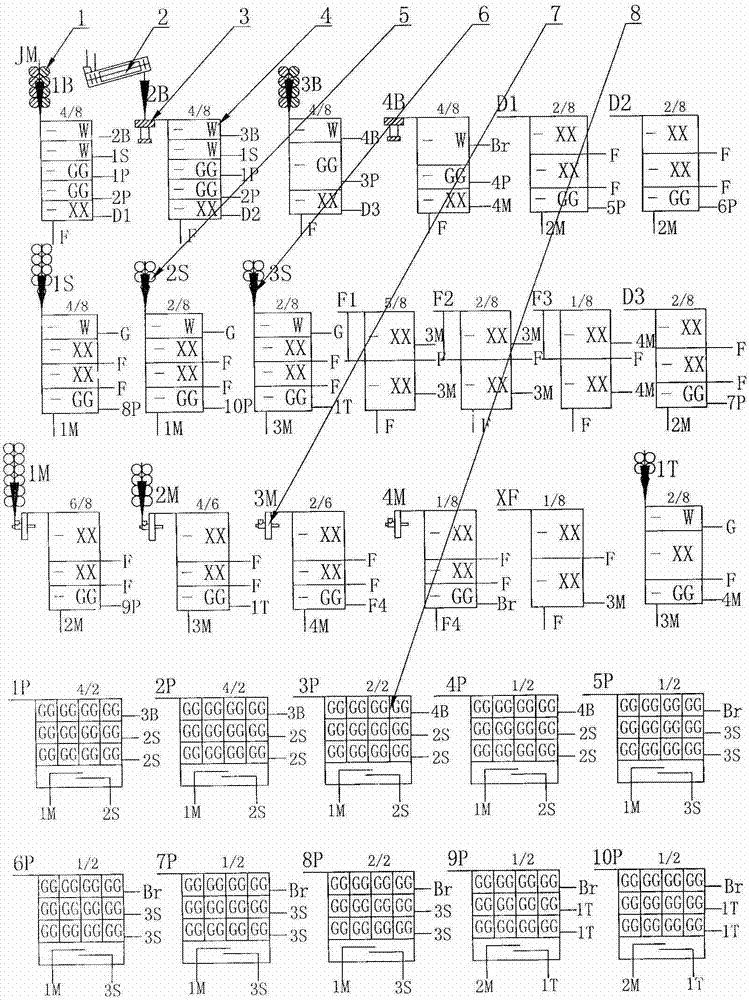

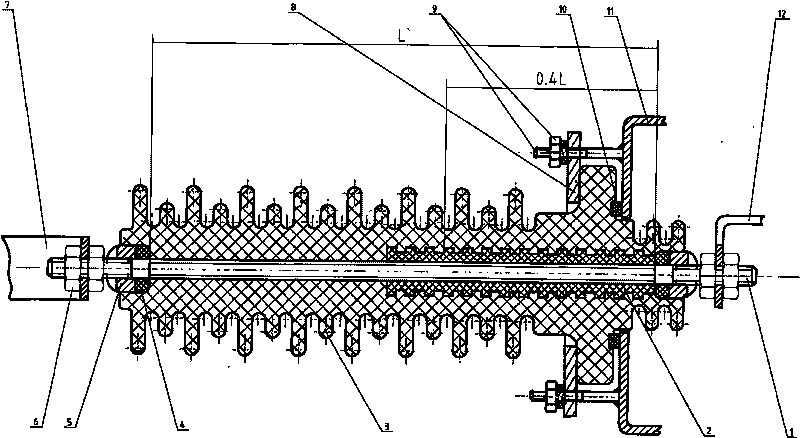

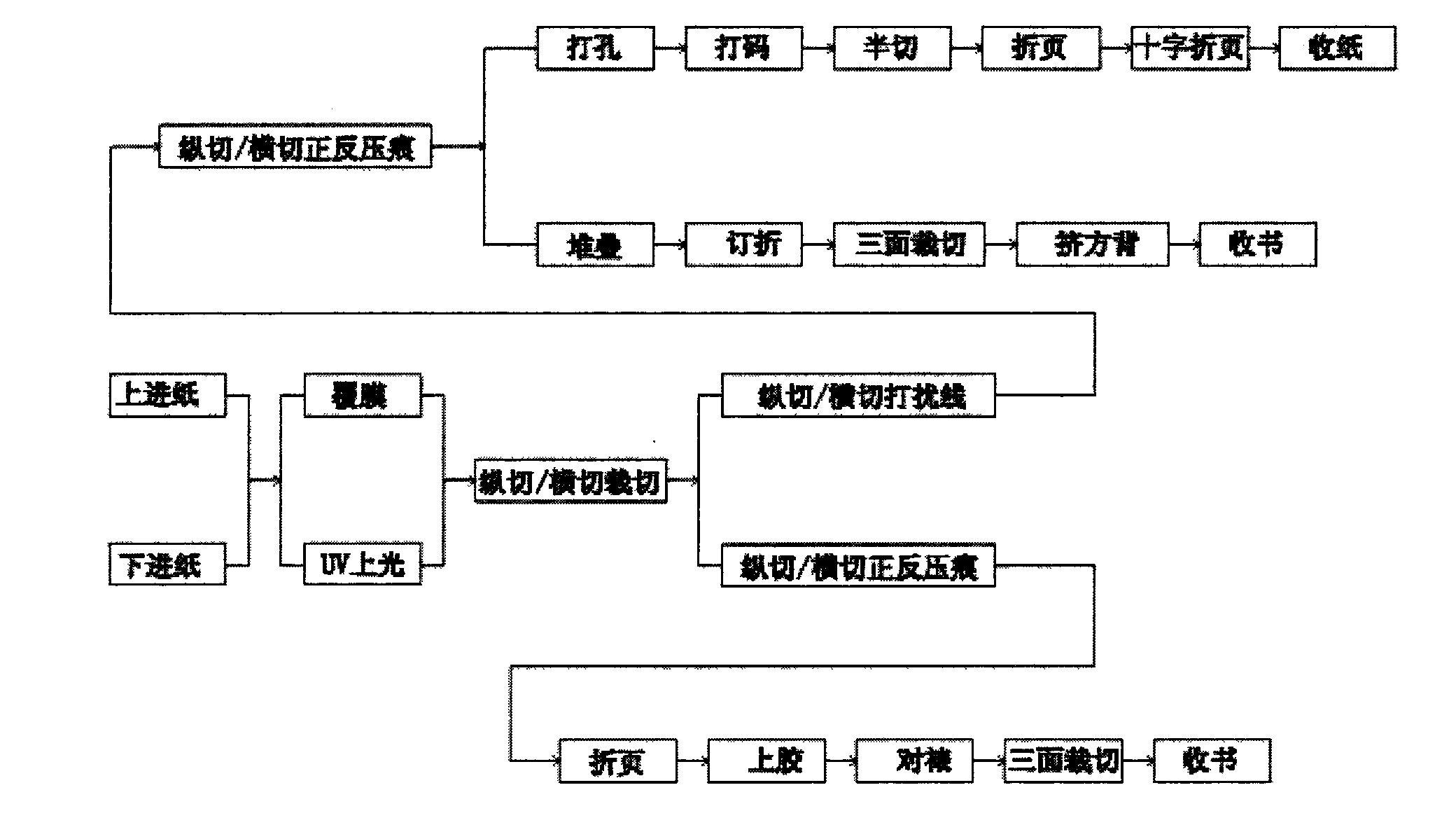

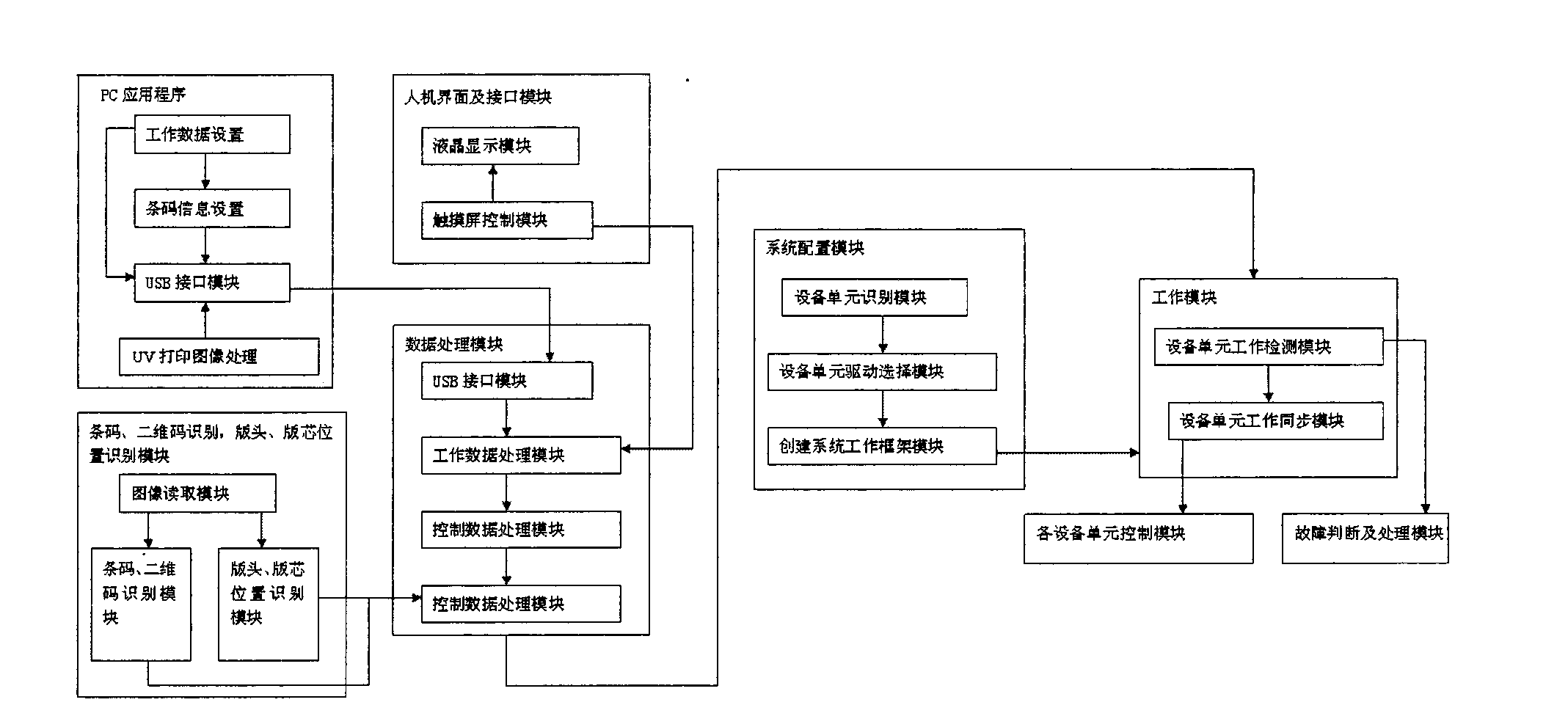

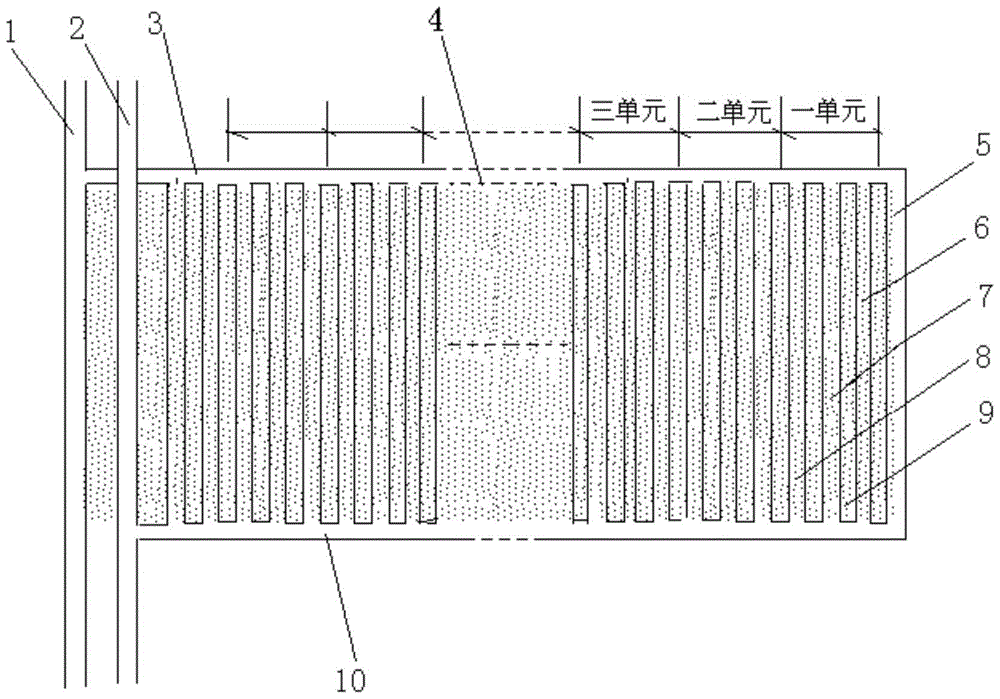

Modularization on-line digital post-printing tidying system

ActiveCN102602131AMeet the actual work requirementsSave moneyRotary pressesPrinting press partsProduction lineHuman–machine interface

The invention discloses a modularization on-line digital post-printing tidying system. A control system adopts a human-machine interface and a control program to detect all post-printing treatment equipments and coordinate the common work of the all the equipments; an automatic paper feeding function, a laminating function, a UV (ultraviolet) function, a longitudinal / transverse cutting or line disturbance or positive / negative indentation function, a punching function, a coding function, a half cutting function, a folding function, a cross folding function, a piling function, a stapling-folding function, a three-surface cutting function, a ridge extruding function, a gluing function, a mounting function and a paper(book) collecting function can be realized through random combination of all modularization units according to the requirements of manufacturing procedures required by a customer, thereby overcoming the defects existing in the traditional post-printing equipment that multi-procedure task operation is not convenient, time and labor are wasted, resources are wasted; in addition, a main control operation system can complete the automatic control for the whole production line, and therefore, the manual intervention time is reduced to the lowest level, the production line of a factory is optimized, and the production management of the factory is simplified.

Owner:GUANGZHOU DUMOR AUTOMATION SYST

Nickel-chromium alloy electroplate liquid

The invention relates to nickel-chromium alloy electroplate liquid. A liter of the electroplate liquid comprises from 25g to 35g of nickel sulfate hexahydrate, from 80g to 100g of chromium trichloride hexahydrate, from 30ml to 40ml of formic acid, from 20g to 30g of boric acid, from 1g to 60g of urea, from 30g to 80g of ammonium chloride, from 40g to 60g of potassium chloride, from 30g to 60g of critic acid, from 0.1g to 0.12g of sodium dodecyl sulfate, from 1.5g to 2.5g of saccharin, from 2ml to 4ml of nickel plating brighteners and the balance water. The urea is used as a coordination additive, and the performance of the electroplate liquid is greatly improved, so that behaviors of electrodes, the covering power and the dispersing power of a cathode and the stability, the coating performance and the contamination status of the electroplate liquid are greatly improved.

Owner:LUDONG UNIVERSITY

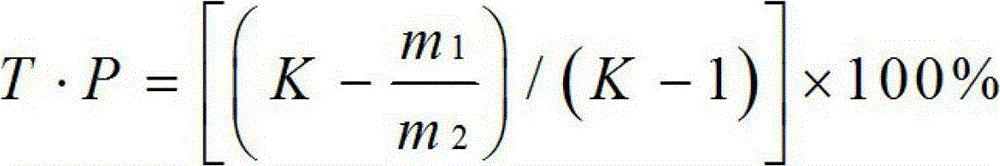

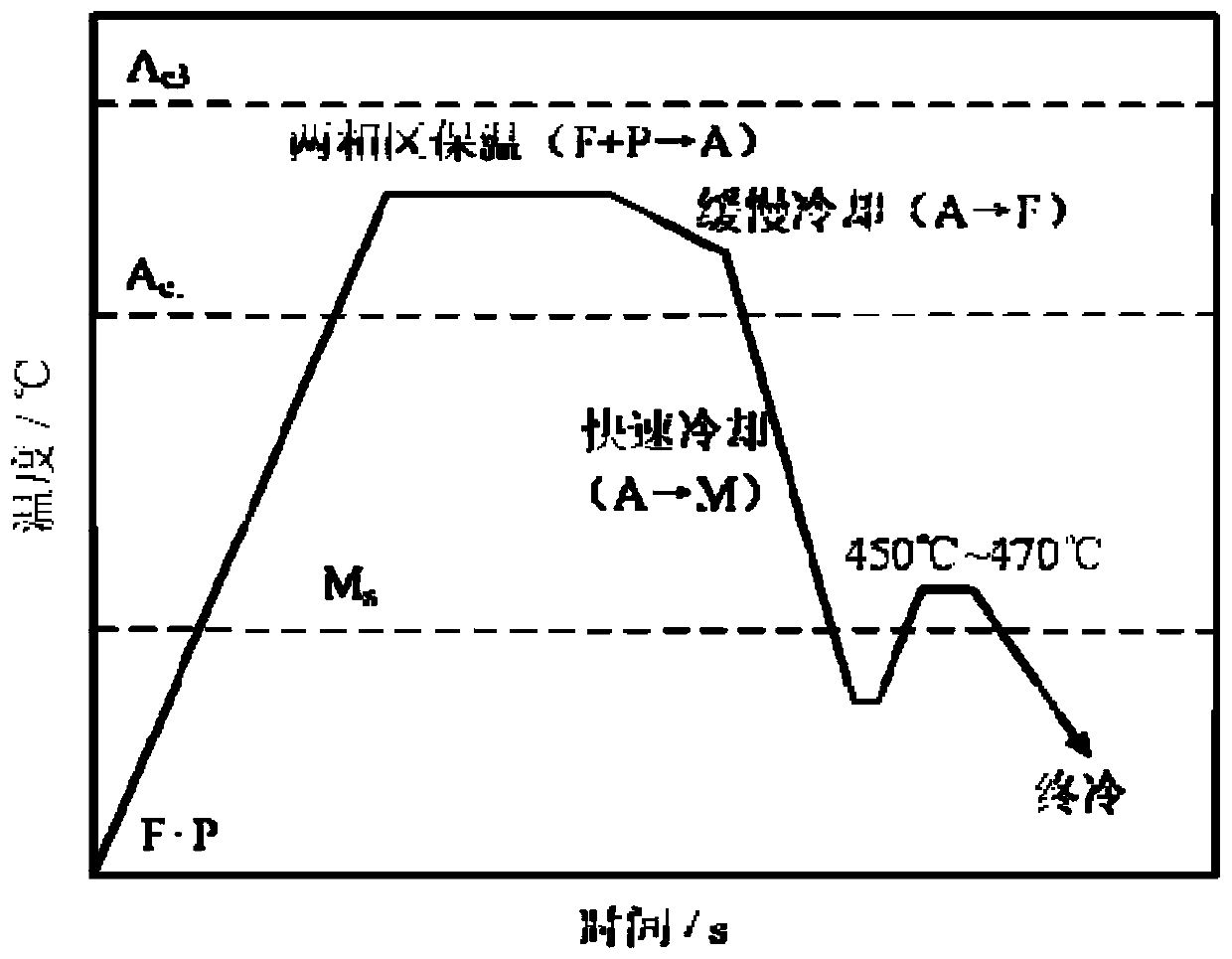

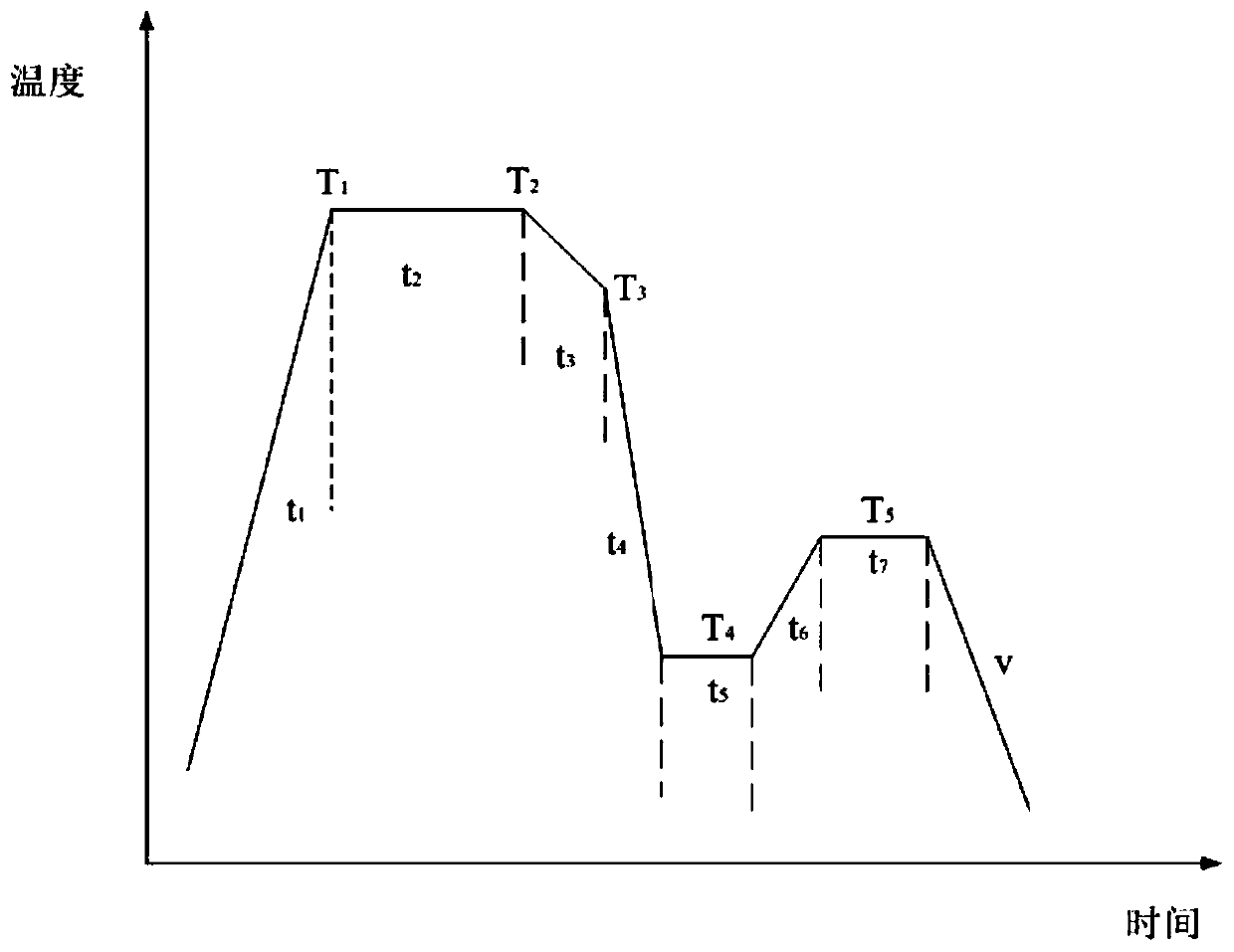

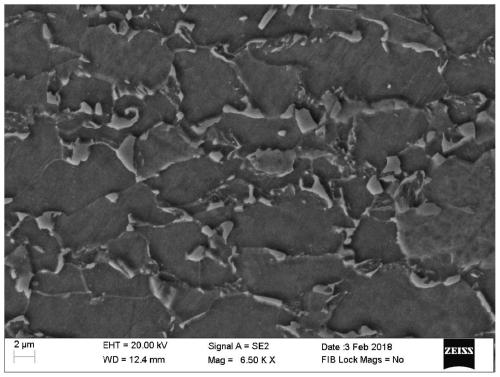

Cold-rolled hot-galvanized duplex steel and manufacturing method thereof

ActiveCN110093491AReduce contentReduce manufacturing costHot-dipping/immersion processesFurnace typesQuenchingCooling speed

The invention provides cold-rolled hot-galvanized duplex steel and a manufacturing method thereof. The method comprises the following steps: 1) cold-state strip steel is heated to 780-840 DEG C; 2) the heated strip steel is insulated within 780-840 DEG C by 50-120 s; 3) the insulated strip steel is cooled to 650-730 DEG C; 4) the strip steel cooled to 650-730 DEG C is quickly cooled below the martensite transformation temperature (Ms point), and is insulated by above 3 s; and the quick cooling speed is not lower than 30 DEG C / s; and 5) the insulated strip steel cooled below the Ms point is heated to the galvanizing temperature of 450-470 DEG C. The martensite quenching phase is arranged in the continuous annealing quick cooling phase, so that the strength, the plasticity and the punching performances of the cold-rolled hot-galvanized duplex steel product meet the requirements; the production cost is reduced; the welding performances of the product are improved; the generality of continuous hot-galvanized and continuous annealing duplex steel raw materials is achieved; and the production management is simplified.

Owner:CISDI ENG CO LTD +1

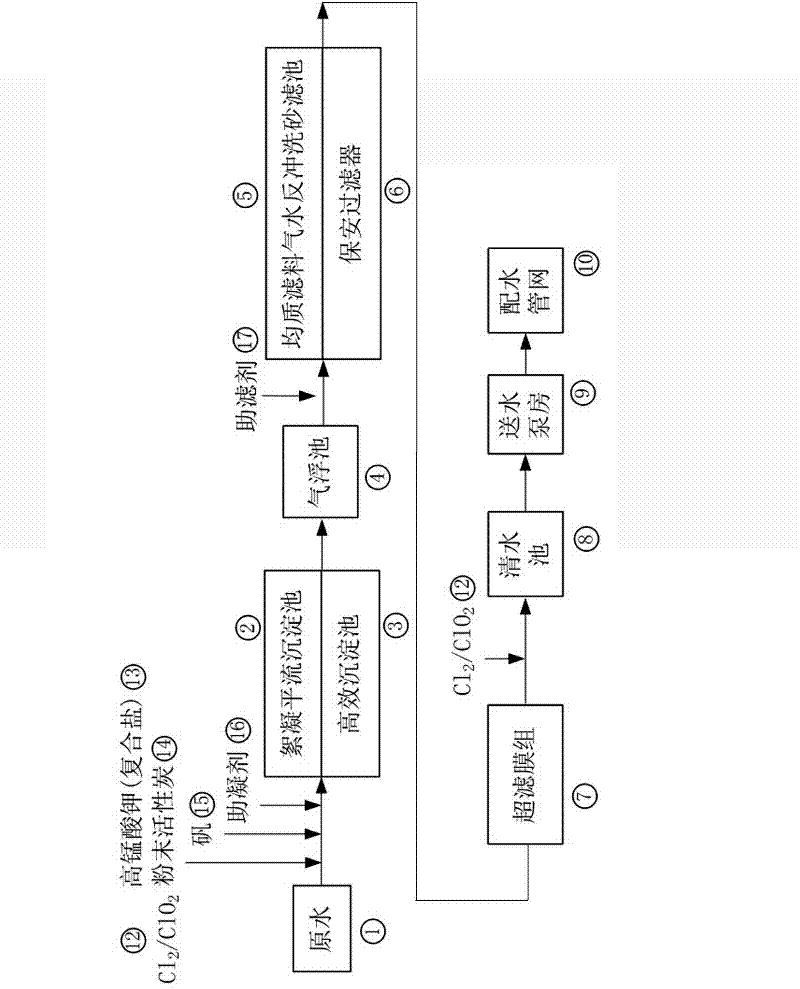

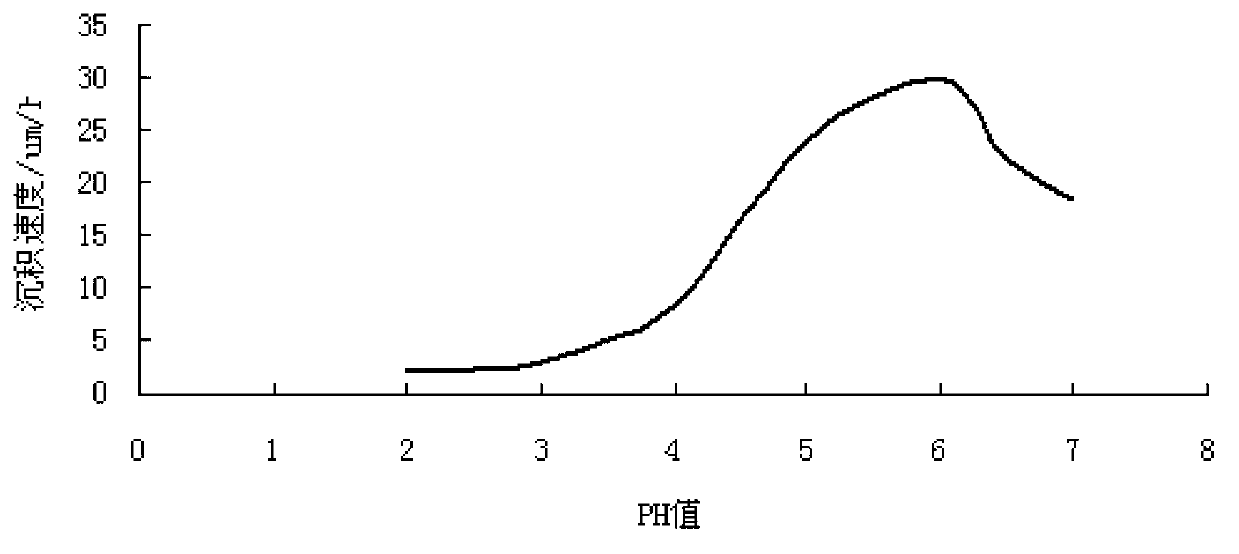

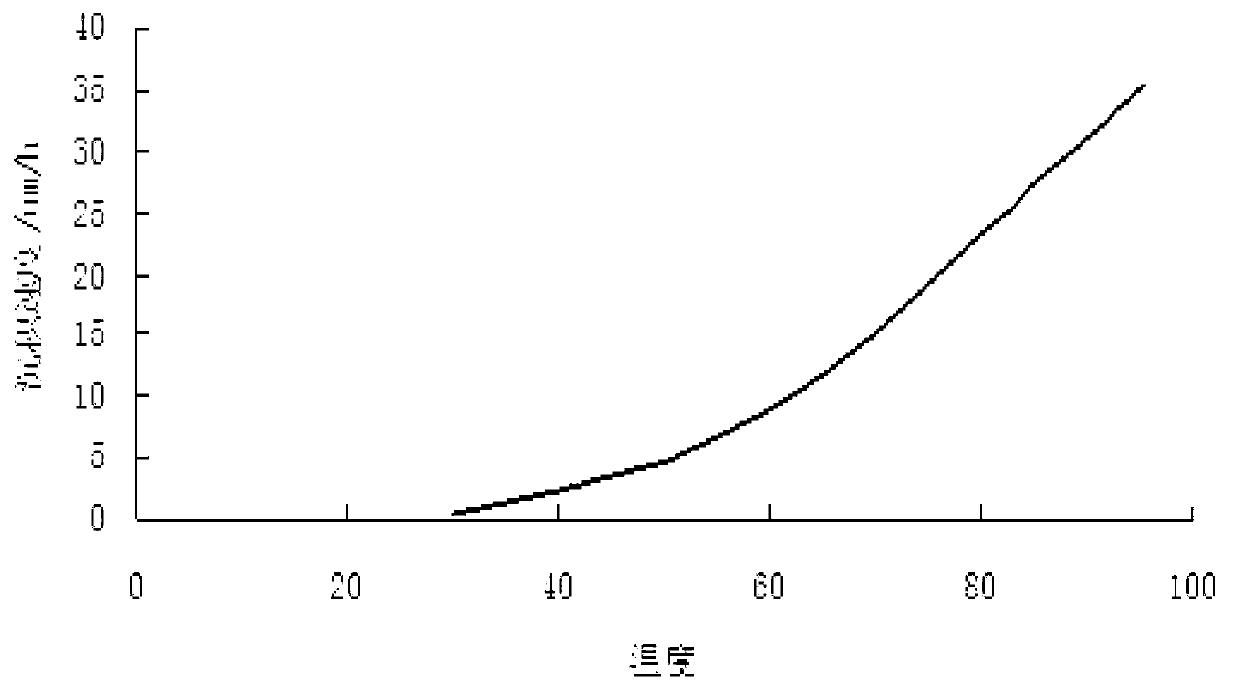

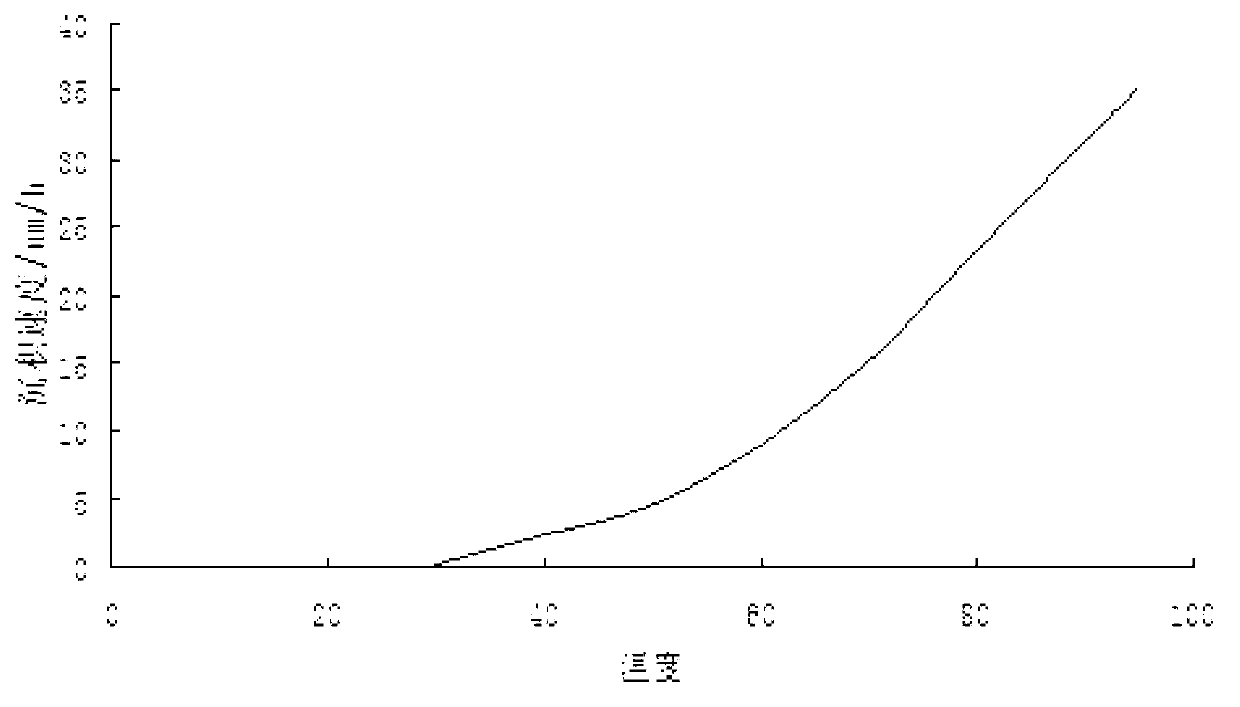

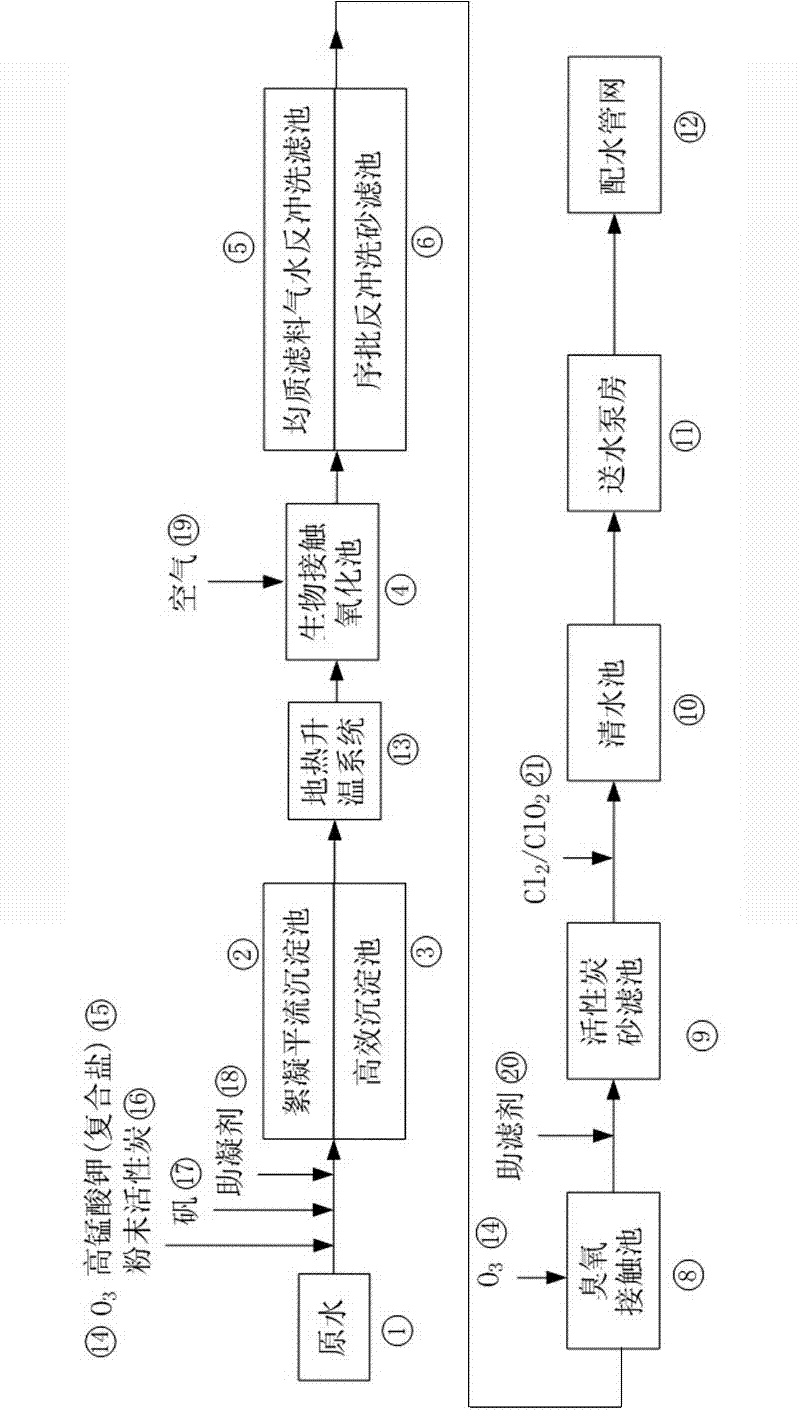

Combined enhanced treatment process for low-turbidity high-alga raw water

ActiveCN102674585ASimple processComplete membrane pretreatment processWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentFlocculationFiltration

The invention discloses a combined enhanced treatment process for low-turbidity high-alga raw water. The treatment process is characterized in that according to raw water, the turbidity in winter is about 5NTU, and temperature less than 5 DEG C, or one liter of raw water contains more than one million algae in summer, and the treatment process comprises the following steps of: settling under the conventional condition by using a flocculation horizontal sedimentation tank or a high-efficiency sedimentation tank, performing air floatation by using an air floatation tank to remove algae, allowing outlet water to flow through an ultra filter membrane further to reduce turbidity and remove algae, adjusting storage by using a clear water tank, and feeding into a water distribution network by using a water feeding pump house. According to the low-turbidity and high-alga characteristics of the water quality of the raw water, the conventional coagulating sedimentation, air floatation, filter and ultra filtration processes are optimized and combined, and the utilization of geothermal resources of plant areas is fully considered, so that an enhanced conventional treatment system is formed. The combined process has the advantages that used land can be saved, the process can be optimized, the geothermal resources can be fully utilized, the production management can be simplified, and the water quality of the outlet water has obvious advantages.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

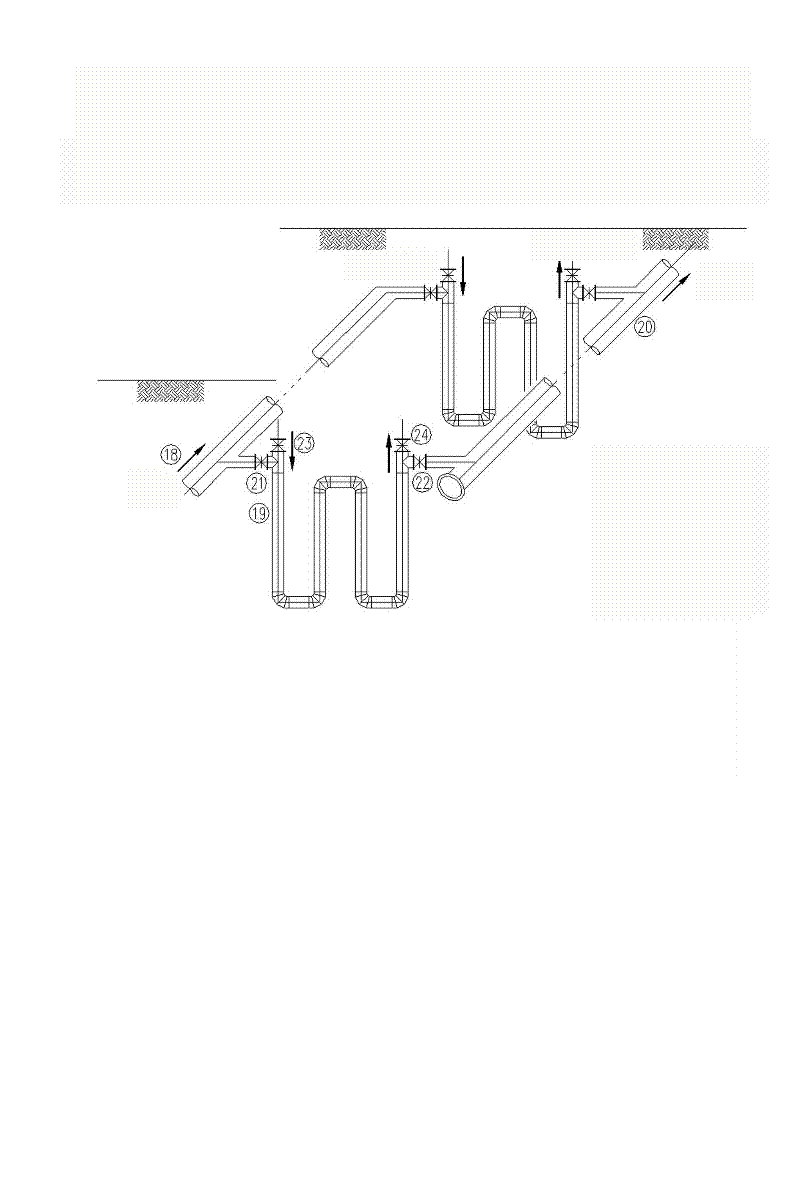

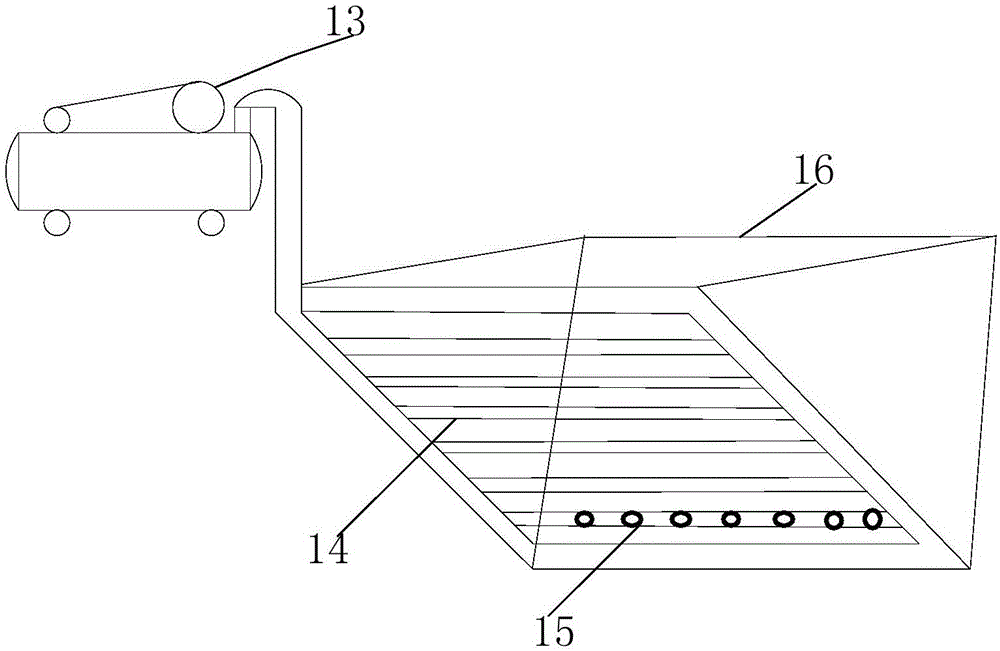

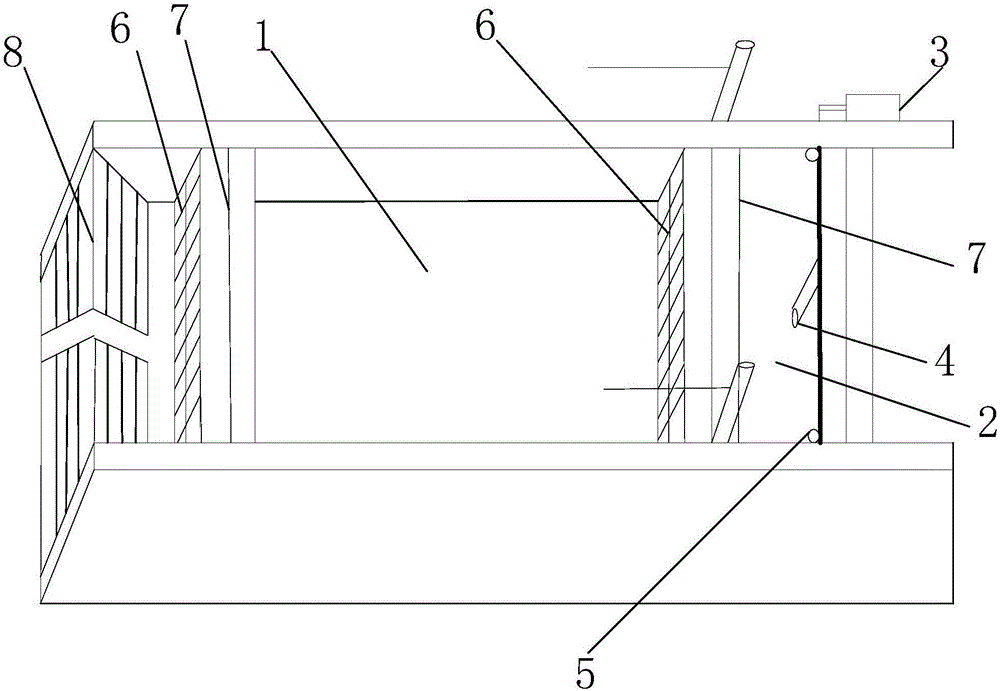

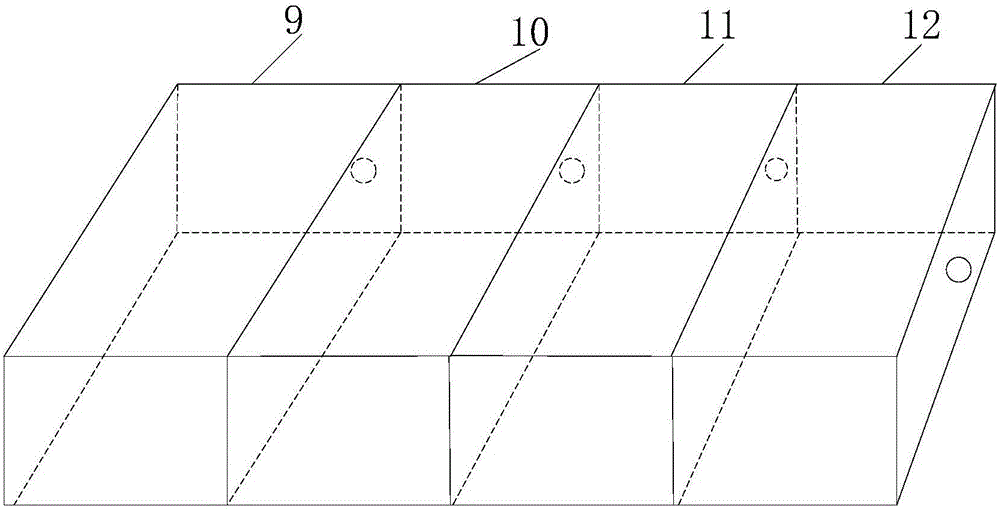

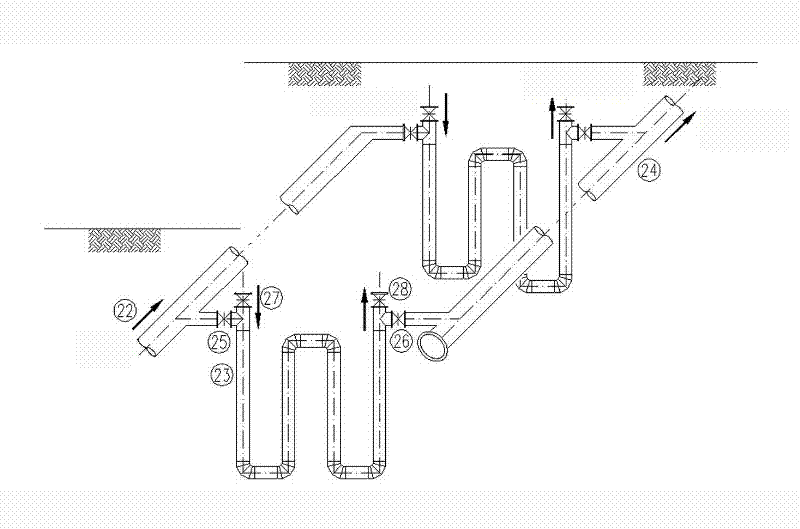

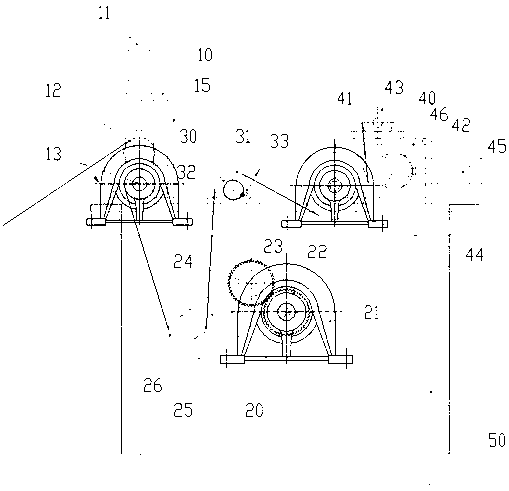

Water push and oxygenation device for pond internal circulation flowing water culture

The invention discloses a water push and oxygenation device for pond internal circulation flowing water culture. the water push and oxygenation device comprises an oxygenation machine which is connected with multiple oxygenation pipes through pipelines; the oxygenation pipes are provided with multiple holes for pushing water and generating oxygenation; the multiple oxygenation pipes are arranged side by side; the oxygenation pipes are welded with a fixing support. The device of the invention is suitable for culture of multi-kinds and multi-sizes; equalized sale is achieved and capital turnover is accelerated; the production cost can be reduced by 35%; 75% fish metabolite and residual forage can be effectively collected so that virtuous circle of the pond is guaranteed. The water push and oxygenation device for pond internal circulation flowing water culture is used for culturing fish with flowing water; air is used for lifting water and water pushing is more efficient; the cost is lower and there is no need of maintenance; water lift by air can effectively realize water push and oxygenation; flowing water passing through the pond can improve water quality and flush excrement of fish to downstream so as to collect and clear the excrement; floating and sunken solid body can be removed.

Owner:SOUTHWEST UNIVERSITY +1

Insulating method for motor stator

The invention relates to an insulating method for a motor stator. The method comprises the following steps of: preparation of an insulating varnish solution, preheating, temperature reduction, varnish impregnation, drying and the like. According to the method, the conventional twice varnish impregnation method for a motor stator component is changed, and the conventional twice varnish dripping treatment is changed into once varnish impregnation treatment by changing the viscosity of insulating varnish, so that a production cycle is shortened, and the consumption of the insulating varnish is reduced; and moreover, the preparation of two kinds of insulating varnish with different viscosities are not required, so that production management is simplified, the volume of a tunnel kiln is reduced, a space is saved, and energy sources are effectively saved.

Owner:HARBIN DONGAN ENGINE GRP

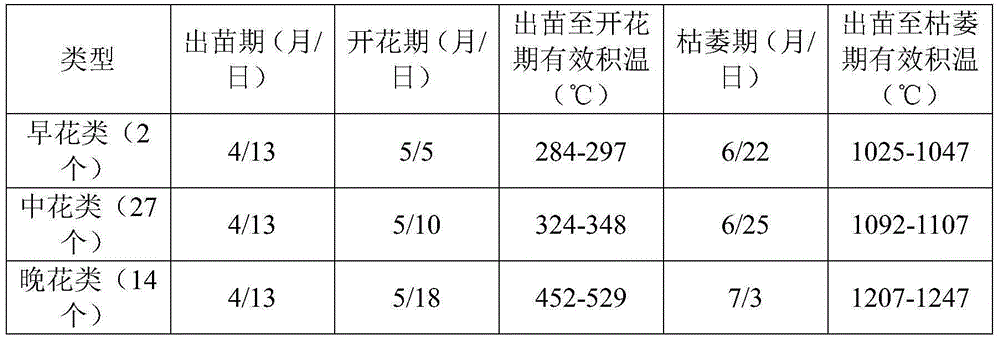

Method for producing bulb and controlling florescence by utilizing effective accumulated temperature in tulip growing period

InactiveCN105075578AExtend photosynthesis timeImproved bulb qualityPlant cultivationCultivating equipmentsPhacusPhases of clinical research

The invention discloses a method for producing bulb and controlling florescence by utilizing effective accumulated temperature in tulip growing period, wherein the method for producing bulb by utilizing effective accumulated temperature in tulip growing period comprises the steps of determining the effective accumulated temperature at the tulip growing period; selecting a low temperature semi-arid climate type area that has an average temperature of 12-16 DEG C and a dryness fraction of 2-3 in July as the production base on the basis of determining the effective accumulated temperature at the tulip growing period; planting the tulip to control the tulip stem and leaf coverage between 95-100%; and covering the organic matter 3-5cm thick. After grasping the effective accumulated temperature at the growing period of the cultivar and the set temperature when planting, namely the temperature of tulip at growing period, calculate the accurate blossom date by the following formula: N=K / (T-C).

Owner:ZHENJIANG AGRI SCI INST JIANGSU HILLY AREAS +1

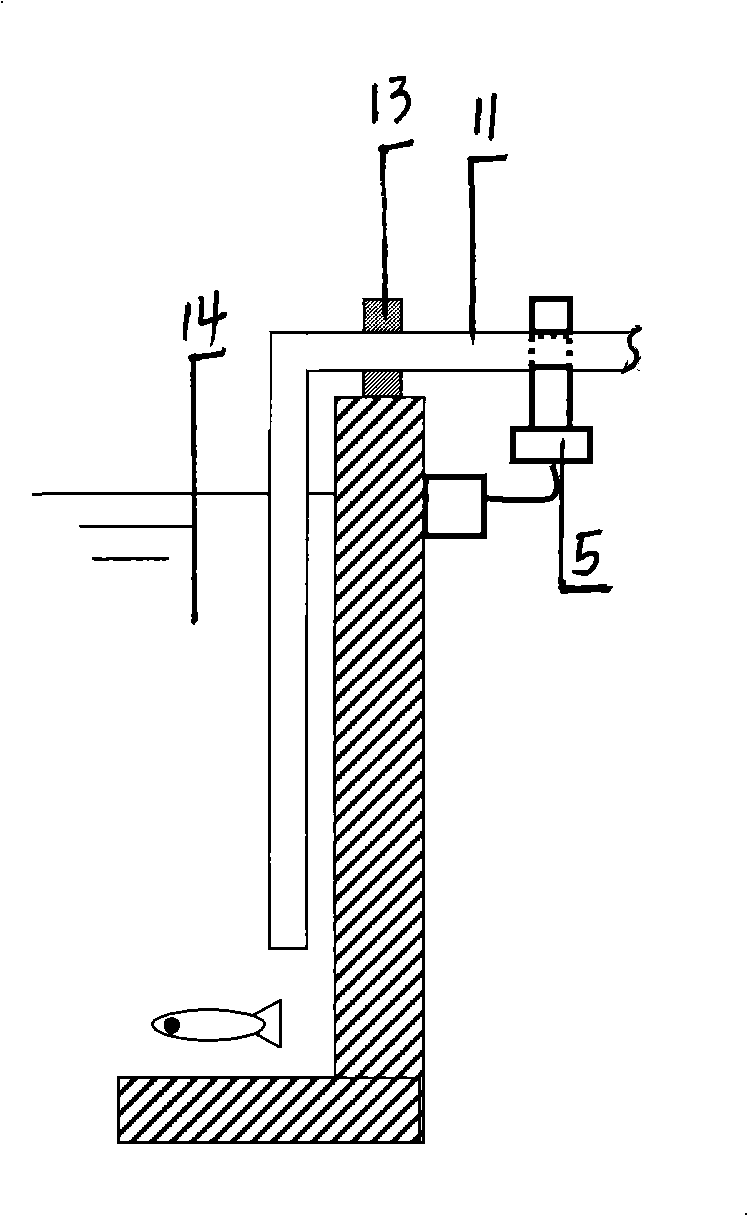

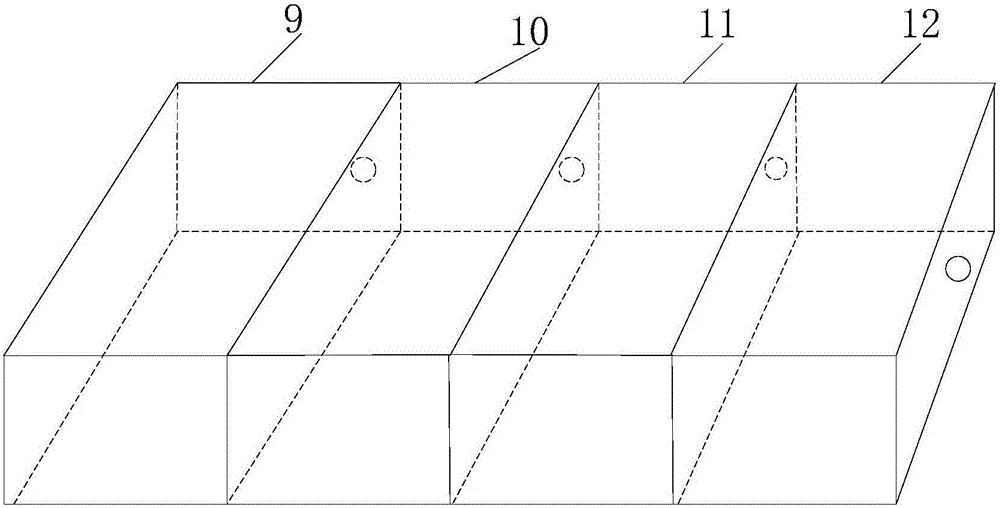

Automatic sewage discharge device for cyclic flowing water aquaculture in pond

InactiveCN106689017ASave energySignificant comprehensive benefitsPisciculture and aquariaWaste managementSand filter

The invention discloses an automatic sewage discharge device for cyclic flowing water aquaculture in a pond. The automatic sewage discharge device comprises a sewage collection area; a desilting water pump is mounted above the sewage collection area; proximity switches are mounted on two side walls of the sewage collection area respectively; a water inlet pipe of the desilting water pump is freely movably inserted in the sewage collection area; a water outlet pipe of the desilting water pump is inserted into a sedimentation tank on one side of the sewage collection area, and the sedimentation tank is connected with a coarse sand filter tank through a through hole in the upper portion of a partition wall of the sedimentation tank; the coarse sand filter tank is connected with a fine sand filter tank through a through hole in the upper portion of a partition wall of the coarse sand filter tank; the fine sand filter tank is connected with a nitrifying tank through a through hole in the upper portion of a partition wall of the fine sand filter tank; the nitrifying tank is connected with the external pond through a through hole in the upper portion of a partition wall of the nitrifying tank. The automatic sewage discharge device is suitable for multi-variety multi-specification aquaculture, balanced marketing can be realized, capital turnover speed is increased, and production cost can be reduced by 35%; 75% of fish metabolites and residual feeds can be collected effectively, and intrinsic virtuous cycle of the pond is guaranteed.

Owner:SOUTHWEST UNIV +1

Chemical nickel-phosphorus alloy plating solution

InactiveCN102953054AImprove autocatalytic activityImprove stabilityLiquid/solution decomposition chemical coatingSodium acetrizoateSodium acetate

The invention relates to chemical nickel-phosphorus alloy plating solution. Each liter of plating solution comprises 20 to 45g of nickel sulfate hexahydrate, 20 to 45g of sodium hypophosphite dihydrate, 15 to 25ml of lactic acid, 10 to 15g of sodium acetate, 2 to 15g of urea and the balance of water. According to the invention, the urea is used as an additive; a coordination complex is formed by the urea and nickel ions; a deposition mechanism of a nickel-phosphorus alloy is changed, so that a deposition temperature is greatly reduced and a better coating can be obtained at lower temperature; the production cost is reduced; and the benefits are increased for enterprises.

Owner:LUDONG UNIVERSITY

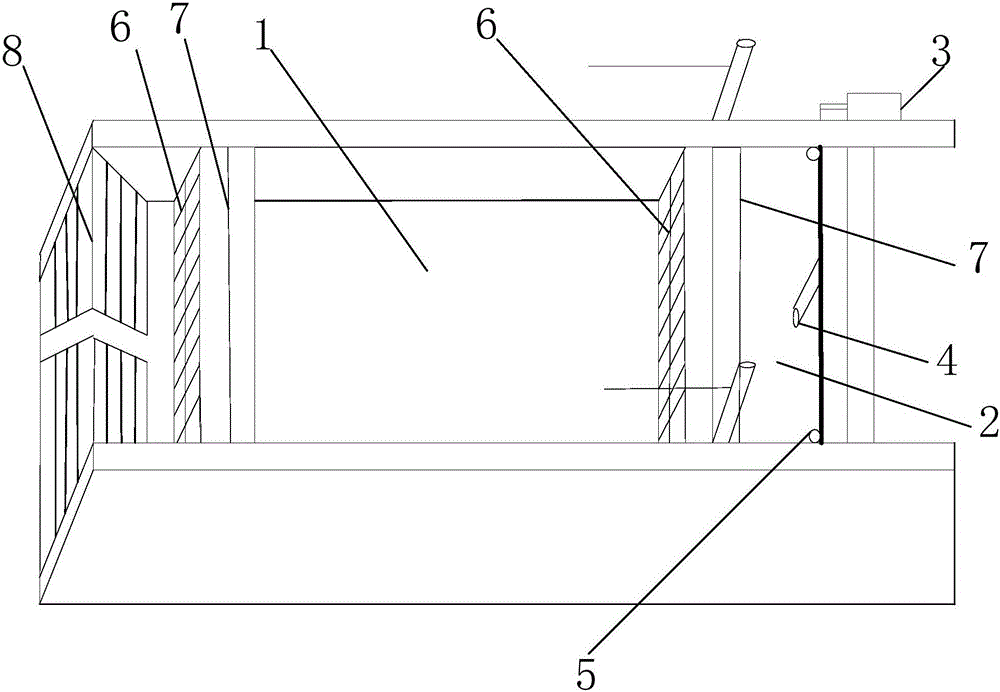

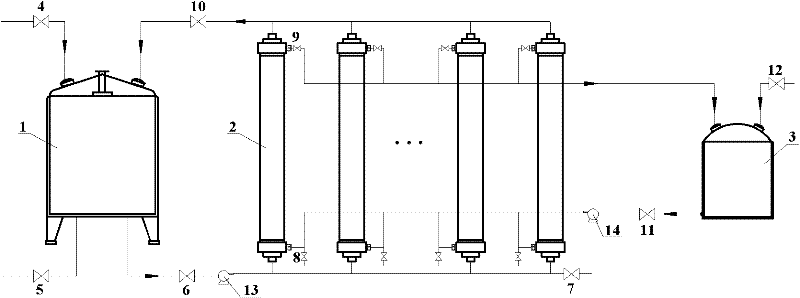

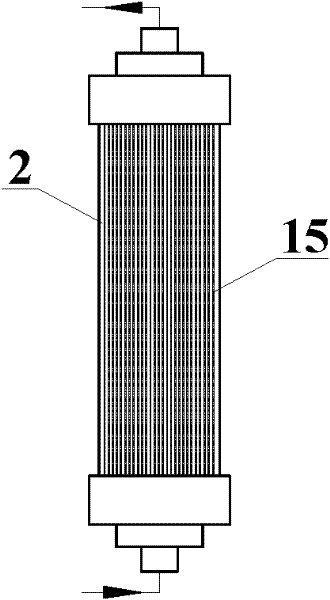

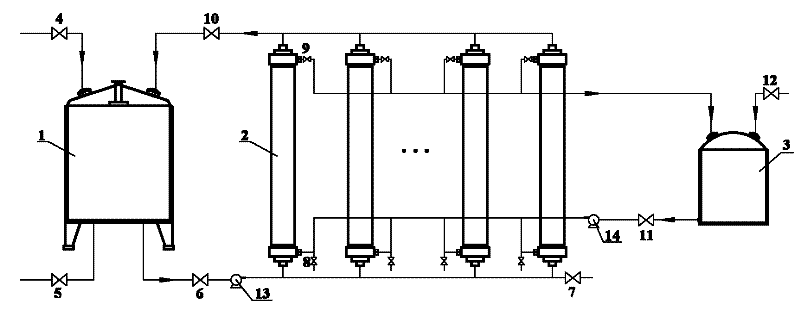

Efficient desalting device and efficient desalting method for salted egg white

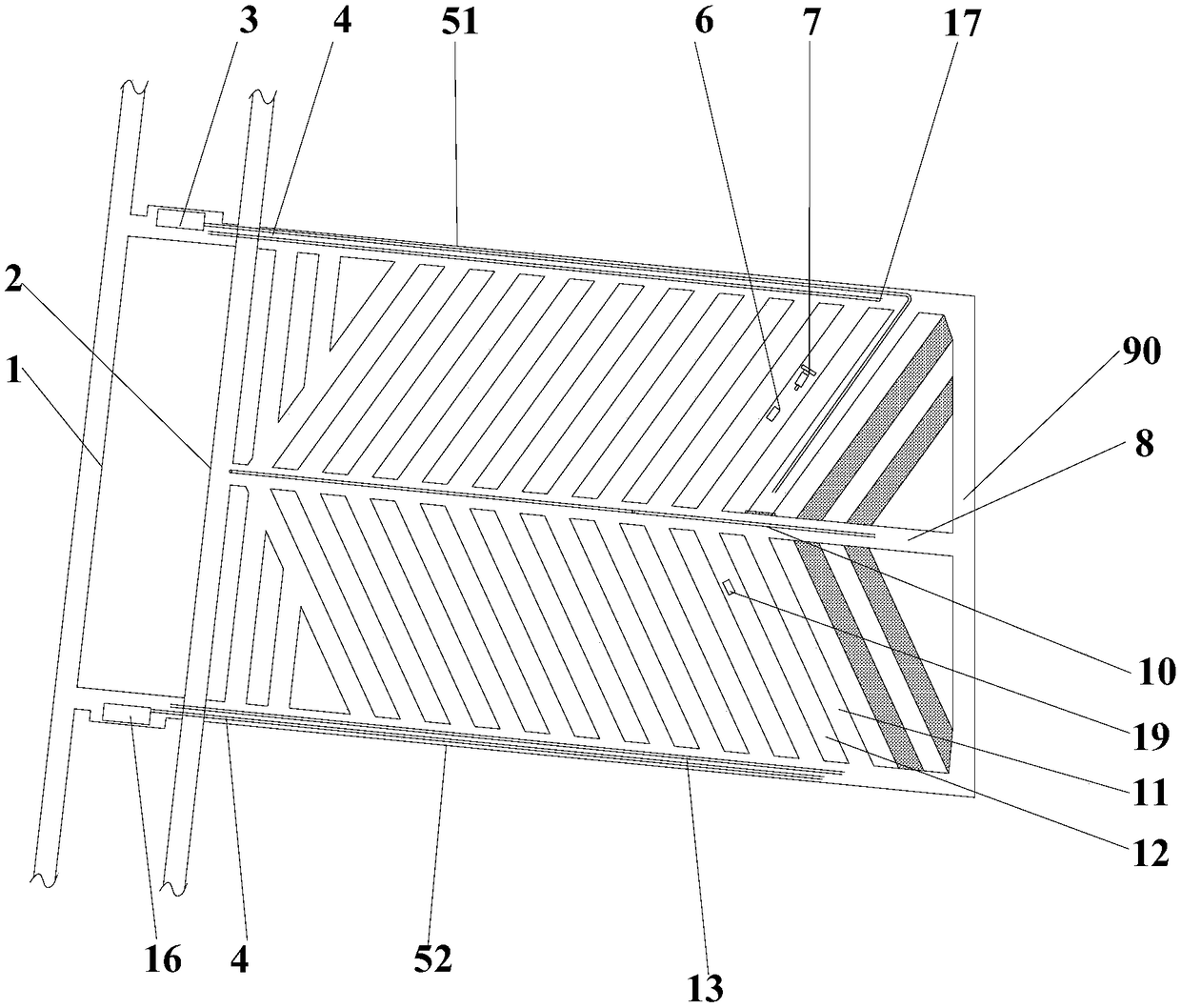

The invention discloses a desalting device and a desalting method for salted egg white, which are characterized in that the desalting device comprises a salted egg white drum (1), a plurality of shunt-wound ultra-filtration assemblies (2) and a backwashing drum (3). The salted egg white drum (1) is connected with the lower ends of the plurality of shunt-wound ultra-filtration assemblies (2) through a valve (6) and a first circulation pump (13), the upper ends of the plurality of shunt-wound ultra-filtration assemblies (2) are connected with the salted egg white drum (1) through a circulation valve (10), the backwashing drum (3) is connected with the lower ends of the plurality of shunt-wound ultra-filtration assemblies (2) through a valve (11), a second backwashing pump (14) and a valve (8), and the upper ends of the plurality of shunt-wound ultra-filtration assemblies (2) are connected with the backwashing drum (3) through a circulation valve (9). The desalting method includes that: the salted egg white is added with water to be diluted to 14-20 wt% and then is input into the salted egg white drum (1) through a valve (4), a first pump (13) is opened, pressure is 0.1-0.3 MPa at room temperature, the egg white is desalted circularly through the plurality of shunt-wound ultra-filtration assemblies (2), saline water is discharged from the position of the valve (8) and sampled for salt content detection, salt content is smaller than or equal to 0.85%, all the valves are closed, a valve (5) is opened, and desalted egg white solution enters the next procedure through the position of the valve (5).

Owner:SICHUAN UNIV

Full negative pressure short wall filling coal mining method

PendingCN108301833AUndamagedEffective isolationUnderground miningSurface miningEngineeringStructural engineering

The invention provides a full negative pressure short wall filling coal mining method. The full negative pressure short wall filling coal mining method comprises the following steps that 10, positionsof a centralized return air lane and a centralized transportation lane are determined, and a transportation roadway, a first return air roadway and a second return air roadway are arranged; 20, tunneling is carried out on a branch lane in a first mining area, and after the branch lane is penetrated, tunneling is carried out on a branch lane in a second mining area, at the same time, supporting iscarried out on a penetrated branch lane, and a communication port between the penetrated branch lane and the transportation roadway is blocked; 30, the penetrated branch lane is filled after pluggingis finished; 40, tunneling is carried out on another branch lane in the first mining area, at the same time, supporting is carried out on a penetrated branch lane in the second mining area and a communication port between the penetrated branch lane and the transportation roadway is blocked; 50, the penetrated branch lane in the second mining area is filled after plugging is finished; 60, steps 10to 50 are cycled until the branch lane is completely filled; and 70, after filling is completed, reserved coal pillar lanes are successively mined according to the direction from the far end to the near end.

Owner:路彬

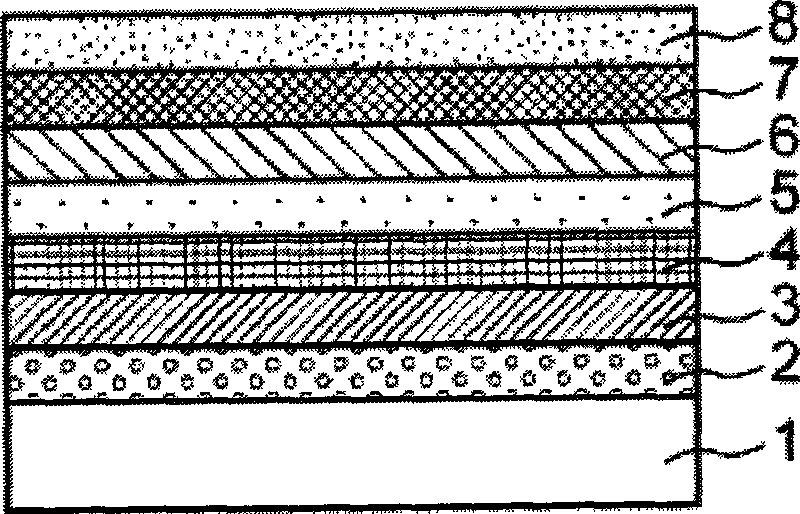

Control system of sterile pharmaceutical device

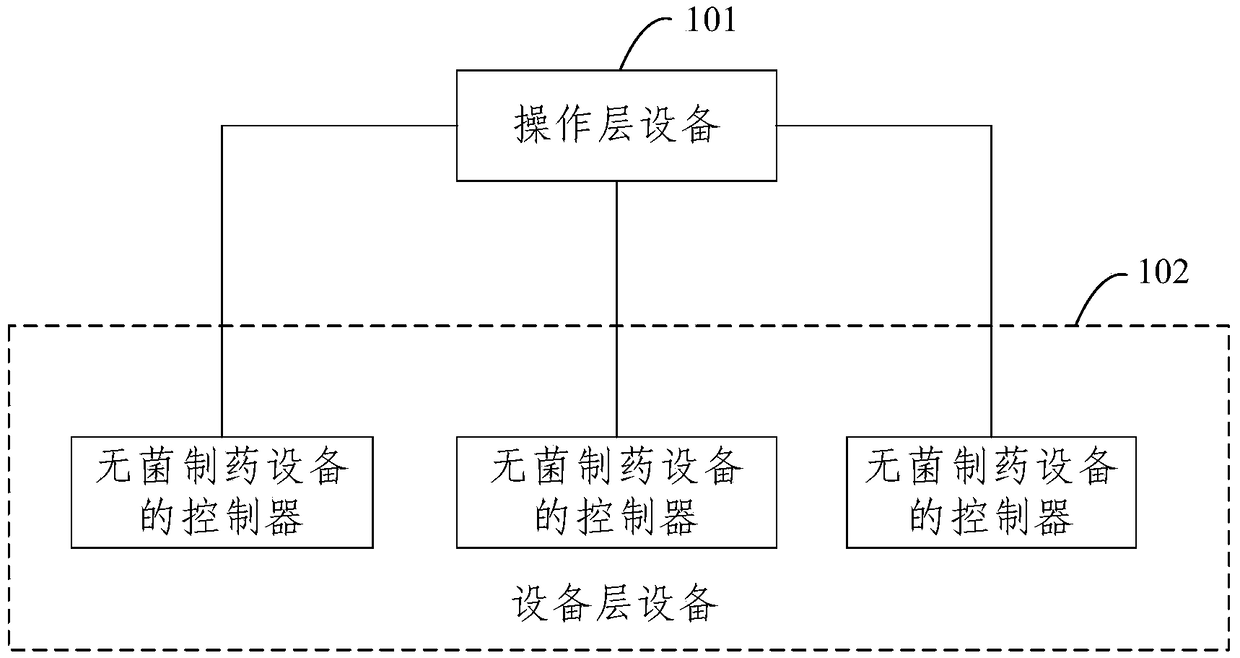

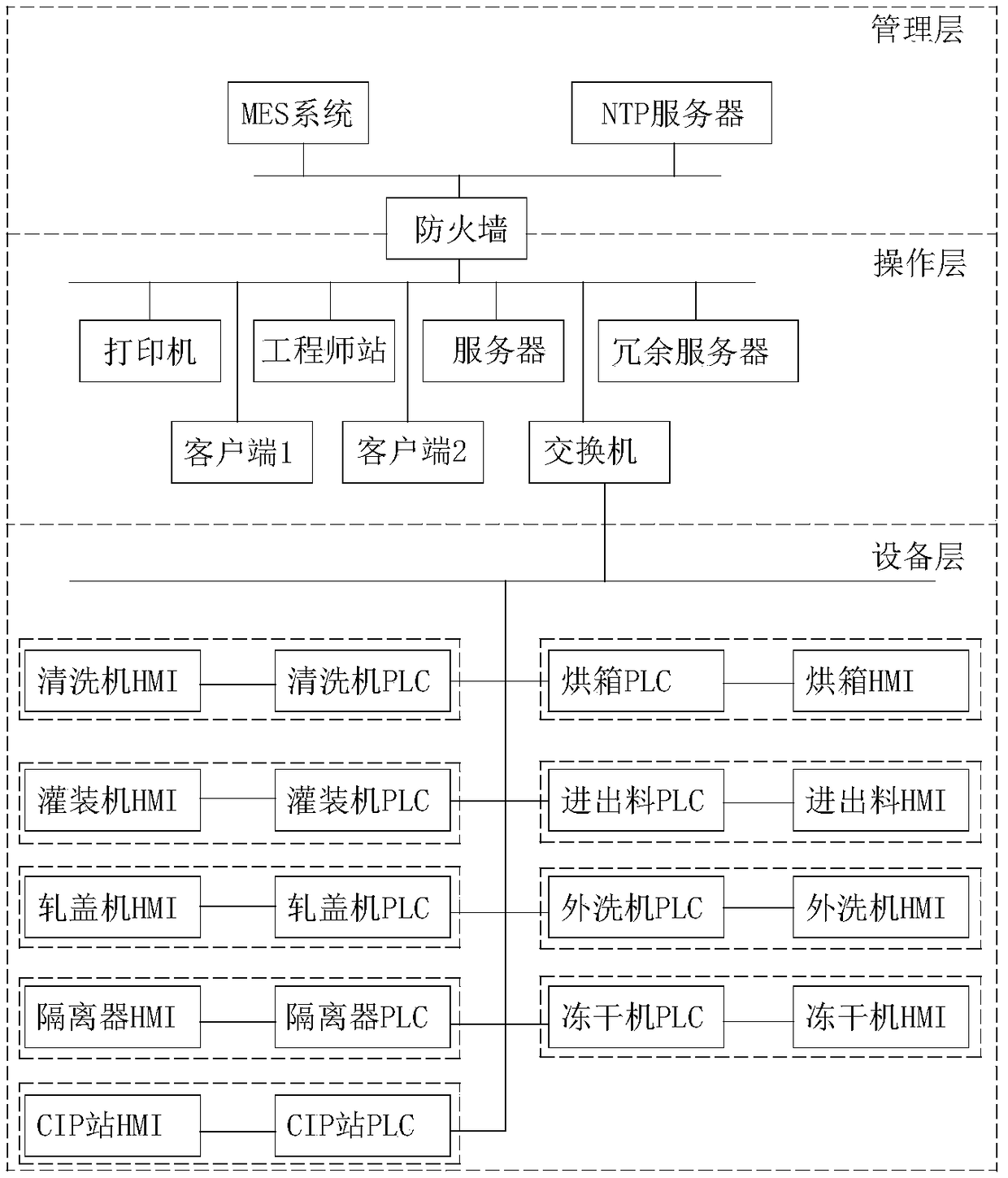

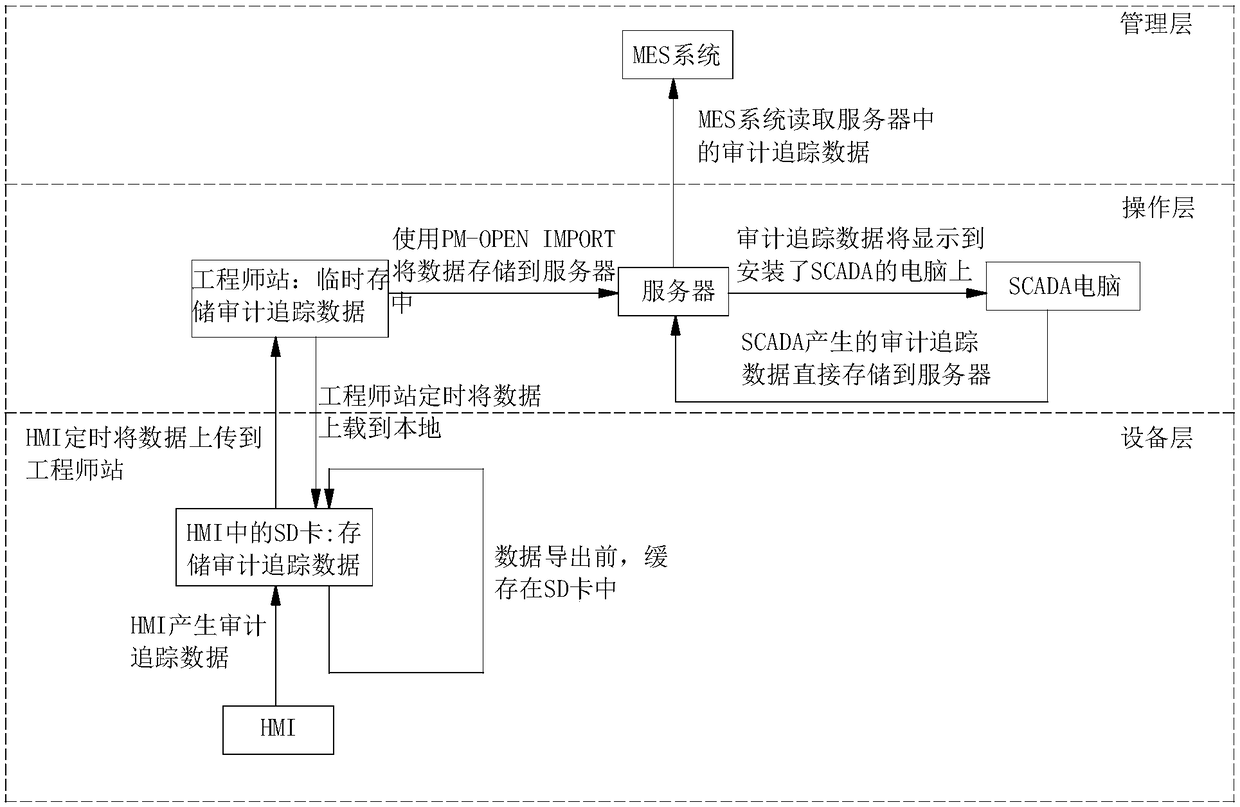

InactiveCN108829072AReduce randomnessSimplify production managementTotal factory controlProgramme total factory controlControl flowControl system

The embodiment of the invention provides a control system of a sterile pharmaceutical device. The system comprises an operation layer device and a device layer device, the device layer device comprises a plurality of controllers of sterile pharmaceutical devices and a man-machine interface, the operation layer device is connected with the controllers of the sterile pharmaceutical devices, and thecontrollers are connected with the man-machine interface; and the operation layer device is configured to control each sterile pharmaceutical device through the controllers of the sterile pharmaceutical devices according to functions of the control system of the sterile pharmaceutical devices. The control system of the sterile pharmaceutical device employs the operation layer device to control each sterile pharmaceutical device through the controllers of the sterile pharmaceutical devices according to the functions of the control system of the sterile pharmaceutical devices to perform integrated control of the sterile pharmaceutical devices with no need for field operation by operators at the scene, reduces the randomness of the whole control flow compared to the control of a single devicein the prior art, and concise in production management and low in management cost.

Owner:TRUKING TECH LTD

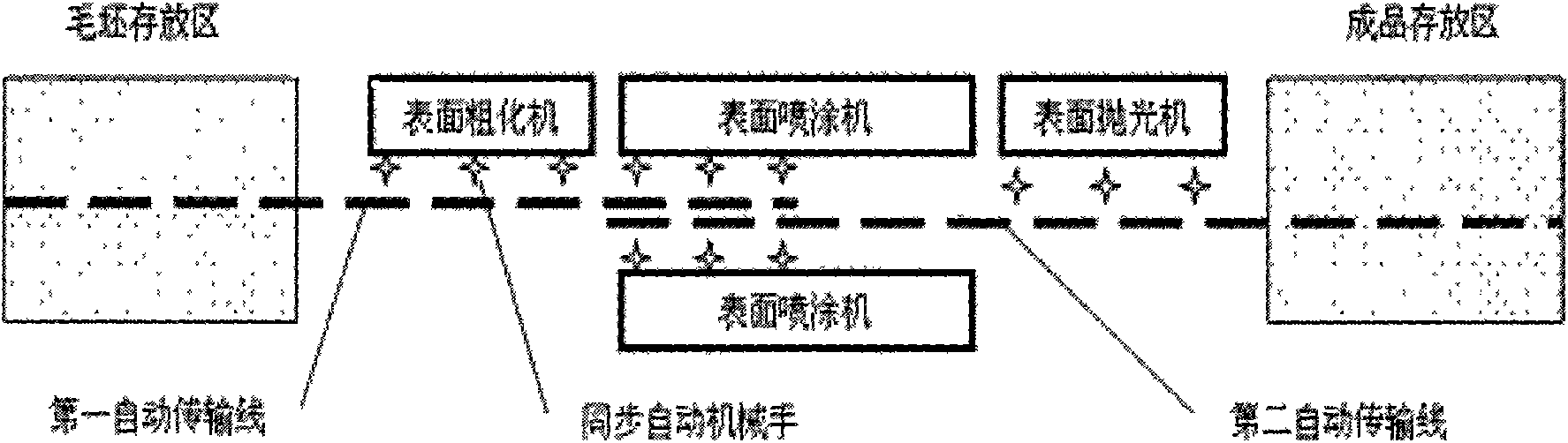

Production technique and devices for hot spraying alloy coating on polished pumping rod

InactiveCN101586448AAutomatically uploadRealize blankingMolten spray coatingDrilling rodsThermal sprayingAlloy coating

The invention relates to a production technique and devices for hot spraying an alloy coating on the surface of a polished pumping rod. The production technique comprises the following steps: (1) carrying out roughening treatment on the surface of the polished pumping rod to prepare for surface spraying; (2) carrying out hot spraying, remelting and tempering treatment on the surface of the polished pumping rod treated by the roughening treatment; and (3) polishing and burnishing the surface with the coating to finish the final surface treatment. The used devices comprise a first surface spray painting machine, a second surface spray painting machine, a surface roughing machine, a surface abrasive finishing machine, a first roller conveying line, a second roller conveying line and an automatic manipulator. The production technique and the devices improve the stability of the devices and the interchangeability of parts, reduce the fault rate and the maintenance time of the devices, reduce the requirement on operator, improve the production quality, and facilitate the further simplification of the production supervision.

Owner:ANTON OILFIELD SERVICES (GRP) LTD

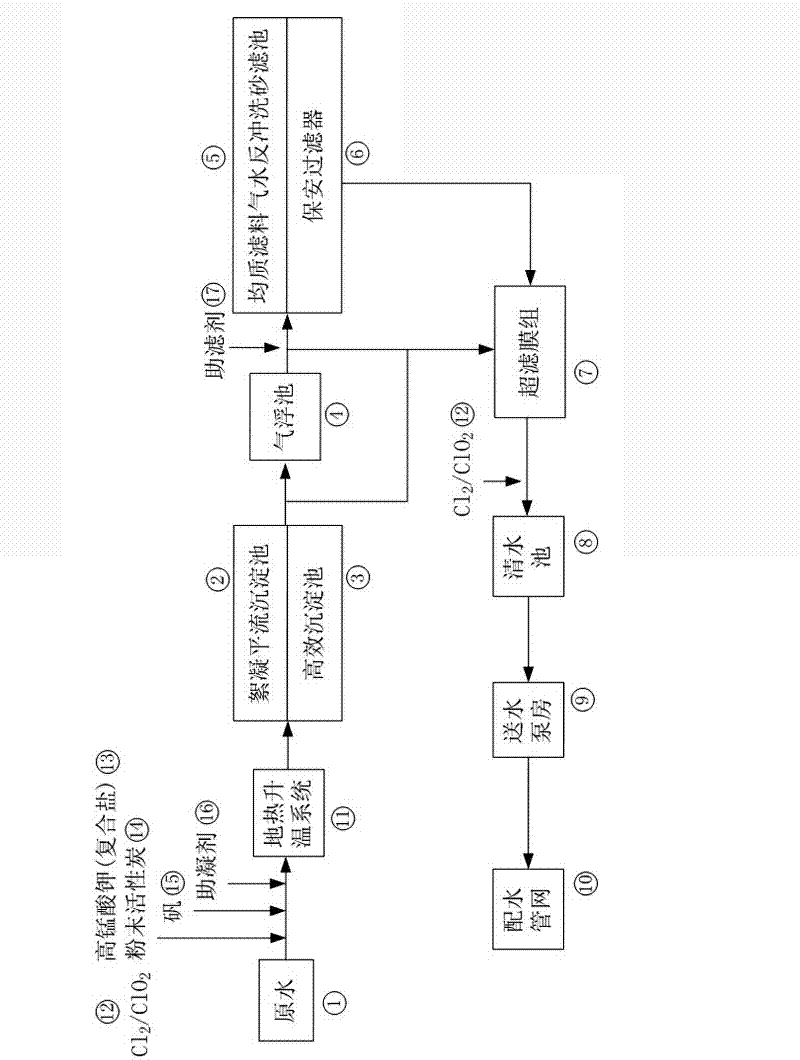

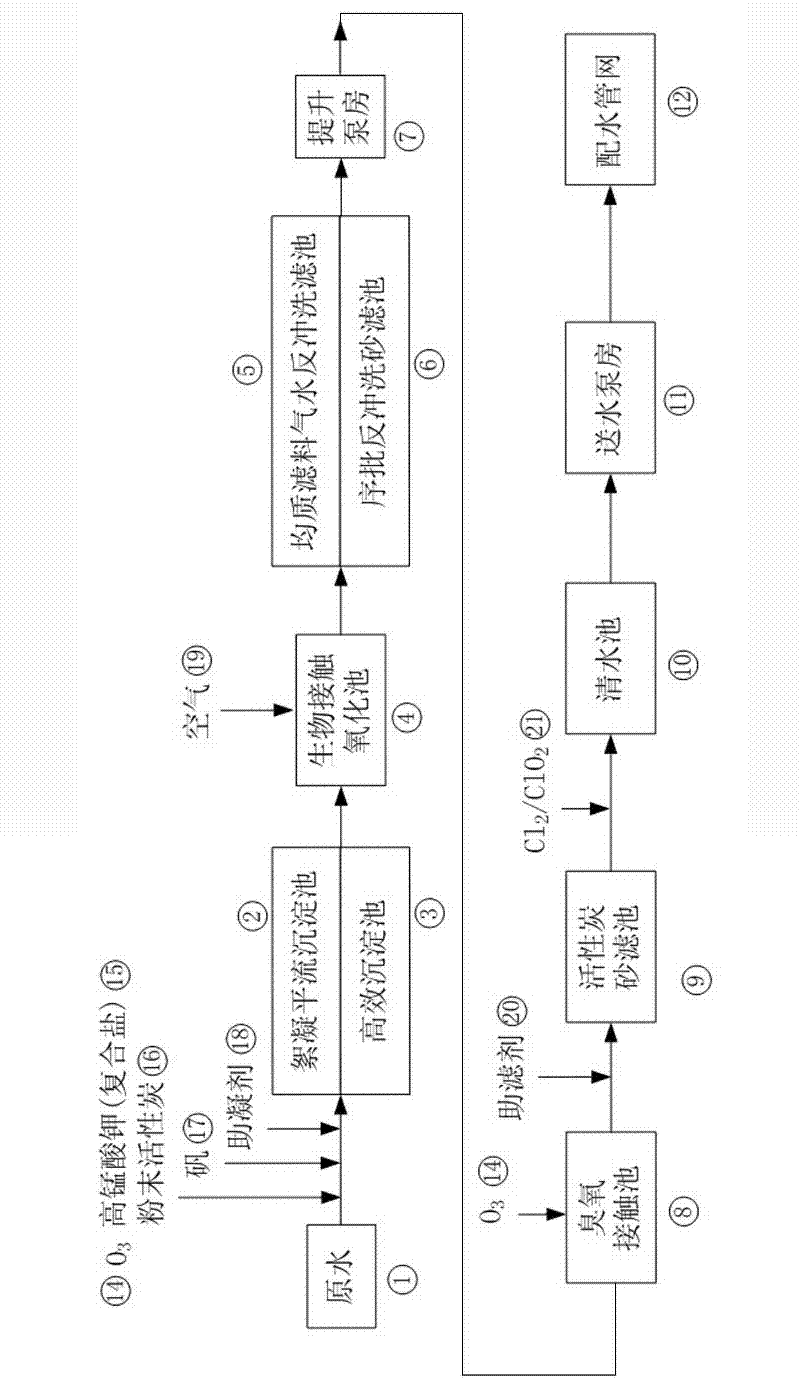

Combined enhanced treatment process for micro-pollution high-ammonia nitrogen raw water

The invention discloses a combined enhanced treatment process for micro-pollution high-ammonia nitrogen raw water. The treatment process is characterized in that under the conventional condition that the content of the ammonia nitrogen in raw water exceeds 3mg / l, the treatment process comprises the following steps: the raw water is firstly subjected to sedimentation by a flocculation horizontal sedimentation tank or a high-efficiency sedimentation tank, and then biological pretreatment is carried out by adopting a biological contact oxidation pond, effluent water enters in a homogeneous filter media air water backwashing sand filter or a sequential backwashing sand filter for filtering and then is conveyed into an ozone contact reactor for oxidation, and enters an active carbon sand filter for filtering, and effluent water is delivered into a water distribution network by a water carriage pump house after passing through a clear water pond for regulation and storage. According to the invention, the biological contact oxidation pond is arranged behind the flocculation horizontal sedimentation tank or the high-efficiency sedimentation tank, thus reducing influence of sludge sedimentation on the running of the biological contact oxidation pond. The combined treatment process has the advantages of being capable of saving land occupation, optimizing flow process, fully utilizing terrain and geothermal resources, simplifying production management, and has obvious advantages on ensuring water quality of effluent water.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

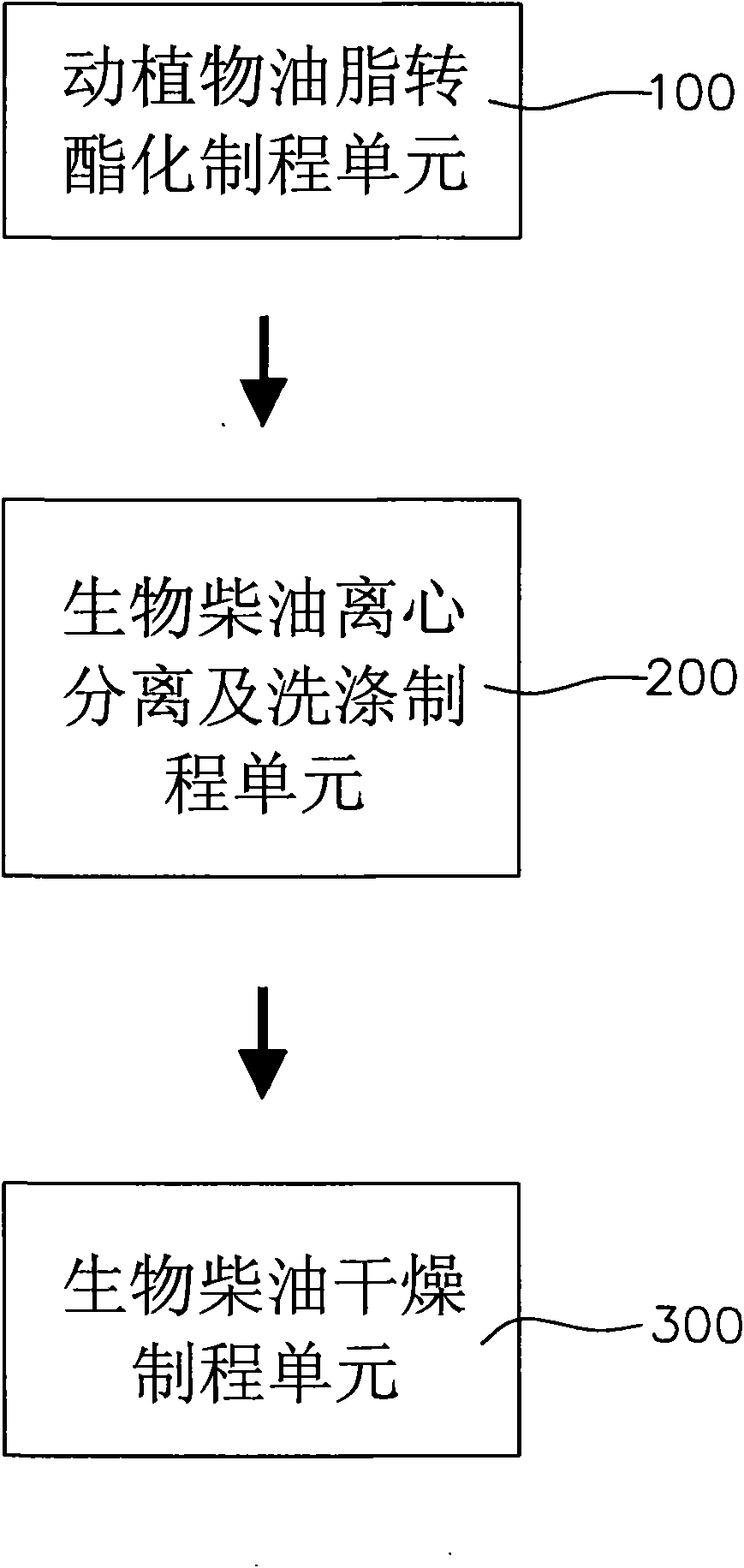

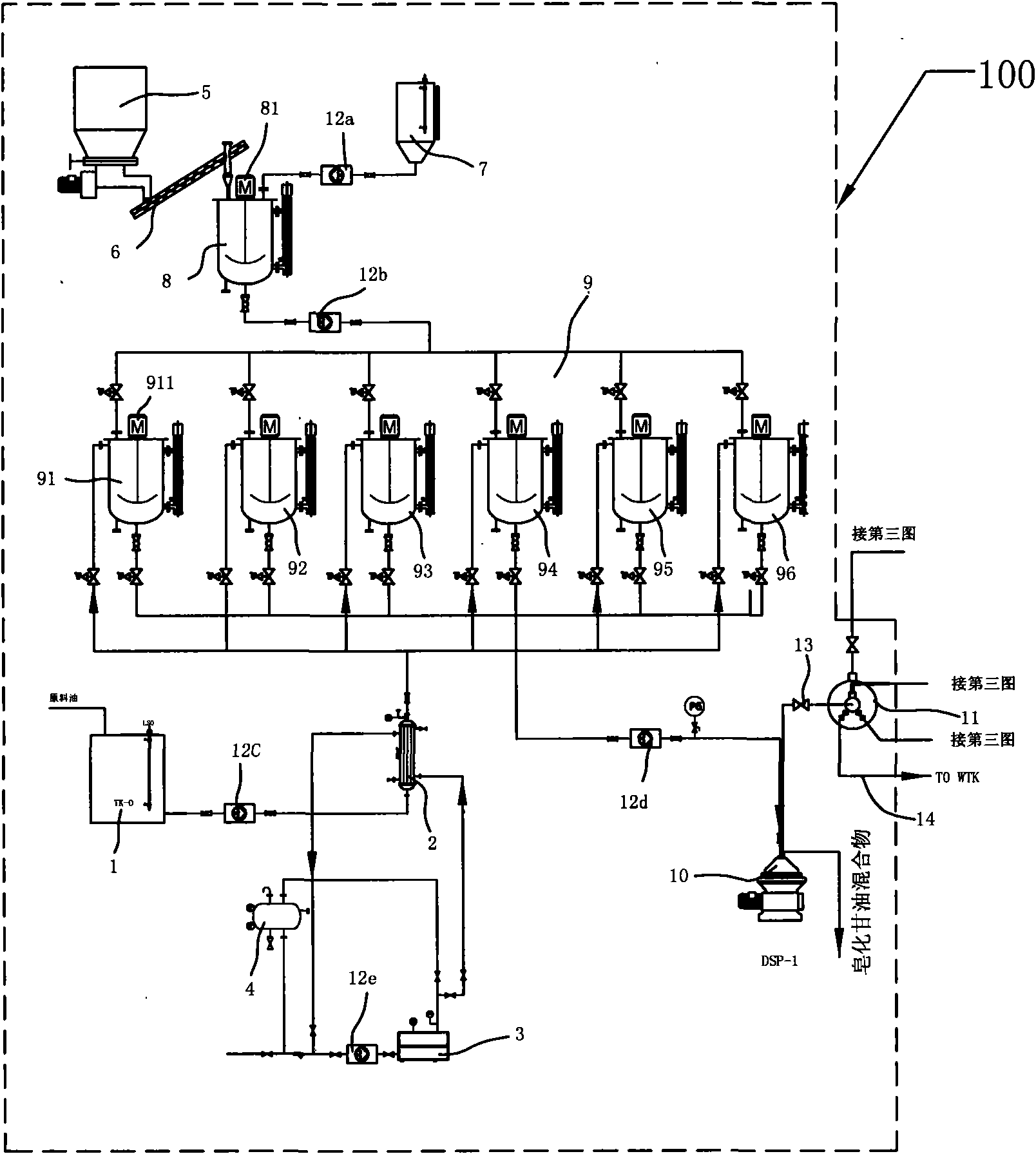

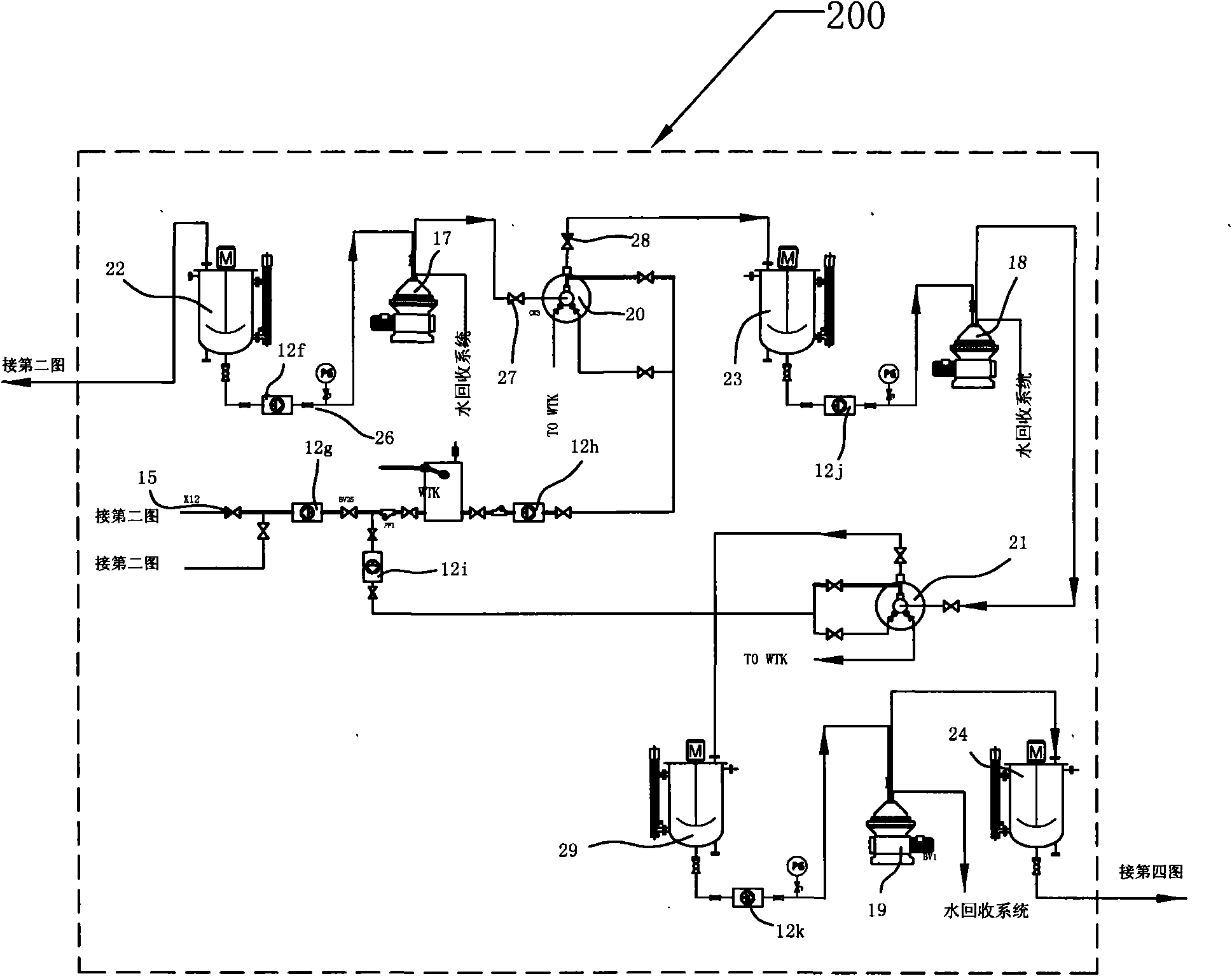

Method for refining biodiesel

InactiveCN101654625AReduce manufacturing costSmooth and efficient processFatty acid esterificationBiofuelsChemistryWork in process

The invention discloses a method for refining biodiesel, comprising the following steps: (1) after heating animal and vegetable fats to 55 DEG C, mixing the animal and vegetable fats with methyl mixture additives for transesterification; (2) using stack disc separators to separate the semi-finished products of the biodiesel from the products of the transesterification to obtain the semi-finished products of the biodiesel; (3) washing and separating the semi-finished biodiesel a plurality of times and then carrying out film vacuum drying on the washed semi-finished biodiesel, thus obtaining the biodiesel, wherein, the methyl mixture additives are obtained by mixing and then stirring potassium hydroxide and methane. Compared with the current methods for refining the biodiesel, the method ofthe invention is smoother, simpler and more efficient, and enables the production management to become quite easy with the aid of mechanical equipment, thus effectively reducing the production cost.

Owner:张伟民 +4

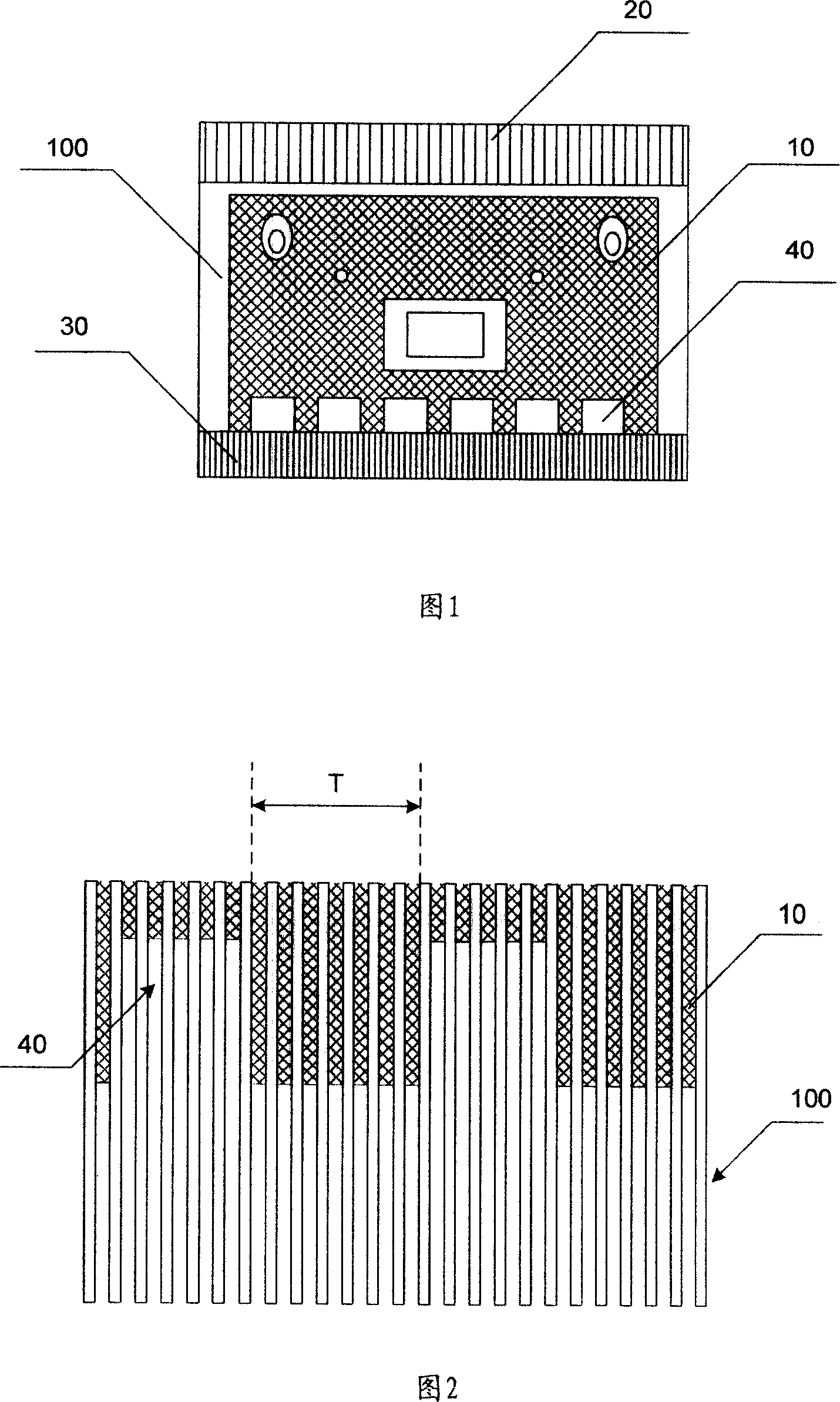

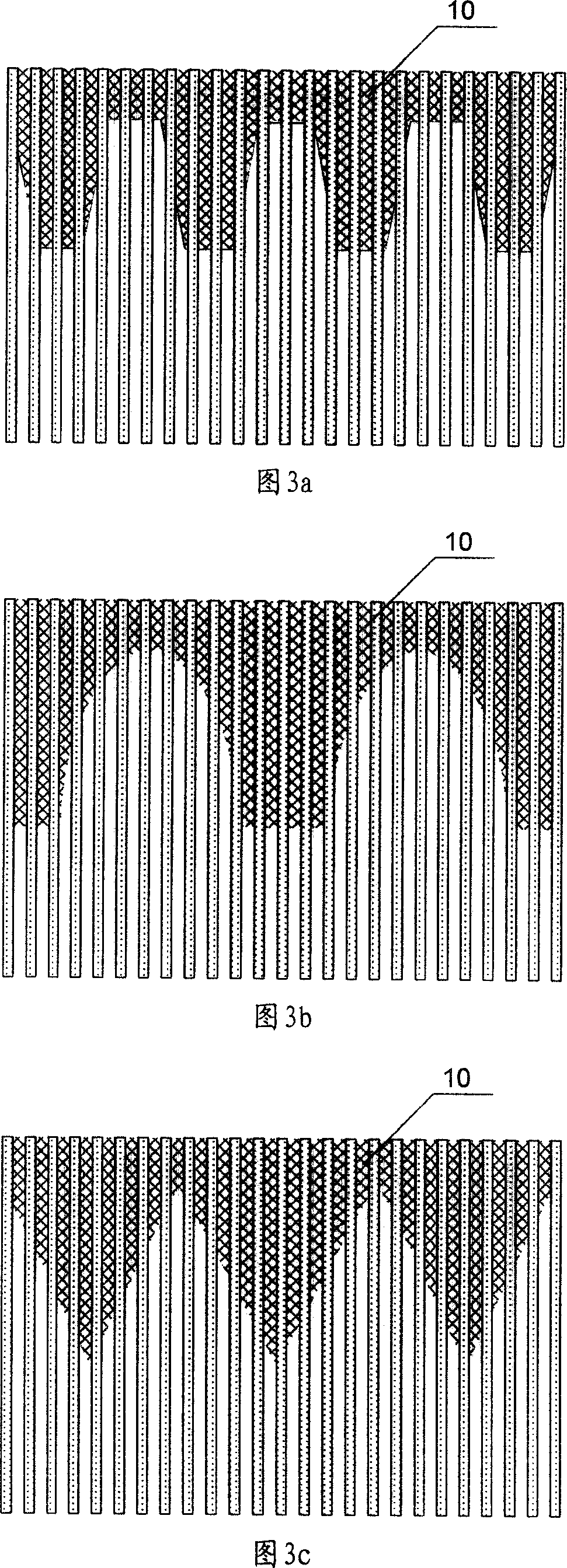

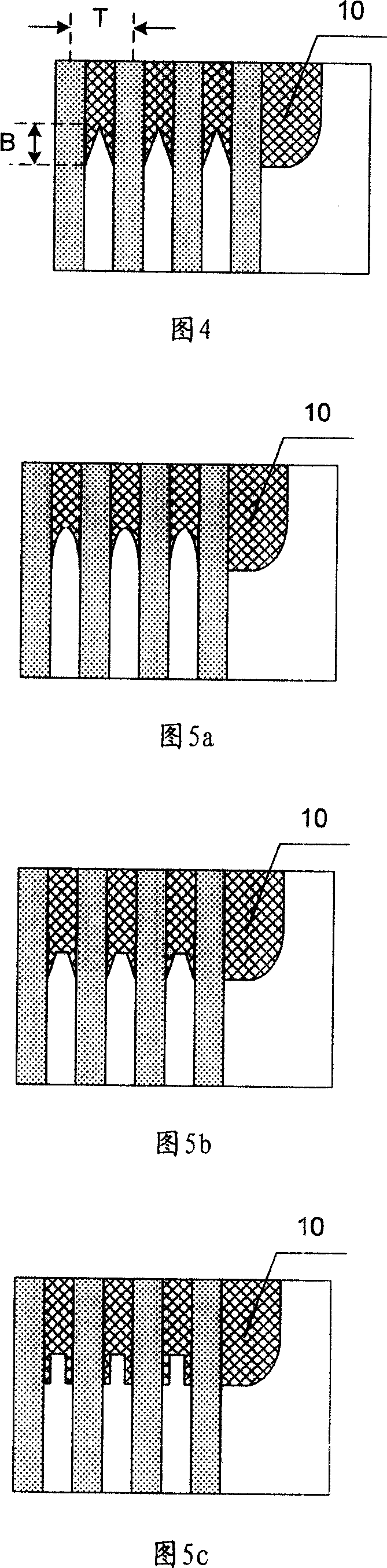

Wave-shaped applying structure

InactiveCN101013237AAvoid enteringIncrease flow spacePrinted circuit aspectsThin material handlingWave shapeParticle packing

The invention relates to a wave-shaped coating structure, including the S / R coating layer coating on the TAB / COF, and the said S / R coating layer installed a number of concave parts to make the edge wave shape. The said concave part width is 1~10 lead line unit, and in the shape of rectangular, trapezoidal, U-shape or V-shape. The invention places a number of concave parts at the edge of S / R coating layer, making the S / R coating layer edge forming wave shape, and the region without coating S / R coating layer in the wave-shape edge forms a space which can exclude ACF particles when pressing, to increase the flow space of ACF particles, and reduce ACF particle packing, and ultimately avoid TAB / COF lead line short circuit.

Owner:BOE TECH GRP CO LTD +1

Dip-dyeing type adjustable anti-crease dye vat device

The invention relates to a dip-dyeing type adjustable anti-crease dye vat device, comprising a traction device, a pickup roll transmission device, an adjustable anti-crease expander roll device and a squeezing device, wherein the traction device and the squeezing device are respectively arranged at the left and the right sides of the upper surface of a dye vat tank, the adjustable anti-crease expander roll device is mounted in the middle of the upper surface of the dye vat tank, and a pickup swing rod and a transmission mechanism of the pickup roll transmission device are respectively mounted inside and outside the dye vat tank. With the dip-dyeing type adjustable anti-crease dye vat device, unwound paper is drawn to a dye bath by traction rolls, the paper is soaked in the dye bath to be dyed through a plurality of angle-adjustable traction rolls, the dyed paper is adjusted and treated by the arc-shaped expander roll, and then excessive dye on the dyed paper is removed by a squeeze roll. The water consumption is very low in the dyeing process, and no sewage is discharged after dyeing; a steam boiler is not needed in the dyeing process; the floor area occupied by a production site is small, the production environment is clean, the production cost is reduced, and the production management is simplified; and zero emission is realized, no pollution is caused, waste water can be recycled, and the cost is saved.

Owner:安徽州来特种纸有限公司

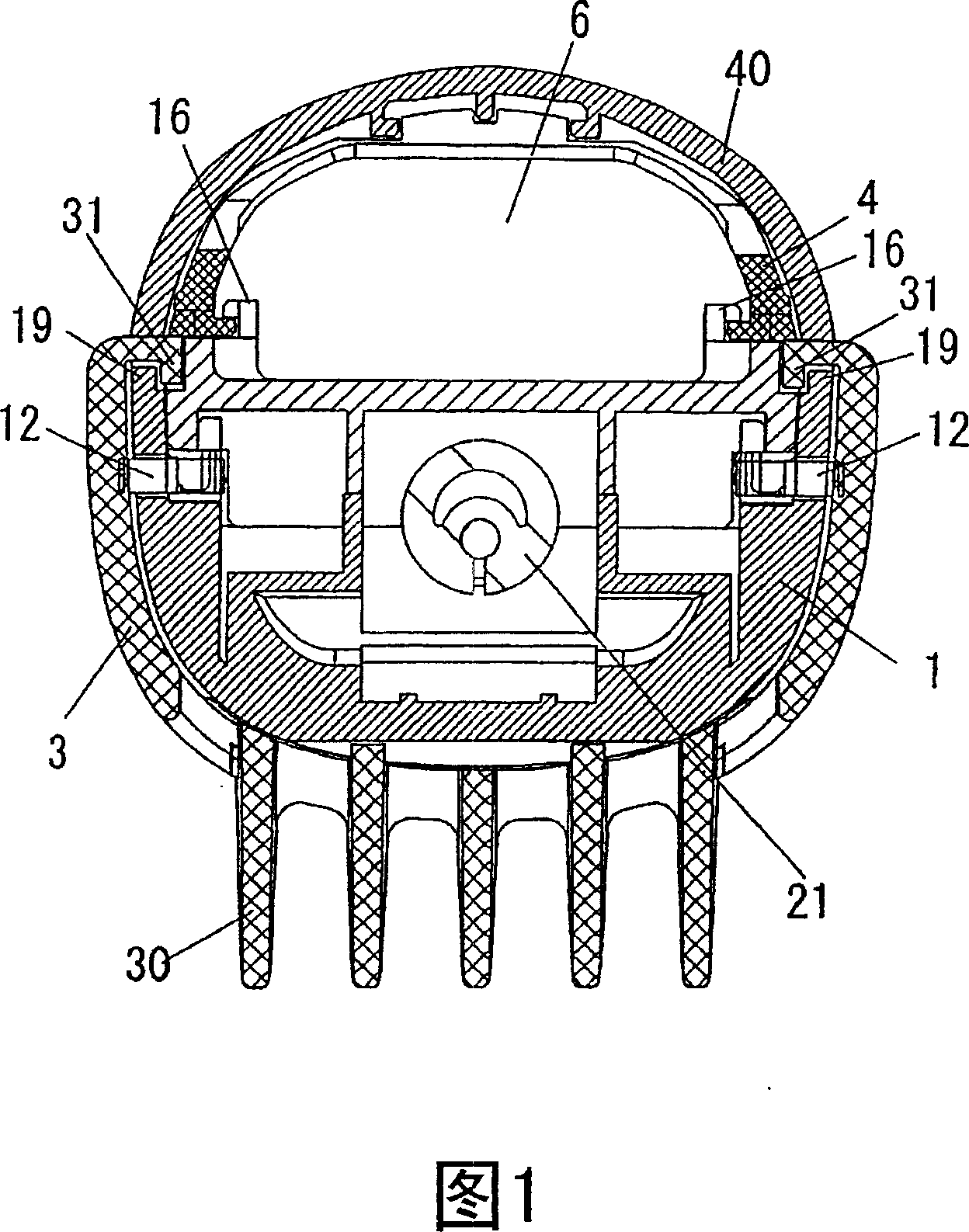

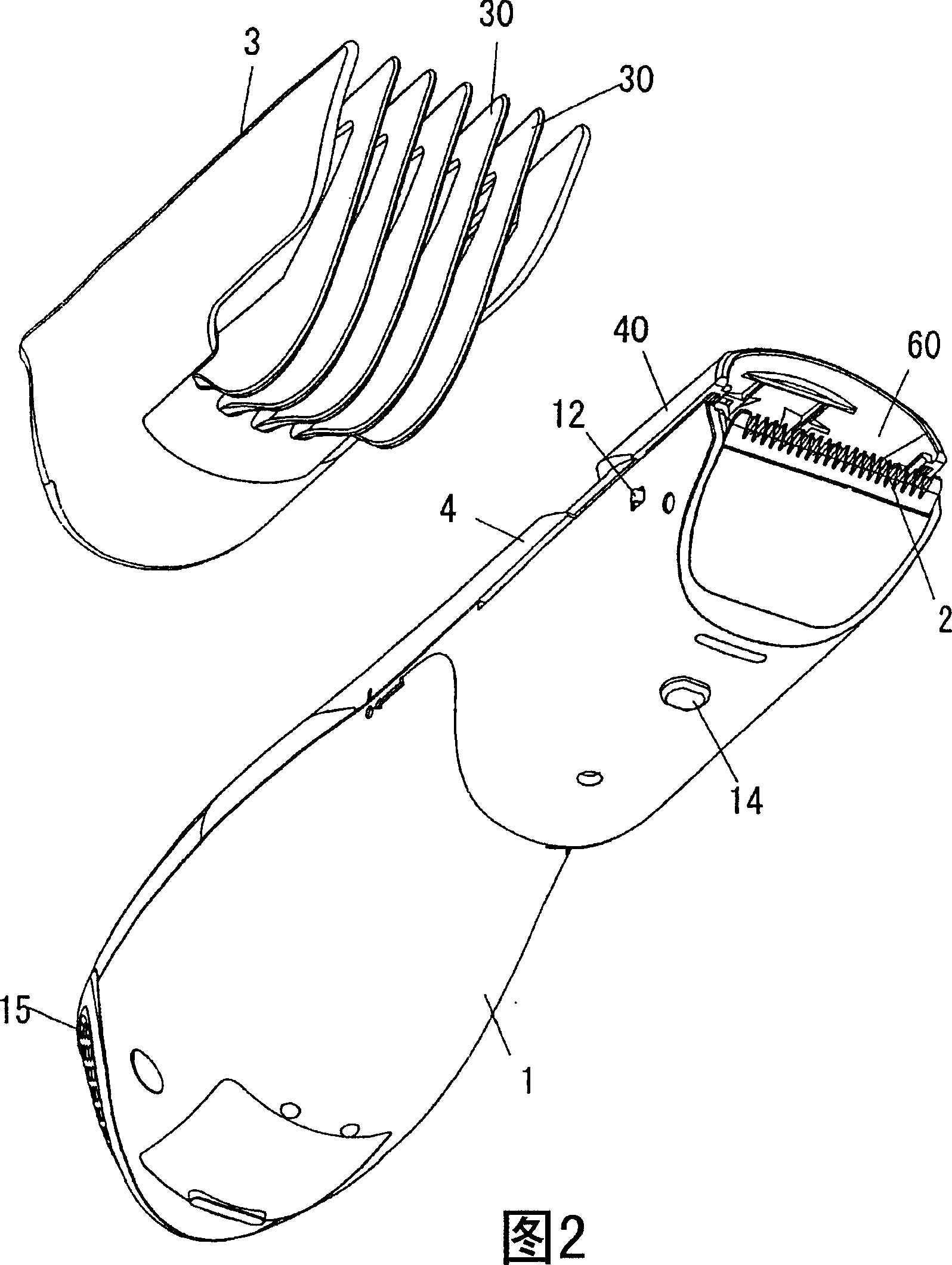

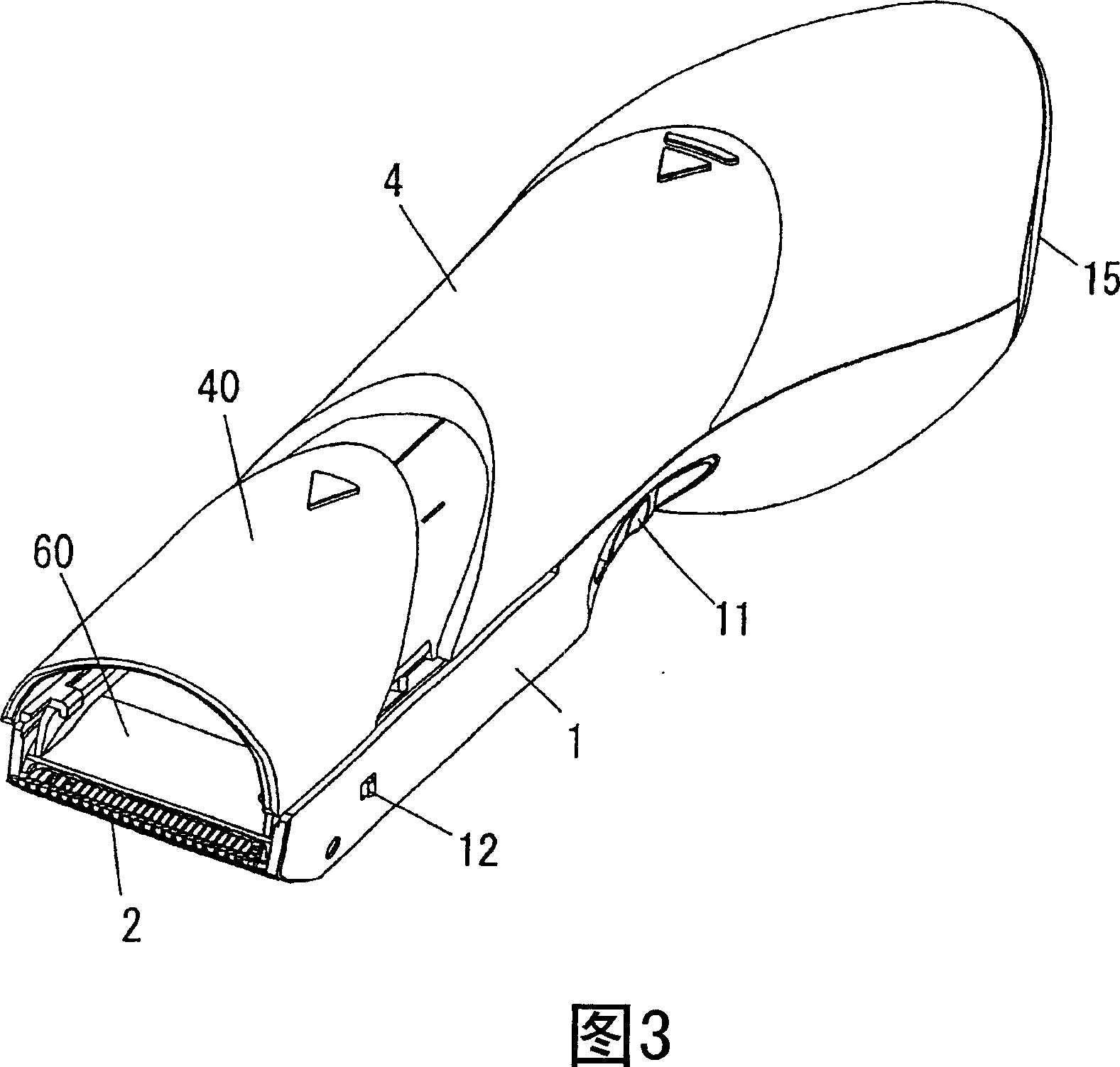

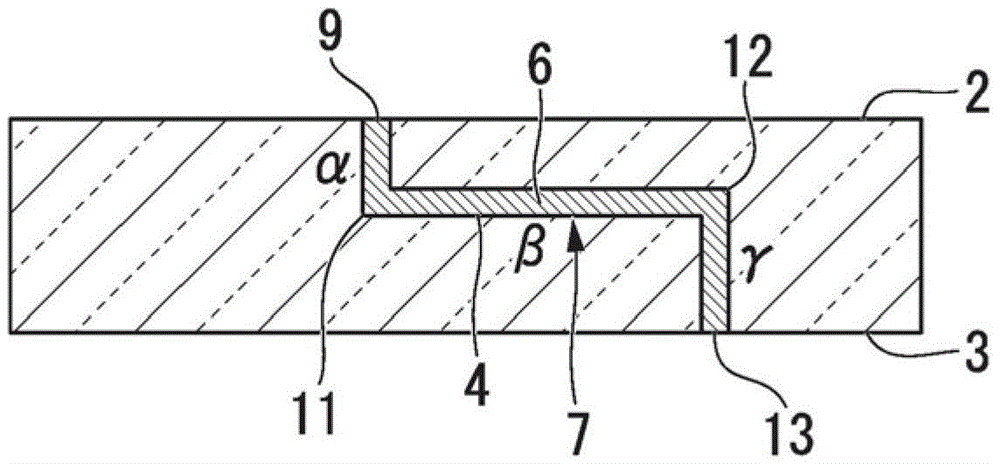

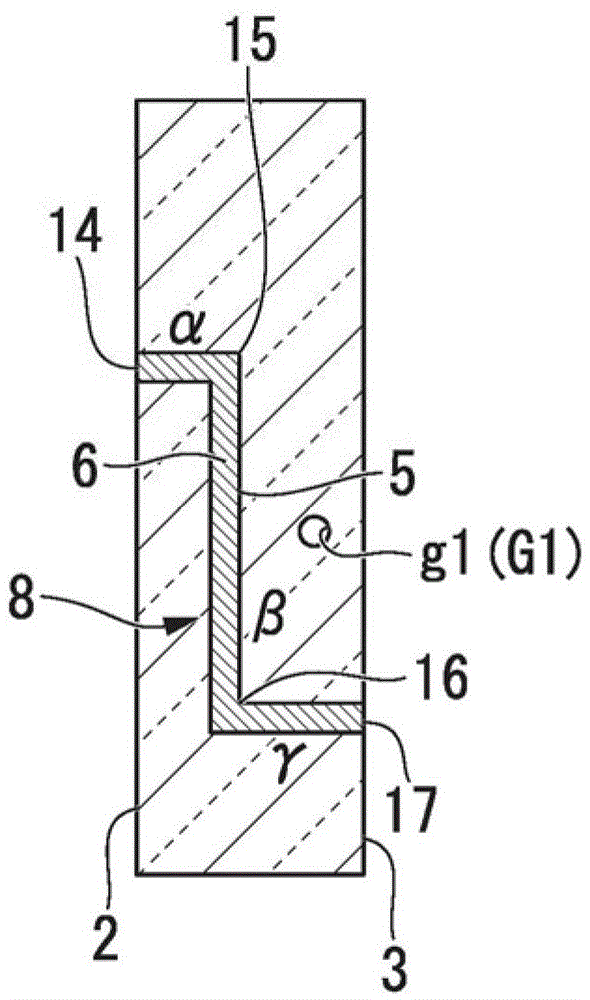

Hair clipper

InactiveCN1986169AEasy for production managementSmooth vibrationMetal working apparatusEngineeringHair characteristics

A hair clipper includes a body of the cutting hair knife part provided in the front end, and accessories for adjusting cutting height which can dismantle and slide and be mounted on the body. The accessories have cross section with ''U'' shape in essence suitable for covering the bottom of the body. In addition, the accessories include hook-shape portions respectively formed on the opposite topside of the accessories to definite the slot opening downwards. The body has guiding ribs mounting in in the slots of the accessories for guiding the accessories to slide. The body includes spring elements poisoned on the opposite sides respectively for pressing outwards the inner side surface of the accessories.

Owner:MATSUSHITA ELECTRIC WORKS LTD

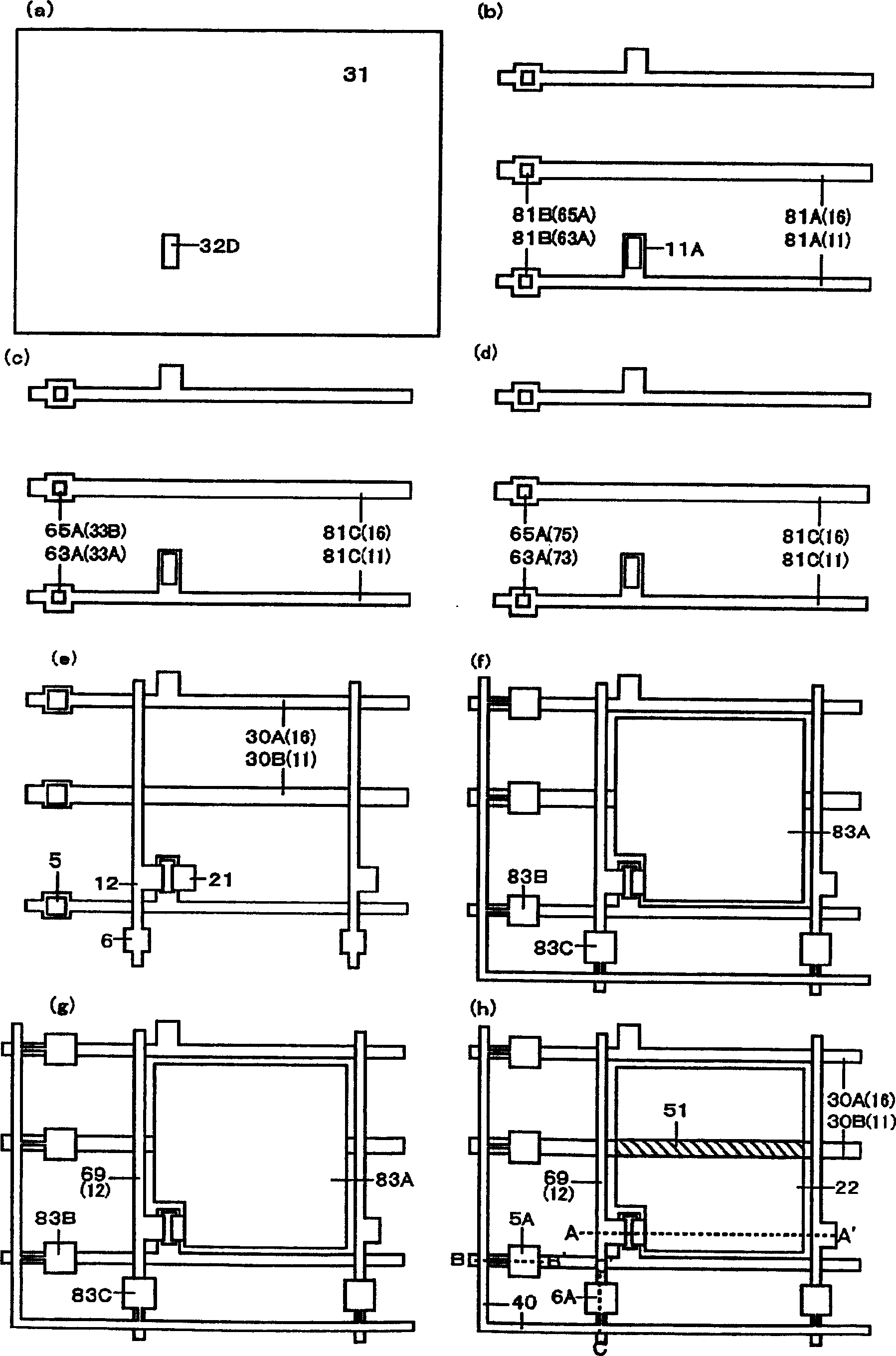

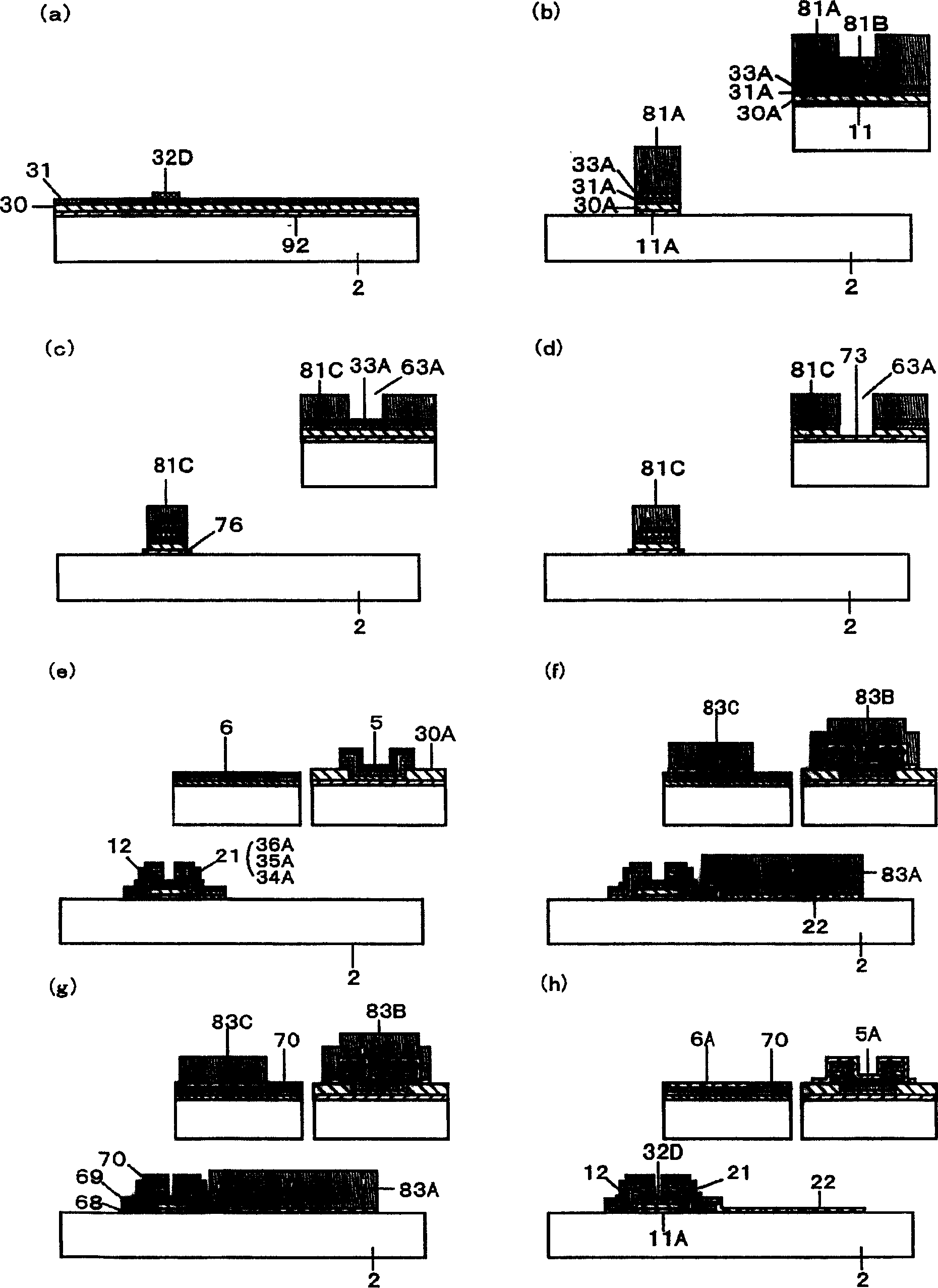

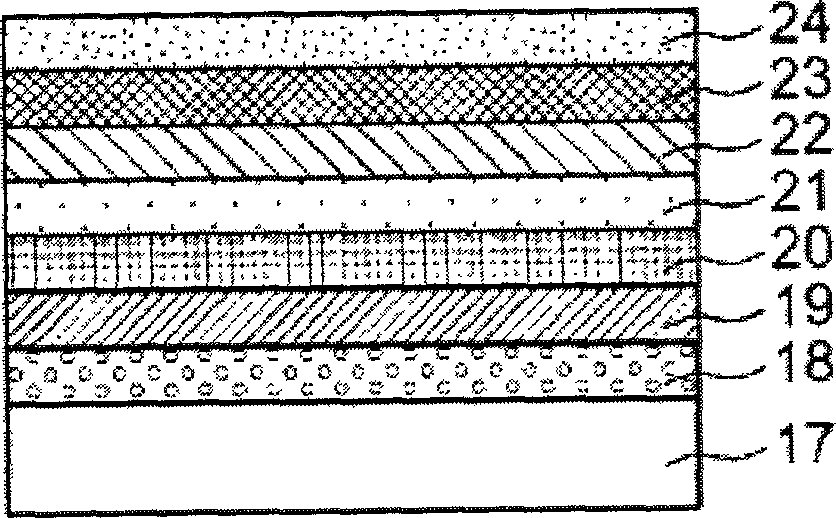

Method of forming microstructures, laser irradiation device, and substrate

InactiveCN102802864AReduce sizePrecise size controlSemiconductor/solid-state device detailsSolid-state devicesOptoelectronicsPicosecond

The disclosed method of forming microstructures involves a step (A) for irradiating, with a laser having a pulse duration on the order of picoseconds or shorter, the region where microstructures configuring holes in a substrate are to be formed and scanning a focus, at which the aforementioned laser is focused, to form a reformed portion, and a step (B) for etching the aforementioned substrate on which the aforementioned reformed portion is formed and removing said reformed portion to form microstructures. In the aforementioned step (A), a linearly polarized laser is used as the aforementioned laser, and said laser is irradiated such that the orientation of the aforementioned linearly polarized light is fixed in direction relative to the scanning direction of the aforementioned focus point.

Owner:FUJIKURA LTD

Liquid crystal display device and its manufacturing method

InactiveCN1603922ADoes not produce the effect of deteriorating electrical propertiesDoes not increase the number of photo-etching processesStatic indicating devicesSolid-state devicesLiquid-crystal displayEngineering

To solve such a problem that in the conventional manufacturing method wherein the number of manufacturing steps is reduced, when a channel length is shortened, a manufacturing margin is small and a yield is lowered. A four sheet mask process and a three sheet mask process of TN type and IPS type liquid crystal display devices are constructed by combining technologies of a novel technology which first forms an etch stop layer and then rationalizes a scanning line forming step and a contact forming step by introducing a halftone exposure technology, a new technology which rationalizes a step for forming a protective layer of an electrode terminal by introducing a halftone exposure technology to an anodization step of a source / drain wiring which is a well-known technology, and a rationalization technology simultaneously forming a pixel electrode and a scanning line which is a well-known technology.

Owner:AU OPTRONICS CORP +1

Drilling and evaluating system for rectangular rubber material

InactiveCN105784535AExclude interventionImprove production efficiencyProgramme controlComputer controlAssembly lineQuality assessment

The invention discloses a drilling and evaluating system for a rectangular rubber material. The drilling and evaluating system comprises a feeding conveyor belt for conveying the rectangular rubber material, wherein a first push plate and a drilling platform corresponding to each other in position are respectively arranged at the left and right sides of the feeding conveyor belt, and a first baffle is arranged at the outer side of the drilling platform; a weighing platform is also arranged at the outer side of the first baffle, and a drill module and a through hole module are respectively arranged at the left and right sides of the drilling platform; infrared geminate transistors corresponding to each other in position are respectively arranged at the lower parts of the first push plate and the first baffle, and a first pressure sensor and an ultrasonic sensor are also arranged on the first push plate; a top plate is also arranged above the drilling platform, and a height measuring module is arranged on the top plate. The drilling and evaluating system provided by the invention has the advantages of automatically drilling and conducting quality evaluation on rubber by adopting an assembly line way, eliminating manual intervention, improving production efficiency, simplifying production management, and greatly reducing production cost.

Owner:SUZHOU UNIV

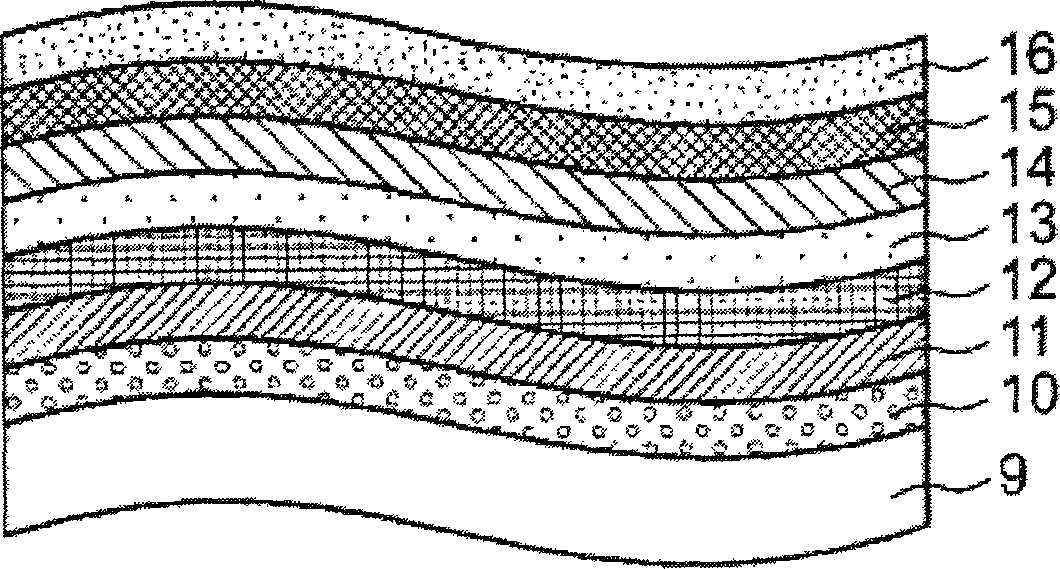

Light-emitting element and light-emitting device

InactiveCN1820552AExtend your lifeImprove sealingNanoinformaticsElectroluminescent light sourcesElectron injectionLight emitting device

Organic materials doped with an alkali metal have been conventionally used for electron-transporting layers or electron injection layers which constitute light-emitting films in organic EL light-emitting elements which are used in displays or illuminating devices. Such conventional organic materials involve problems such that a strict process control is required since the alkali metal is highly reactive and thus likely to be formed into a hydroxide, such that the resulting light-emitting element or light-emitting device needs complete sealing, and such that life of the light-emitting element cannot be sufficiently long. The present invention uses an alkali metal-containing fullerene or an organic material doped with an alkali metal-containing fullerene for electron-transporting layers or electron injection layers which constitute light-emitting films in organic EL light-emitting elements. The alkali metal-containing fullerene or the organic material doped with an alkali metal-containing fullerene is not very reactive with moisture in the atmosphere or other impurities and thus the process control thereof is easy. Furthermore, even with a simple sealing structure, the resulting light-emitting element can have sufficiently long life.

Owner:IDEAL STAR INC

Full Negative Pressure Continuous Mining Continuous Full Step Replacement "Three Down" Coal Mining Method

ActiveCN104775817BUndamagedRealize full negative pressure ventilationUnderground miningTunnel/mines ventillationEngineeringProduction unit

Owner:路彬 +1

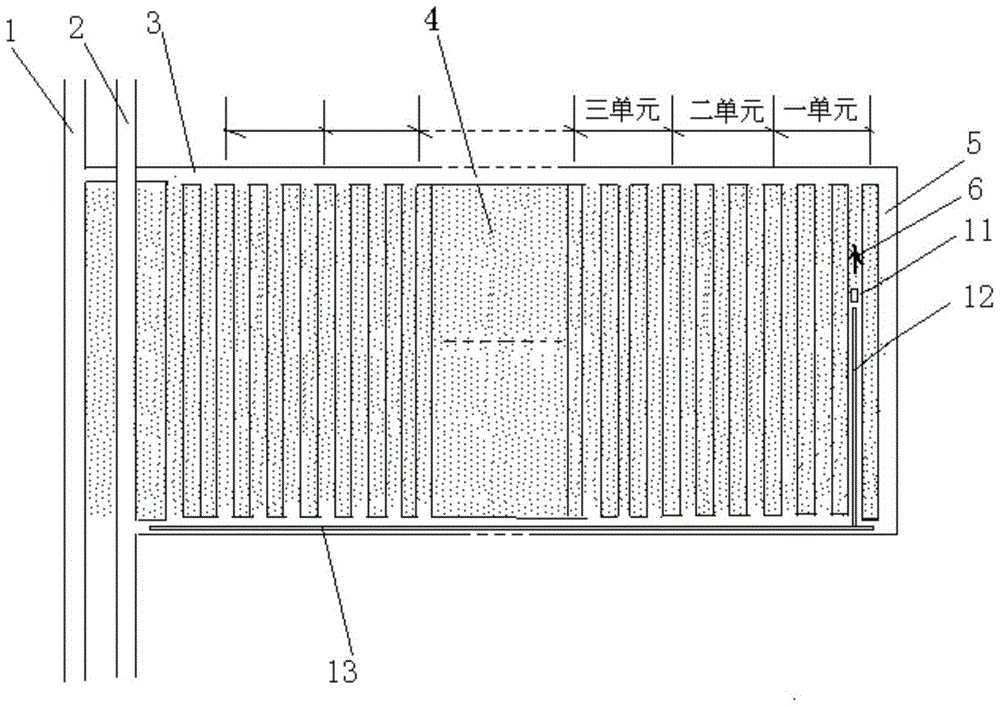

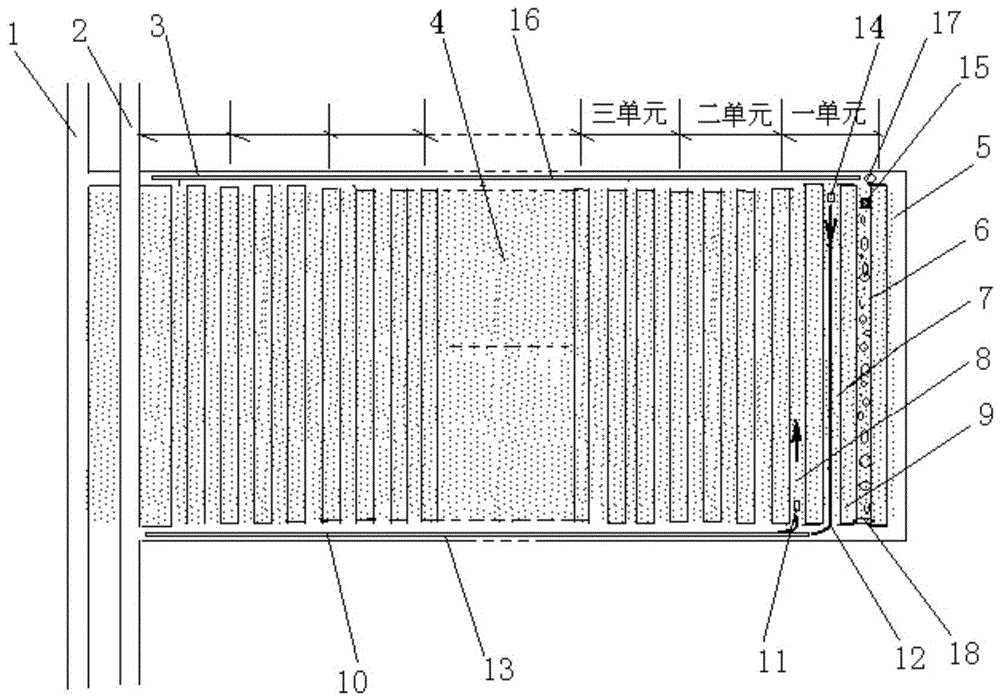

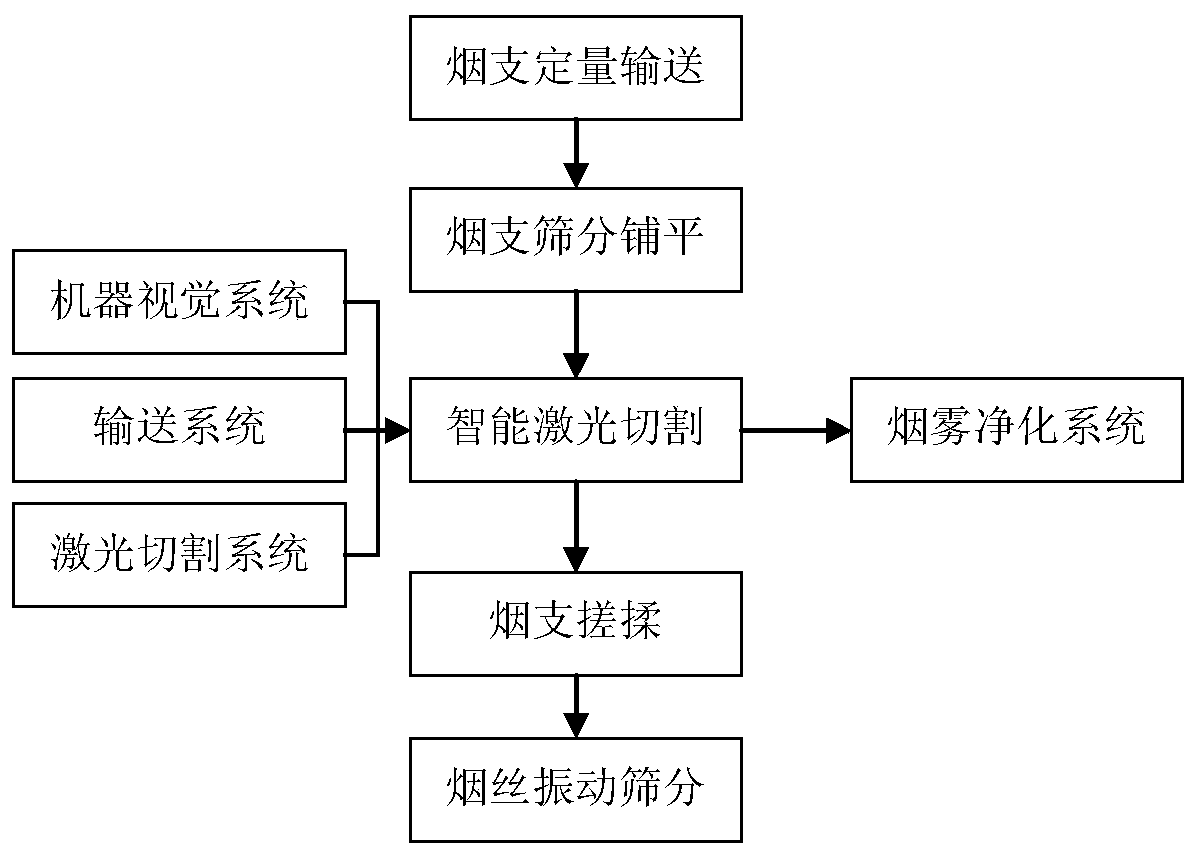

Intelligent laser cutting treatment method for filter capsule waste cigarettes

ActiveCN111000287AQuick cutImprove recycling efficiencyCigarette manufactureProcess engineeringLaser cutting

The invention relates to an intelligent laser cutting treatment method for filter capsule waste cigarettes. The method comprises the steps that waste cigarettes are screened and flatly laid; a machinevision recognition device is used for recognizing the relative position and form of the waste cigarettes in the transportation process, then the optimal path of laser cutting operation is planned, and the waste cigarettes are conveyed to a laser cutting device; the laser cutting device completes the cutting action of the waste cigarettes according to an instruction; the cut waste cigarettes are mechanically kneaded, and then cut tobaccos and bobbin paper filter tips are effectively separated through vibrating screen powder. According to the waste cigarette treatment method, the filter tips and the cigarette sections do not need to be manually separated, the cigarettes do not need to be strictly sorted, and the waste cigarette cutting and tobacco shred recycling efficiency can be greatly improved. The method is high in adaptability to cigarettes, and materials, such as bent, duplex and empty filter sticks and paper scraps, frequently existing in waste cigarettes can be slit.

Owner:HUBEI CHINA TOBACCO IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com