Liquid crystal display device and its manufacturing method

A liquid crystal display device, liquid crystal technology, applied in identification devices, semiconductor/solid-state device manufacturing, static indicators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

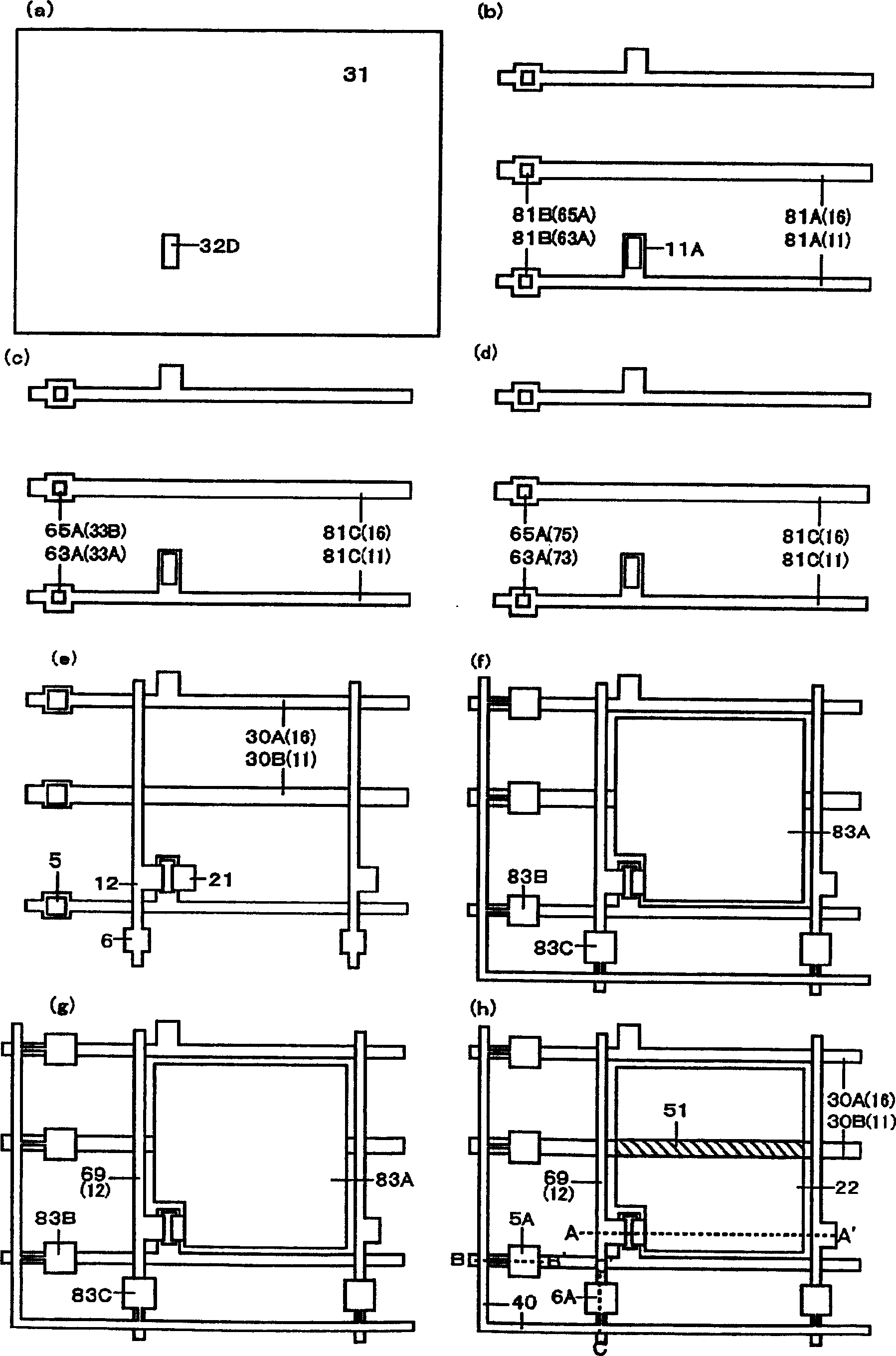

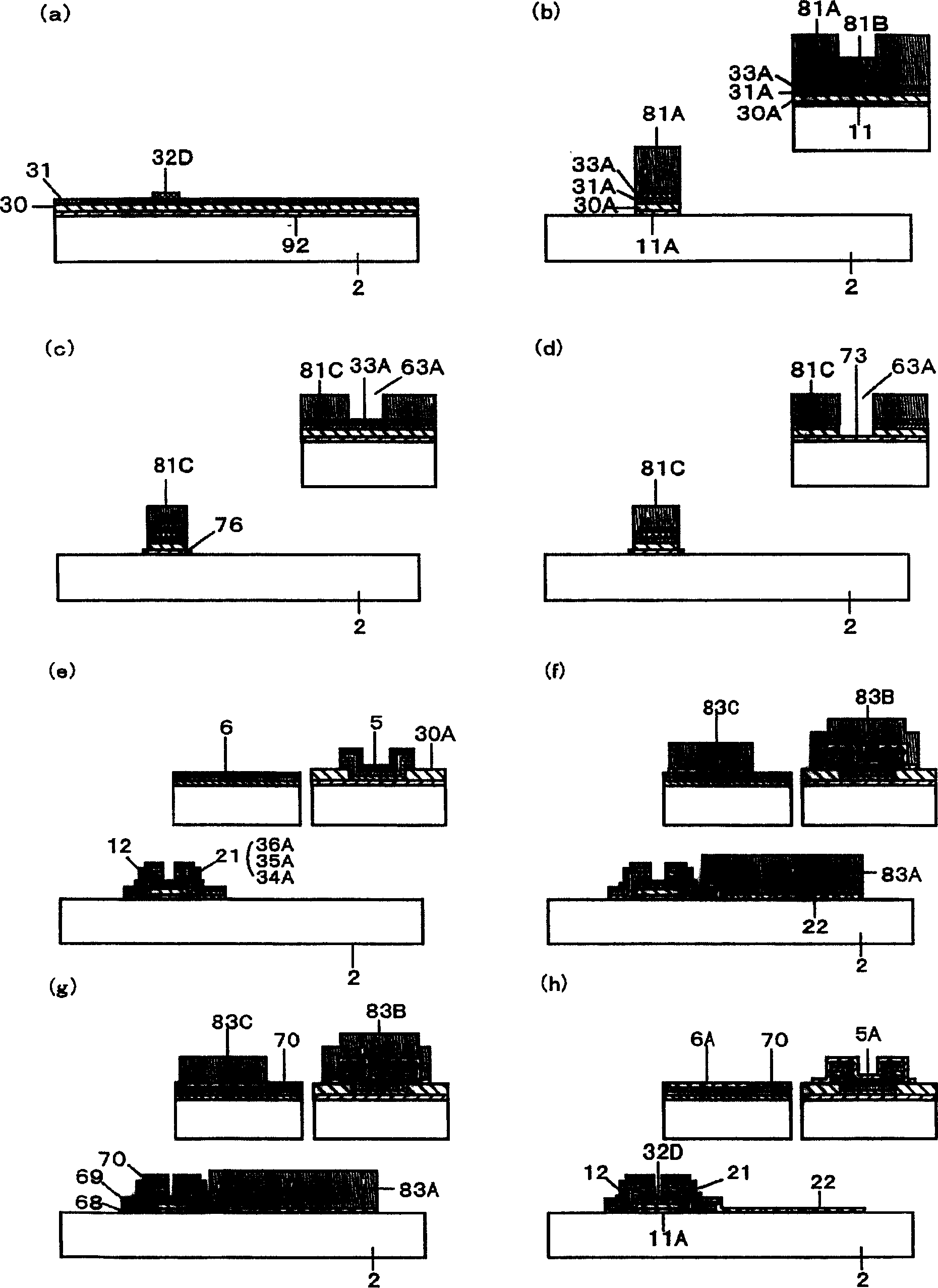

Embodiment 1

[0111] In Example 1, as in the conventional example, first, on the main surface of the glass substrate 2, use a vacuum film forming device such as SPT to coat, for example, Cr, Ta, Mo, etc. or alloys or silicides of these metals to form a film thickness The first metal layer is about 0.1 to 0.3 μm. In the present invention, in the case of selecting an organic insulating layer as the insulating layer formed on the side of the scanning line, there is almost no limit to the material of the scanning line; but in the case of selecting an anodized layer as the insulating layer formed on the side of the scanning line , It is necessary to keep the anodized layer insulating. In this case, considering the high resistance of Ta alone and the lack of heat resistance of Al alone, the heat resistance can be selected for the low resistance of the scanning line. Higher single-layer structure of Al(Zr, Ta, Nd) alloy or layered structure of Al / Ta, Ta / Al / Ta, Al / Al(Ta, Zr, Nd) alloy as the struct...

Embodiment 2

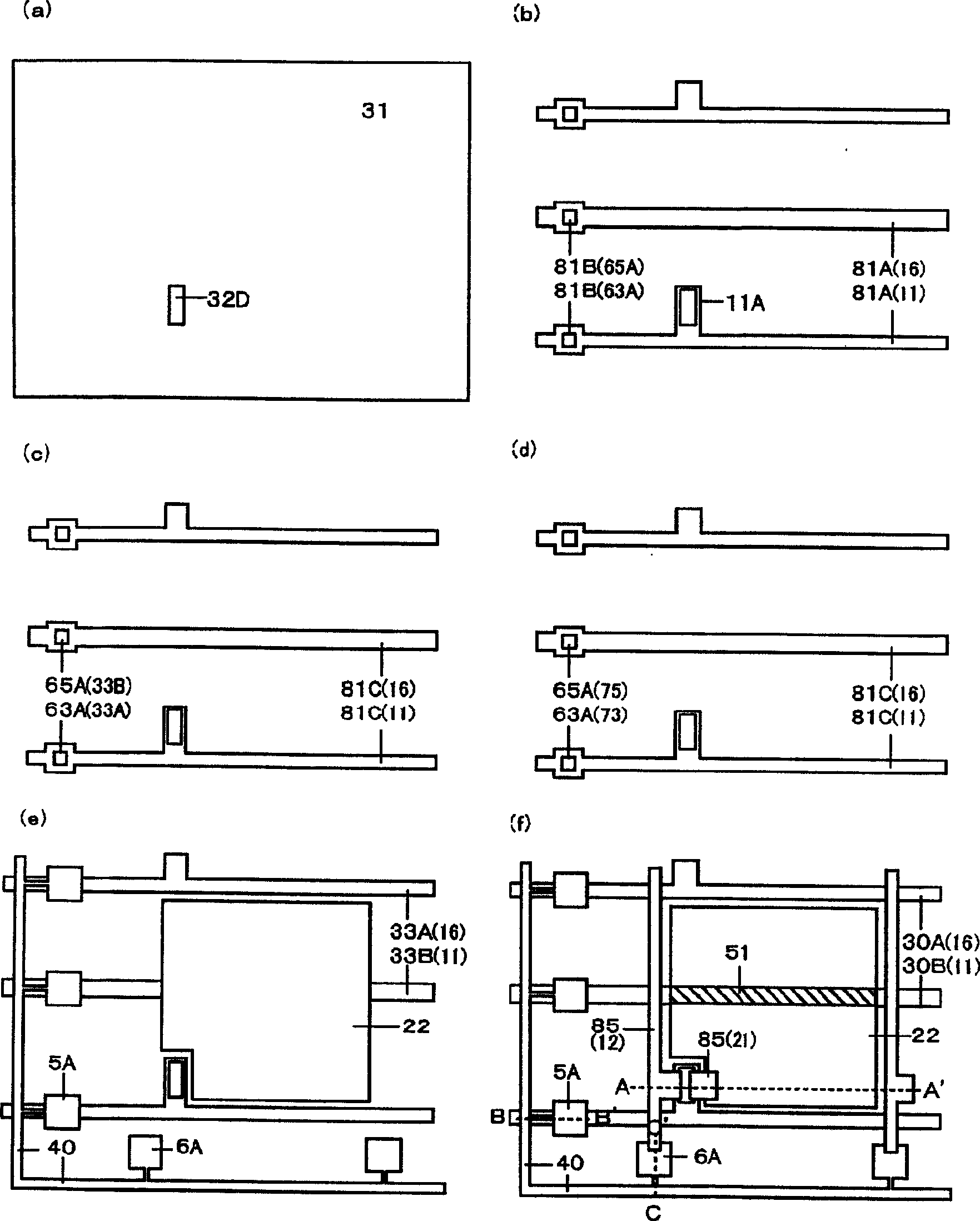

[0127] In Example 2, such as image 3 (d) and Figure 4 As shown in (d), the contact forming process is performed, that is, the second amorphous silicon layer 33A, 33B in the opening 63A, 65A, the first amorphous silicon layer 31A, 31B, and the gate insulating layer are selectively etched. 30A, 30B, and before exposing a part 73 of each scanning line 11 and a part 75 of the storage capacitor line 16, the same manufacturing process as in the first embodiment is performed.

[0128] Next, the entire surface of the glass substrate 2 is covered with, for example, ITO as a transparent conductive layer with a film thickness of about 0.1 to 0.2 μm using a vacuum film forming apparatus such as SPT, and the image 3 (e) and Figure 4 As shown in (e), pixel electrodes 22 are selectively formed on the glass substrate 2 by microfabrication technology. At this time, in the area outside the image display portion, the scanning line electrode terminal 5 and the signal line electrode termina...

Embodiment 3

[0133] In Example 3, first, the main surface of the glass substrate 2 is coated with, for example, ITO and the first metal layer 92 with a film thickness of about 0.1 to 0.3 μm using a vacuum film forming apparatus such as SPT, as a film thickness of 0.1 to 0.2 μm. left and right transparent conductive layers 91 . In Embodiments 3 to 5, the scanning lines are stacked layers of a transparent conductive layer and a metal layer. Therefore, it is impossible to form an insulating layer on the side of the scanning lines during anodic oxidation, which will be clearly explained below. Here, the organic insulating layer is formed by electrodeposition in the insulating layer. Therefore, for example, high melting point metals such as Cr, Ta, Mo, or these alloys or silicides are selected as the first electrode that does not cause battery reaction with the transparent conductive layer ITO. 1 metal layer, used as scan line material. If Al is used for low resistance, a single layer such as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com