Method for refining biodiesel

A biodiesel, animal and vegetable oil technology, applied in the field of petrochemical industry, can solve the problems of time-consuming waiting for uniform mixing, unfavorable investors, consumption of waiting time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Relevant technical content of the present invention and detailed statement, now coordinate drawing description as follows:

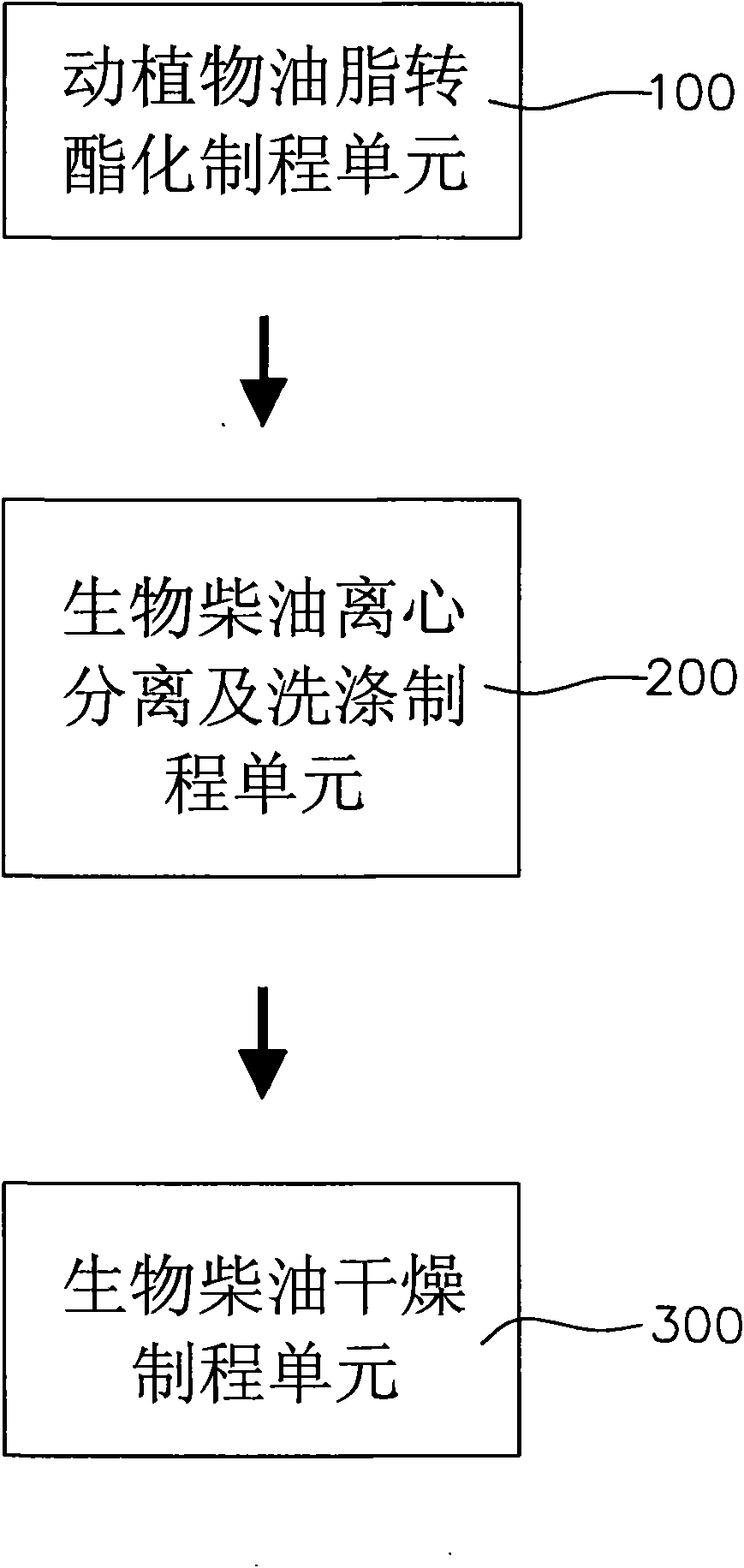

[0023] Please refer to the first figure, which is a schematic flow chart of the biodiesel refining process of the present invention. As shown in the figure: the biodiesel refining process of the present invention includes a transesterification process unit 100 of animal and vegetable oil, a biodiesel centrifugal separation and washing process unit 200 , and a biodiesel drying process unit 300 .

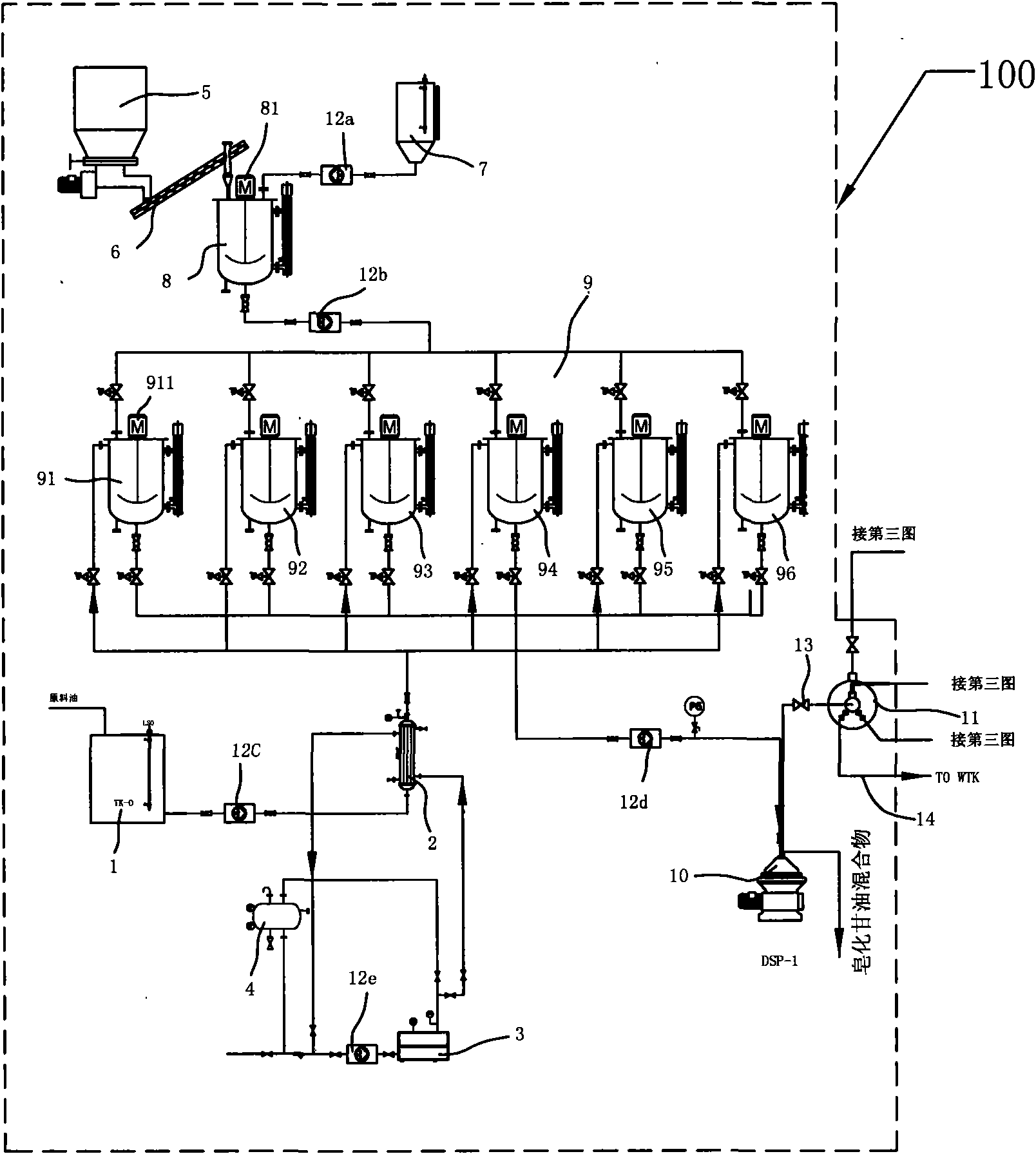

[0024] First, please refer to the second figure for the schematic diagram of the animal and vegetable oil transesterification process unit of the present invention. As shown in the figure: the main equipment required for this unit process includes an animal and vegetable oil storage tank 1, a preheater 2, a heat conduction oil heating furnace 3, a heat conduction oil expansion tank 4, a hydrogen oxidizer Potassium (KOH) storage tank 5, a screw pump for p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com