Efficient desalting device and efficient desalting method for salted egg white

The technology of a desalination device and salted egg white is applied in the processing field of food or egg products, which can solve the problems of large loss of nutrients such as protein, large amount of acid and alkali, and long production cycle, so as to simplify production management links and reduce protein loss rate. , the effect of shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

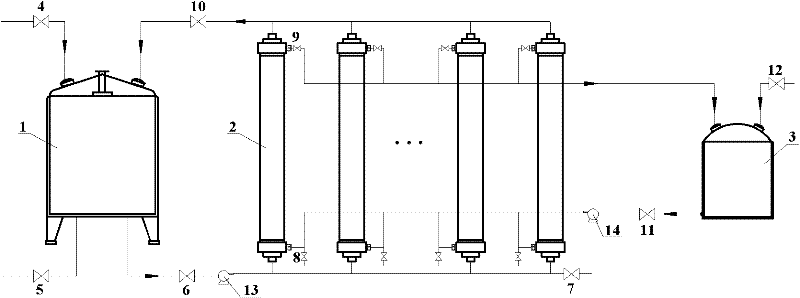

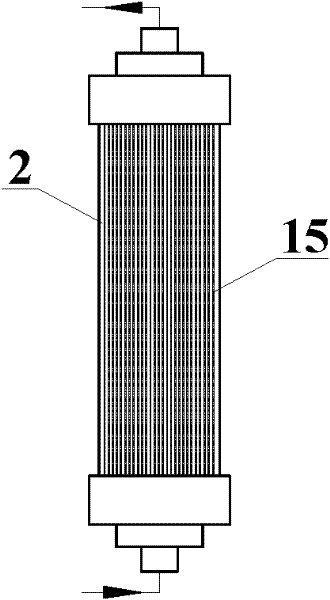

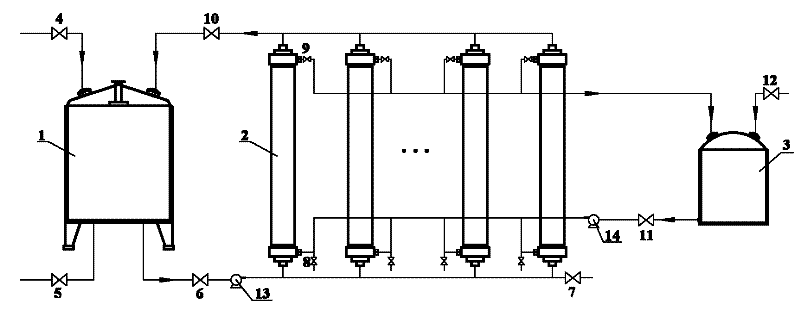

[0034] Dilute according to the ratio of process water and salted egg white weight 4: 1, measure 1000 kg of process water, 250 kg of salted egg white liquid, input the diluted egg white liquid through valve 4 in egg white bucket 1, close valve 4, open pump 113, and At room temperature, the pressure is 0.3MPa, the egg white is desalinated 5 times through a plurality of parallel ultrafiltration modules 2, and the brine is discharged from the valve 8, and the salt content at the valve 8 is sampled to detect that the salt content is ≤0.85%. Close all valves and open Valve 5, the desalted egg white liquid enters the next process through valve 5.

[0035] Turn on the backwash pump II 14 to perform circular cleaning on multiple parallel ultrafiltration modules 2 , turn off the backwash pump II 14 after cleaning, and discharge the sewage from the valve 7 .

Embodiment 2

[0037] According to the ratio of process water and salted egg white weight of 5:1, measure 1000 kg of process water and 200 kg of salted egg white liquid, input the diluted egg white liquid into egg white bucket 1 through valve 4, close valve 4, open pump 113, and Under the pressure of 0.2MPa, the egg white is desalinated 4 times through a plurality of parallel ultrafiltration modules 2, and the brine is discharged from the valve 8, and the salt content at the valve 8 is sampled to detect that the salt content is ≤0.85%, all valves are closed, and the valve is opened 5. The desalted egg white enters the next process through the valve 5.

[0038] Turn on the backwash pump II 14 to perform circular cleaning on multiple parallel ultrafiltration modules 2 , turn off the backwash pump II 14 after cleaning, and discharge the sewage from the valve 7 .

Embodiment 3

[0040] According to the ratio of process water and salted egg white weight of 6:1, measure 1100 kg of process water and 185 kg of salted egg white liquid, and input the diluted egg white liquid into egg white bucket 1 through valve 4, close valve 4, open pump 113, and Under the pressure of 0.1MPa, multiple parallel ultrafiltration modules 2 are used to circulate the egg white for desalination 3 times, and the brine is discharged from the valve 8, and the salt content at the valve 8 is sampled to detect that the salt content is ≤ 0.85%, all valves are closed, and the valve is opened 5. The desalted egg white enters the next process through the valve 5.

[0041] Turn on the backwash pump II 14 to perform circular cleaning on multiple parallel ultrafiltration modules 2 , turn off the backwash pump II 14 after cleaning, and discharge the sewage from the valve 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com