Production technique and devices for hot spraying alloy coating on polished pumping rod

A technology for oil sucking polished rod and production process, which is applied in the field of new alloy coating thermal spraying oil sucking polished rod production line, can solve the problems of high operation requirements, low production efficiency, decline in yield, etc., to reduce processing difficulty, simplify production management, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

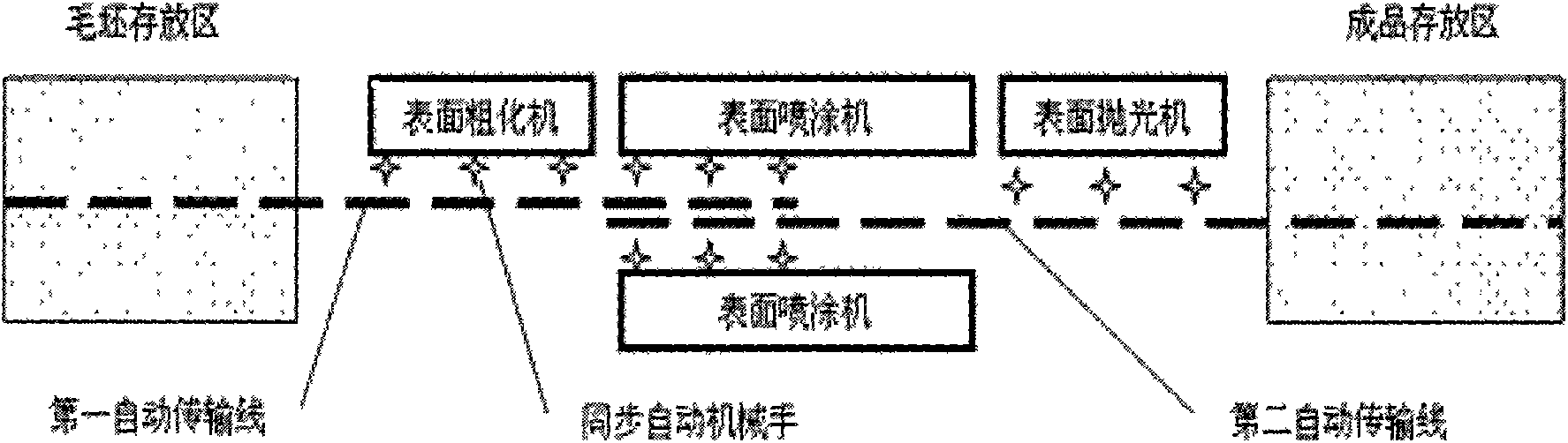

[0029] Such as figure 1Shown, the production device of a kind of alloy coating thermal spraying polished rod surface of the present invention, it comprises: the first surface spraying machine 2, the second surface spraying machine 4, surface roughening machine 1, surface polishing machine 3, the first The roller conveying line 5 and the second roller conveying line 6, the first surface spraying machine 2 and the second surface spraying machine 4 are placed relatively parallel, and the distance between the first surface spraying machine 2 and the second surface spraying machine 4 is 2 meters, The first roller conveying line 5 and the second roller conveying line 6 are arranged in parallel, the tail of the first roller conveying line 5 is adjacent to the head of the second roller conveying line 6 and is located at the first surface spraying machine 2 and the second surface spraying machine 4 Between, the surface roughening machine 1 is arranged on the left side of the first surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com