Battery string film inserting device

A technology for inserting membranes and batteries, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as low efficiency and high labor costs, and achieve the effect of improving the efficiency of membrane insertion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

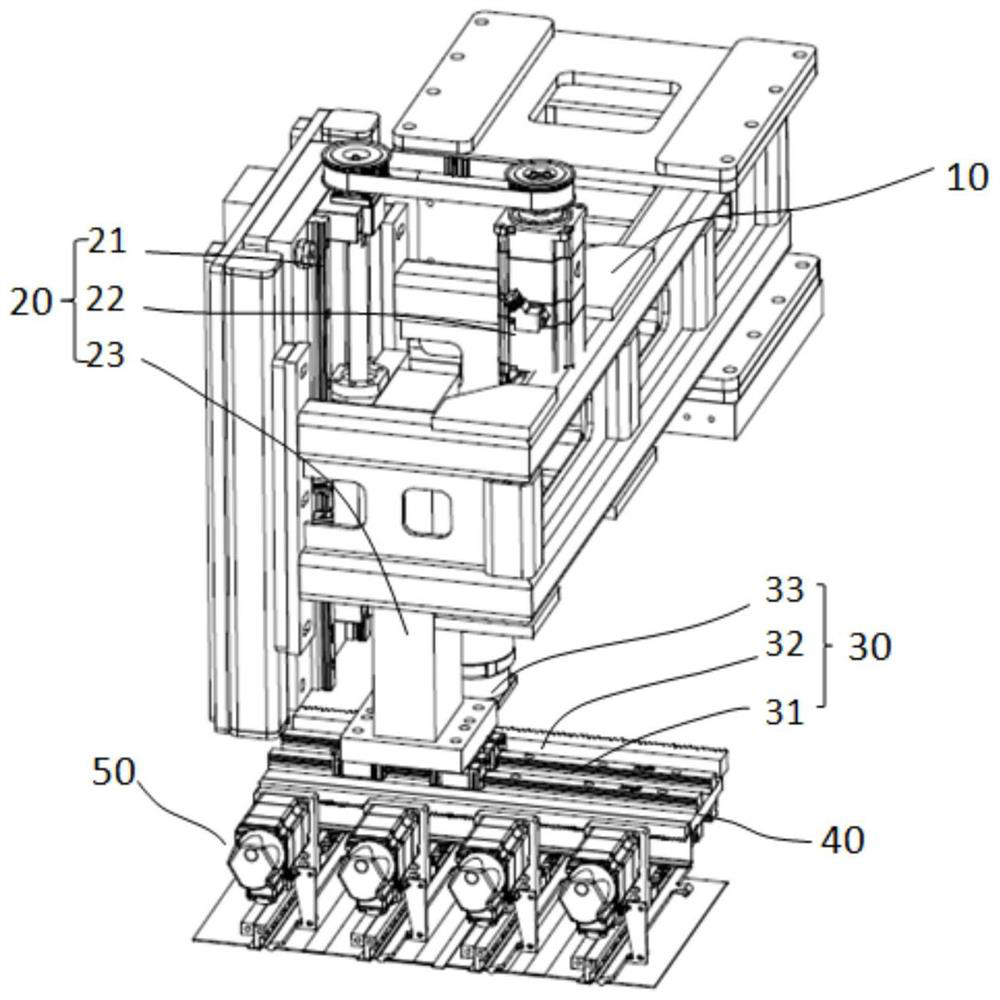

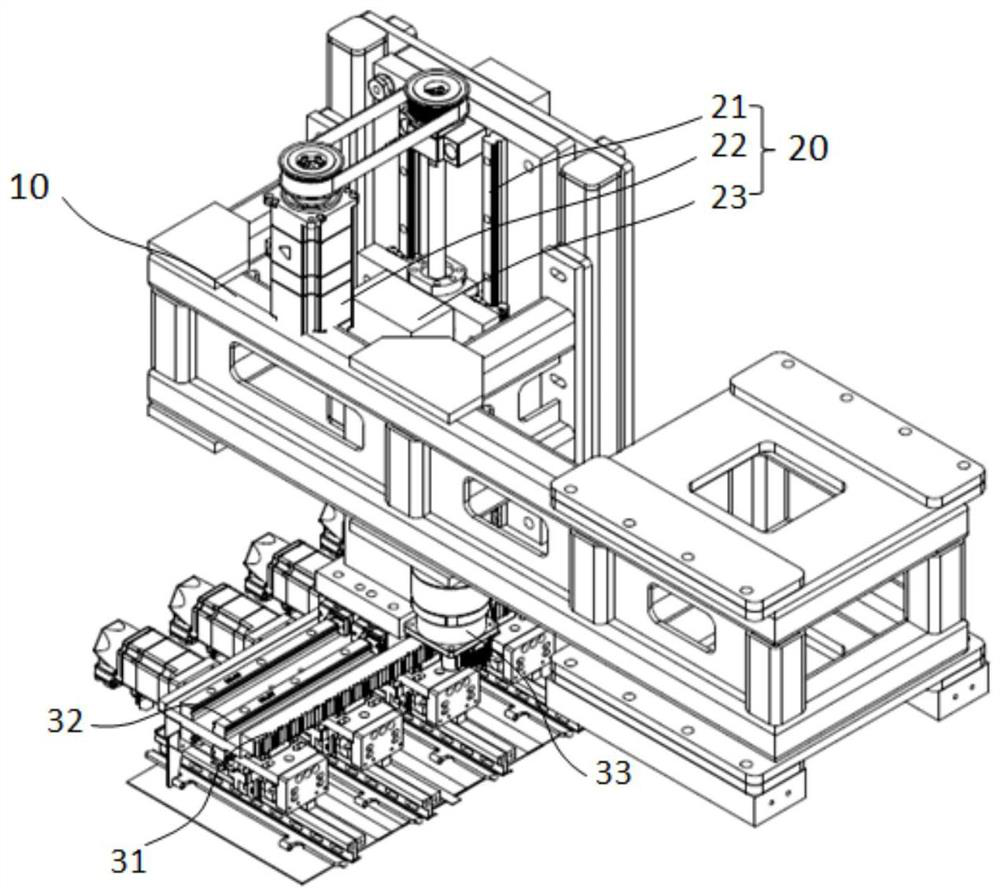

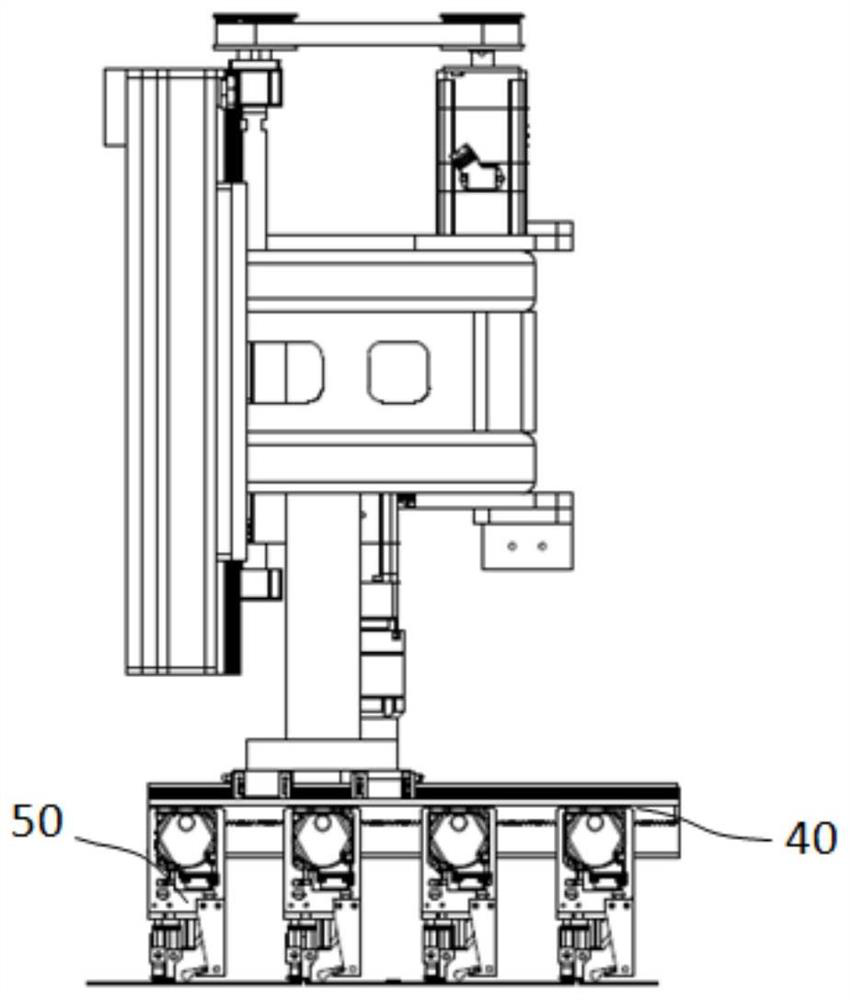

[0038] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0039] After the battery sheets are welded into strings by ribbons, they undergo a series of post-processing processes, and finally are laminated to form battery components. During this process, cracks and damage are likely to occur at the overlapping positions of adjacent battery sheets in the battery string due to excessive rigid extrusion force. In order to alleviate the rigid extrusion force between adjacent battery sheets, the traditional solution is to manually insert film strips (such as EVA film) into the superimposed position of adjacent battery sheets, and then insert the battery string after the film is completed. Heat is applied to achieve melt solidification of the film tape. The traditional manual insertion method i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com