Automatic body paper feeding and discharging device and diving and cutting machine with same

A technology of automatic loading and unloading and slitting machine, which is applied in thin material processing, transportation and packaging, winding strips, etc., and can solve the problems of inability to unload paper at one time, inaccurate placement, and injury to equipment and staff , to achieve the effect of avoiding base paper slipping, high work efficiency and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

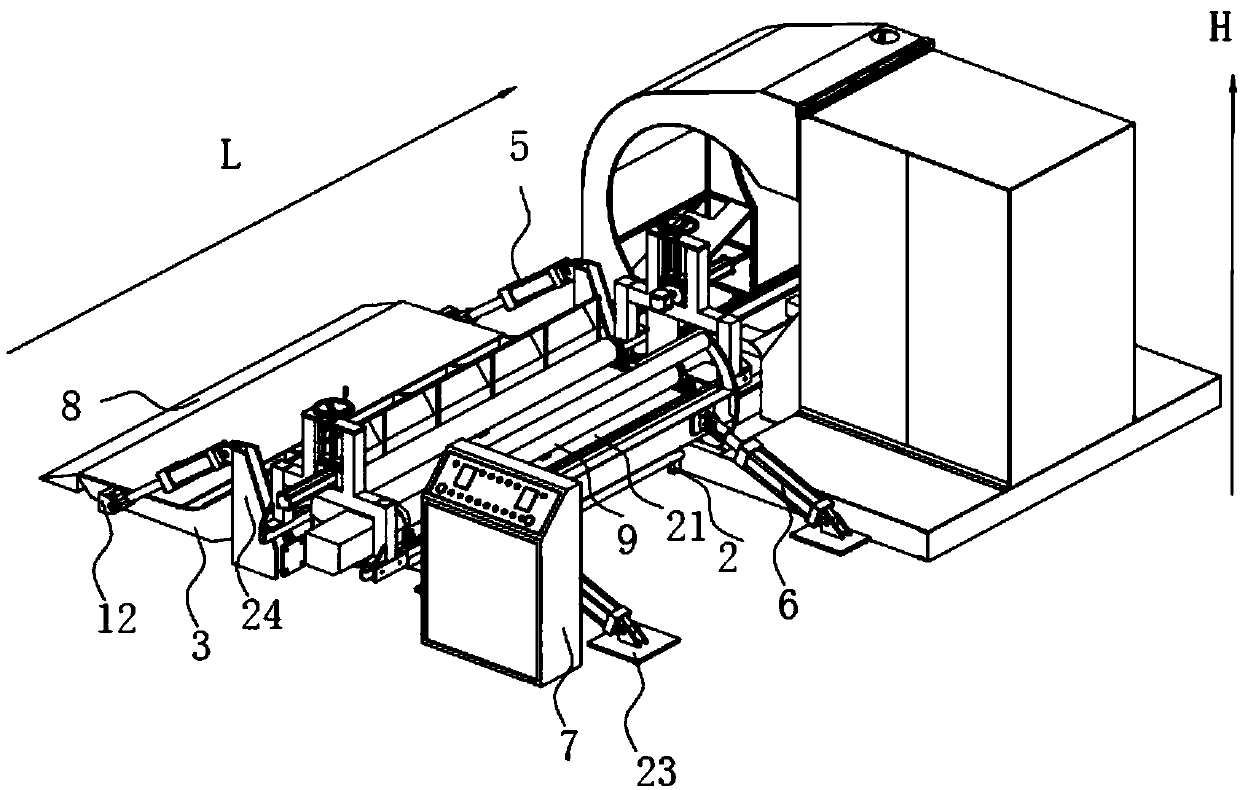

[0047] Some orientation words are defined in the present invention. In the absence of a contrary statement, the "length direction" refers to the attached figure 1 The direction indicated by "L", "height direction" and "up and down" all refer to the attached figure 1 in the direction indicated by "H". These orientation words are adopted for easy understanding, and thus do not constitute a limitation of the protection scope of the present invention.

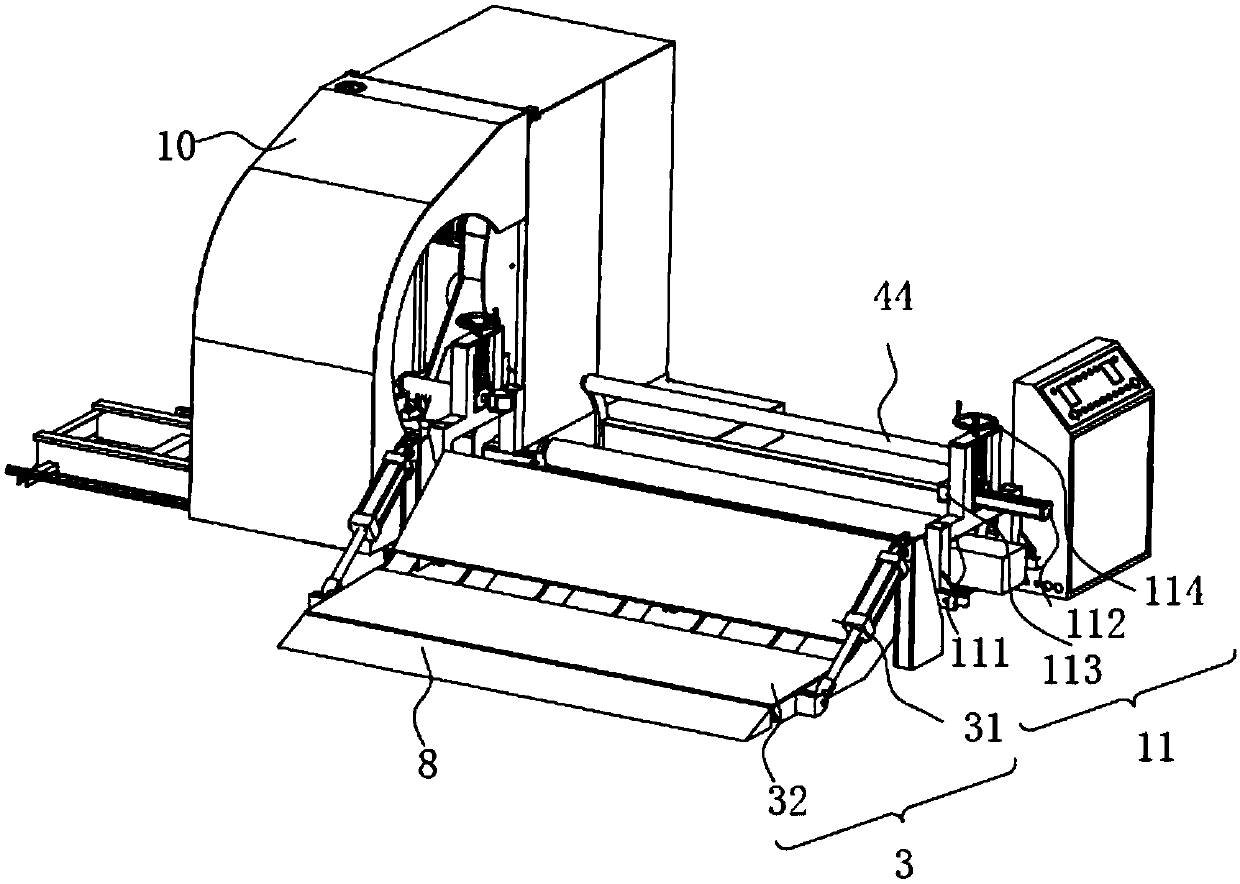

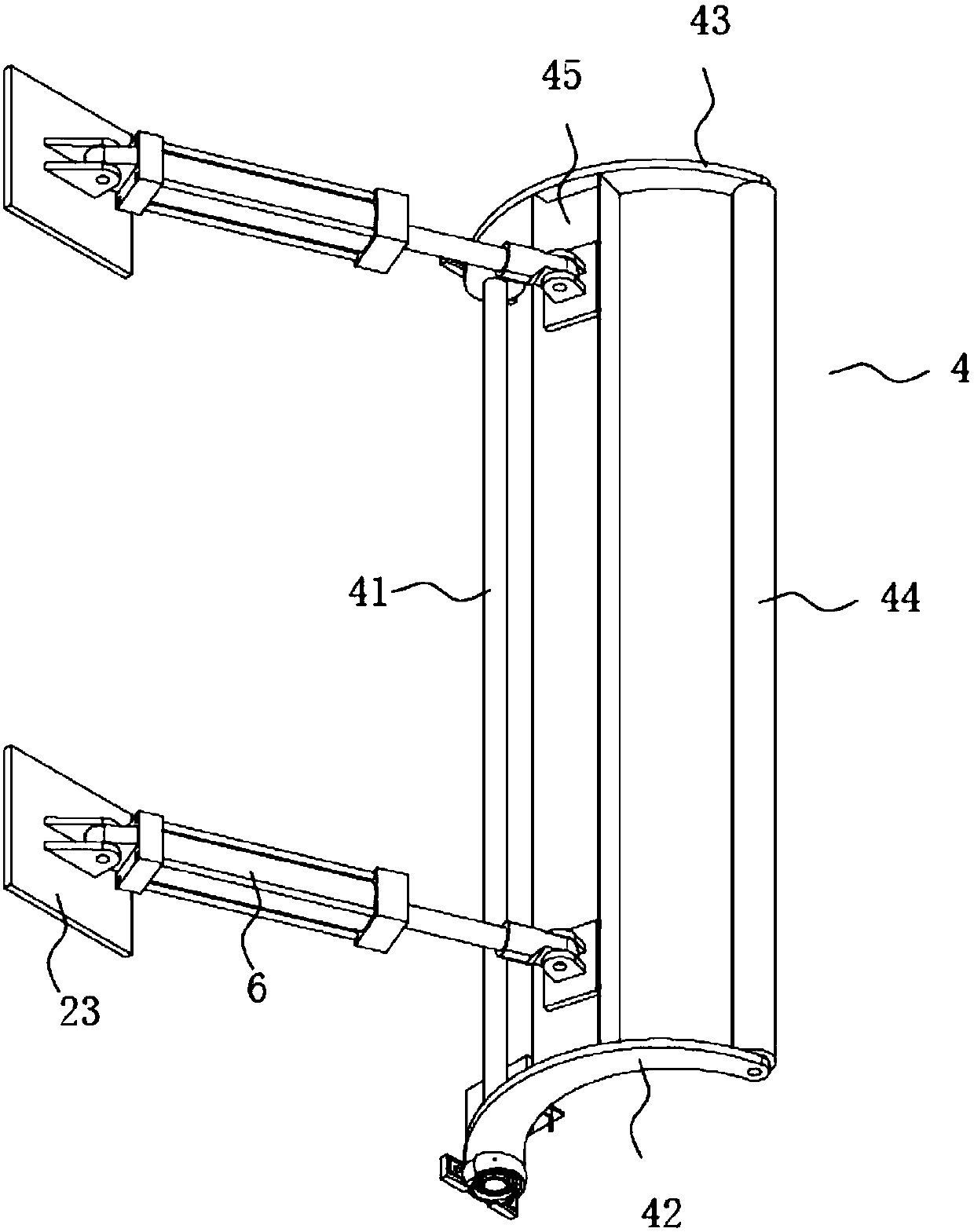

[0048] Such as Figure 1-4 As shown, the present embodiment provides a kind of base paper automatic loading and unloading device, comprises working support 2; Upper paper support 3, top paper support 4, are respectively arranged on the opposite two sides of described working support 2 and are all connected with described working support 2 Rotate conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com