Improved structure of production device burning lamp filaments in glass bulb

A production device and filament technology, applied in the direction of machines with sequentially arranged working positions, can solve the problems of manual placement, continuous production of light bulb obstacles, design difficulties, etc., and achieve the effect of less power types and convenient automatic glass bulb loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

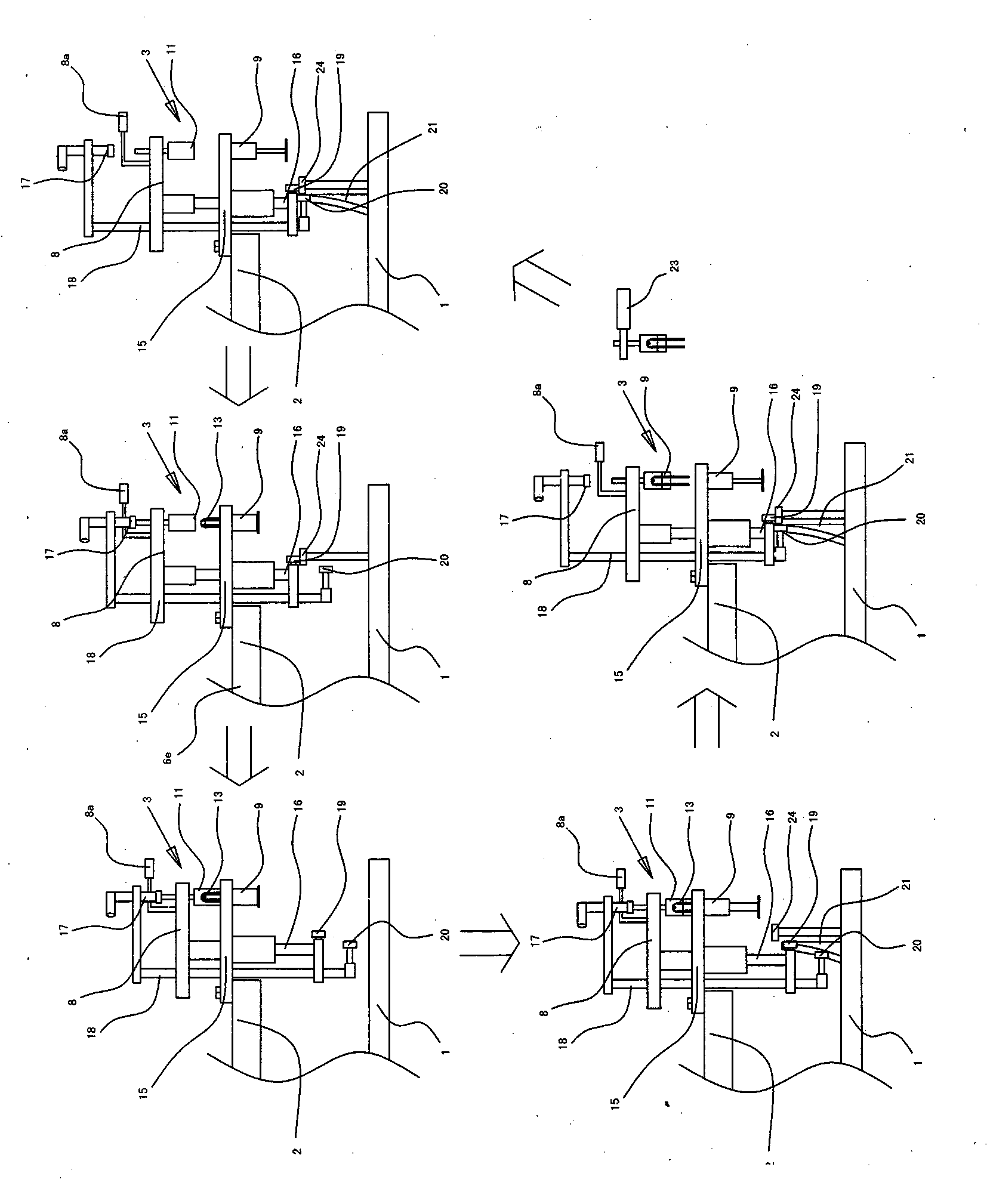

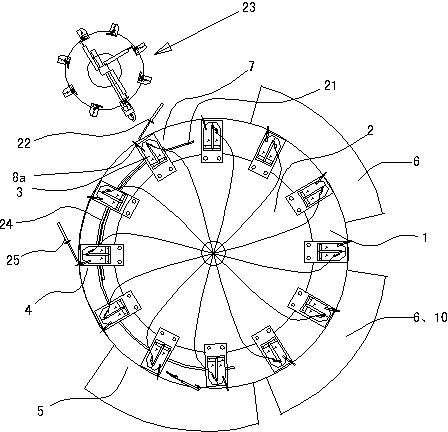

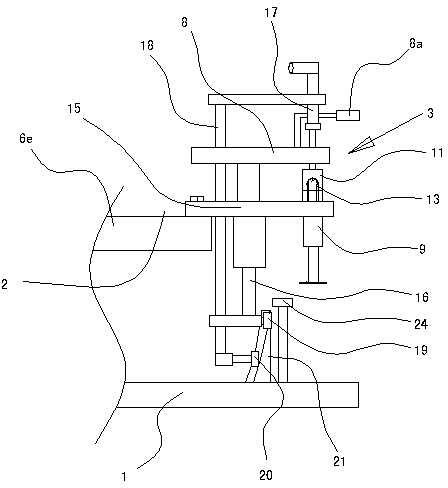

[0010] Now in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

[0011] As shown in the figure, the frame 1 of the present invention, the turntable 2 arranged on the frame 1, the power mechanism that drives the turntable 2 to rotate, several filaments fixed on the turntable 2, the glass tube fixing device 3, and the feeding station 4 , the upper filament station 5, the firing station 6 that fixes the filament in the glass bulb, the blanking station 7, the filament and glass tube fixing device 3 includes a glass bulb holder 8 with a handle 8a, located in the glass bulb The filament holder / filament lifting device assembly 9 below the holder 8, the filament lifting device in the filament holder / filament lifting device assembly 9 includes a lifting seat 9b with a filament holder 9a, which is slidably arranged on The top inside the lifting seat 9b is the lifting rod 9c of the filament hook, the lifting rod positioner 9d (the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com