Automatic testing system of production line of vehicle information terminal and testing method of system

An automatic test system, vehicle-mounted information terminal technology, applied in the direction of signal transmission system, measuring device, special data processing application, etc. Problems such as normal work, to achieve the effect of shortening regression testing time, improving testing efficiency, and improving testing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

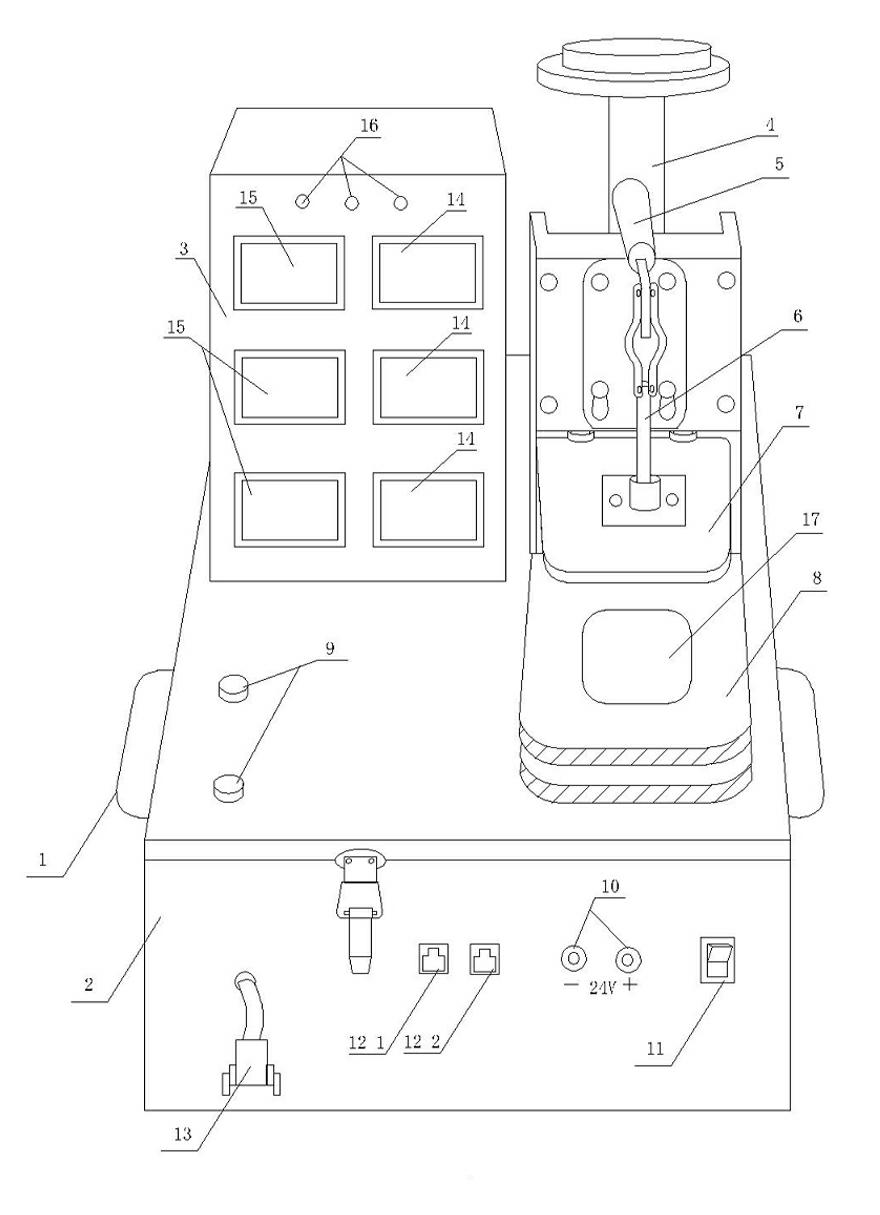

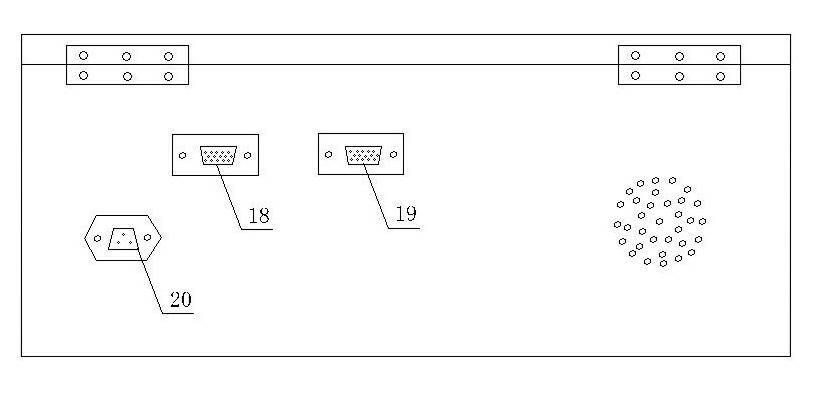

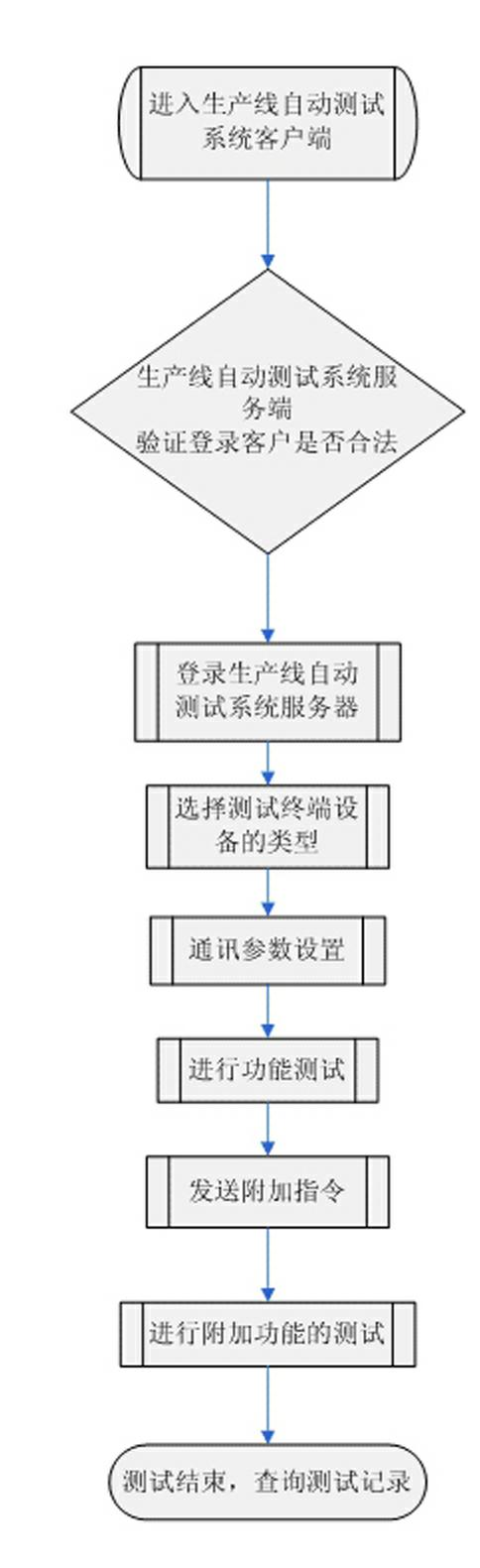

[0040] Refer to attached Figure 1~3 , the automatic test system of the vehicle information terminal production line includes the production line automatic test system client, the production line automatic test system server, the system central database, the production line automatic test system auxiliary equipment, the production line automatic test system test fixture and the computer;

[0041] The client of the production line automatic test system is a terminal test program installed on the client computer. The server of the production line automatic test system is the server host. The system central database and server program are installed on the server host. The test results of the production line automatic test system client are stored in the system. The central database and the production line automatic test system client send the test data to the production line automatic test system server at the same time, and the production line automatic test system server forward...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com