Wet type grinding equipment for automatic robot

A robotic and fully automatic technology that can be used in grinding/polishing equipment, metal processing equipment, grinding feed motion, etc., and can solve problems such as dust hazards, personnel loss, and high labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

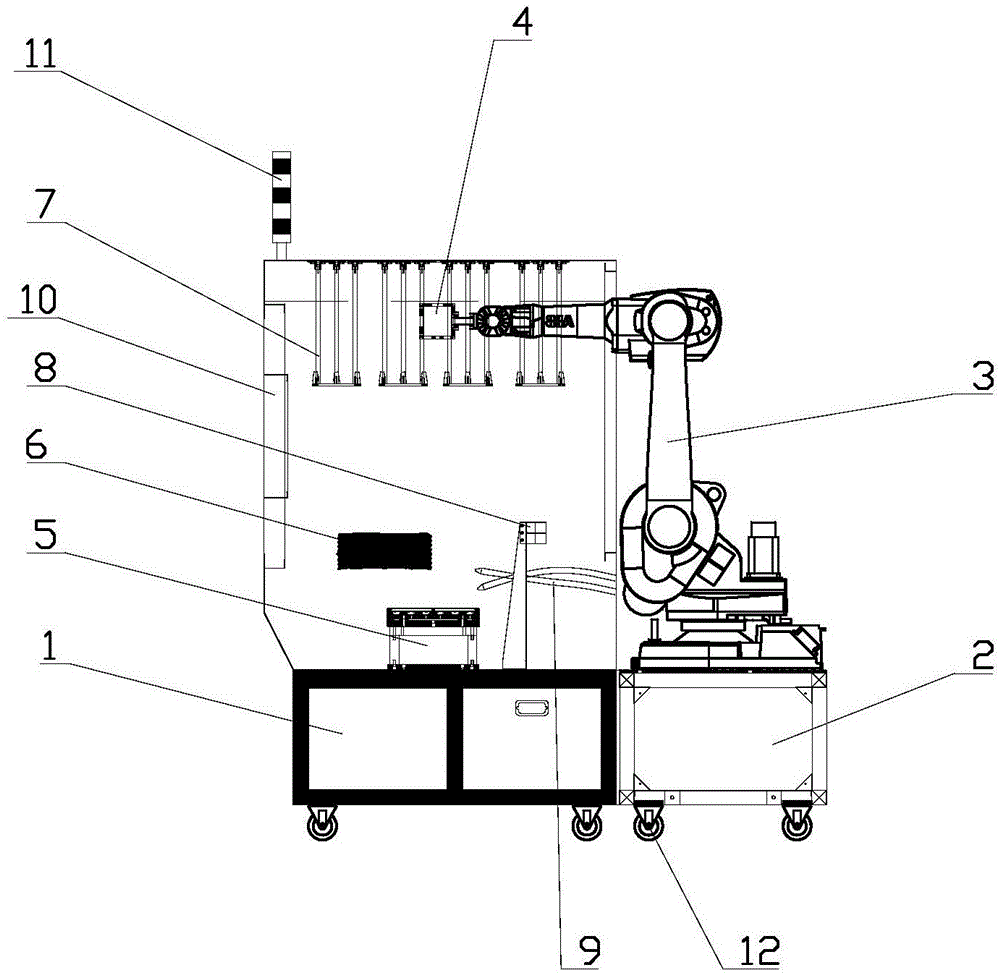

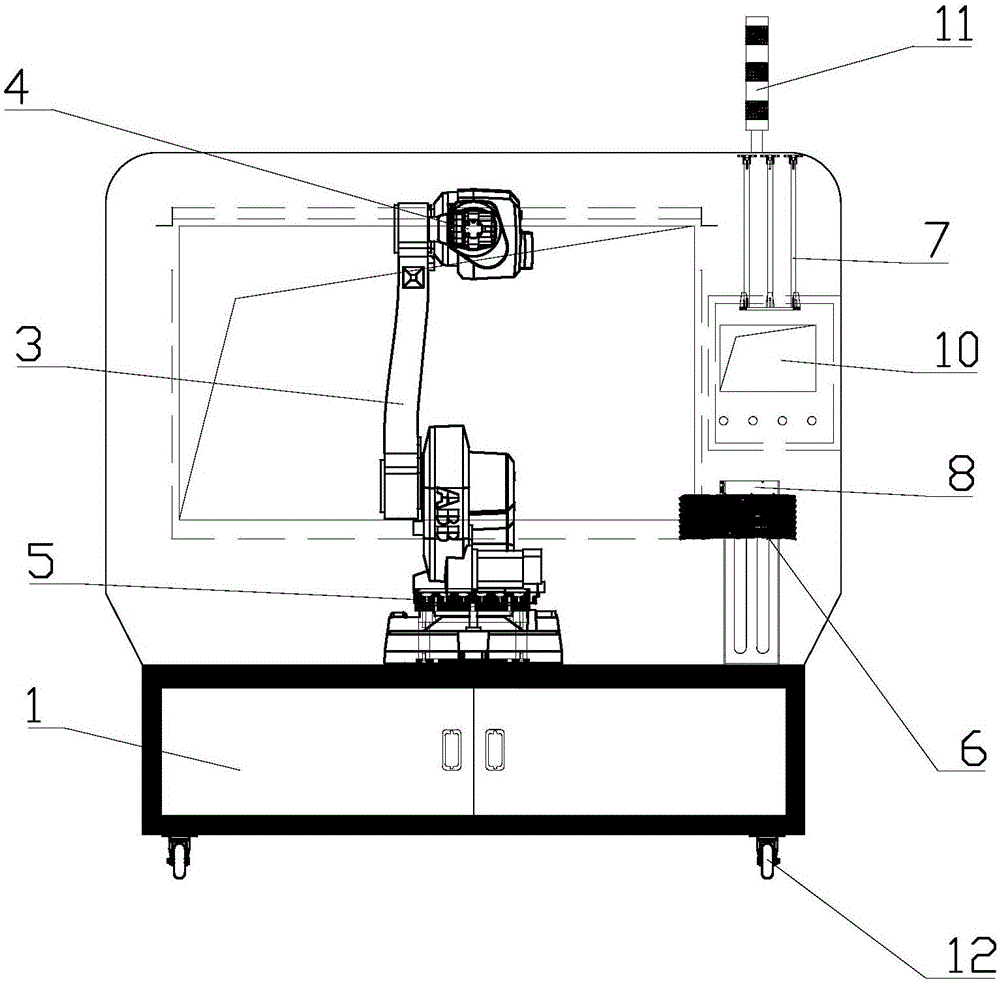

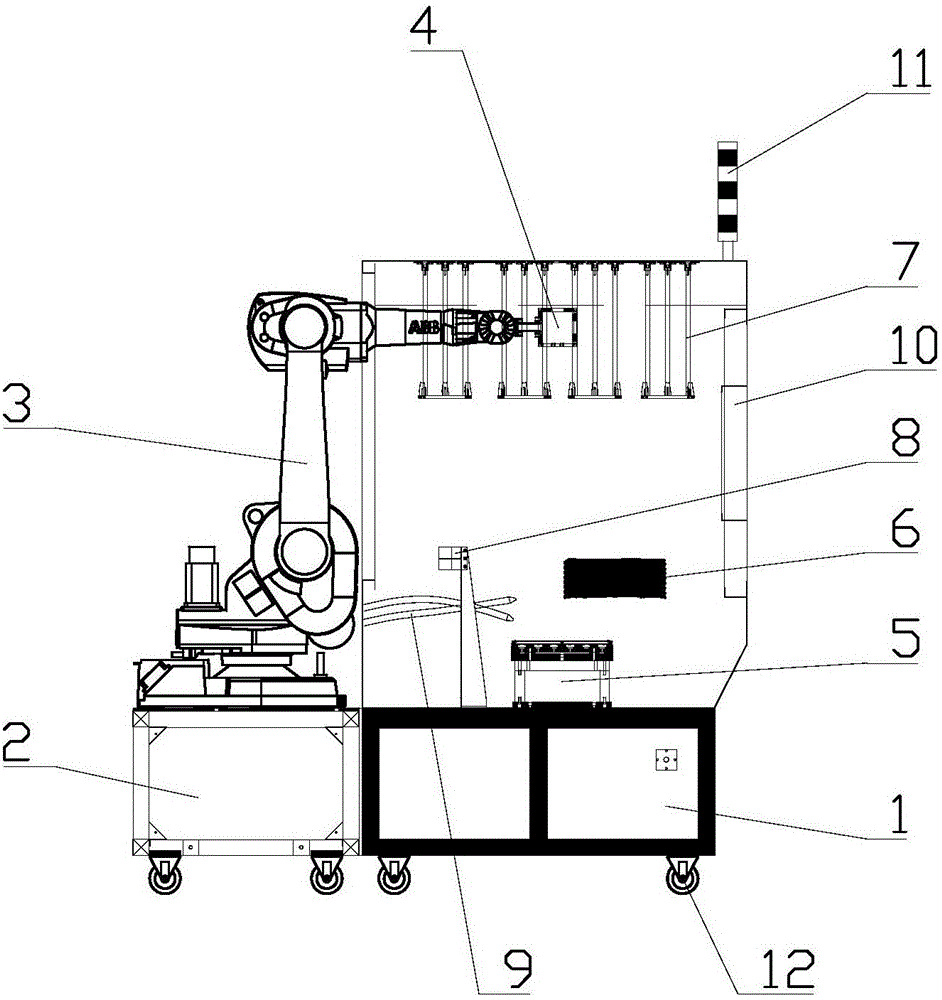

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a fully automatic robot wet grinding equipment includes a grinding machine body 1, a robot base 2, a robot body 3, a grinding head fixing mechanism 4, a grinding fixing fixture 5, an automatic feeding mechanism 6, a sandpaper loading mechanism 7, Automatic sandpaper tearing mechanism 8, automatic water spraying mechanism 9, man-machine interface 10 and three-color sound and light alarm 11; described robot base 2 is close to the rear side of described grinding machine body 1, and described robot body 3 is placed on On the robot base 2, the grinding head fixing mechanism 4 is installed on the working end of the robot body 3, the lower part of the grinding machine body 1 is a machine, the upper part is a chassis, and the grinding fixing fixture 5 is arranged on In the middle position on the machine platform, the machine platform on one side of the grinding fixture 5 is provided with the automatic feeding mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com