Corn straw particle board and manufacturing method thereof

A technology of particle board and corn stalks, which is applied in the field of wood-based panels and its manufacturing, can solve the problems of shortening the hot-pressing time, achieve the effects of shortening the hot-pressing time, ensuring the appearance quality, and improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

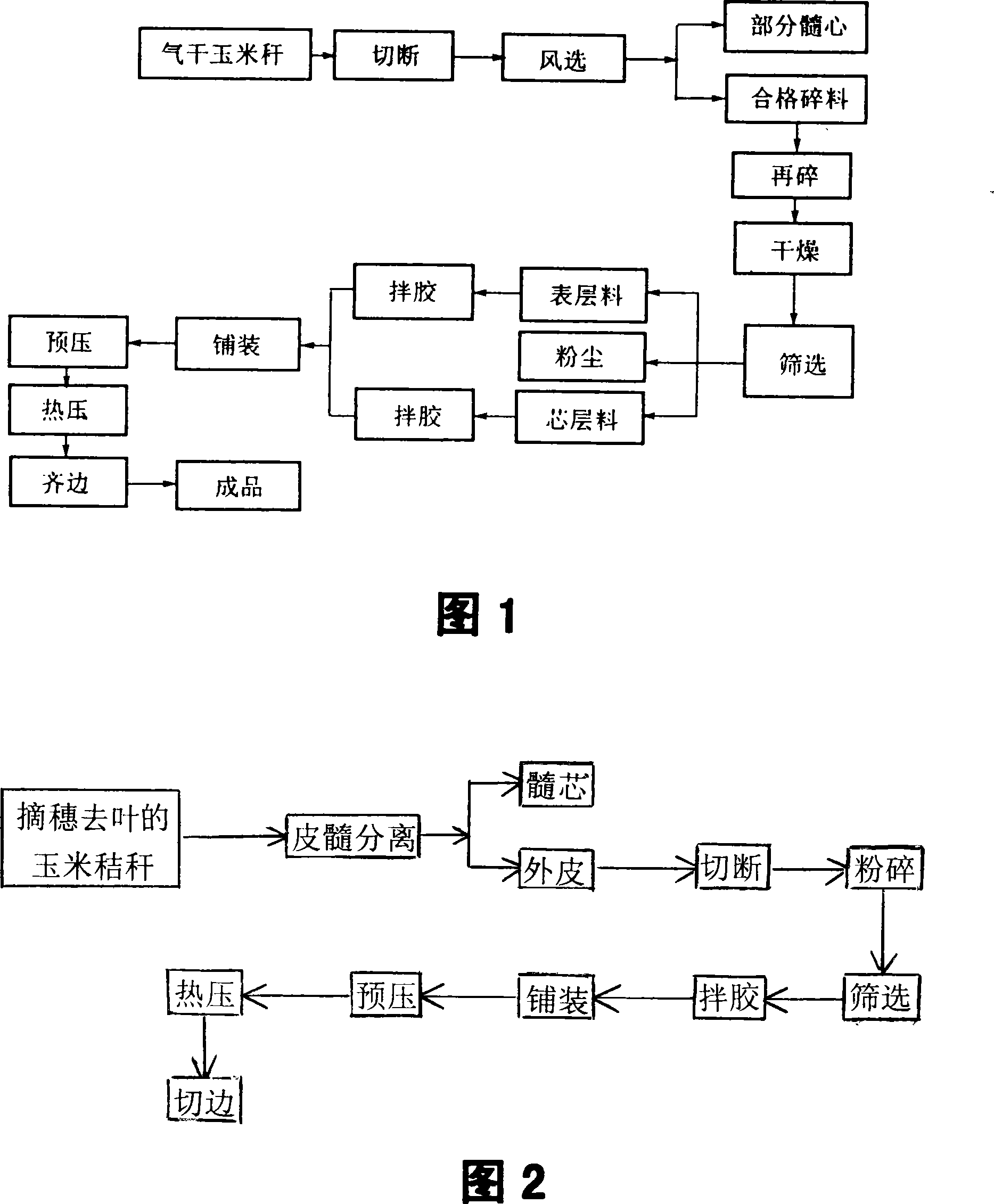

[0014] Please refer to Fig. 2, the present invention uses a peeling machine to separate the pith from the corn stalks after ear removal and leaf removal, the pith core after separation is used for other purposes, and the epidermis after separation is then cut off as a board-making raw material , usually cut according to the length of 20cm. The cut corn stalk epidermis is then crushed into crushed material with a pulverizer. The mesh size of the pulverizer is 6mm, and the composition of the crushed material is in the following range:

[0015] Particle size (mm)

<6~4.75

<4.75~2.26

<2.26~1.63

<1.63~1.41

<1.41~1.096

<1.096~0.56

<0.56~0.216

<0.216

weight percentage (%)

1.00~1.50

6.90~7.30

11.00~11.50

8.20~8.70

6.75~7.15

29.80~30.50

25.00~25.40

9.40~10.40

[0016] Then apply 3.2-3.7% isocyanate adhesive of the weight of the corn stalks to the crumbs and stir evenly,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com