Patents

Literature

172 results about "Peeling skins" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Peeling skin can occur as a reaction to a number of inflammatory processes of the skin or damage to the skin. Sunburn is a classic example, but other conditions that can cause peeling skin include various forms of dermatitis, eczema, and certain infections. Burns of any degree of severity can result in peeling skin.

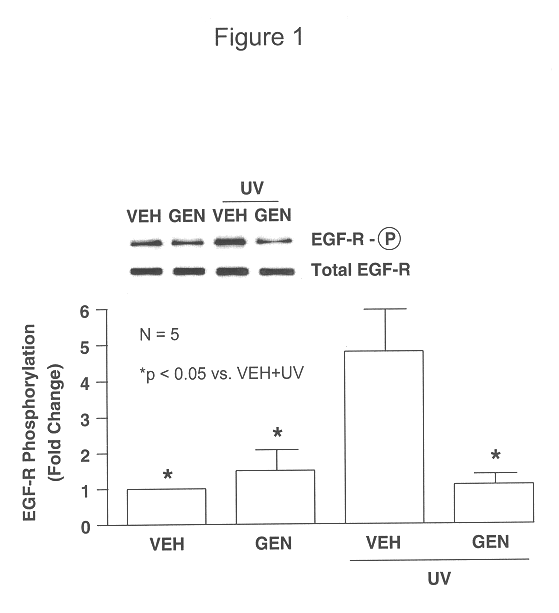

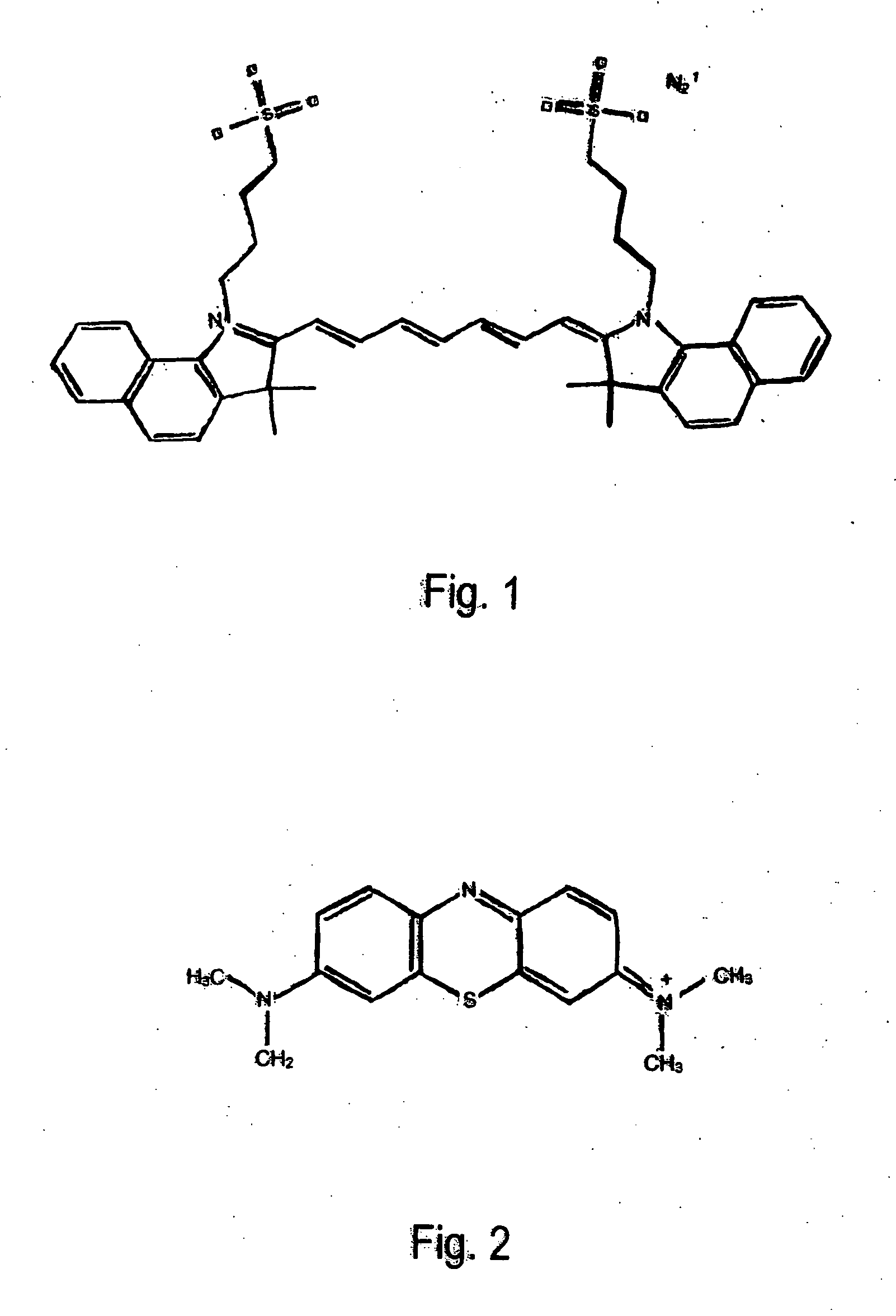

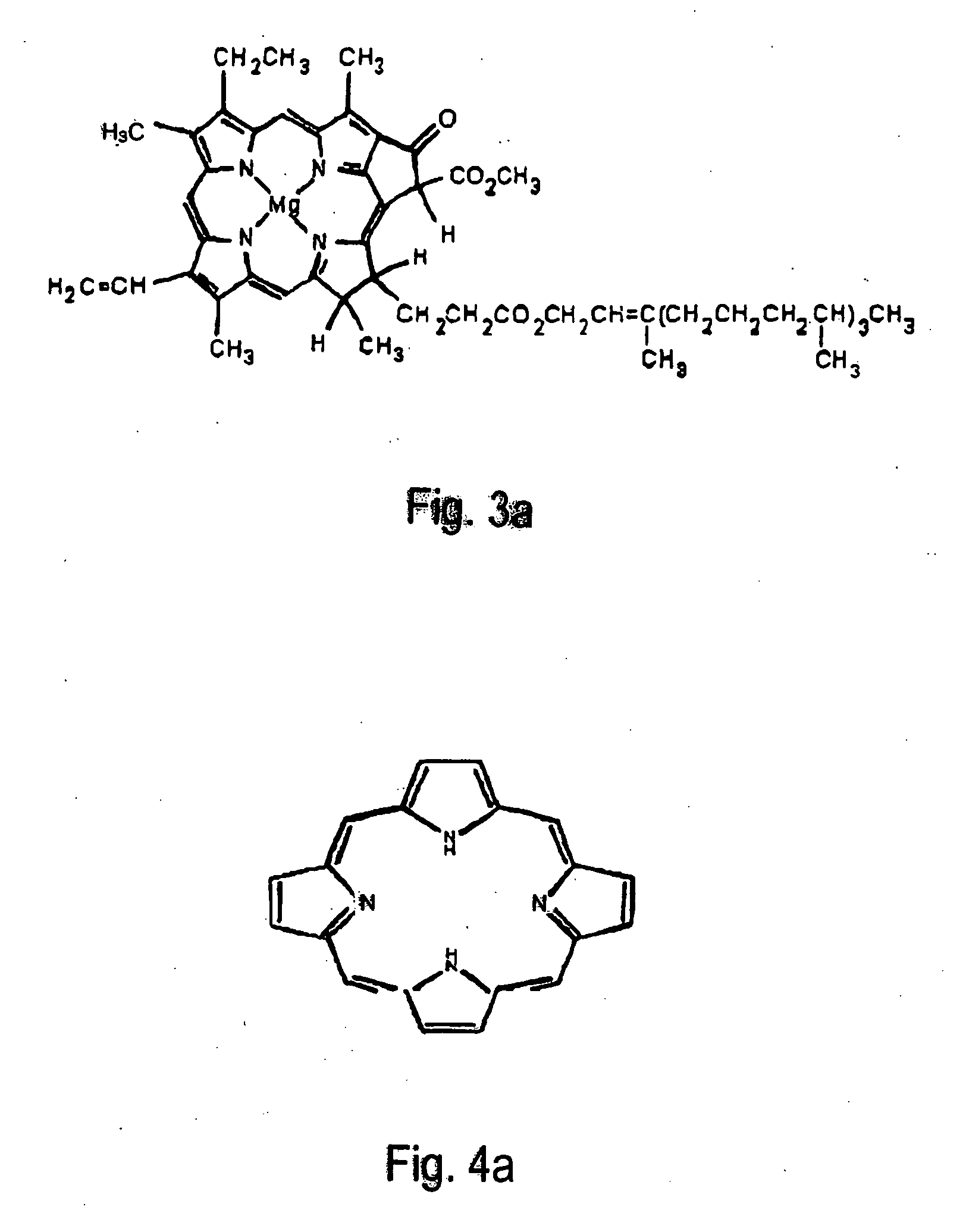

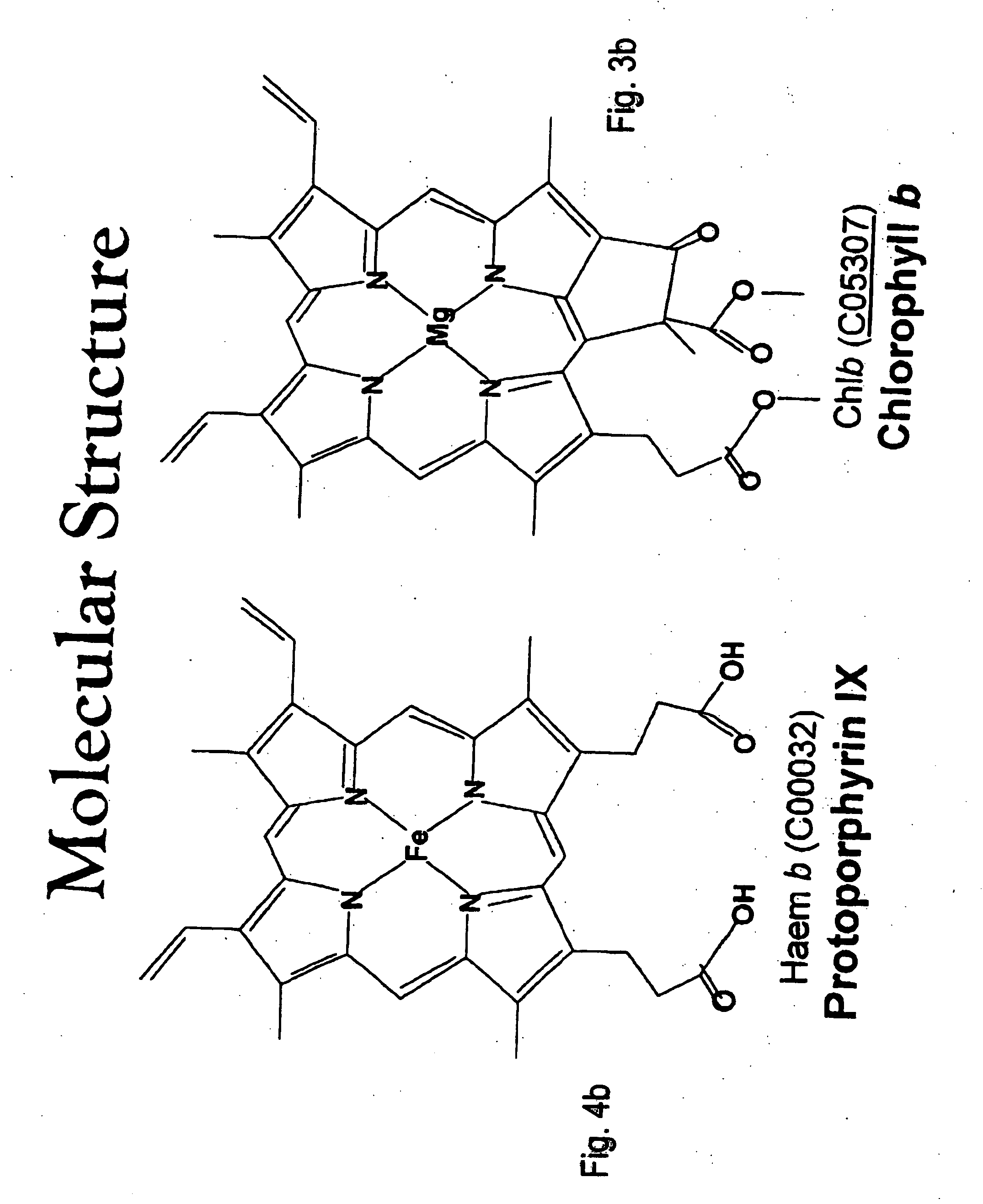

Use of natural EGFR inhibitors to prevent side effects due to retinoid therapy, soaps, and other stimuli that activate the epidermal growth factor receptor

InactiveUS6638543B2Diminishing desired therapeutic effectPrevent drynessBiocideCosmetic preparationsSide effectRetinoid

Many human conditions, often skin conditions, are treated topically or orally with a retinoid such as retinoic acid or acetretin, which treatment often has the side effect of dry, irritated, and / or peeling skin. The use of soaps, detergents, chemical irritants, and such can also cause these same side effects. These side effects can be reduced or eliminated by the topical administration of an inhibitor, especially a natural inhibitor, of the epidermal growth factor receptor (EGFR), administered concomitantly with the retinoid, separately from the retinoid (such as on an as needed basis), or both. Administration of the two together is facilitated by a composition suitable for topical application and comprising both the retinoid and a natural EGFR inhibitor. Preferred natural inhibitors are genistein and other isoflavones extracted from natural occurring substances, or simple derivatives of such substances.

Owner:RGT UNIV OF MICHIGAN

Method and apparatus for acne treatment

InactiveUS20050261750A1Organic active ingredientsPhotodynamic therapyTreatment acneUltraviolet lights

Owner:LOREAL SA

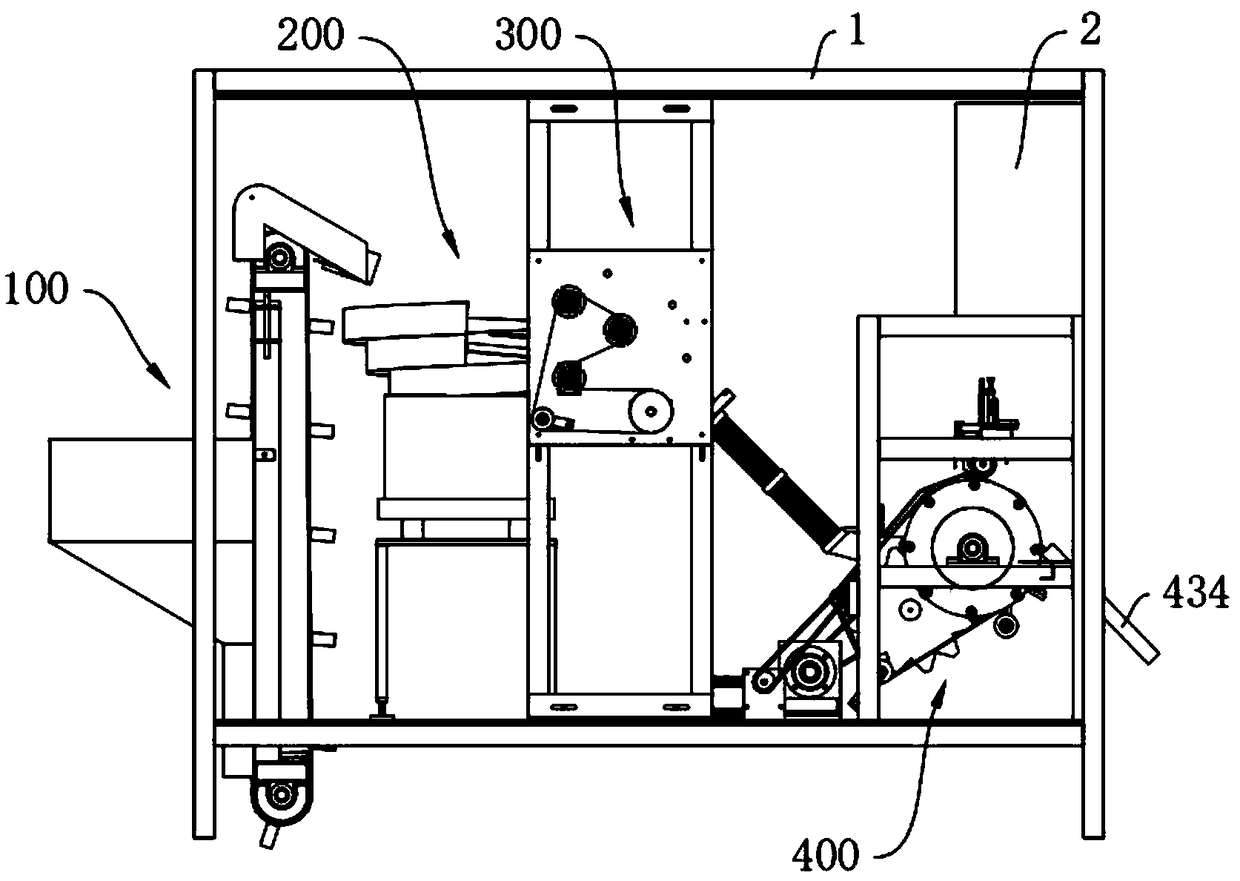

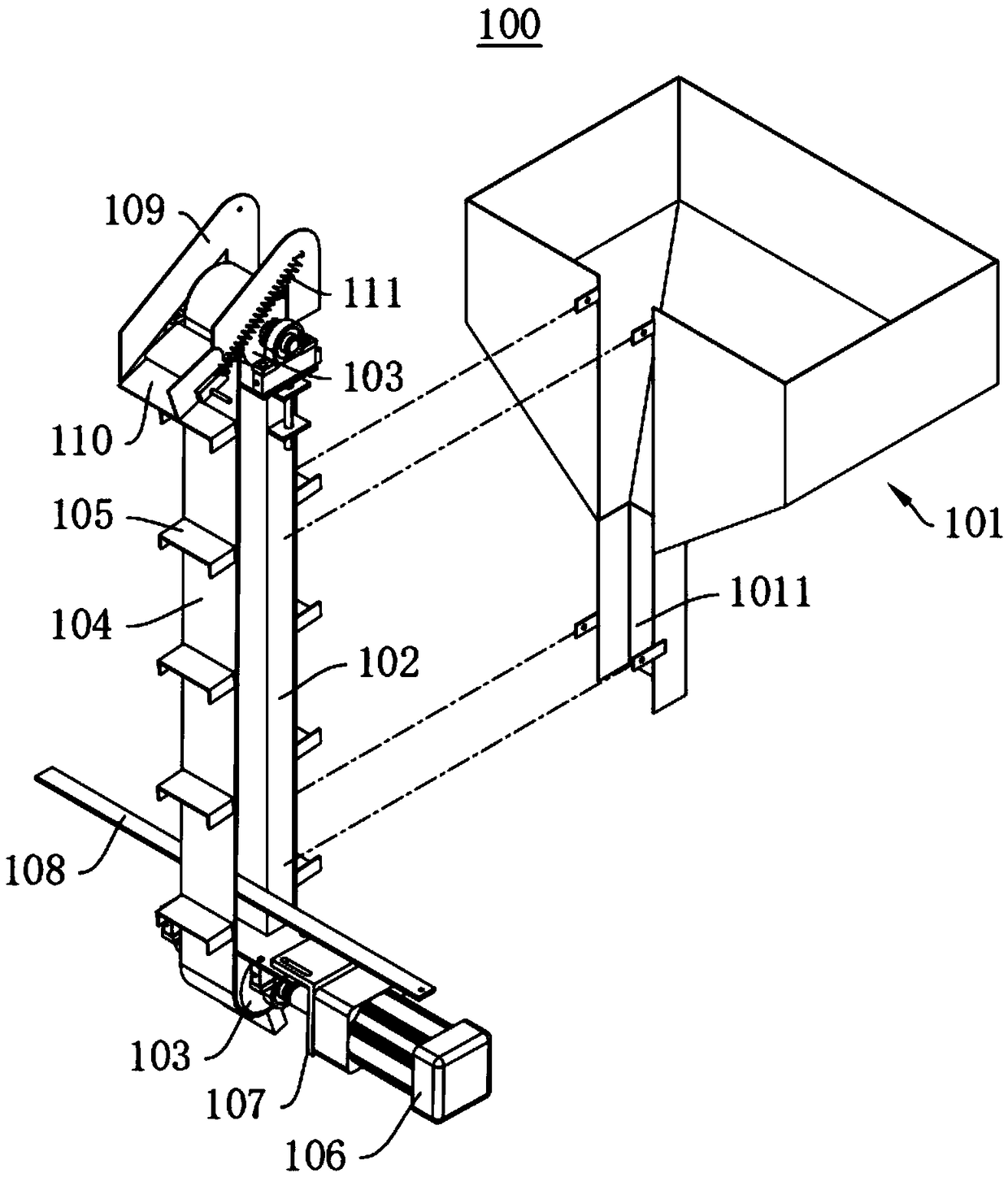

System for cleaning, cutting and handling fish

InactiveCN102458133ALow costProduction modernizationProgramme-controlled manipulatorFish filletingWaste productEngineering

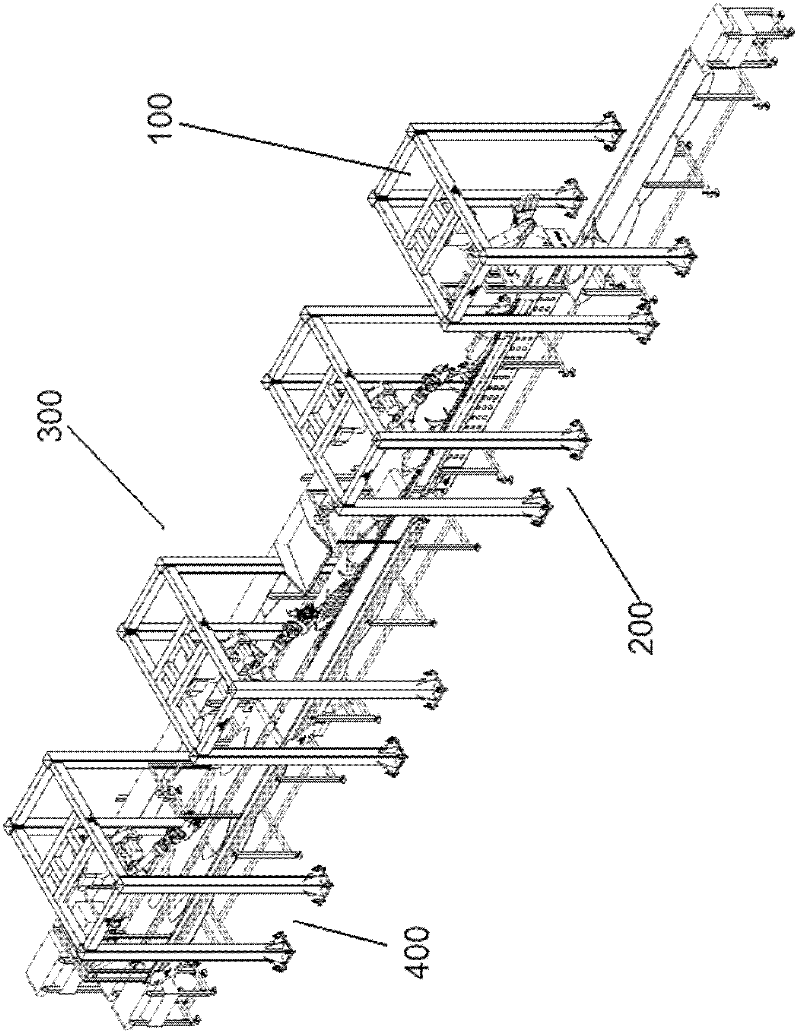

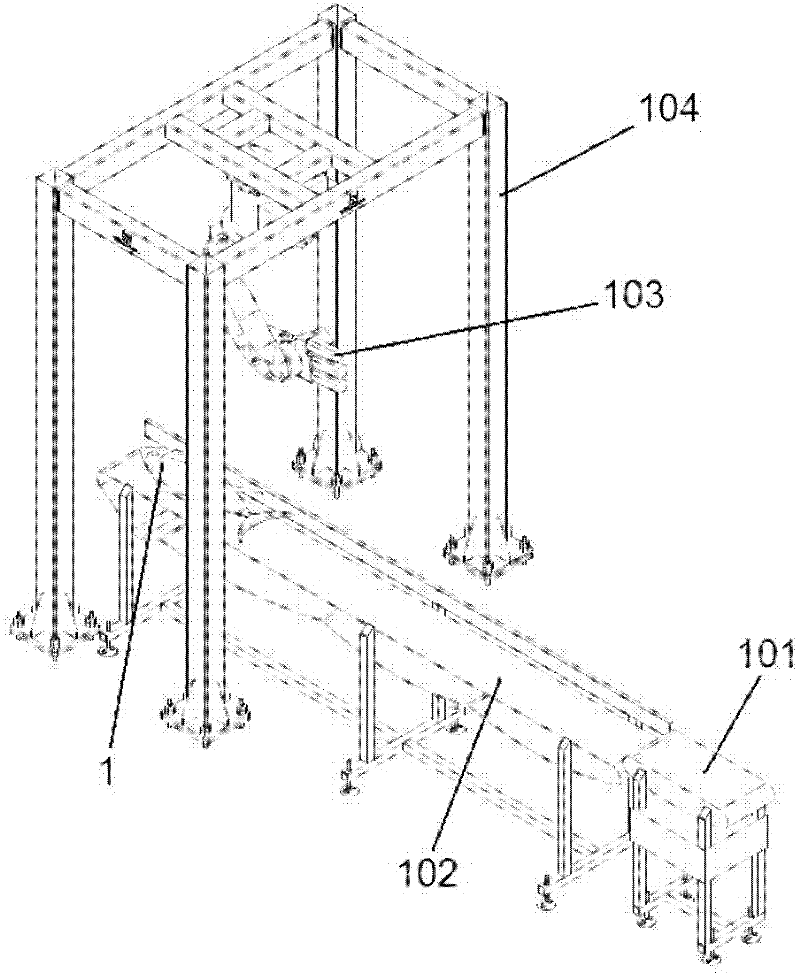

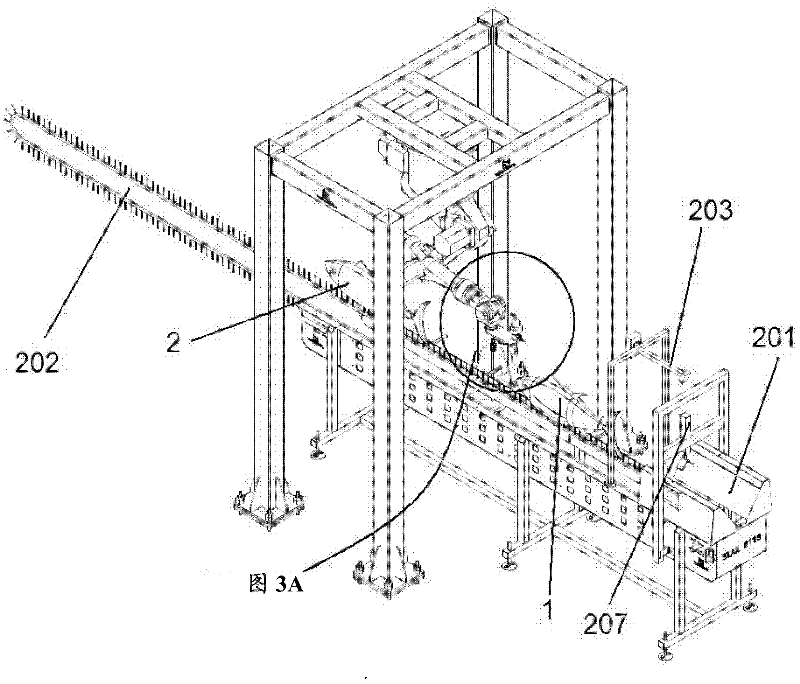

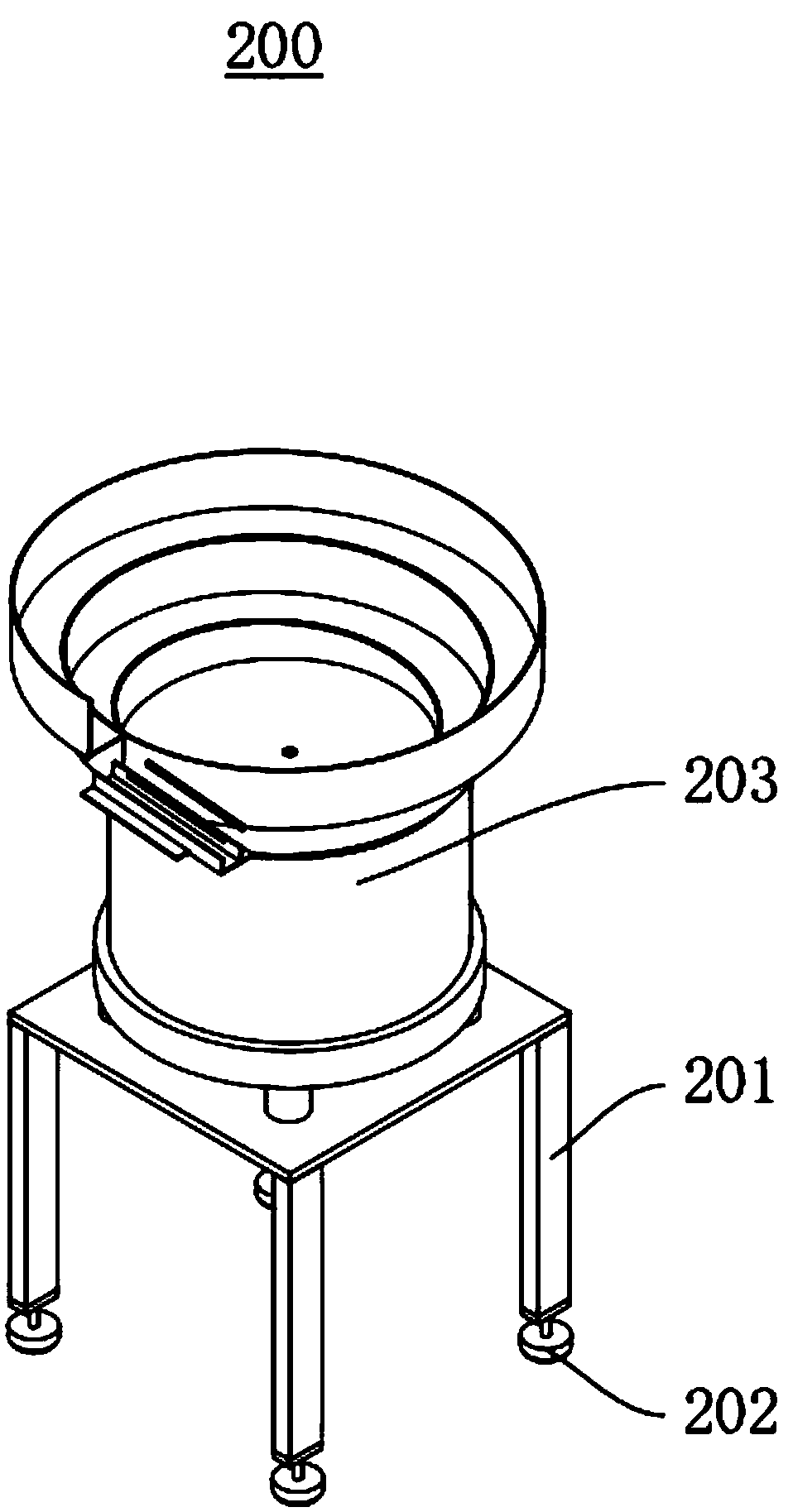

System for cleaning, cutting and handling fish (1), comprising: a first station (100) for positioning the fish (1), configured to place said fish (1) vertically on the second station (200), for skinning; a second, skinning station (200) configured to skin the fish (1) by abrasive means without damaging the flesh; a third station (300) for cutting the fish (2) skinned in the second station (200), configured to detect and remove the spine of the skinned fish (2), separating the two cut loins (3) from the backbone of said skinned fish (2), said backbone following a different path to the loins (3); and a fourth station (400) for gutting the loins (3), configured to remove the head and guts by means of pressurized water, while the tongs for grading clean and dirty fish remove the guts and send them to a grinder for waste products.

Owner:朱利奥・塞萨尔・冈萨雷斯阿尔瓦雷斯

Making method of dried duck meat slices with excellent taste

The invention discloses a making method of dried duck meat slices with excellent taste. The making method comprises the following production steps of: removing skin and fat of fresh dust breast meat, eliminating bones, trimming, shaping and mincing duck skin for later use; uniformly mixing to prepare sauce for later use; cutting the duck breast meat into meat slices; placing the meat slices into the sauce for soaking, further increasing the temperature of the sauce for stewing the meat slices, taking out the meat slices, draining and then placing into a refrigerating chamber; preparing auxiliary materials for later use; placing the auxiliary materials and the meat slices into a vacuum rolling and kneading machine for rolling and kneading; loading the meat slices which are well rolled and kneaded into a mold, and placing into a freezing chamber for freezing; cutting the meat slices which are well frozen into the meat slices, and then placing into a drying room for drying; placing the meat slices after drying into a far-infrared dried meat slice roasting machine for roasting; and cooling the meat slices to normal temperature, then packaging through an automatic packaging machine, and further performing conventional microwave sterilization to prepare a product disclosed by the invention. The dried duck meat slices made by the making method disclosed by the invention have the advantages of aromatic flavor, abundant nutrition, good product elasticity, excellent taste and broad market prospects.

Owner:广东真美食品股份有限公司

Automatic potato peeling machine

InactiveCN104287062APrevent fallingEasy to dropVegetable peelingFood treatmentPush and pullPulp and paper industry

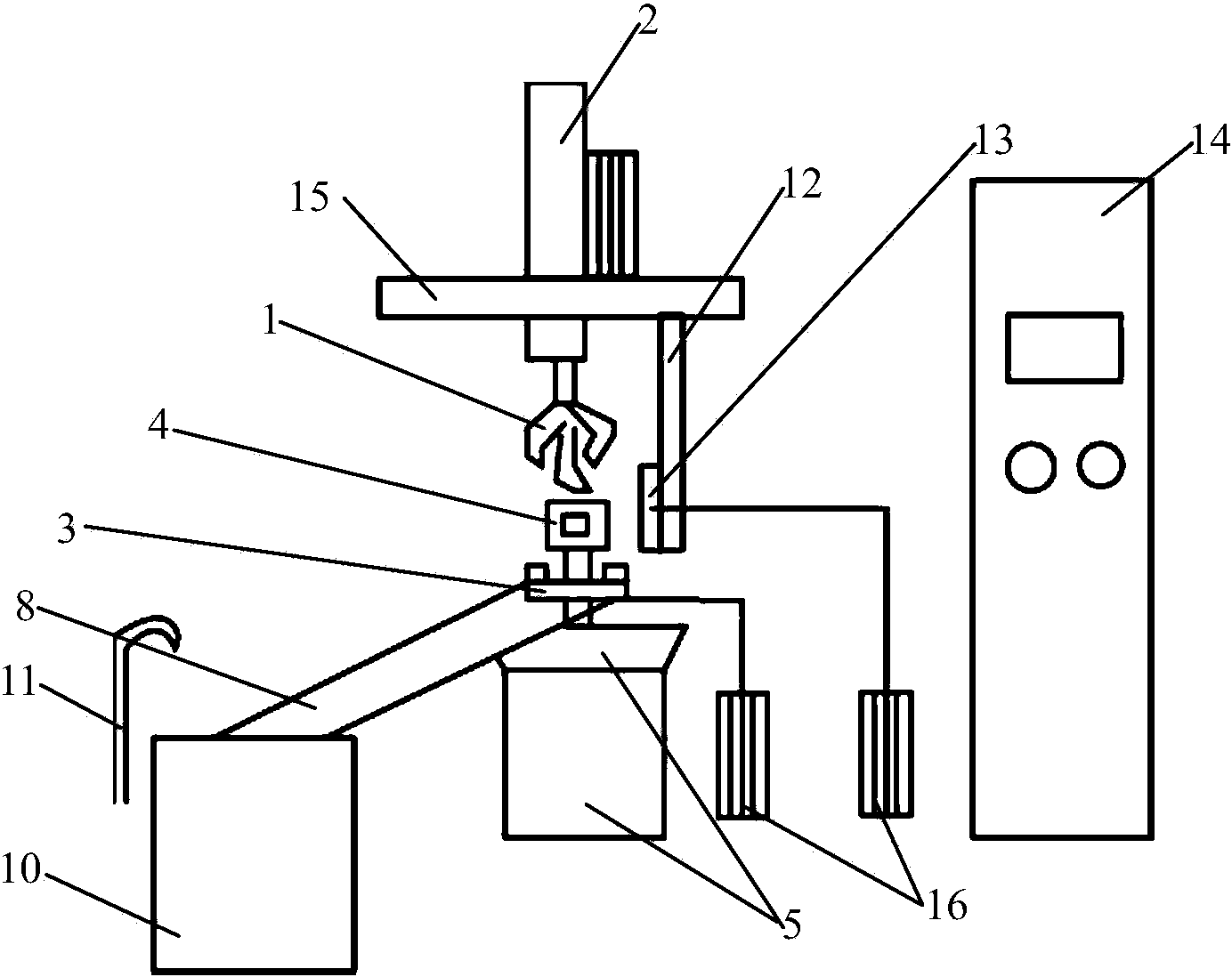

The invention belongs to the technical field of vegetable peeling, and particularly relates to an automatic potato peeling machine. The automatic potato peeling machine comprises a hoisting air cylinder, an air claw, a rotation tray, a push and pull air cylinder and a collection box, wherein the hoisting air cylinder is fixed on a support through a fixing plate, the lower portion of the hoisting air cylinder is connected with the air claw, the rotation tray is arranged at the lower end of the air claw, the collection box is arranged below the rotation tray, the push and pull air cylinder is arranged at the rear of the rotation tray, the height of the push and pull air cylinder is 3-6cm higher than the rotation tray, a conveyor belt is arranged in front of the rotation tray, the conveyor belt is obliquely arranged relatively to the horizontal direction, a washing pool is arranged in front of the conveyor belt, a water supply pipeline is arranged above the washing pool, a knife rest is fixed on one side of the rotation tray and below the fixing plate, and a peeling knife is arranged on the knife rest. The automatic potato peeling machine has the advantages of thoroughly peeling skin of potatoes, easily washing the surfaces of the potatoes after being peeled, and being capable of directly collecting the skin of the potatoes and completing washing processes, and high in overall automation degree.

Owner:天津费斯特餐饮管理有限公司

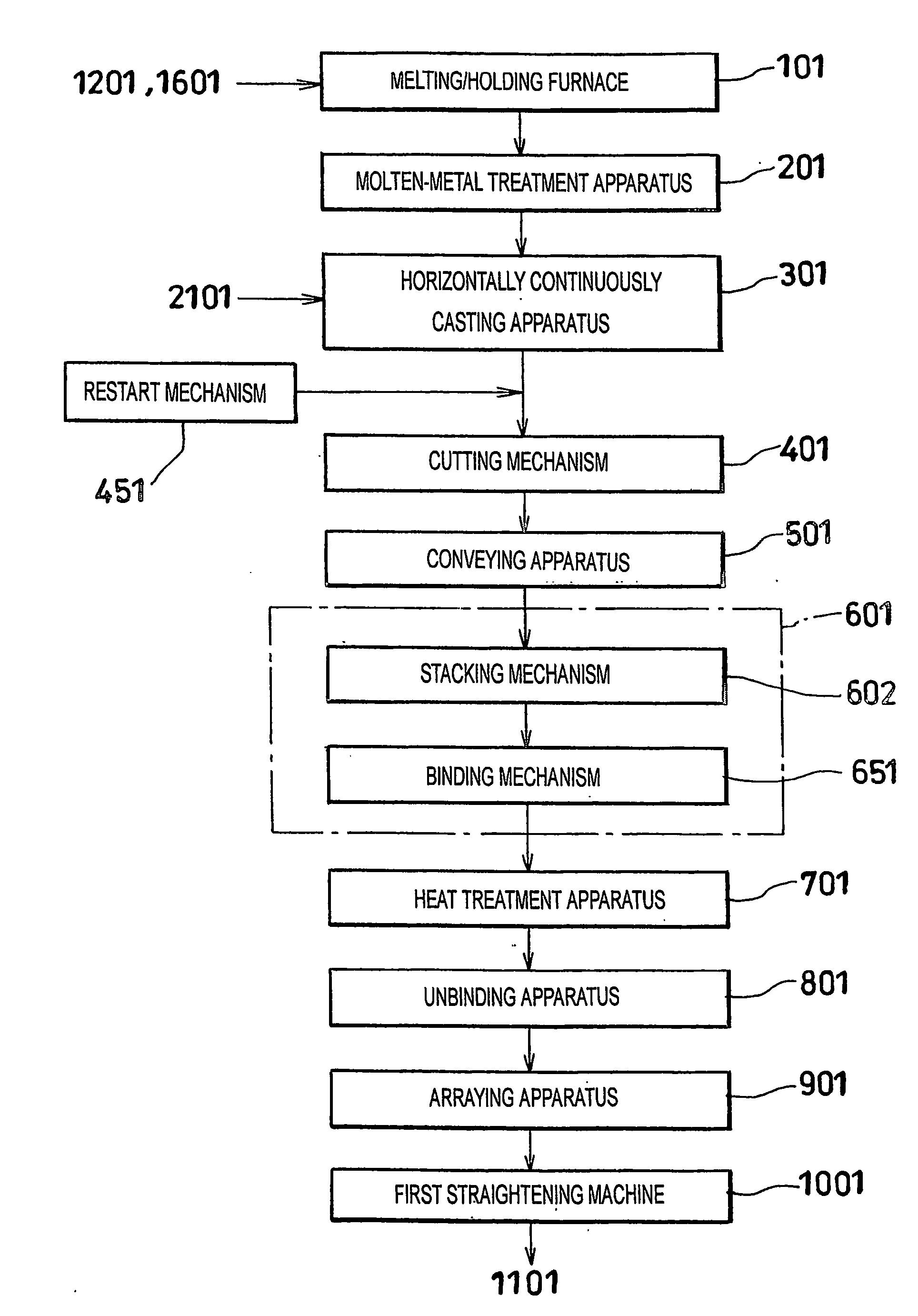

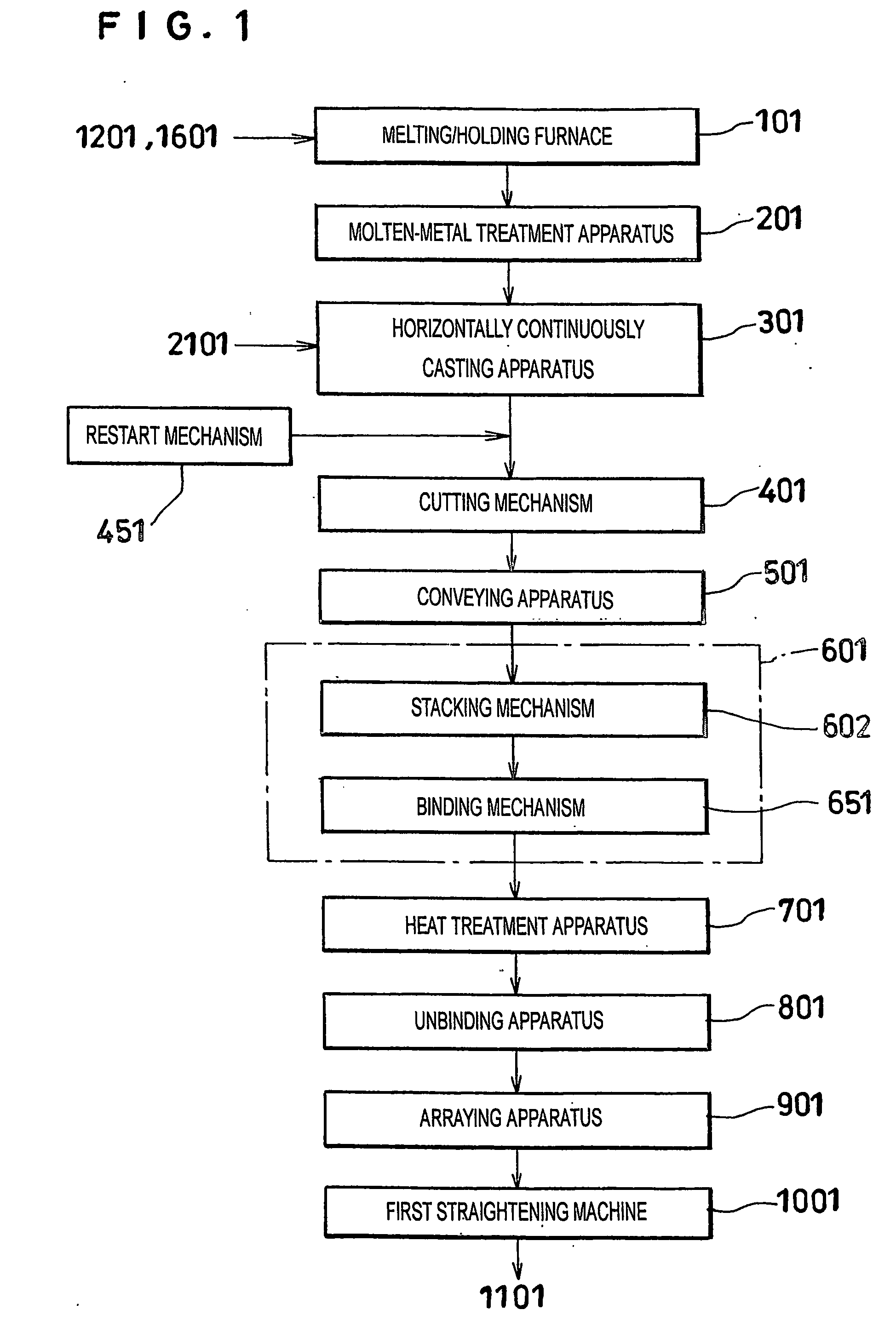

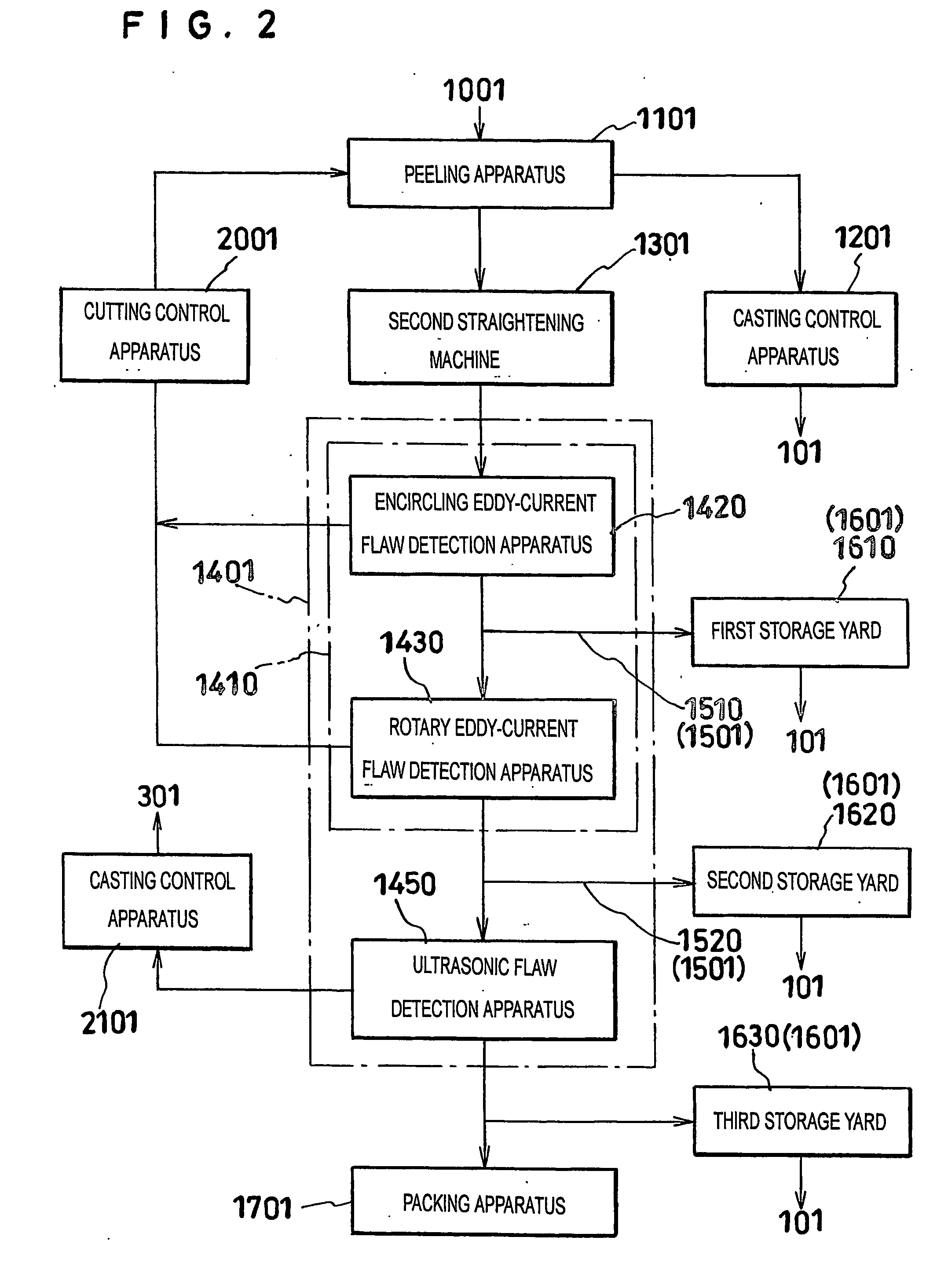

Horizontally continuously cast rod of aluminum alloy and method and equipment for producing the rod

Horizontally continuously cast aluminum alloy rods excellent in quality are efficiently manufactured using a melting / holding furnace (101) to produce molten aluminum alloy, a molten-metal treatment apparatus (201) to remove aluminum oxide and hydrogen gas from the molten aluminum alloy, a horizontally continuously casting apparatus (301) to cast the treated molten aluminum alloy into horizontally continuously cast aluminum alloy rods, a cutting machine (408A, 408B) to cut to a standard length the cast rods, a first straightening apparatus (1001) to straighten bend of the cut rods, a peeling apparatus (1101) to peel skin portions of the straightened rods, a nondestructive inspection apparatus (1401) to inspect surface and internal portions of the peeled rods, a sorting apparatus (1501) to sort the inspected rods judged non-defective based on results of the nondestructive inspection step and a packing apparatus to pack the sorted rods, and continuously using at least the first straightening apparatus (1001) et seq.

Owner:RESONAC CORP

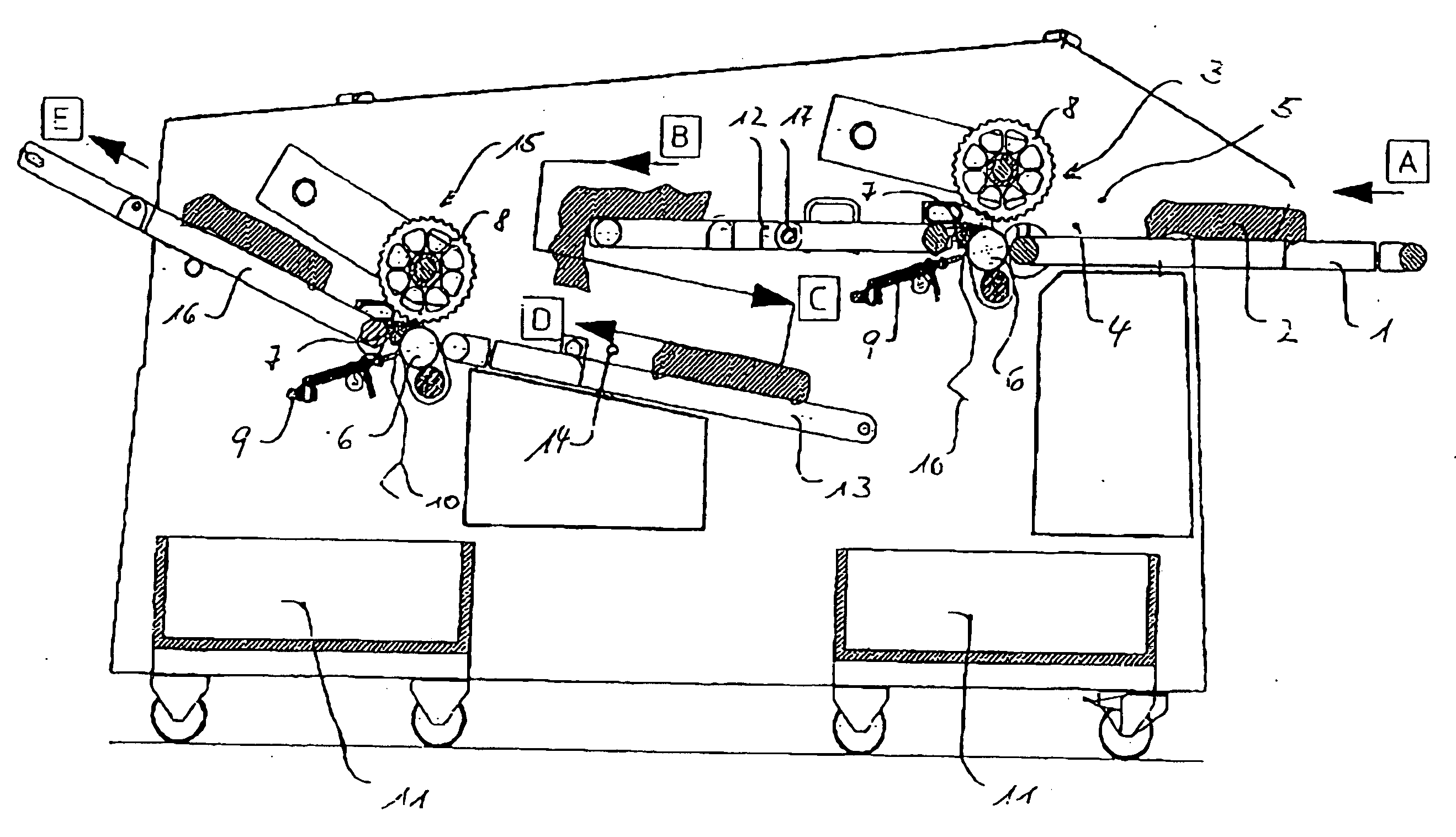

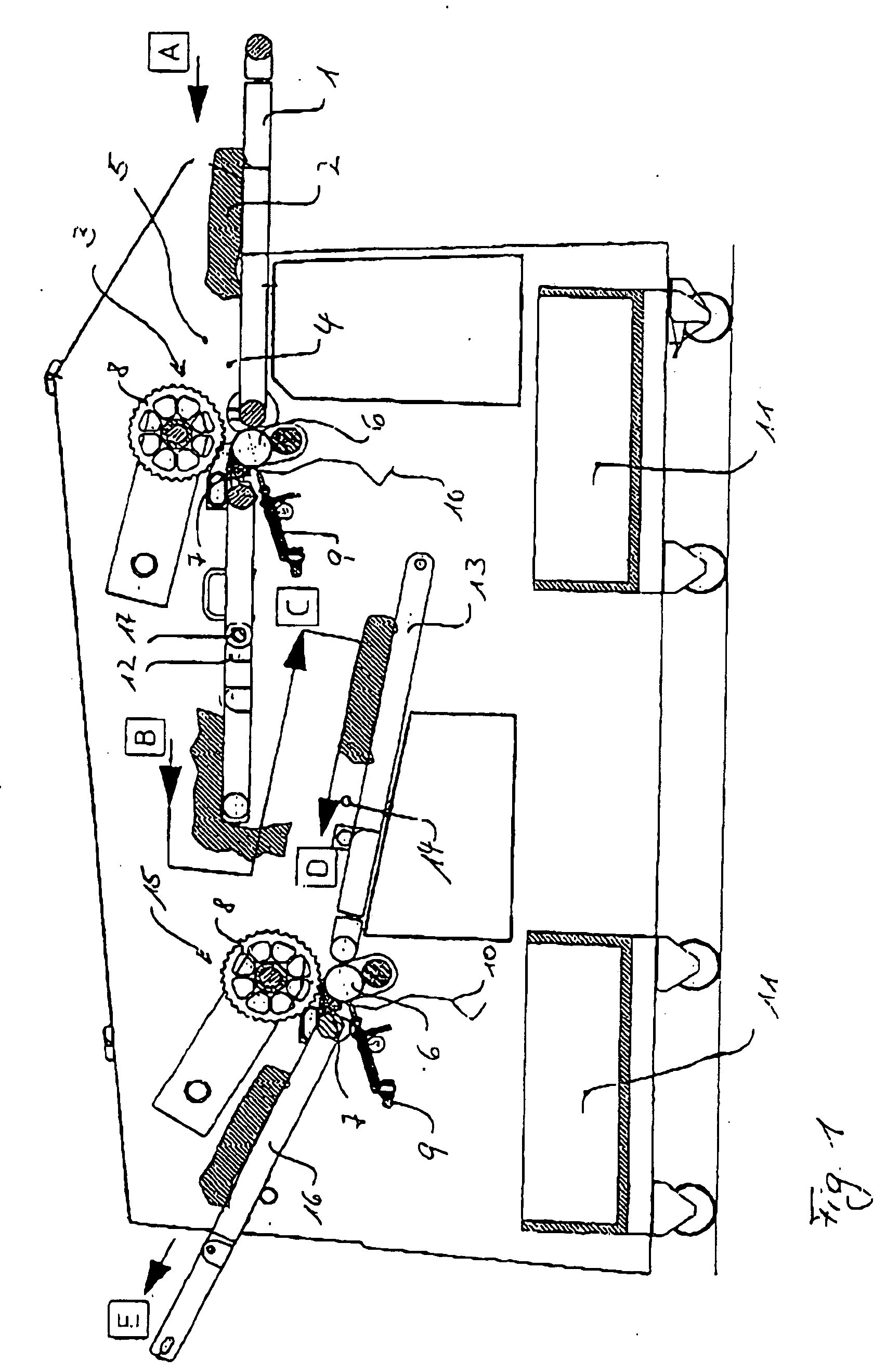

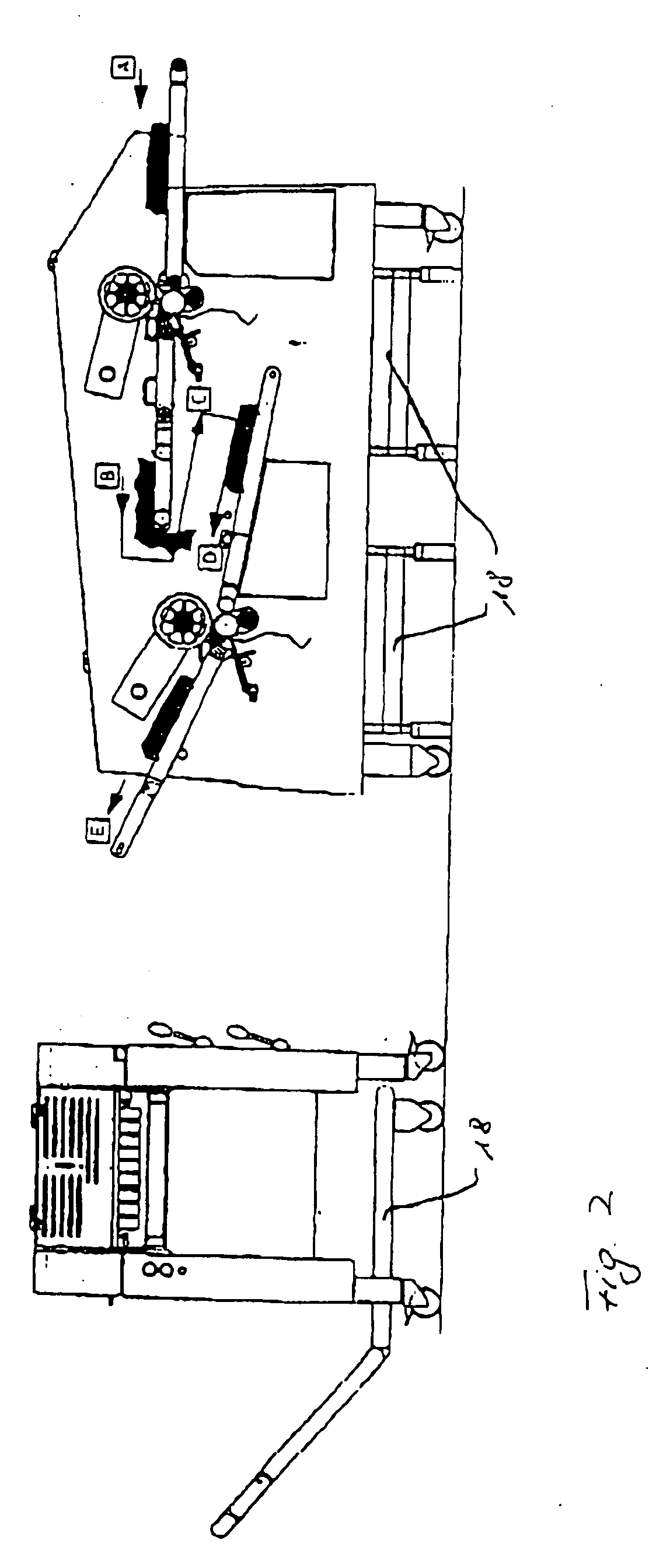

Device for de-rinding and skinning a product to be treated

InactiveUS20040248509A1Skinning instrumentsRind cutting-off apparatusFish filletMechanical engineering

The invention relates to a device for skinning and de-rinding a product to be treated such as pieces of meat or fish and similar products (2), said product to be treated being first skinned from one side by means of a first skinning unit (3). A combination of a first conveyer belt (12) and a reversing belt (13) reverses the piece of meat. A second skinning unit (15 removes the remaining fat and skin (10) from the other side of the product (2) to be treated.

Owner:MAJA-MASCHINENFABRIK HERMAN SCHILL KG

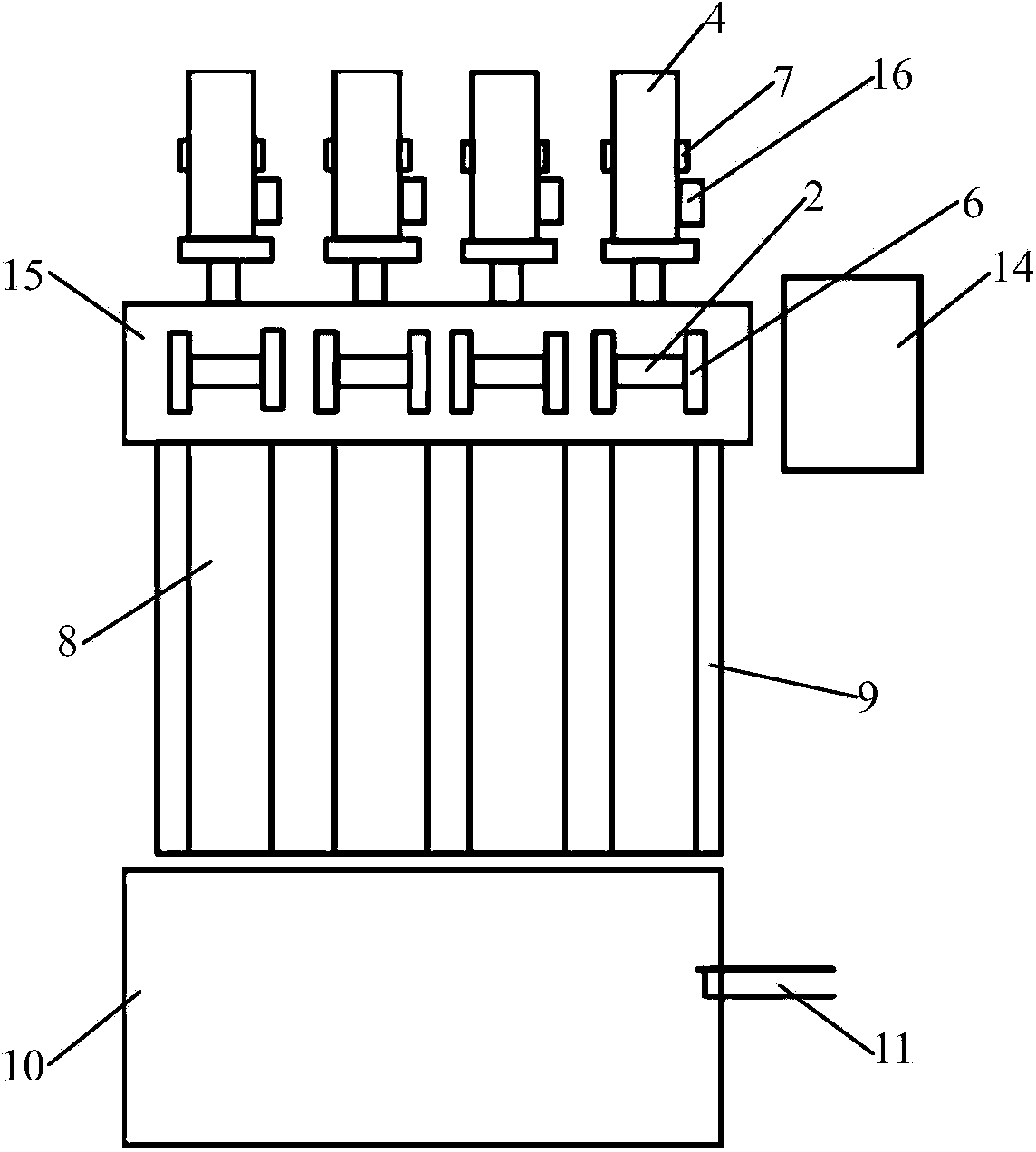

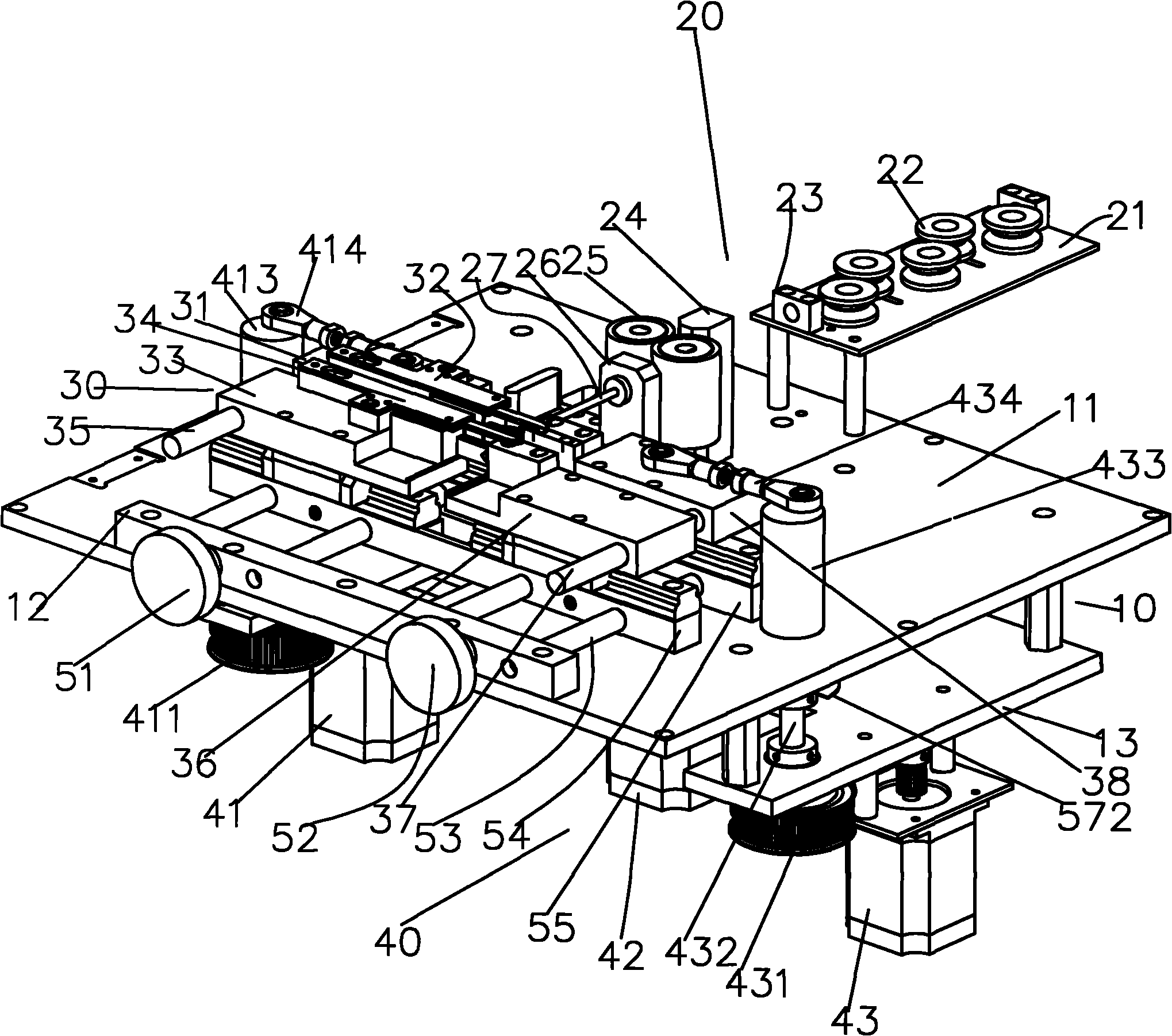

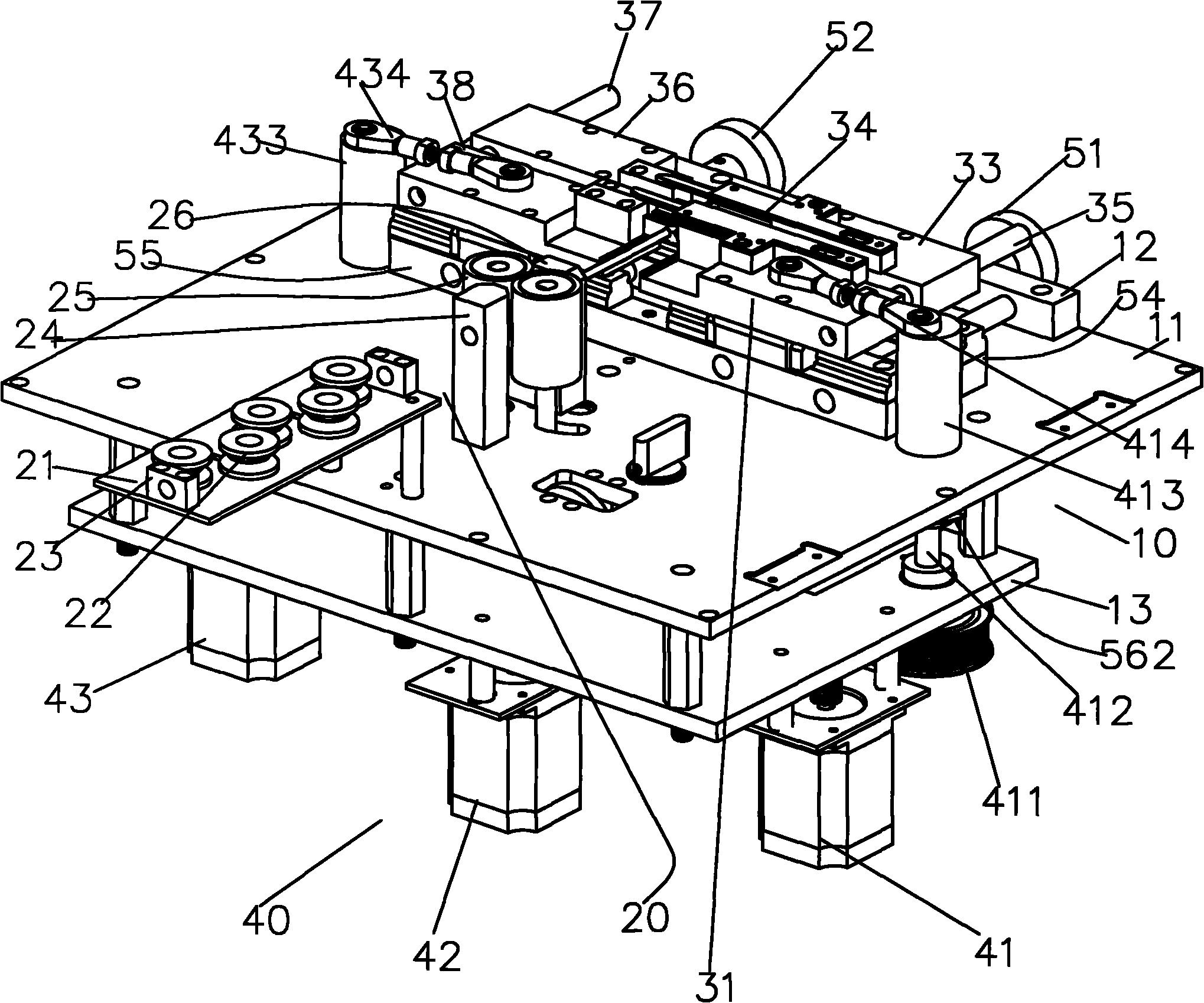

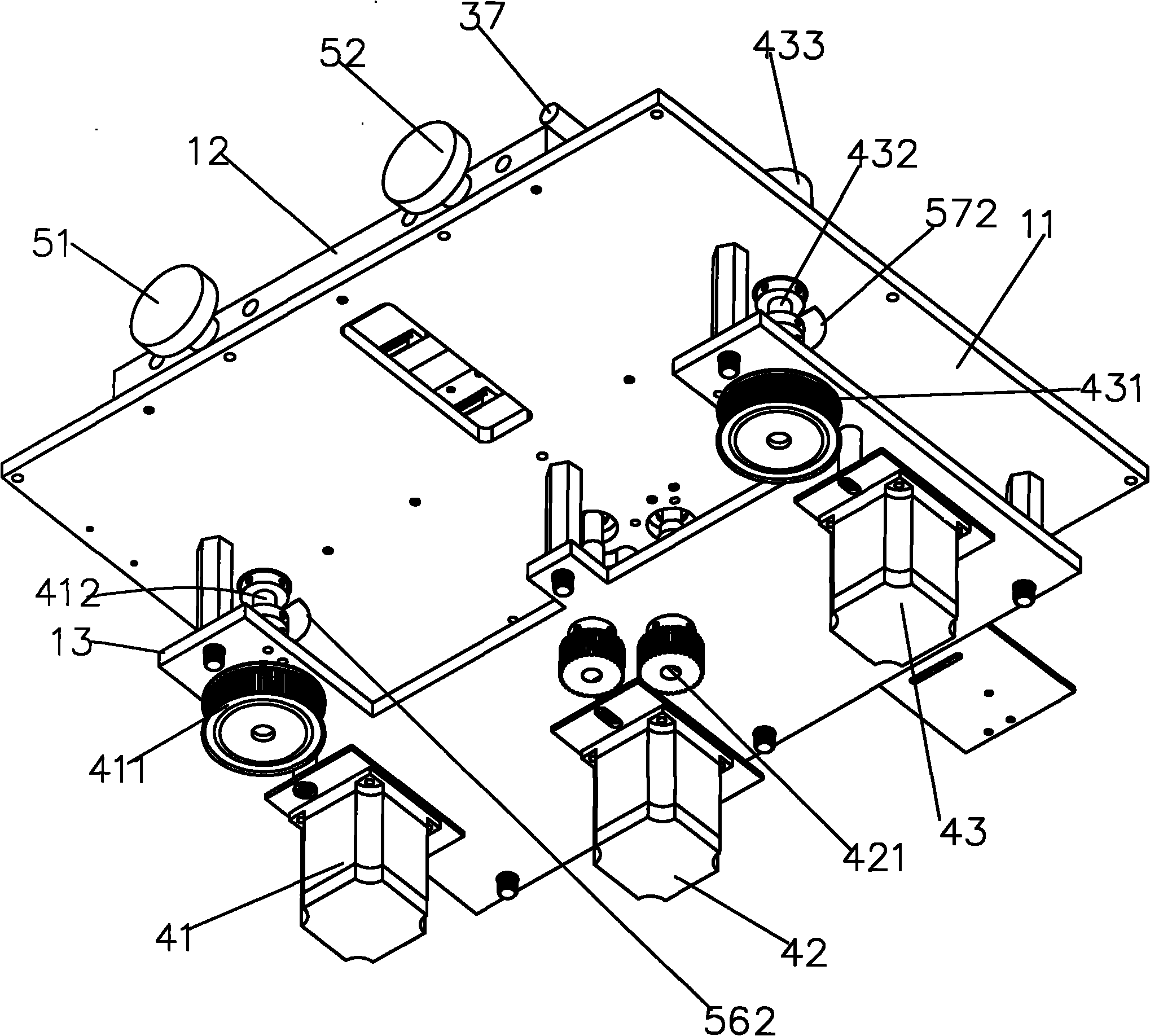

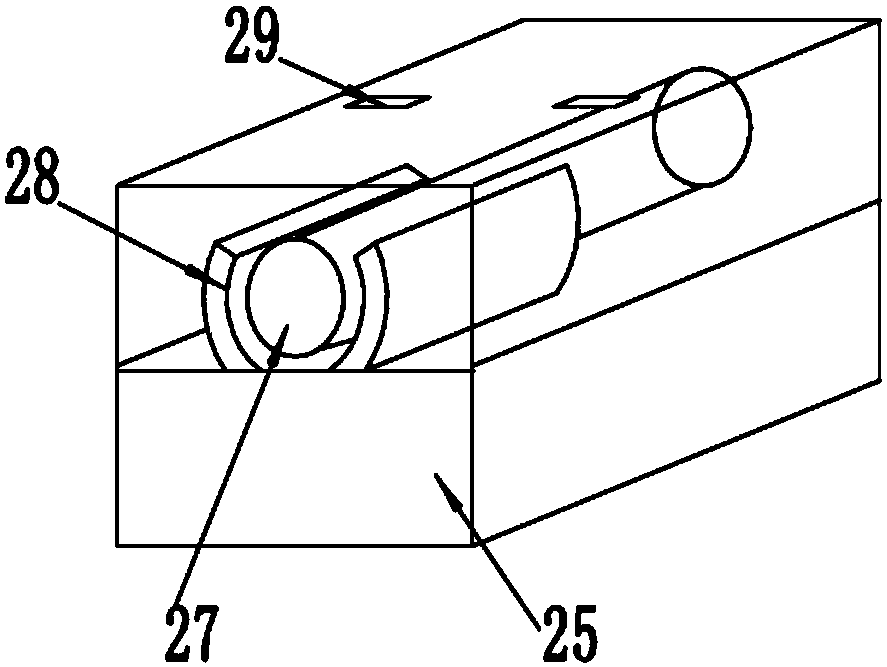

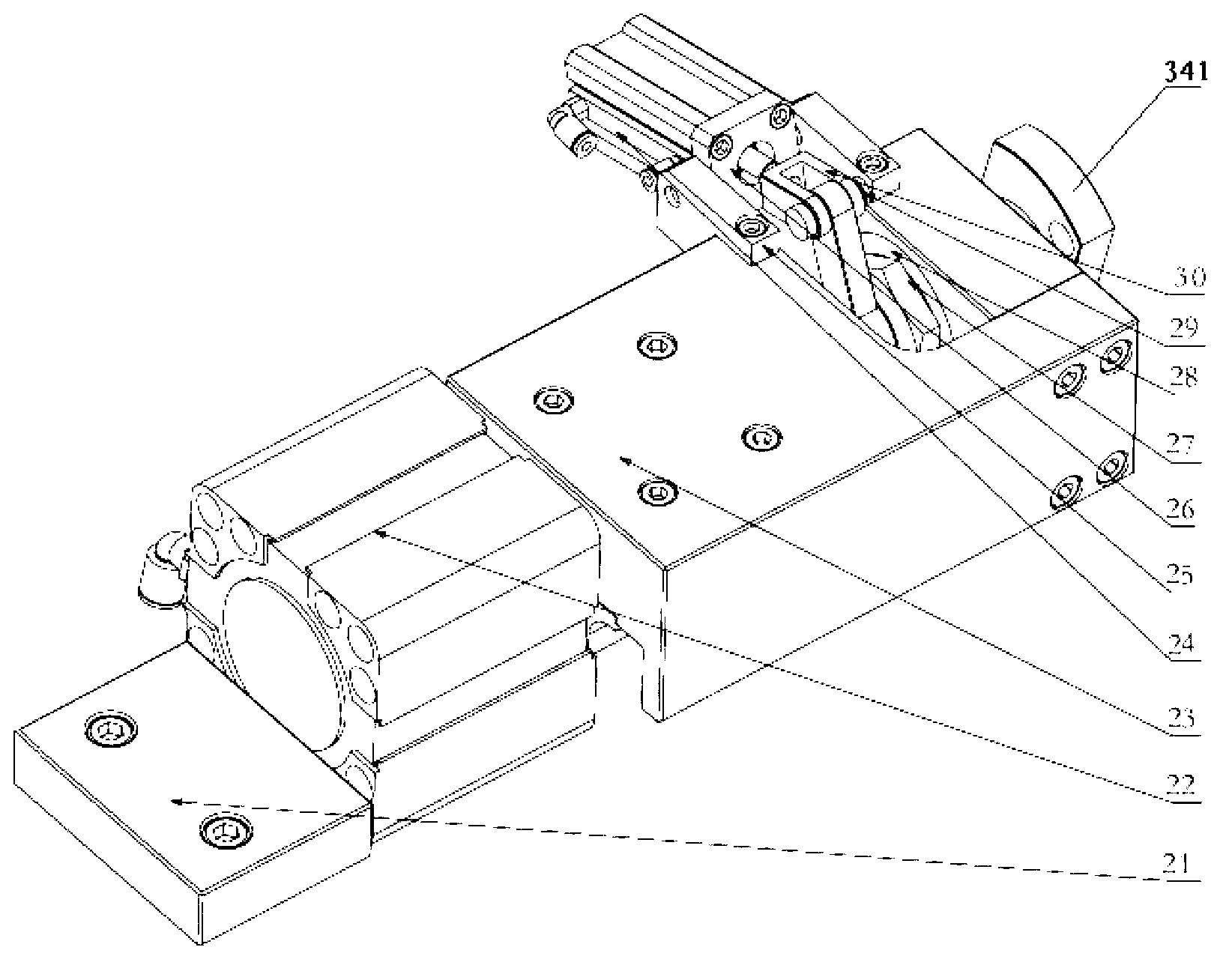

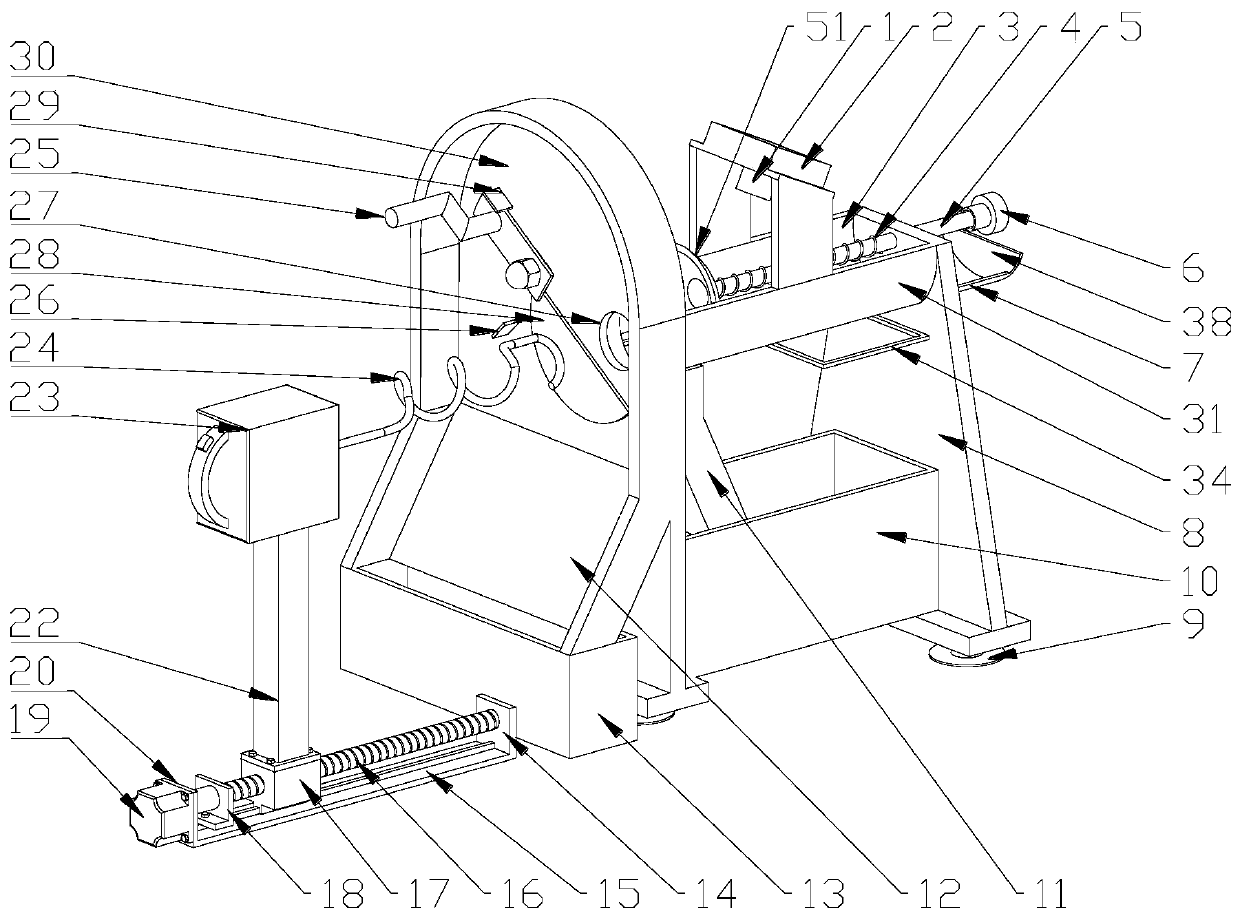

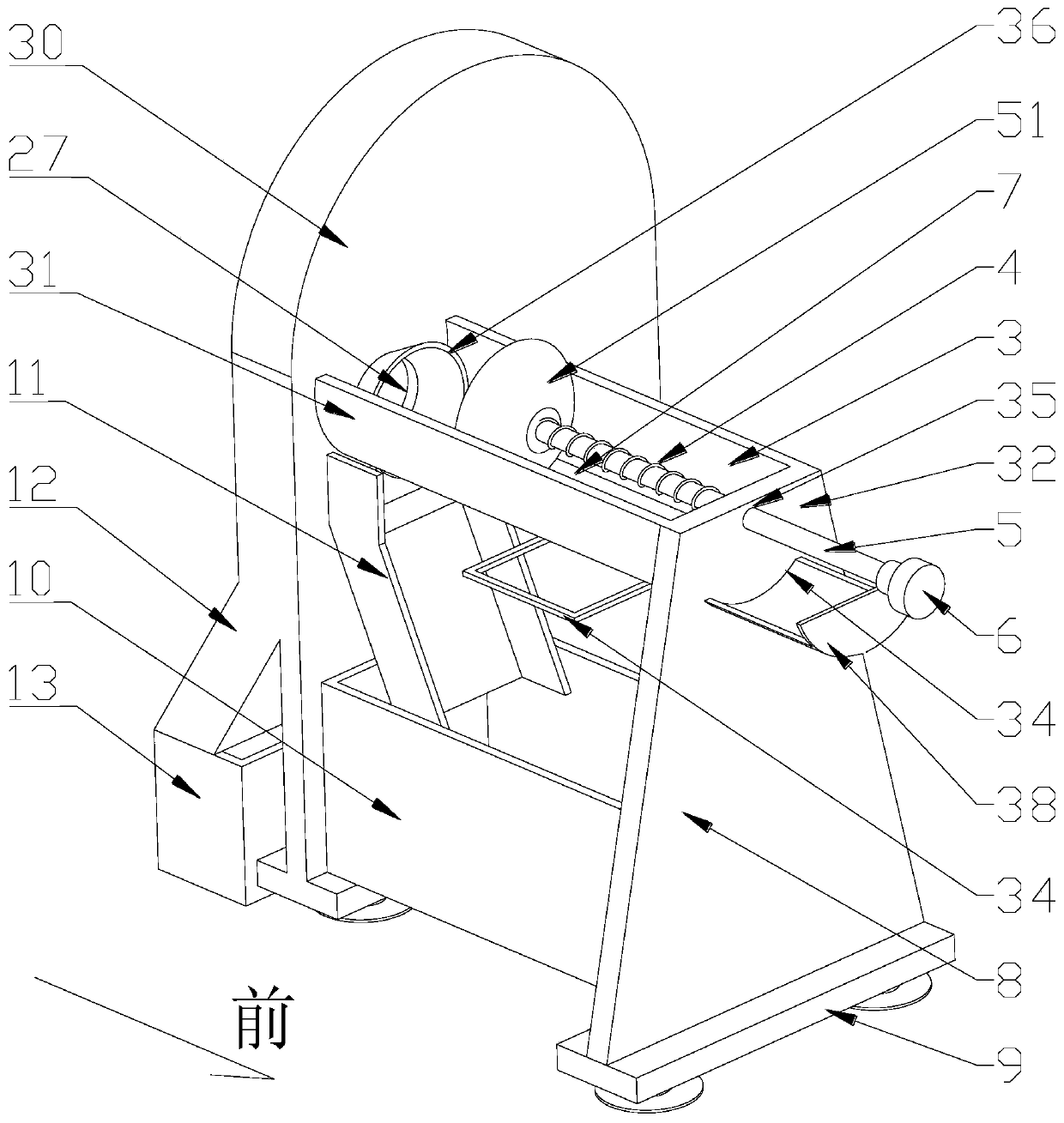

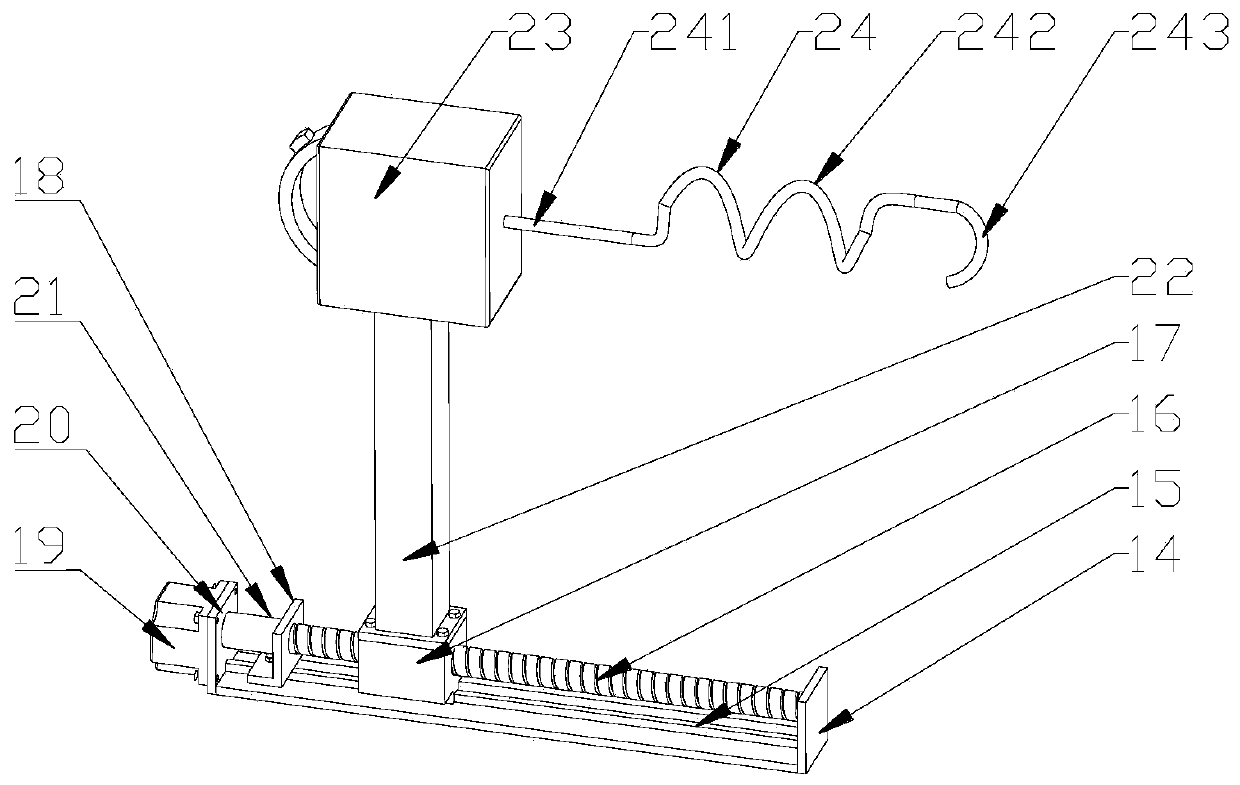

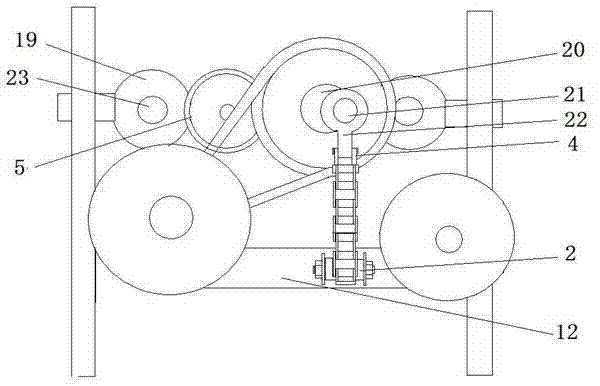

Skinned jumper wire shaping mill

InactiveCN102074876AWon't happenIncrease productivityLine/current collector detailsEngineeringWaste material

The invention belongs to the technical field of electronic element manufacturing and provides a skinned jumper wire shaping mill. The skinned jumper wire shaping mill comprises a frame, and a wire feeding device for feeding a wire to a processing station, a skinning and shaping device for skinning and shaping the fed wire, a driving device for driving the wire feeding device and the skinning and shaping device, and a control part for controlling the wire feeding device, the skinning and shaping device and the driving device, which are arranged on the frame. According to the skinned jumper wire shaping mill, a jumper wire with insulated skin is processed mechanically and automatically, so that the production efficiency is high; the skinning and the shaping are continuously performed, and the action is scientific, so that waste materials cannot be produced, and the applicable wire diameter range is wide; and the peeled skin and the processed jumper wire are put separately, so that manual sorting is not needed.

Owner:深圳市星迅电子科技有限公司

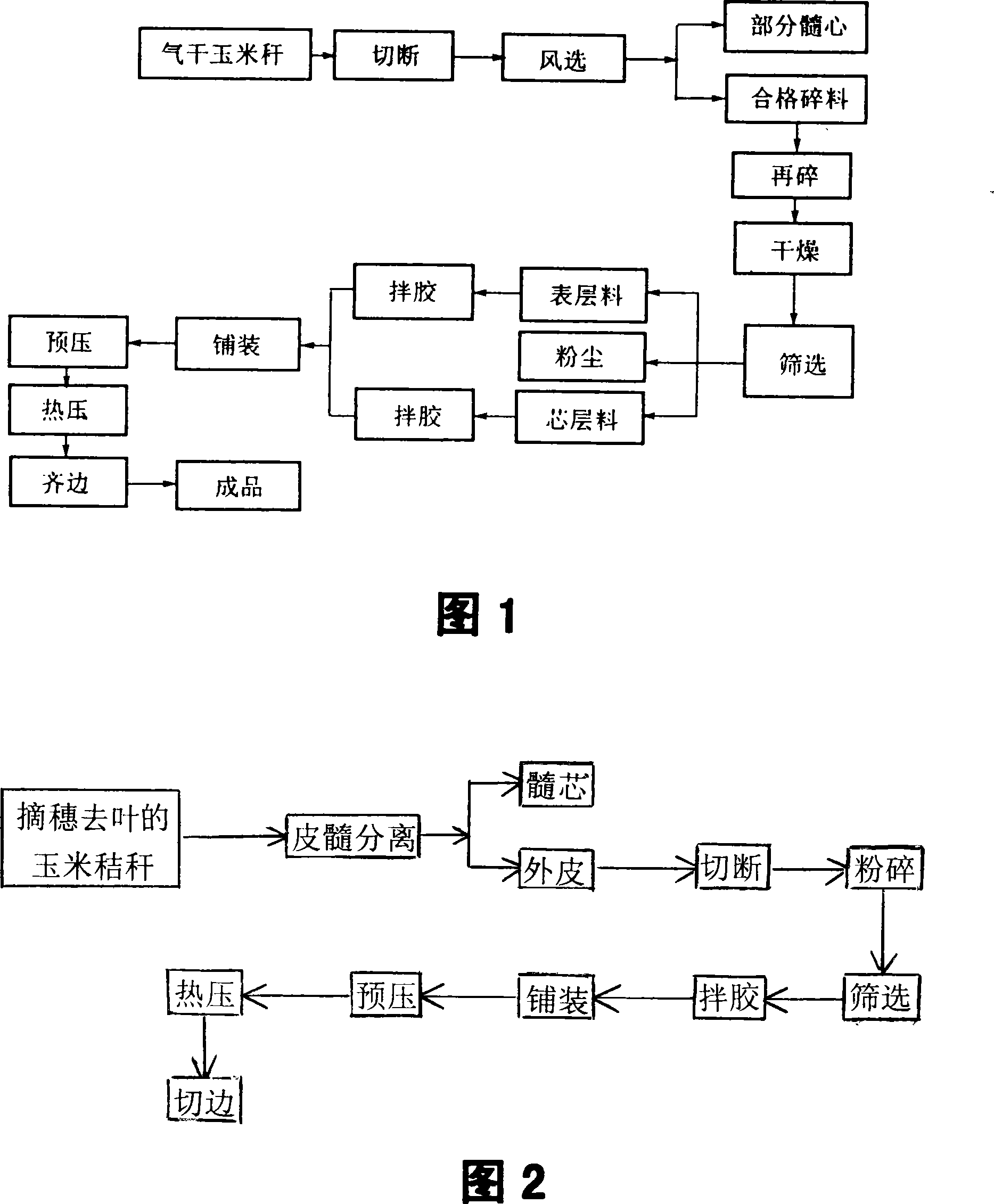

Corn straw particle board and manufacturing method thereof

The invention belongs to the category of cropper straw wood based panel. A maize straw grain plate comprises maize straw broken material and isocyanate adhesive. The invention is characterized in that the maize straw broken material is the grain of the skin of the marrow-removed maize straw; the weight percentage of the grain composition can be seen in the table; the content of the isocyanate is 3.2% to 3.7% times of the weight of the maize straw broken material. The manufacturing method of the maize straw grain plate is that the skin and marrow of the maize straw are removed; the peeled skin of the maize straw is cut off, crushed, screened, glued, paved, pre-pressed, hot pressed under the temperature ranging from 170 DEG C to 175 DEG C and edge cut. The invention solves the technical problems of improving the strength of maize straw crushed grain plate, simplifying gluing and glue mixing process, raising hot pressing temperature and shortening hot pressing time.

Owner:SHANGHAI COMPAK ENVIRONMENTAL PROTECTION EQUIP CO LTD

Topical composition in the form of a gel for treating skin burns

The present invention relates to novel topical compositions for treating burns, grazes, erythema, eczema, herpes infection, evulsion, sores and any skin damage leading to sloughing, including at least three components, namely a first barrier gel, a second barrier gel and an active principle having proteolytic activity. The novel compositions have enhanced pain-killing, protective, débrding and anti-inflammatory effects relative to the conventional products used in the art.

Owner:GOMEZ TORRES HAROLD ARMANDO

Integrated cable peeling skin collecting device

InactiveCN108281240AEasy to cutInnovative designBasic electric elementsElectronic waste recyclingPulp and paper industryElectric cables

Owner:山东博发智能科技有限公司

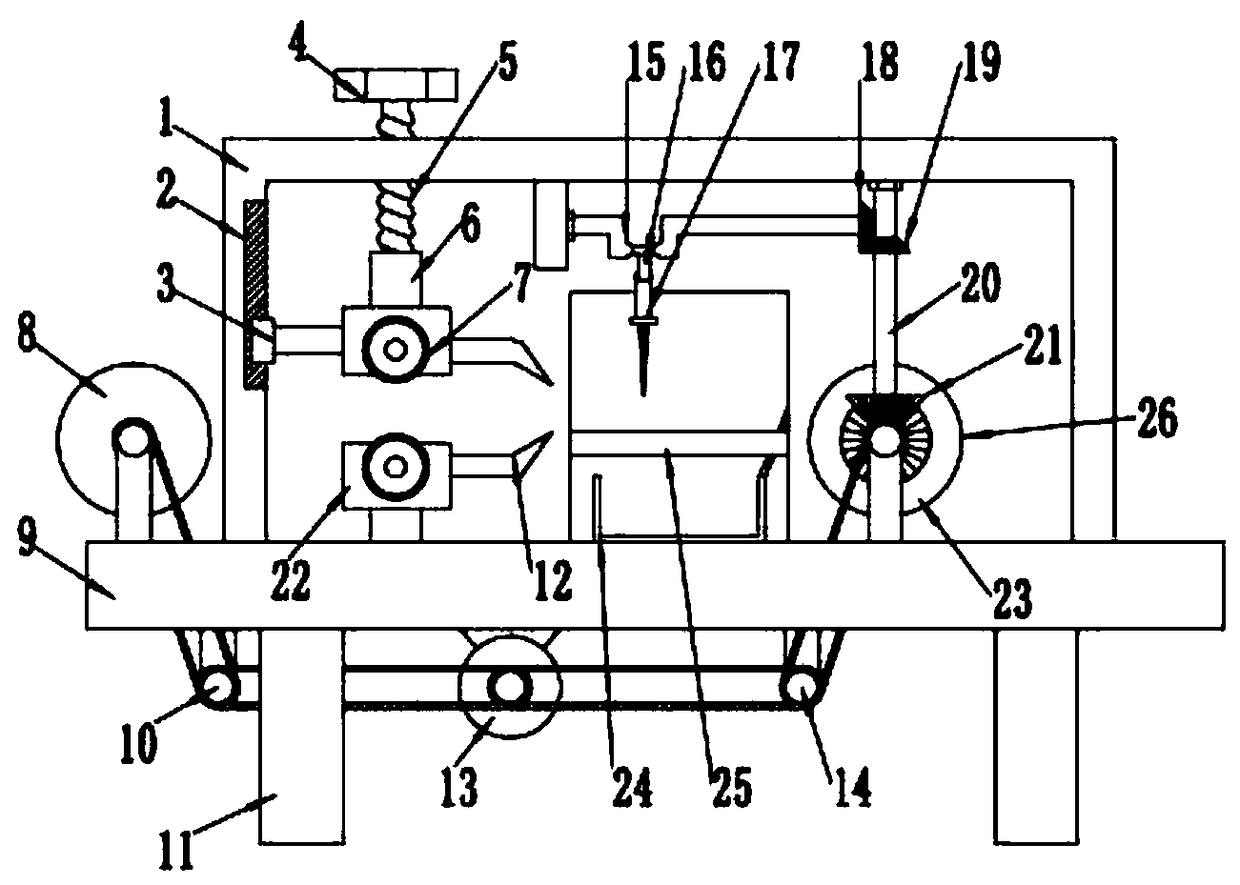

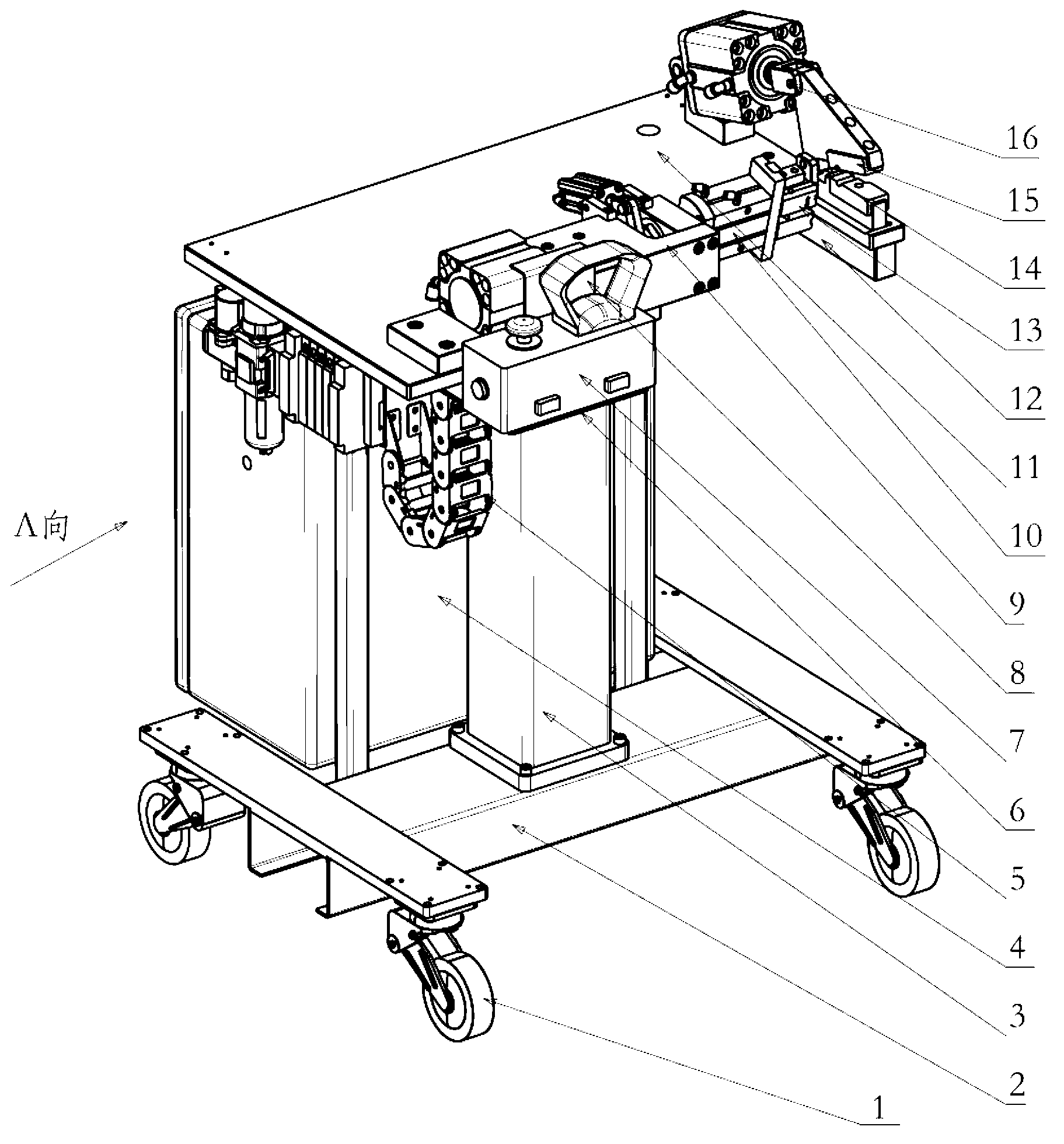

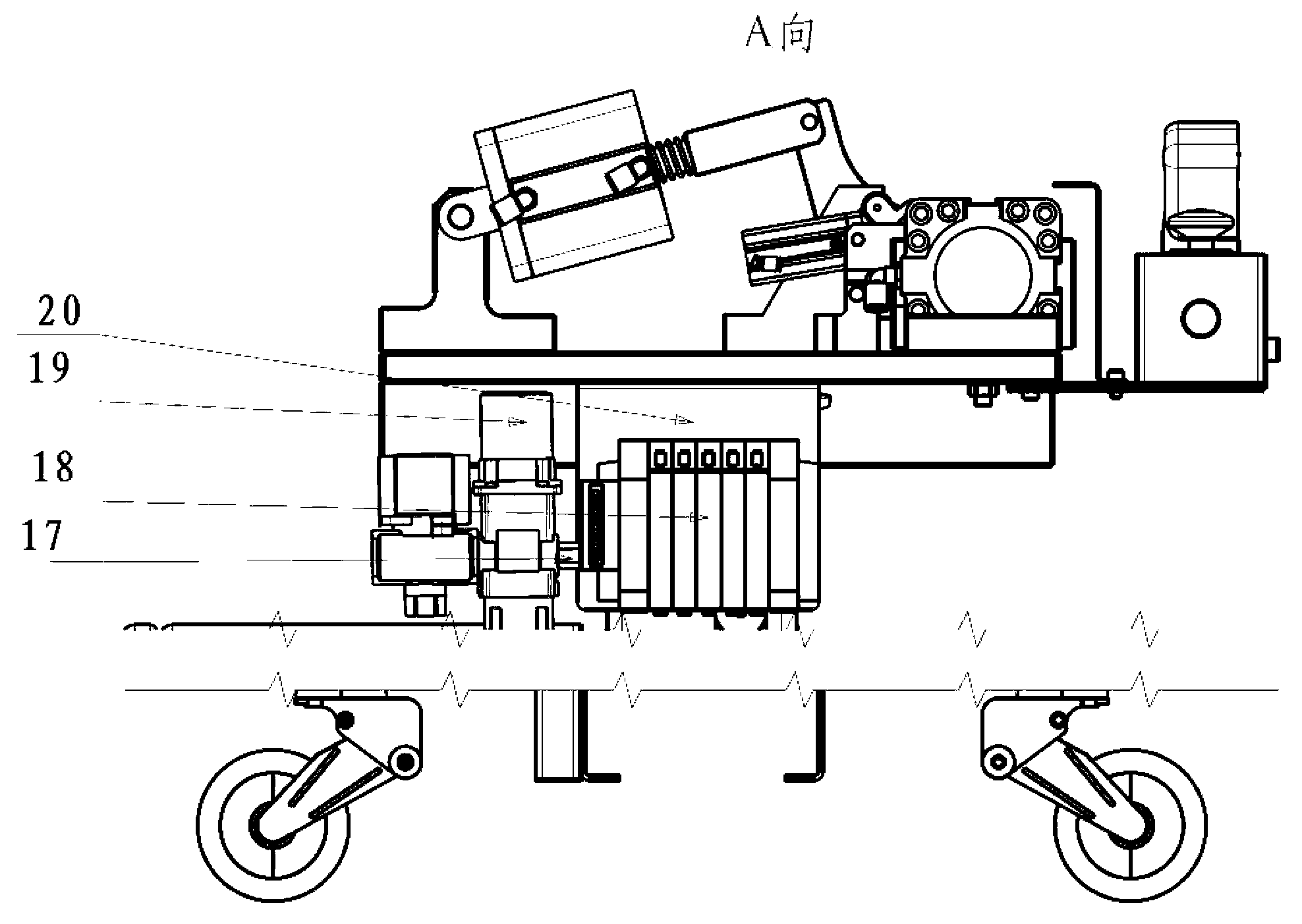

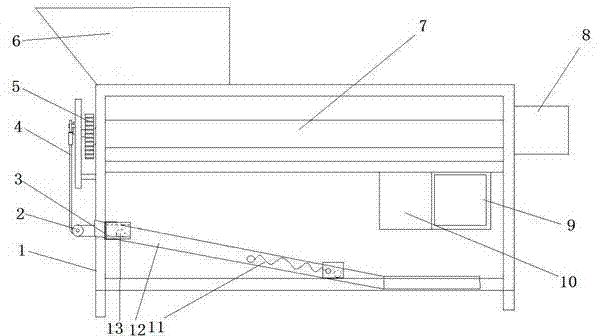

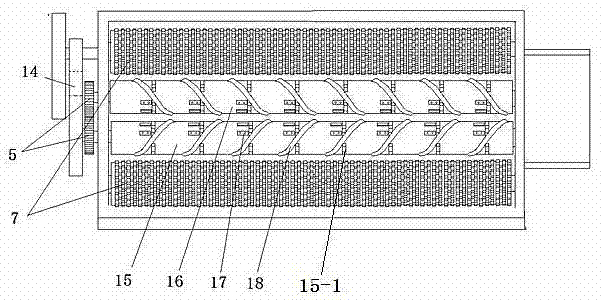

Peeling device and coated pipe peeling machine

ActiveCN103056897AReduce labor intensityEven strengthMetal working apparatusReciprocating motionEngineering

The invention discloses a peeling device and a coated pipe peeling machine, and relates to the technical field of automobiles. Technical problems of poor consistency and low production efficiency of products in the prior art are solved. The peeling device comprises a cutting mechanism, a connecting seat and a peeling mechanism; the cutting mechanism is arranged on the connecting seat and comprises a cutter and a cutter driving mechanism, and the cutter driving mechanism can drive the cutter to at least cut a required-to-be-peeled skin coated on the peripheral surface of a pipe or a rod along the radial direction of the pipe or the rod; and the peeling mechanism is connected with the connecting seat and can drive the cutting mechanism via the connecting seat, so that the cutting mechanism can reciprocate along the axial direction of the pipe or the rod. The coated pipe peeling machine comprises the peeling device, the pipe is a coated pipe, and a chuck driving mechanism can drive a chuck to clamp or release the coated pipe. The peeling device and the coated pipe peeling machine are used for improving the consistency and the production efficiency of products.

Owner:HEBEI CHINAUST AUTOMOTIVE PLASTICS CORP LTD

Process for peeling skins of yams with low-alkali and low peeling agent circulating water composite method

InactiveCN102240061AMaintain effective concentrationComplete formVegetable peelingWastewaterImpurity

Owner:FUJIAN NORMAL UNIV

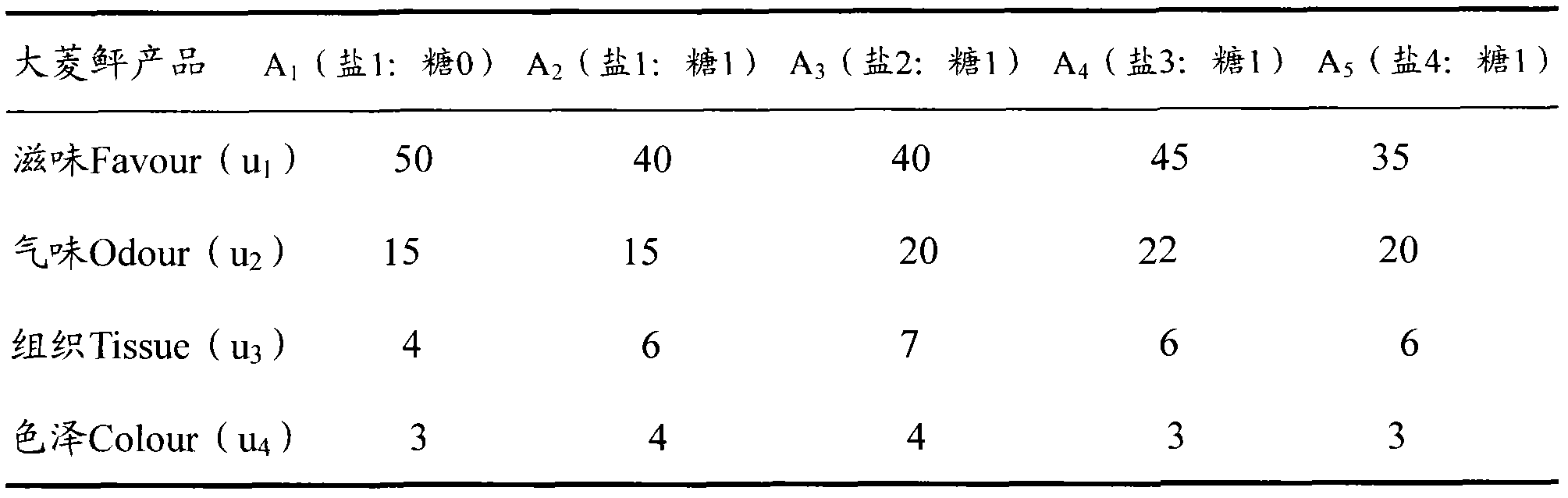

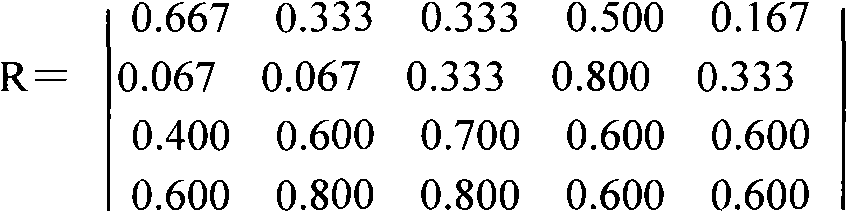

Method for preparing smoked turbot fillets

The invention relates to a method for preparing smoked turbot fillets, which comprises the following steps of: cultivating food raw materials temporarily, sacrificing, peeling skin off, slicing, pickling, drying, smoking, drying again, finishing, freezing quickly, probing by using gold and boxing, wherein the temperature of the food which is dried twice and smoked is below 20 DEG C; performing special seasoning by using pickling solution of table salt, granulated sugar and water; and selecting a high-quality hardwood jujube sawdust smoking material with low resin content, and smoking at the cold smoking temperature of below 20 DEG C according to the conventional process for smoking fish. By the method, the primary taste essence of turbot can be kept, damage to nutritional ingredients is minimum, and the method is safe and sanitary; and characteristic smoked fish products which are delicious in taste, tender in meat quality and golden yellow in color and luster can be produced, wherein the content of benzopyrene (a) in the products is 0.1ug / kg and is far below the limit standard, which is specified by GB7104-94, of smoked fish, namely is less than or equal to 5ug / kg, and the smoked turbot fillets do not contain clostridium botulinum by detection.

Owner:SHANDONG MEIJIA GROUP

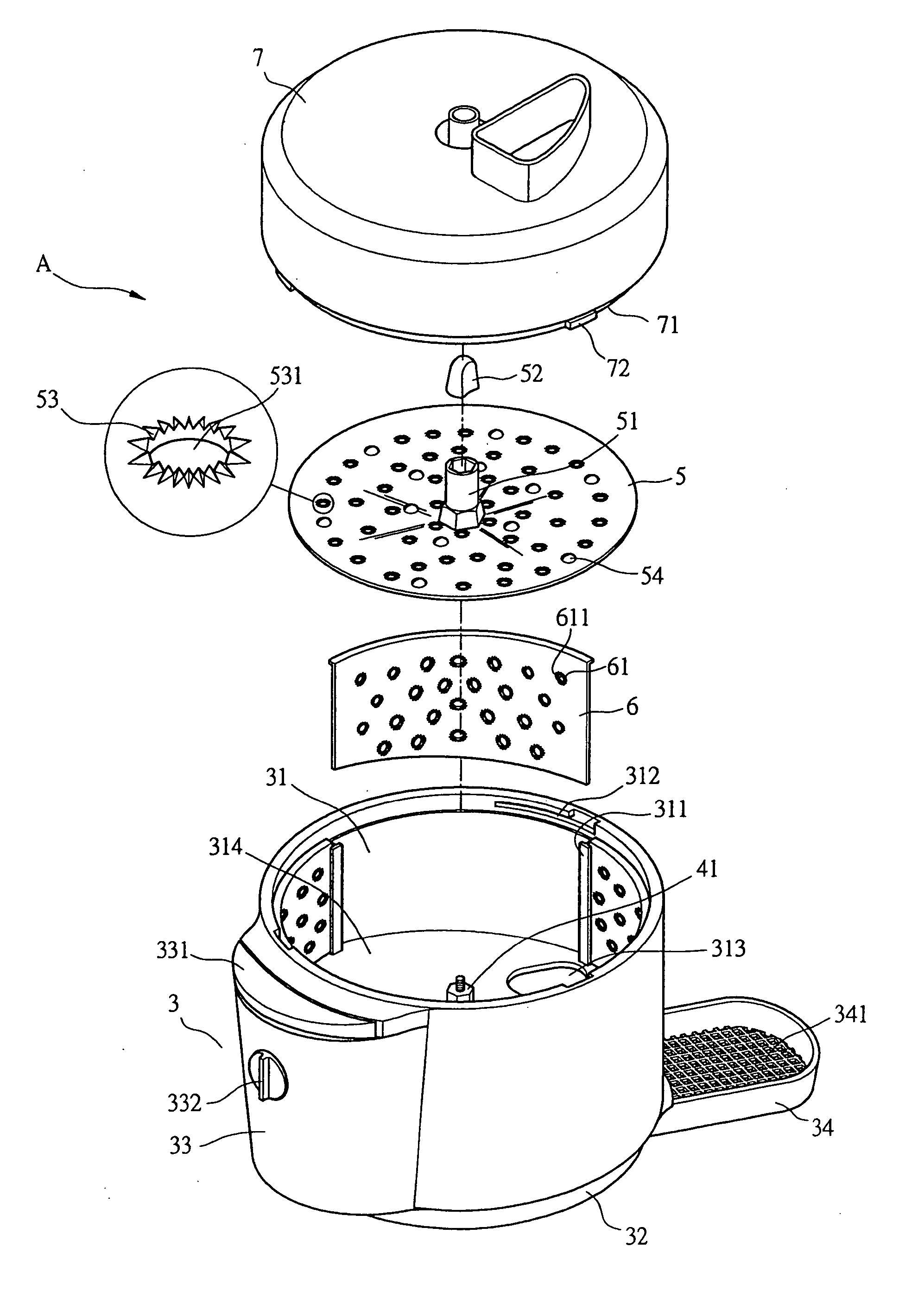

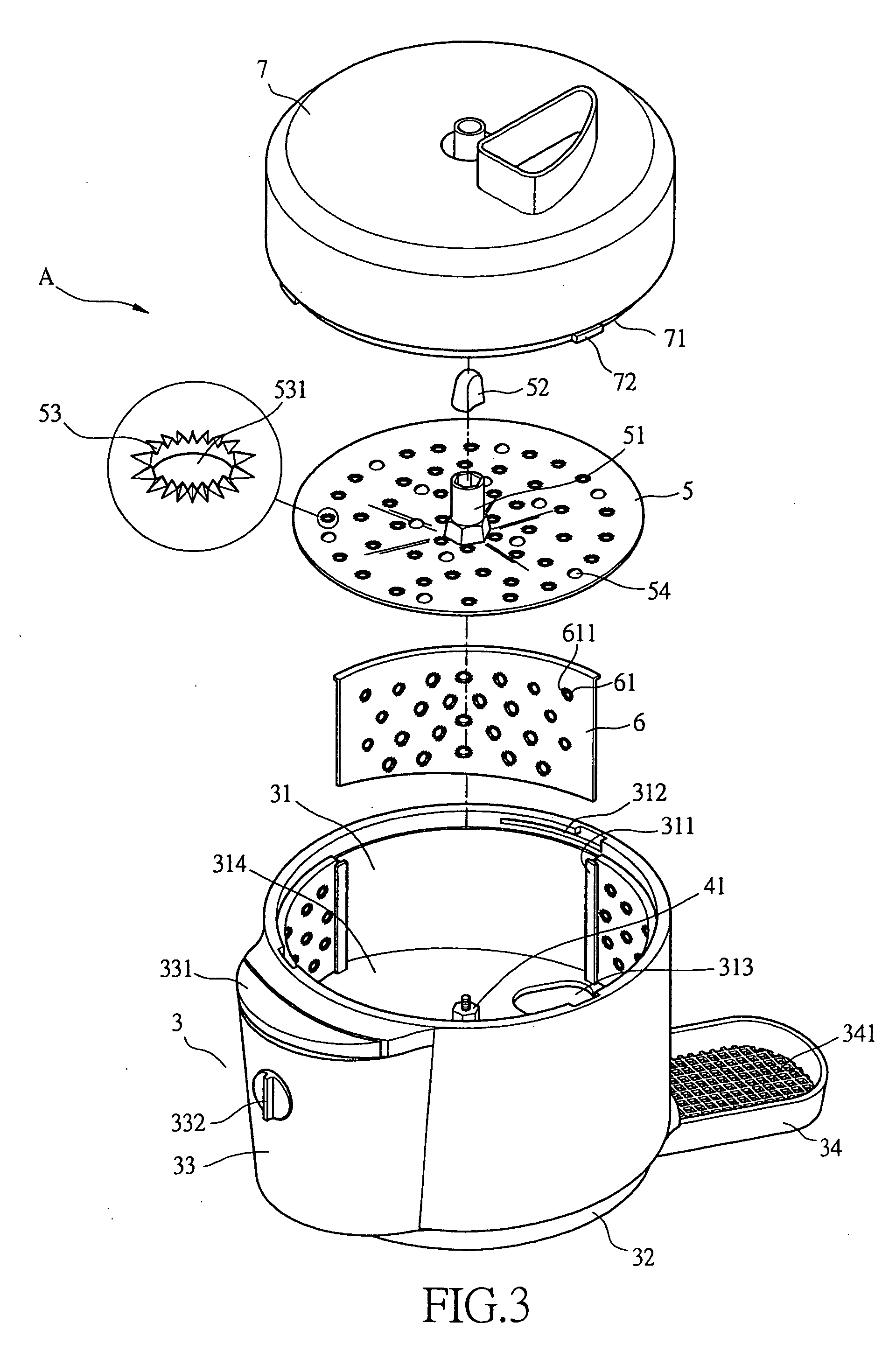

Fruit skin peeling device

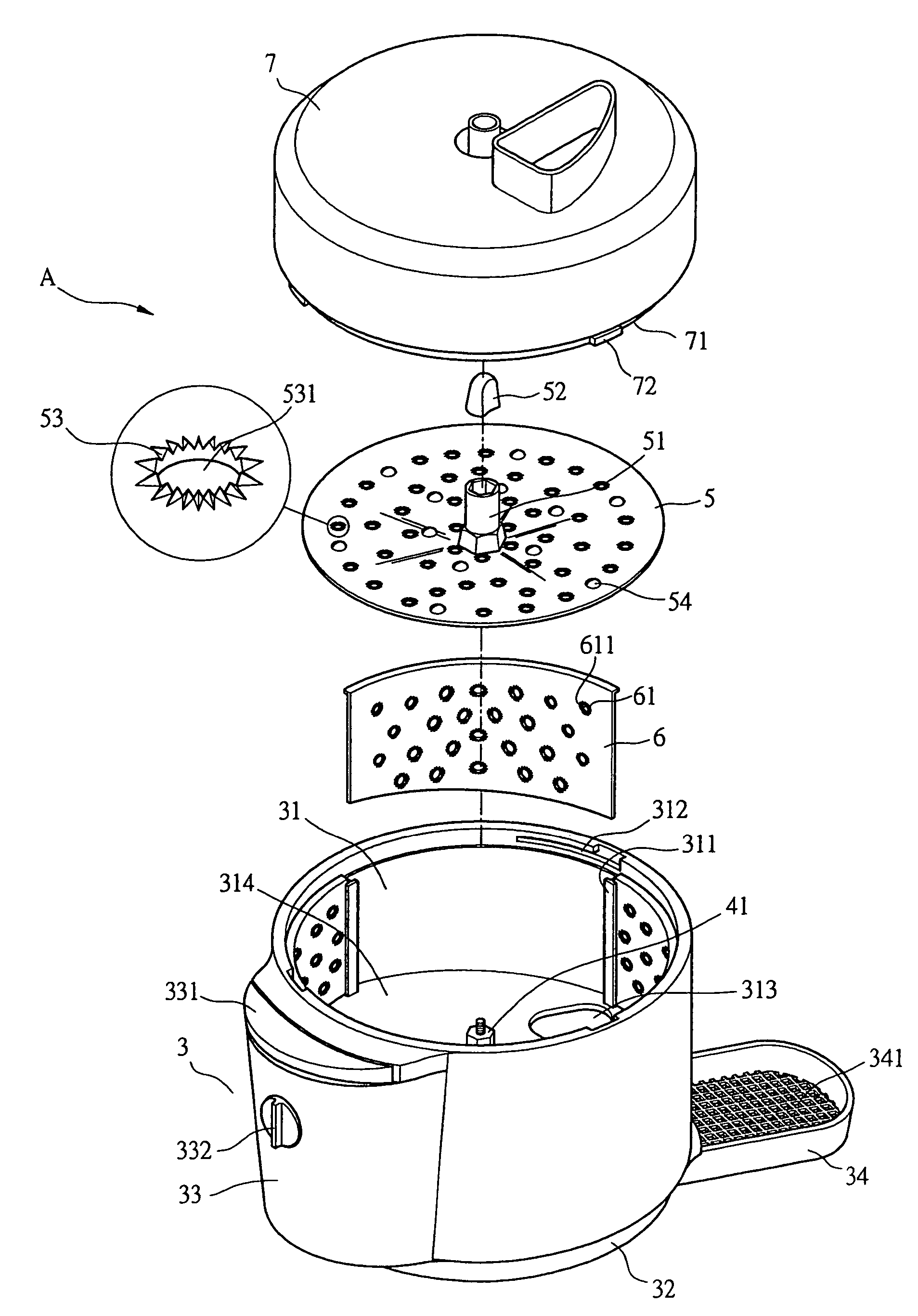

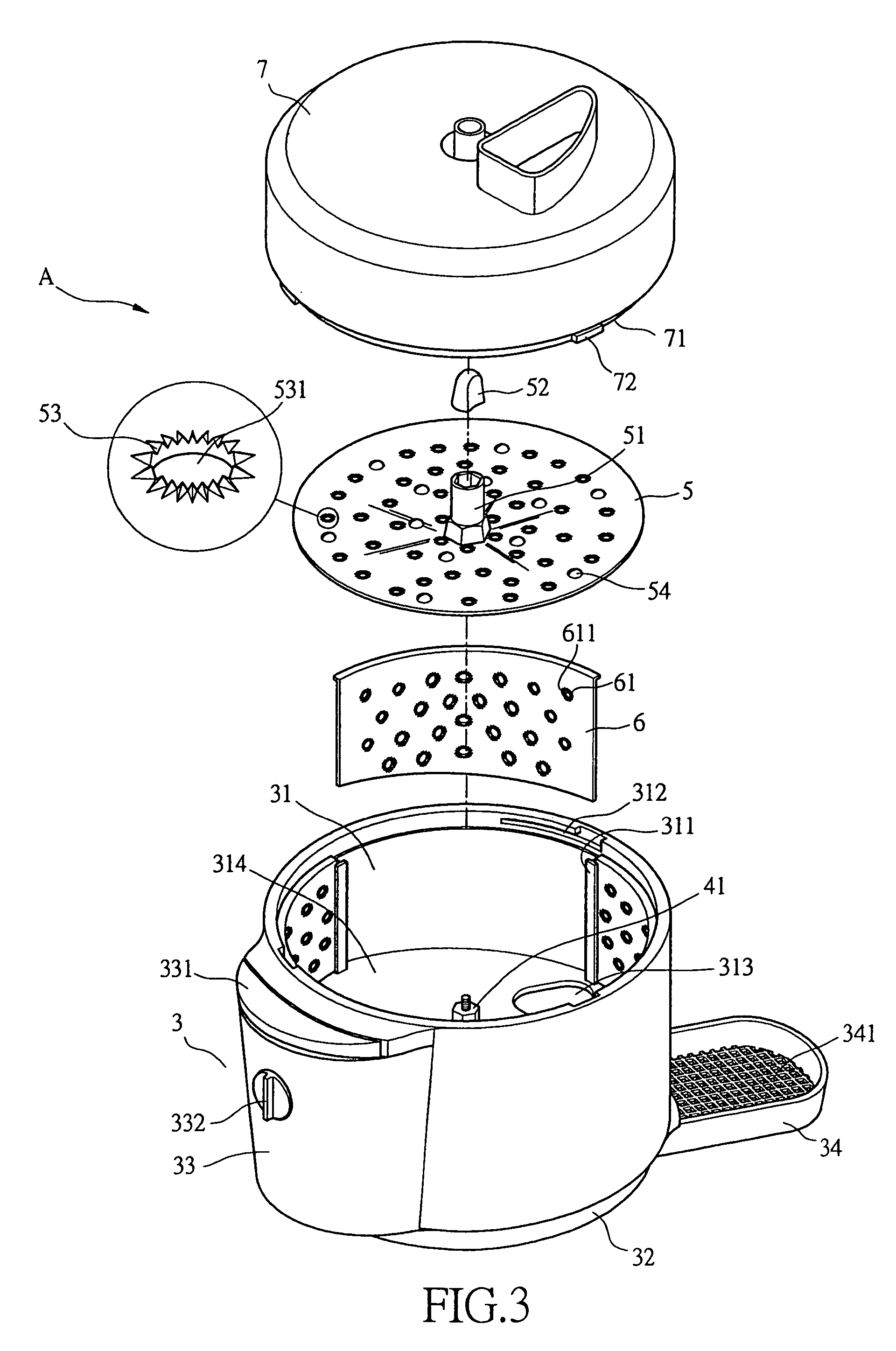

A fruit skin peeling device is disclosed. The device comprises a base, a driving means, a rotating disc, a plurality of lateral plates and a top cover, the base having a top and a lower cavity, wherein the base is divided into an upper chamber and a lower chamber and the lower chamber encloses the driving means having an axle protruded at the lower chamber and connected to the rotating disc, the bottom section of the upper chamber is provided with a debris opening and the lateral plates are position around the circular side of the upper chamber, characterized in that the rotating disc and the lateral plates are mounted with circular toothed-blade, the driving means drives the rotating disc to rotate such that fruits or the like placed in the upper chamber is driven to rotate and in contact with the circular toothed-blade to peel off the skin of the fruit or the like, and the peeled skins are discarded through the debris opening.

Owner:LIN KUAN CHIH

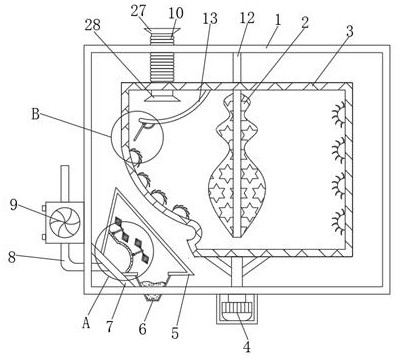

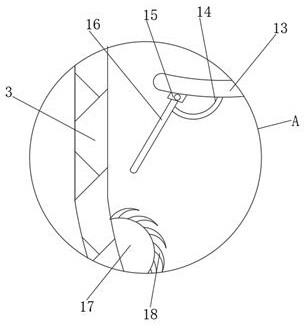

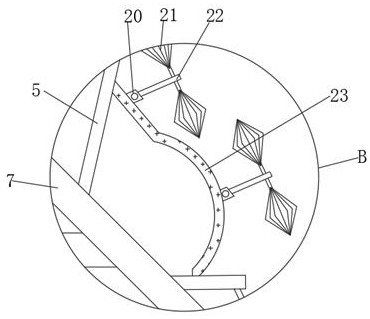

Water chestnut peeling machine

PendingCN108142956AImprove peeling efficiencyReduce lossesVegetable peelingFood treatmentWater ChestnutsEmbryo

The invention discloses a water chestnut peeling machine which comprises a rack. A two-plane peeling device and an outer edge peeling device are arranged in the rack,, the outer edge peeling device comprises a rotating-rolling spindle, an outer fixing disc a, an inner fixing disc a, an inner fixing disc b, an outer fixing disc b, a movable ejector rod, a static ejector rod, a fly cutter peeling device, a graduated wheel, a graduated sensor and a controller, a material waiting disc is rotatably connected on the rack, multiple material waiting grooves are uniformly formed in the material waitingdisc, and a discharging port of the two-plane peeling device and the material waiting grooves are in opposite arrangement. The two-plane peeling device is used to cut off embryos and roots on two sides of water chestnut in one time, the water chestnut is sent to a clamping position of the movable ejector rod and the static ejector rod by rotating the material waiting disc after being sent to thematerial waiting grooves and then sent to a workstation of the fly cutter peeling device to peel skin at the outer edge of the water chestnut, and the water chestnut after being peeled falls down automatically to complete processing. The water chestnut after being processed in this way is high in peeling efficiency and little in pulp loss, and a whole processing line is high in automation level and convenient for mass production.

Owner:宁波市奉化晨驹仪器制造厂

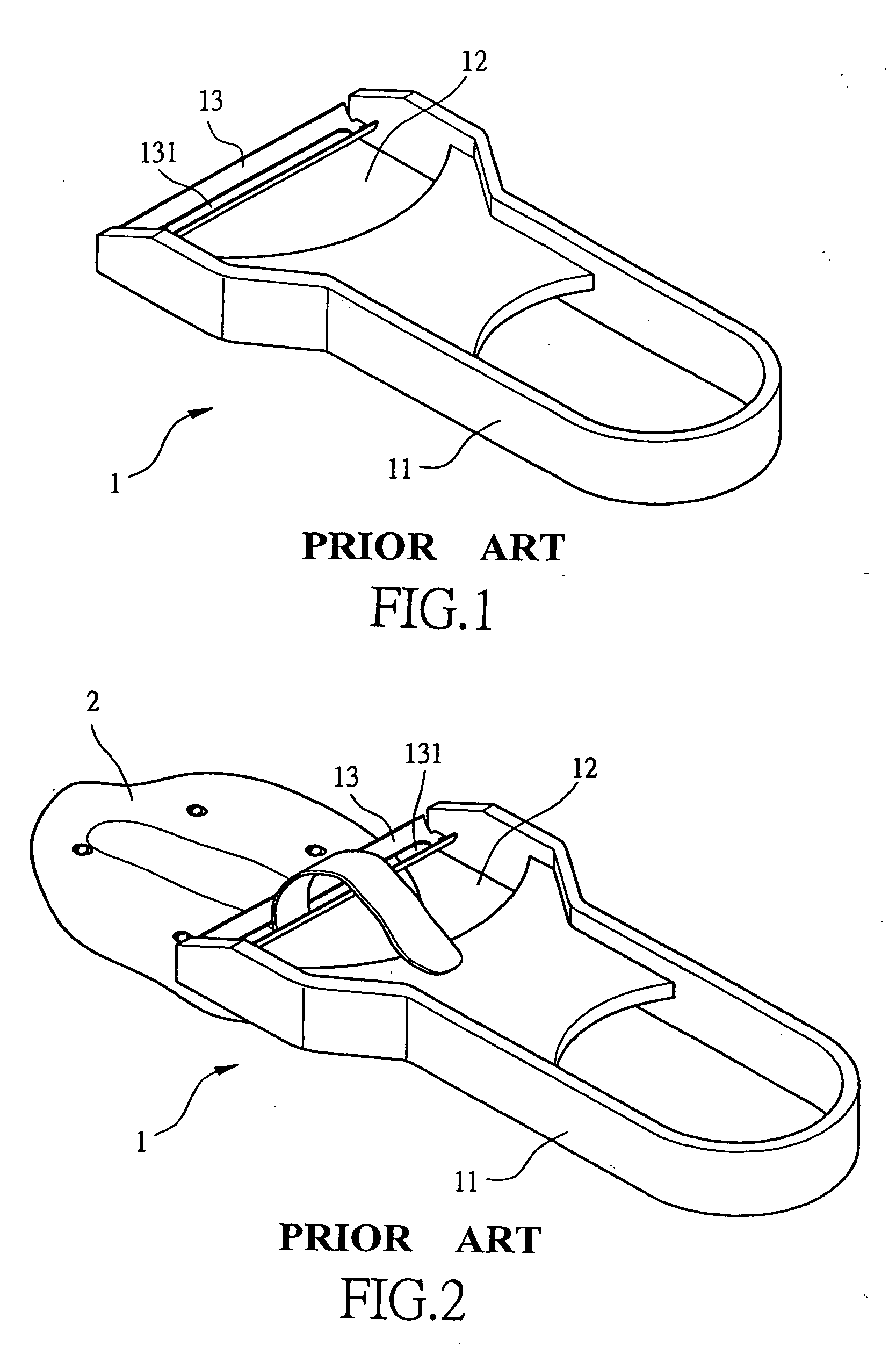

Fruit skin peeling device

InactiveUS7270052B2Easy to discardWashing of the device is very convenientJuice extractionVegetable peelingKnife bladesRotating disc

A fruit skin peeling device is disclosed. The device comprises a base, a driving means, a rotating disc, a plurality of lateral plates and a top cover, the base having a top and a lower cavity, wherein the base is divided into an upper chamber and a lower chamber and the lower chamber encloses the driving means having an axle protruded at the lower chamber and connected to the rotating disc, the bottom section of the upper chamber is provided with a debris opening and the lateral plates are position around the circular side of the upper chamber, characterized in that the rotating disc and the lateral plates are mounted with circular toothed-blade, the driving means drives the rotating disc to rotate such that fruits or the like placed in the upper chamber is driven to rotate and in contact with the circular toothed-blade to peel off the skin of the fruit or the like, and the peeled skins are discarded through the debris opening.

Owner:LIN KUAN CHIH

Regeneration mulberry bark nano-fiber anti-bacteria health-care mask and production method of regeneration mulberry bark nano-fiber anti-bacteria health-care mask

InactiveCN104000318AEpidemic preventionProtect healthProtective garmentSpecial outerwear garmentsYarnFiber

The invention relates to a regeneration mulberry bark nano-fiber anti-bacteria health-care mask and a production method of the regeneration mulberry bark nano-fiber anti-bacteria health-care mask. Mulberry branch peeled skin and unglued product mulberry bark fibers serve as raw materials, the mulberry bark fibers are manufactured into non-woven fiber felts with the certain strength and the certain thickness with the non-woven production method, and the non-woven fiber felt serves as framework materials of the mask. The mulberry bark fibers are dissolved in certain reagents to prepare uniform spinning solutions, a three-dimensional non-woven felt formed by the nano-scale mulberry bark fibers is manufactured with the electrospining method, the non-woven mulberry bark fiber felt, the electrospining nano-scale mulberry bark fiber felt and the non-woven mulberry bark fiber felt are compounded in sequence, seaming fixation is carried out with mulberry bark fiber yarns, and the regeneration mulberry bark nano-fiber anti-bacteria health-care mask is manufactured.

Owner:YANCHENG INST OF IND TECH

Facial mask powder prepared by avicennia marina fruit

ActiveCN103479564APrevent melanin precipitationMild performanceCosmetic preparationsToilet preparationsCuticleAvicennia marina

The invention provides facial mask powder which is used for facial beautifying and prepared by adopting avicennia marina fruit as a main raw material and adding other auxiliary materials. The invention further discloses a method for preparing the facial mask powder prepared by the avicennia marina fruit. The method comprises the steps of cleaning, water removing, peeling, barking, smashing, mixing, sterilizing, packaging and the like. A product of the facial mask powder contains no chemical additive, can be used for nourishing epidermis cells of skins, has a whitening effect, can effectively prevent melanin precipitation, and can be safely and reliably used for a long time.

Owner:WUHU LUYE PHARMA

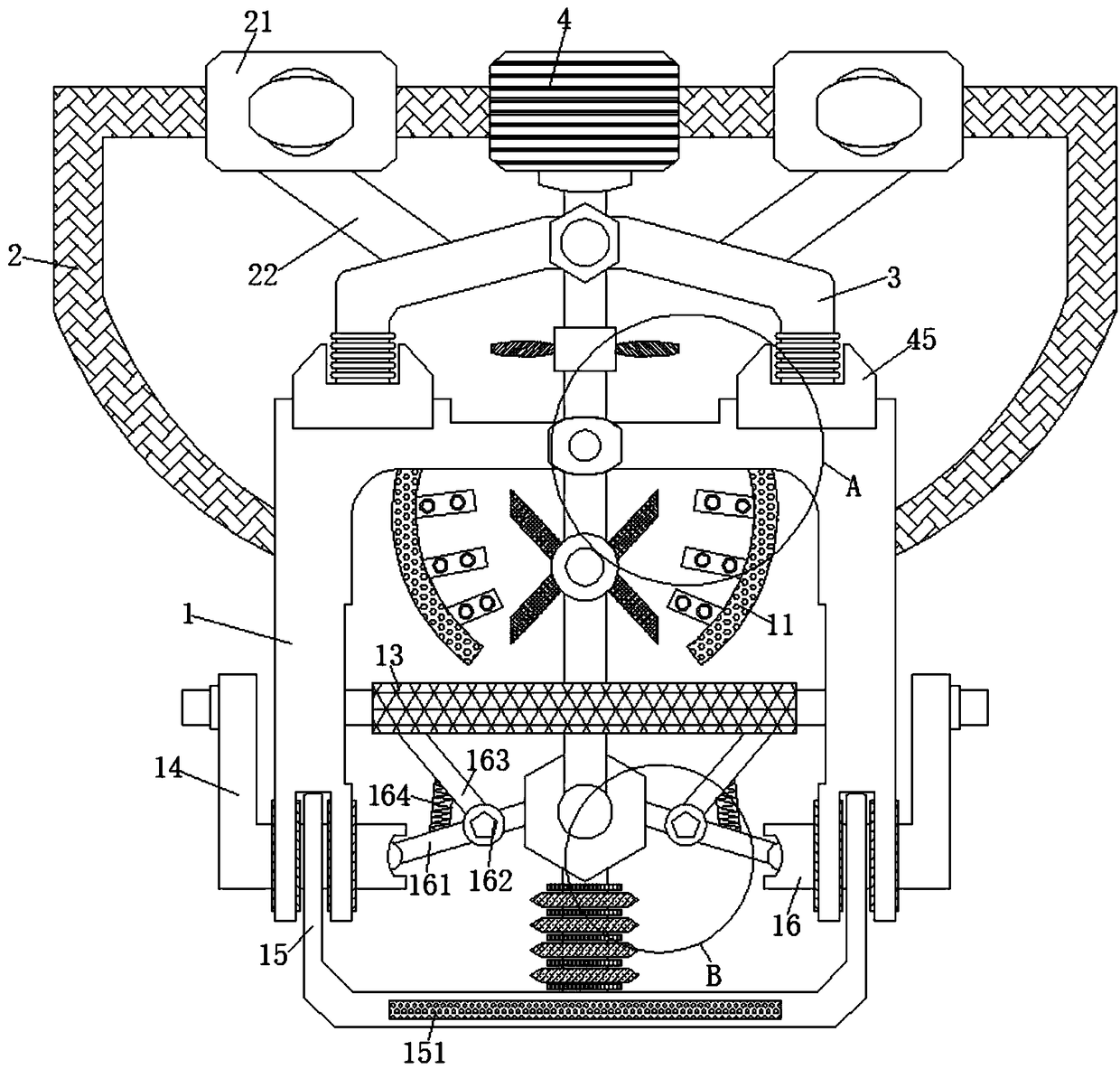

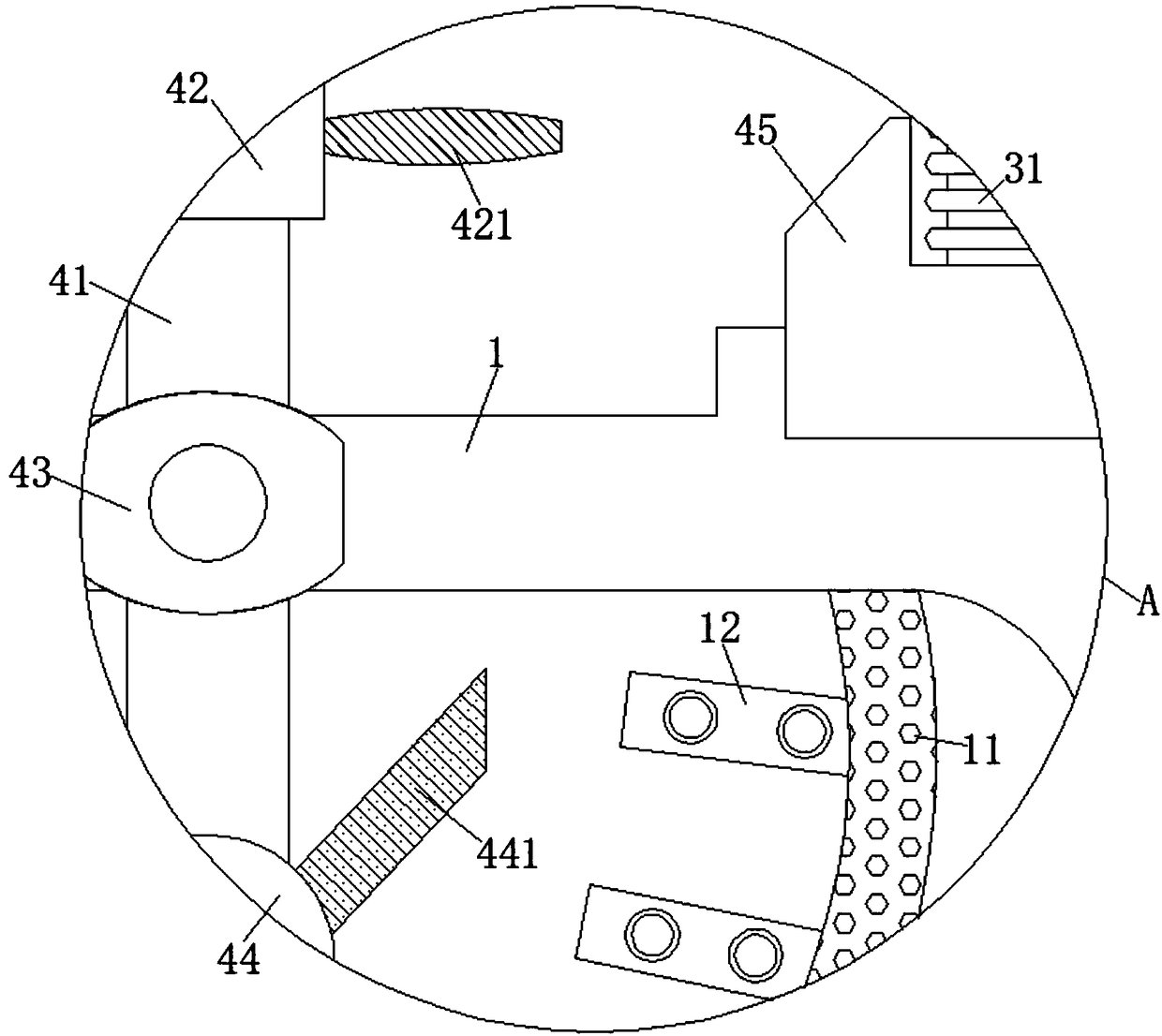

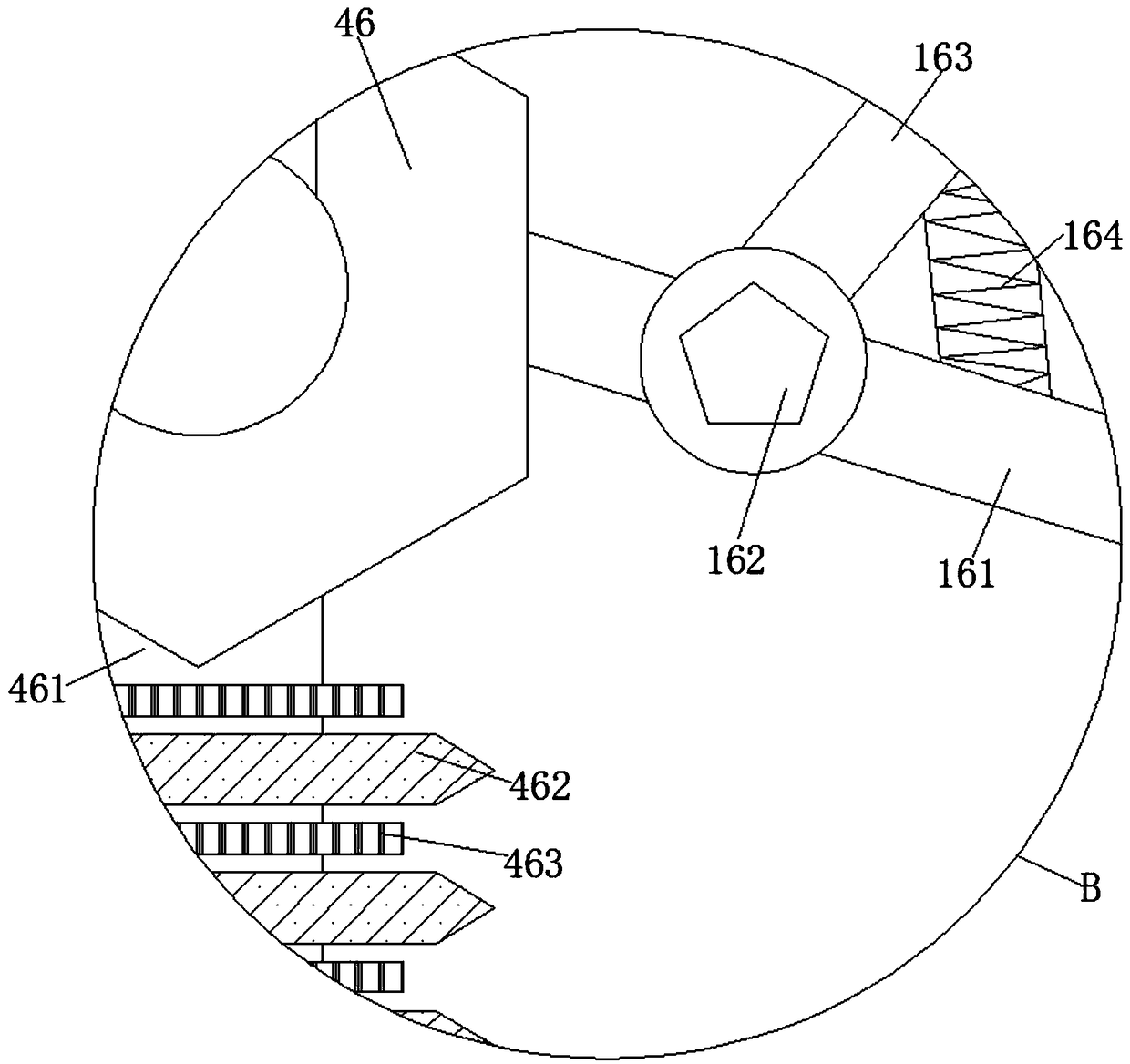

Screening-type micro-processing equipment for peeling of highland barley

InactiveCN108906168AGood peeling effectReduce the burden onGrain huskingSievingEngineeringCentrifugal force

The invention relates to the technical field of food processing, and discloses screening-type micro-processing equipment for peeling of highland barley. The screening-type micro-processing equipment comprises a peeling processing device, the two sides located at the top of the peeling processing device are welded to the two ends of the bottom of a feeding supporting device respectively, putting openings are clamped in inner cavities in the two sides of the top of the feeding supporting device, putting pipes are welded to the bottoms of the two putting openings, one ends of the bottoms of the two putting pipes are inserted into the two sides of the top of a feeding hopper respectively, the two sides of the bottom of the feeding hopper are welded to the inner sides of two fixing clamping bases, the two fixing clamping bases are welded to the two sides of the top of the peeling processing device respectively, and the two sides of the top of a discharging hopper are inserted into inner cavities of the bottoms of the two sides of the peeling processing device. According to the screening-type micro-processing equipment for peeling of the highland barley, a user puts highland barley required to be peeled into the feeding hopper, highland barley skins can be subjected to hull breaking through a hull breaking device, peeled skins can be effectively reduced through generated centrifugalforce, and fall down along with the highland barley, and the peeling effect on the highland barley is thus improved.

Owner:庞成军

Chinese medicine prescription orally taken for curing chronic atrophic gastritis

InactiveCN101181451AGood effectTo achieve the effect of treating both symptoms and root causesDigestive systemPlant ingredientsWestern medicineCodonopsis

The invention discloses a traditional Chinese medicine formula for oral administration for treating chronic atrophic gastritis, which belongs to the field of traditional Chinese medicines. The raw material medicine that forms its active ingredient is by following weight: fried Radix Paeoniae Alba 15 grams, bergamot 10 grams, clove 10 grams, perilla 10 grams, Radix Astragali 6 grams, pinellia 10 grams, Codonopsis 10 grams, woody 6 grams, 10 grams of fried Atractylodes macrocephala, 5 grams of Chuanpu, 5 grams of tangerine peel and 9 grams of citron peel. Soak the above medicines in cold water for 20 minutes, decoct after soaking. After the first boiling, simmer for 30 minutes, and after the second boiling, simmer for 20 minutes. After decocting, mix the two decoctions evenly. The total amount should be 200ml. Take 1 dose a day, in the morning and evening, and take warmly two hours before or after meals. During the course of taking the medicine, stop taking other Chinese and Western medicines. After the above-mentioned medicines are mixed in the present invention, the medicine effects are synergistic, and the effect is remarkable in the treatment process of chronic atrophic gastritis. Reach the effect of treating both symptoms and root causes.

Owner:宋敏 +1

Shaddock peel skin-care hand sanitizer

InactiveCN103550124ATo promote metabolismEffective absorption of nutrientsCosmetic preparationsToilet preparationsChlorhexidine AcetateGlycerol

The invention discloses a shaddock peel skin-care hand sanitizer. The shaddock peel skin-care hand sanitizer is characterized by comprising the following raw materials according to mass percentage: 40%-50% of shaddock peel juice, 2%-6% of citric acid, 2%-6% of amino acid, 5%-8% of de-ionized water, 3%-7% of chlorhexidine acetate, 0.17%-0.55% of glycerol, 0.3%-0.5% of vitamin E, 2%-6% of honey and 1%-3% of essences. The shaddock peel skin-care hand sanitizer has the advantages that cuticles on a skin surface can be softened and cleaned so as to accelerate the metabolism of the skin; the nutrients of shaddock peels can be effectively absorbed, and thus the skin of hands can be white, tender and moist.

Owner:张言军

Chamomile smoothing toner

InactiveCN102961291AMeet various needsBalance secretionCosmetic preparationsToilet preparationsEssence oilGeranium

The invention belongs to the field of skin care products, and in particular relates to chamomile smoothing toner. The chamomile smoothing toner consists of purified water, a humectant, nutritional agents and EDTA (ethylene diamine tetraacetic acid)-2Na, wherein the humectant is hyaluronic acid, the nutritional agent is a mixture of chamomile essential oil, rose essential oil and geranium essential oil in a ratio of 6:3:1. The smoothing toner provided by the invention contains chamomile, rose and geranium essential oil, wherein the chamomile can be used for improving sensitive skin and improving water-shortage suncrack and peeling skin, the rose can nourish skin, and the geranium has deep purifying and convergence effect and the efficacy of balancing sebum secretion, so that the smoothing toner provided by the invention can meet various requirements of skin only utilizing various plant extracts and extremely less chemical substances.

Owner:DALIAN CHUANGDA TECH TRADE MARKET

Production technology of canned tuna

The invention relates to the technical field of can production and especially relates to a production technology of canned tuna. The production technology of canned tuna comprises the following steps: step one, steaming and dewatering; step two, showering and cooling; step three, removing skin and bone; step four, cutting the cooked tuna into pieces and packaging in a can. The production technology may also comprise a step A of raw-material treating before the step one; the production technology may also comprise a step five of vacuum-sealing and a step six of sterilizing and cooling after the step four. According to the production technology of canned tuna, water is showered onto the steamed tuna body obtained in the step one for a certain time period, so that the purpose of cooling the steamed fish body is achieved; therefore, the skin of the fish body is separated from the fish-meat by instantaneous temperature difference, so that the surface-skin of the fish body can be easily removed in the step three of removing skin and bone and the fish-skin removal cleanliness is good.

Owner:广东鹰金钱海宝食品有限公司

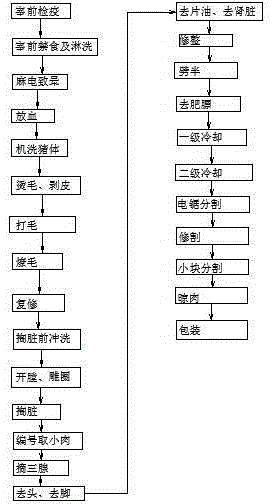

Processing method of chilled meat

InactiveCN105341123ASimple stepsEasy to operateMeat/fish preservation by freezing/coolingSlaughterhouse arrangementsEngineeringQuarantine

The invention relates to the technical field of a processing method of edible meat, in particular to a processing method of the chilled meat. The processing method specially comprises the following steps of quarantine inspection before slaughter, fasting before slaughter, drip washing, tingling through electricity for stunning, bloodletting, machine washing of a pig body, scalding for removing hair, peeling skins, dehairing, burning hair, cutting and repair, flushing before removing internal organs, disembowelling, cutting of around anus, removal of internal organs, numbering, taking out of a small meat block, removal of thyroid, adrenal and lymph node lesions, beheading, removal of feet, removal of oil and the kidney, trimming, cutting of the pig body into two parts, removal of prime condition, first-stage cooling, second-stage cooling and the like. According to the processing method, any additives are not added in the processing course, so that the edible safety of products is guaranteed; besides, the juice flowing rate is greatly reduced, and can be controlled to 1.8% or below; secondly, vacuum packing is adopted, so that the quality guarantee period can achieve 30 days or above, and the refreshing time can achieve 20 days or above; finally, quarantine inspection is performed before slaughter, and the second-stage cooling is performed, so that not only is the cooling rate effectively increased, the energy consumption is reduced, but also the product quality is greatly improved.

Owner:汉寿县华乐农业发展有限公司

Dry pulp segment product of fresh Siraitia grosvenorii fruits and processing technology thereof

InactiveCN103385463AKeep moreSweet tasteFood processingFood preparationSiraitia Grosvenorii FruitFruit Flavor

The invention discloses a peeling and baking process of fresh fructus momordicae. The peeling and baking process comprises the following steps of: naturally saccharifying the picked fresh fructus momordicae; peeling off the saccharified fructus momordicae, taking seed and flesh out, dividing the seed and flesh into a plurality of segments and flatly placing on a baking screen; placing the baking screen in a baking room or an electrical baking box for baking; baking at the temperature of 60-70 DEG C for 6-7 hours to dry the surface skin layer; ripening at the temperature of 70-80 DEG C for 5-6 hours; and baking at the temperature of 55-60 DEG C for 10-12 hours. The peeling and baking process has the advantages that the fruit flesh baked by the process is tawny, the baking time is shortened by 60 percent compared with that of the conventional drying process, the structure is compact, an extremely attractive appearance is achieved, the time and the energy are saved, the nutrient content loss is low, and the original fruit flavor is kept.

Owner:龙胜各族自治县和平罗汉果农民专业合作社

Peeling device for garlic processing

InactiveCN111789274AAvoid uneven peelingPrevent incompleteGas current separationFood treatmentElectric machineryStructural engineering

The invention discloses a peeling device for garlic processing. The device comprises a box body and a net cage, a motor is arranged on the outer wall of the bottom of the box body, the outer wall of one end of an output shaft of the motor is fixedly connected to the bottom outer wall of the net cage, a fixing rod is arranged on the inner wall of the top of the box body, a friction block wraps theouter wall of the circumference of the fixing rod, the cross section of the friction block is wavy, corrugations are gradually enlarged from top to bottom, a through hole is formed in the outer wall of the top of the box body, a corrugated pipe is inserted into the through hole, and a feeding hopper and a discharging hopper are inserted into the inner walls of the two ends of the corrugated pipe respectively. The net cage is an irregular net cage, so that centrifugal force can be generated while the net cage rotates, garlic in the net cage makes full contact with tooth blocks, garlic skin canbe cut off, meanwhile, the cross sections of the tooth blocks are arc, the radian of the tooth blocks ranges from 20 degrees to 30 degrees, and the situation that garlic is incomplete due to the factthat the tooth blocks cut the garlic too deep can be effectively prevented.

Owner:萧县华野农业科技有限公司

Compound tea seed powder foot bath agent and preparation method thereof

InactiveCN105999010AImprove skin qualityNo side effectsAntisepticsPharmaceutical delivery mechanismSide effectMugwort

The invention relates to a compound tea seed powder foot bath agent, made from tea seed powder, Alpinia japonica, bamboo leaf, mugwort, Radix Sophorae Flavescentis, Cortex Pseudolaricis, Cortex Dictamni, radish, garlic, pomelo peel and Xanthoxylum pepper; a preparation method comprises: taking the Alpinia japonica, mugwort, bamboo leaf, Radix Sophorae Flavescentis, Cortex Pseudolaricis, Cortex Dictamni, radish leaf, garlic, pomelo peel and Xanthoxylum pepper, crushing with a traditional Chinese medicine crusher to obtain powder less than 40-60 mesh, stirring well, adding parts by weight of the tea seed powder into a container, and hermetically storing at normal temperature. Eleven Chinese herbs are added and compounded in the formulation, the unique pharmacological actions of the Chinese herbs are used to provide the effects of removing damp and stopping itching, drying dampness and killing insects, cleaning skin, killing foot germs, removing foot odor, removing peeled skin and assisting in improving foot skin, the agent is natural and nonirritating, free of side effect and chemical residue, and suitable for long-term usage.

Owner:陈琼燕

Automatic holboellia latifolia skin-and-flesh separation device

ActiveCN110710695AHigh speedImprove efficiencyFruit stoningVegetable peelingControl systemHolboellia latifolia

The invention discloses an automatic holboellia latifolia skin-and-flesh separation device, and belongs to the field of agricultural machinery. A flesh advancement device, a shielding disc, an end-cutting device and a flesh scraping device are sequentially installed on the ground from front to back, a fixing device for fixing holboellia latifolia to be processed is arranged on the upper part of the flesh advancement device, an information acquisition module in a control system is installed on the upper part of the fixing device, a driver in the control system is connected with a stepping motorin the flesh scraping device, the flesh advancement device and the end-cutting device are separately arranged outside the front end face and the rear end face of the shielding disc which is vertically arranged, and a suction cup for fastening is arranged at the lower end of the shielding disc. The one-time skin-and-flesh separation of holboellia latifolia is achieved, high speed and high efficiency are achieved, fruit seeds and fruits are separated in a rotating mode together to make up for the lack of mechanical peeling of the whole holboellia latifolia, time is greatly saved, and clean separation, high speed, high efficiency and simple and convenient operation are achieved.

Owner:CHINA AGRI UNIV

Corn cob skinning machine

InactiveCN103535156AImprove removal efficiencyAvoid easy cloggingHarvestersThreshersAgricultural engineeringStructural engineering

A corn cob skinning machine comprises a feeding hopper, rubber twisting rollers, a vibration sieve, a transmission mechanism and a machine frame. The corn cob skinning machine is characterized in that the two parallel rubber twisting rollers are connected to the machine frame in a rotary mode, two parallel rib rollers are arranged between the two rubber twisting rollers, a spiral rib and a rubber twisting block are arranged on each rib roller, the rotating directions of the spiral ribs on the two rib rollers are opposite, roller shafts of the two rib rollers are connected with a transmission gear and are meshed with each other, and a suction ventilator is assembled above the tail portion of the vibration sieve. The corn cob skinning machine has the advantages that the structure is simplified, corn skin removing efficiency is high, blocking does not happen easily, and machining cost is reduced.

Owner:曹福成

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com