Water chestnut peeling machine

A peeling machine and horseshoe technology, which is applied in the peeling of vegetables or fruits, food processing, food science, etc., can solve the problems of poor peeling effect, low peeling rate, waste of pulp, etc., and improve the cutting of horseshoe High production efficiency, high peeling efficiency, and less pulp loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

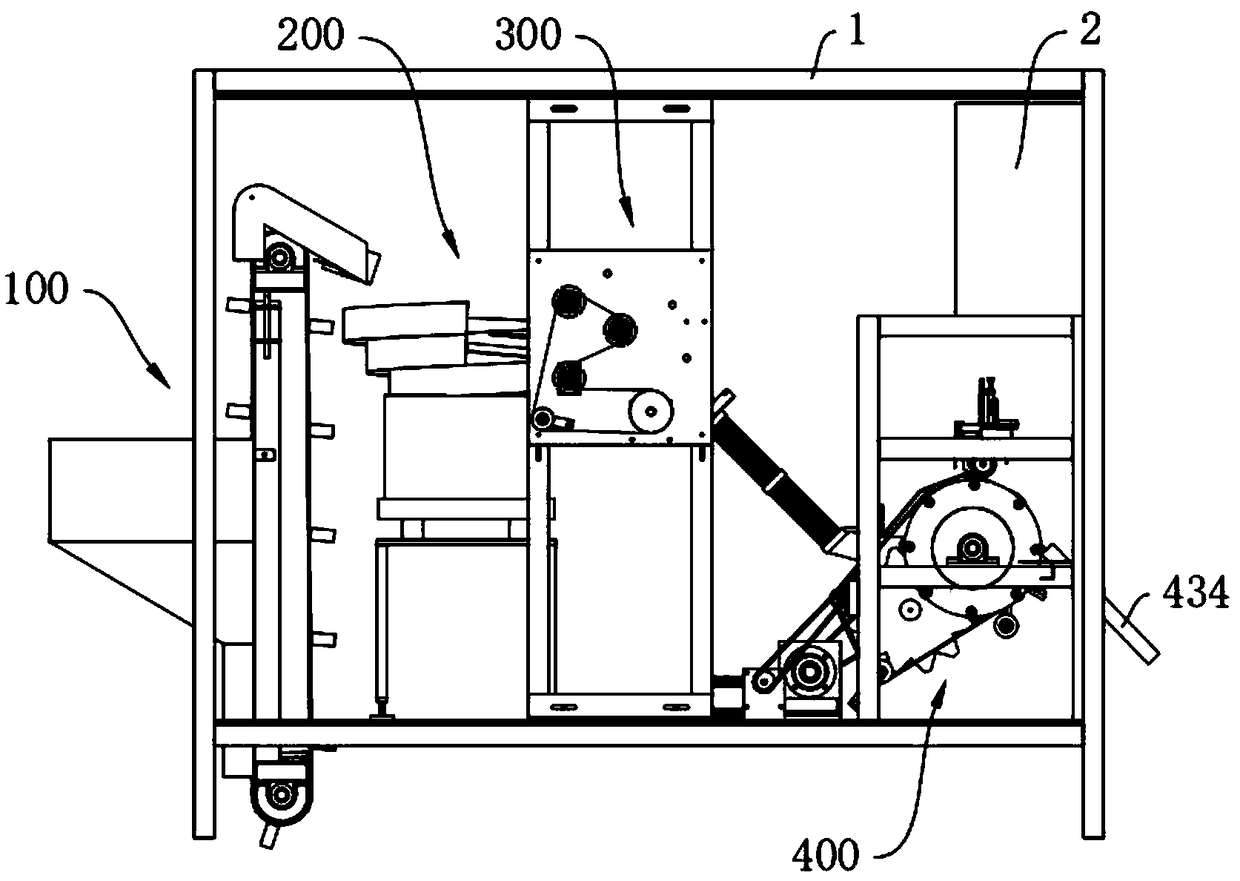

[0057] see figure 1 , a horseshoe peeling machine, including a frame 1 welded by stainless steel pipes, in the frame 1, a feeding device 100, a vibrating discharge device 200, a two-plane peeling device 300, an outer edge Peeling device 400 and control box 2.

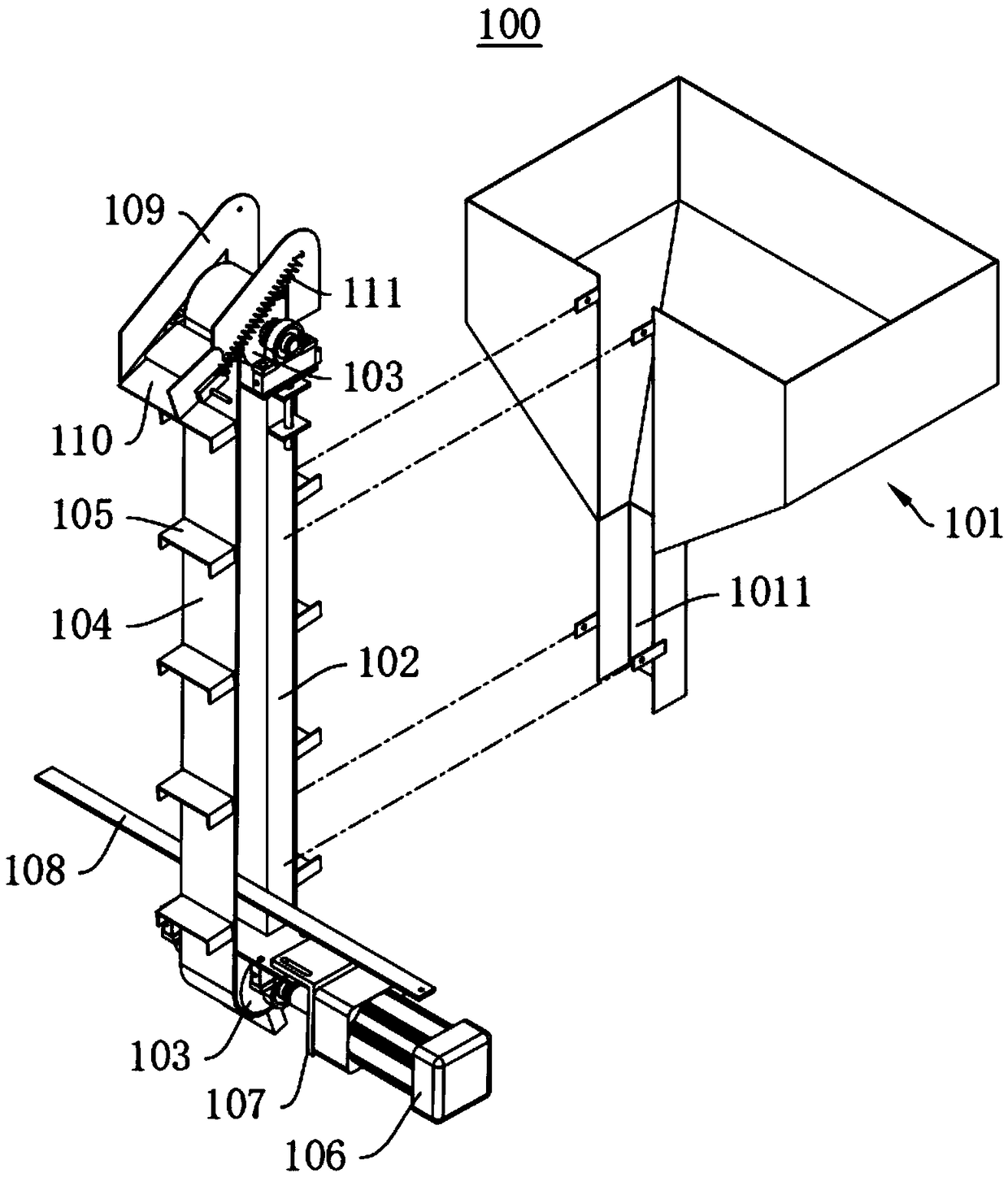

[0058] see figure 2 , the feeding device 100 includes a lifting bucket 101, the rear side of the lifting bucket 101 has a gap 1011, the gap 1011 is closed and installed with a belt fixing bracket 102, the upper and lower ends of the belt fixing bracket 102 are respectively equipped with pulleys 103, between the two pulleys 103 There is a conveyor belt 104 connected between them, the belt fixing bracket 102 is located inside the conveyor belt 104, the part of the conveyor belt 104 is located in the lifting bucket 101, and a plurality of small lifting buckets 105 are evenly installed on the outer ring of the conveyor belt 104, and the small lifting The loading area of the bucket 105 is consistent with the size of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com