Induction-type fruit peeling machine

A peeling machine and inductive technology, applied in the peeling of vegetables or fruits, fruit core removal devices, applications, etc., can solve the problem of no way to control the peeling thickness, low quality and low stability of peeling and other problems, to achieve the effect of improving the practicality and peeling quality, and improving the peeling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

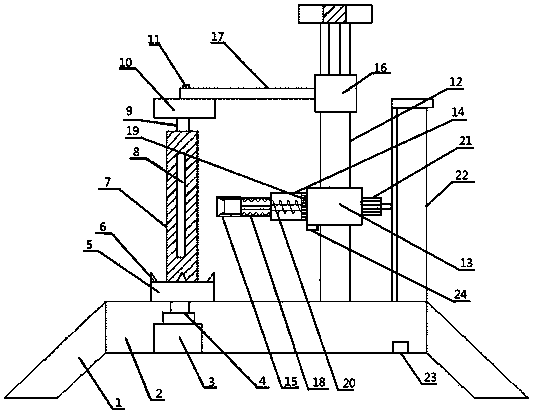

[0018] An inductive fruit peeling machine, comprising a leg 1, a base 2, a motor 3, a telescopic rod 4, a supporting plate 5, a shelling tube 7, a connecting rod 9, a turntable 10, a rotating shaft 11, a peeling knife 15 and a support rod 12;

[0019] The damping legs 1 are welded on both sides of the base 2, and the base 2 is provided with a motor 3; The motor 3 is connected by transmission; the center of the surface on the supporting plate 5 is welded with a nuclear tube 7; 7 is provided with a U-shaped hole 8; the top of the denuclearization tube 7 is threadedly connected with a connecting rod 9, and the connecting rod 9 is fixedly connected with the turntable 10 through the rotating shaft 11; the base 2 is located on one side of the supporting plate 5 A pillar is welded; the support rod 12 is provided with a sleeve 16; the sleeve 16 is connected to the turntable 10 through a connecting cross bar 17;

[0020] Described pole 12 is provided with movable casing 13, and movab...

Embodiment 2

[0022] An inductive fruit peeling machine, comprising a leg 1, a base 2, a motor 3, a telescopic rod 4, a supporting plate 5, a shelling tube 7, a connecting rod 9, a turntable 10, a rotating shaft 11, a peeling knife 15 and a support rod 12;

[0023] The damping legs 1 are welded on both sides of the base 2, and the base 2 is provided with a motor 3; The motor 3 is connected by transmission; the center of the surface on the supporting plate 5 is welded with a nuclear tube 7; 7 is provided with a U-shaped hole 8; the top of the denuclearization tube 7 is threadedly connected with a connecting rod 9, and the connecting rod 9 is fixedly connected with the turntable 10 through the rotating shaft 11; the base 2 is located on one side of the supporting plate 5 A pillar is welded; the support rod 12 is provided with a sleeve 16; the sleeve 16 is connected to the turntable 10 through a connecting cross bar 17;

[0024] Described pole 12 is provided with movable casing 13, and movab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com