Patents

Literature

32 results about "Peeling action" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Embolic filtering devices

Owner:ABBOTT CARDIOVASCULAR

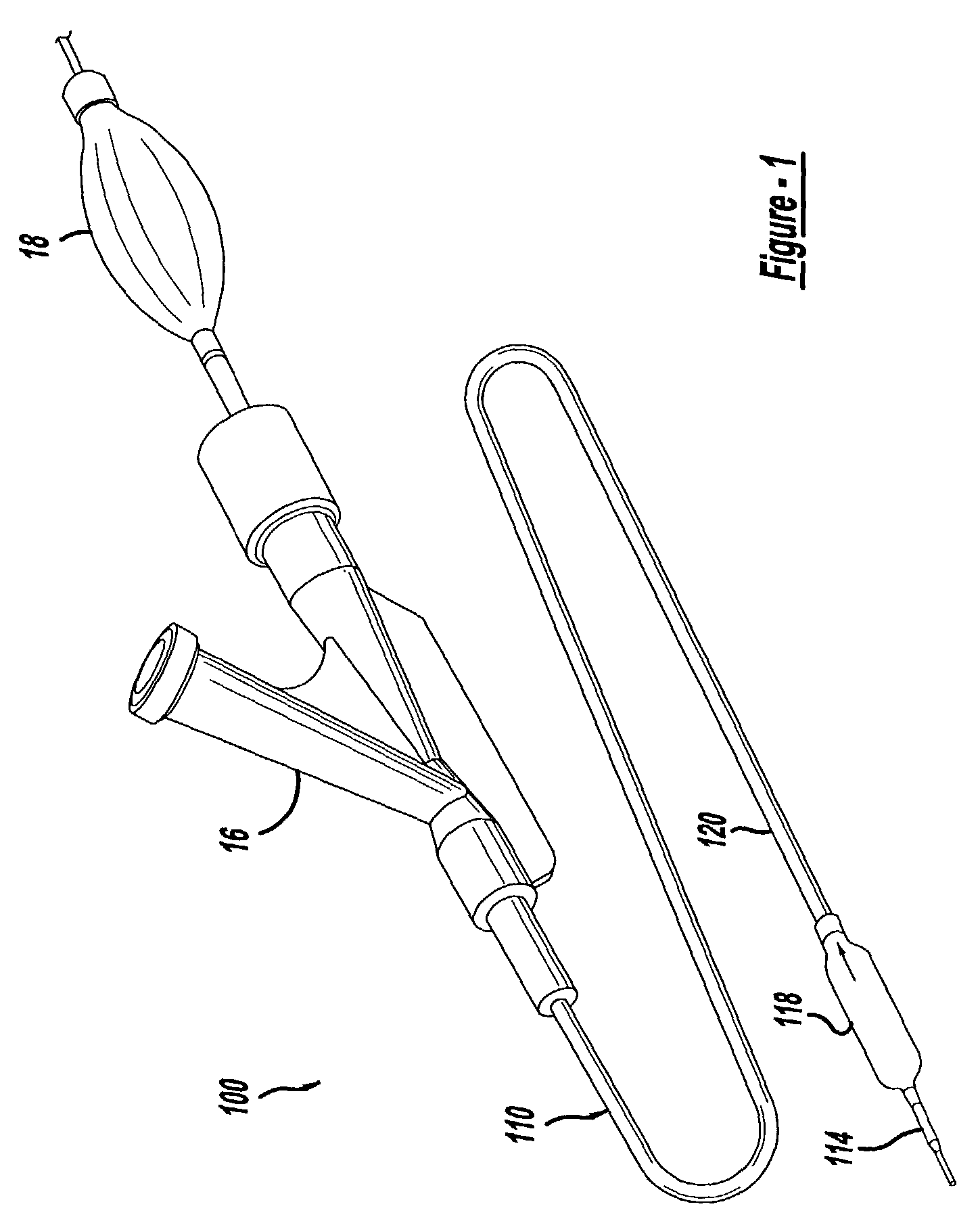

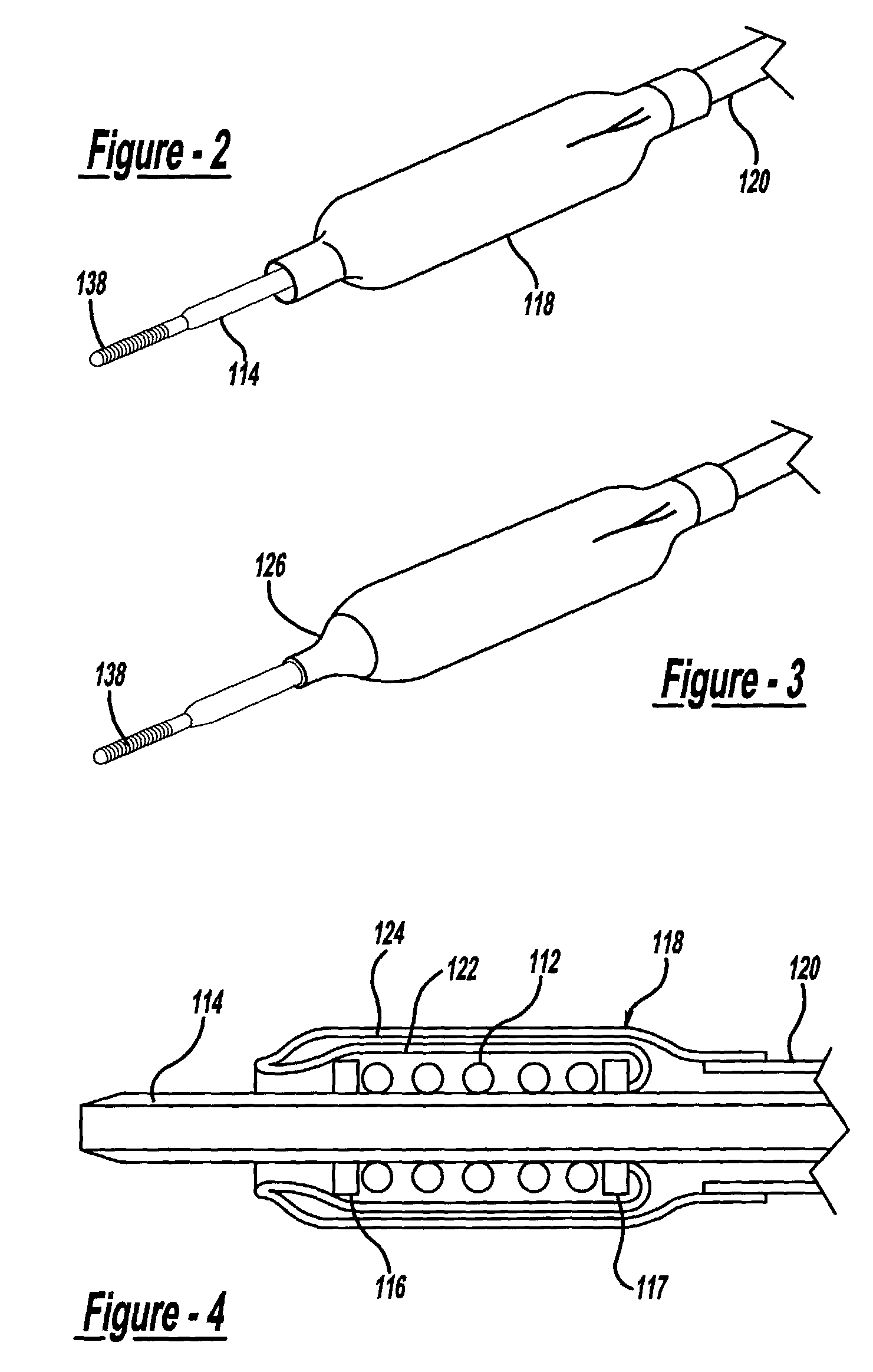

Everting balloon stent delivery system having tapered leading edge

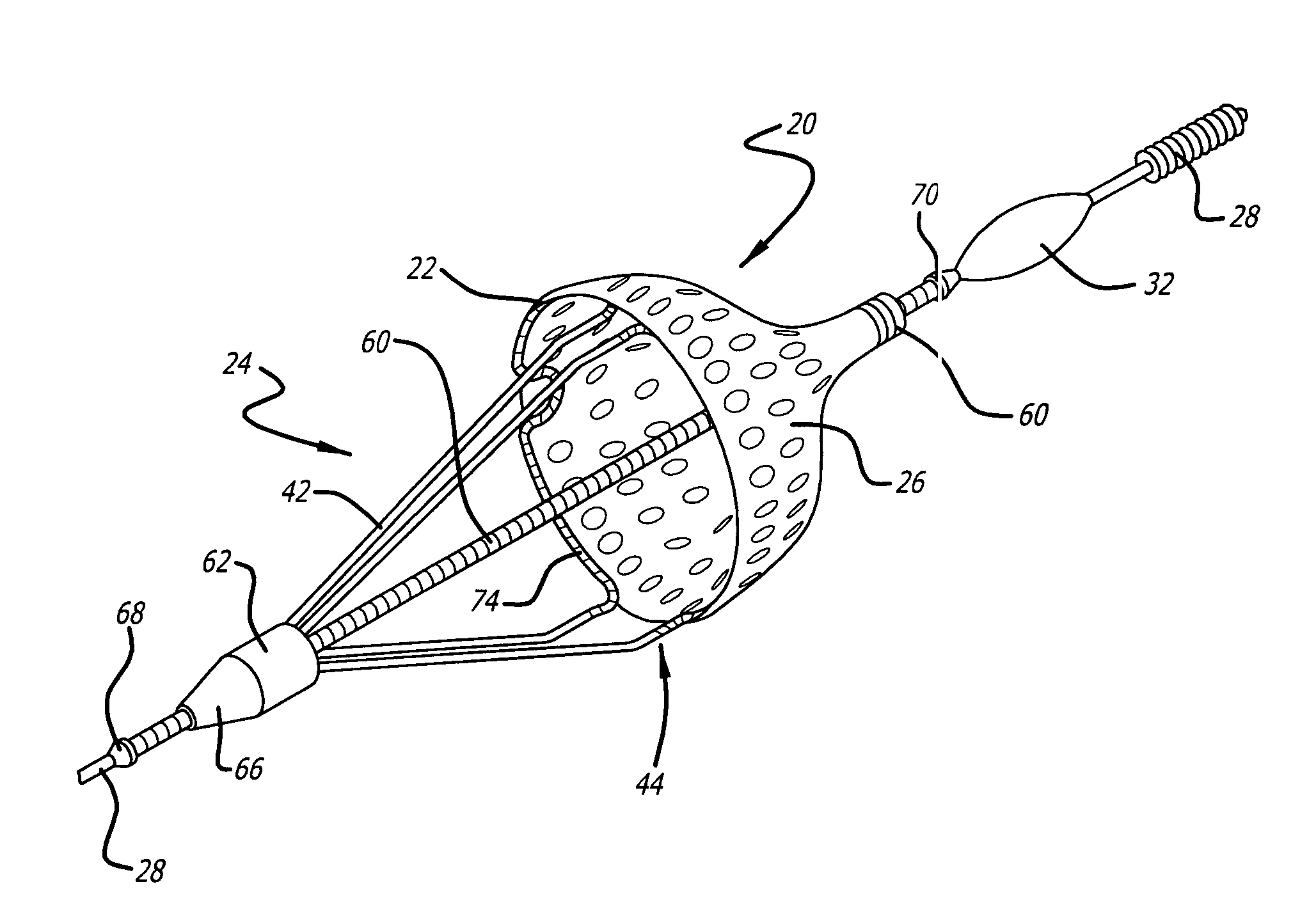

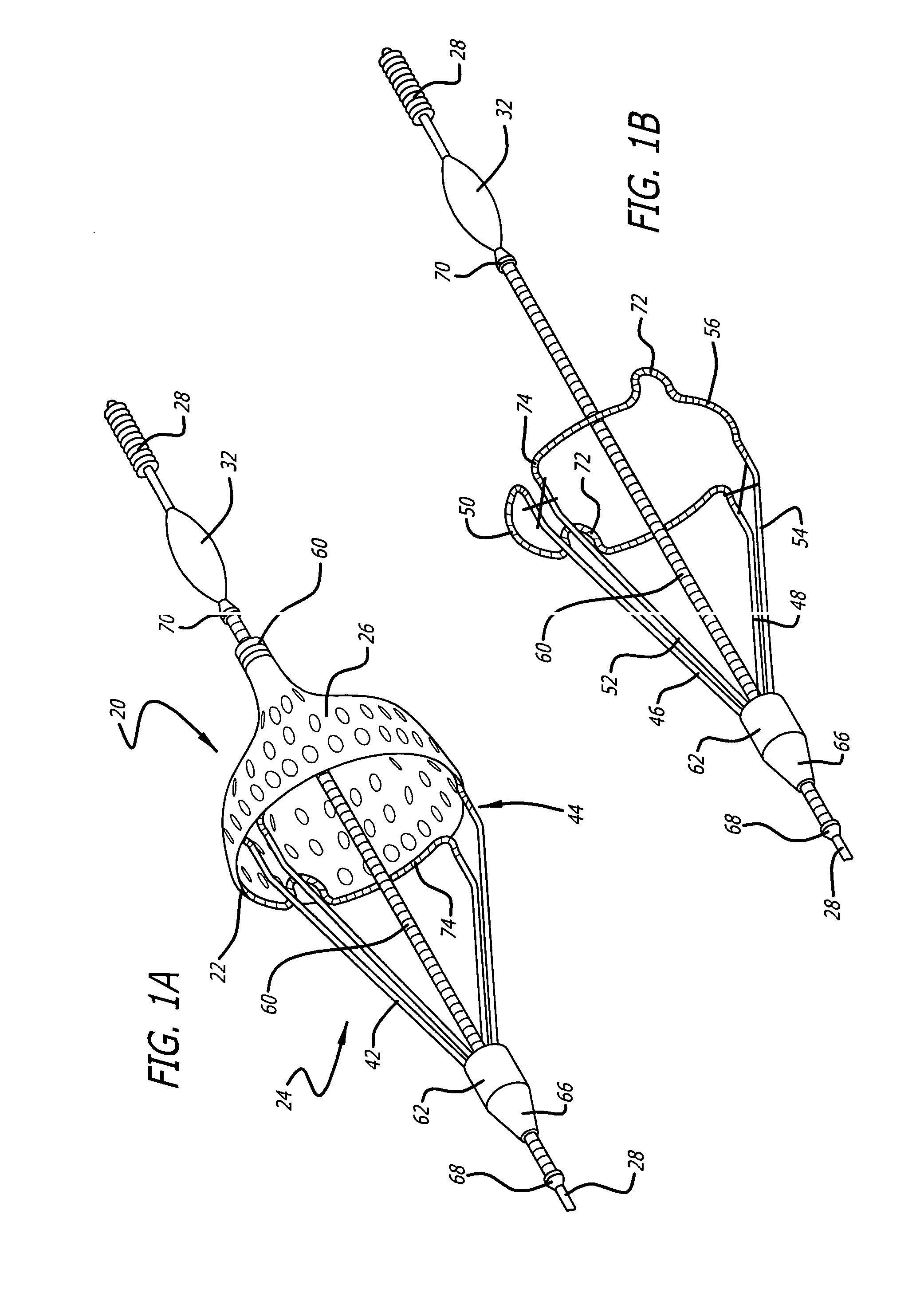

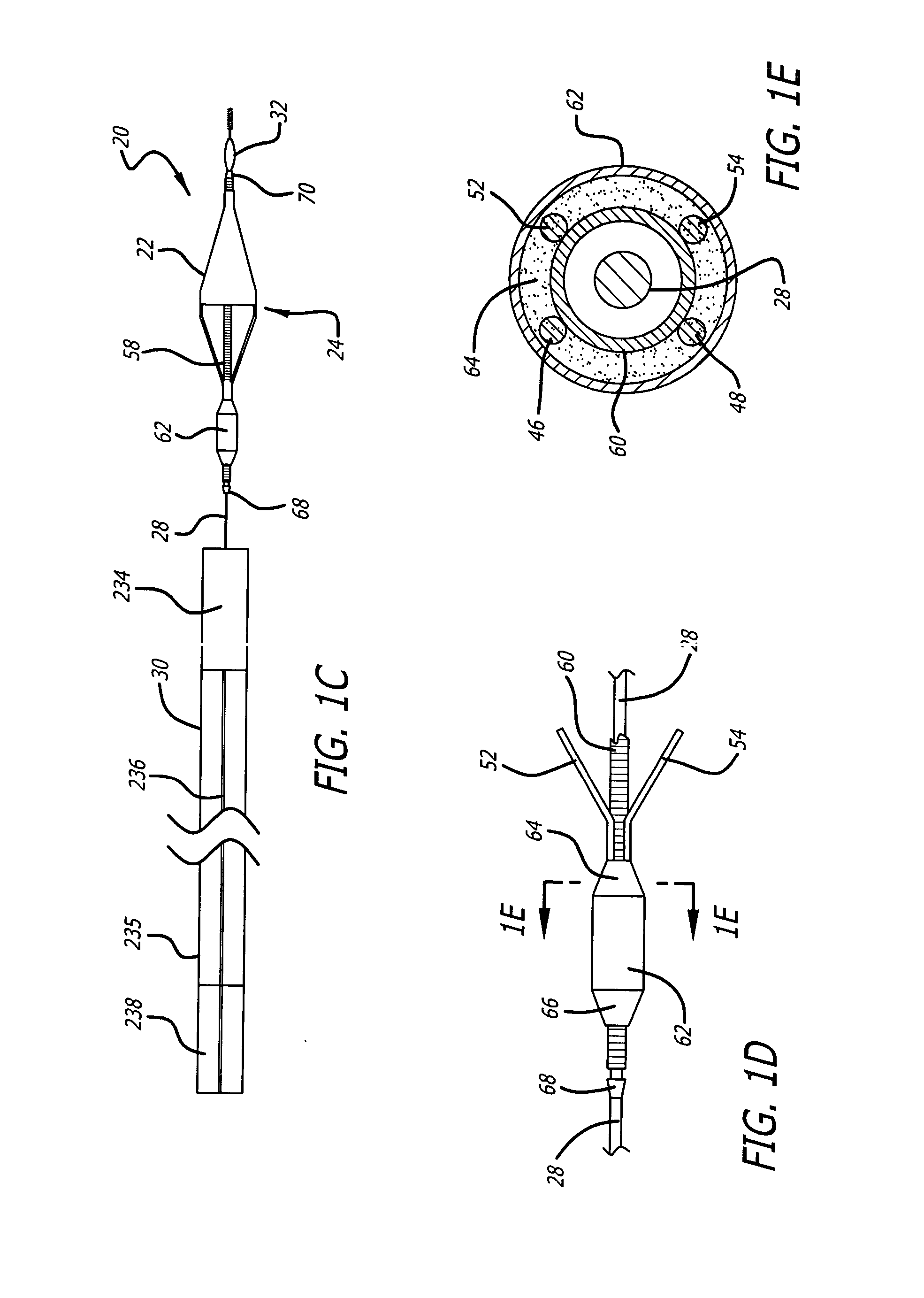

A stent delivery catheter includes at least an inner and outer body, and a specially shaped balloon affixed near one end of both of the inner and outer bodies. At least the outer body is tubular, and the space between the outer and inner bodies defines an inflation lumen for inflating and deflating the balloon. The balloon is designed to surround and hold a compressed self-expanding stent in a small initial size. An inner portion of the cylindrical balloon extends from where it is affixed to the inner body of the catheter shaft at a point proximal to the stent to a distal leading edge at a point distal to the stent. At this leading edge, the balloon is folded back upon itself, and an outer portion of the balloon extends proximally from the leading edge to a point proximal of the stent where it is affixed to the outer body of the catheter shaft. When the outer body is retracted in the proximal direction, the balloon progressively peels back or everts, to progressively release the stent. This peeling action minimizes any friction that may exist between the stent and balloon during stent deployment. The leading distal folded edge of the balloon, both inner and outer portions, are tapered inward. This inner and outer tapering of the balloon portions tends to protect the leading edge of the stent, provides for easier advancement of the catheter system along the desired body passageway for treatment, and minimizes friction as the balloon is retracted or peeled back upon itself.

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

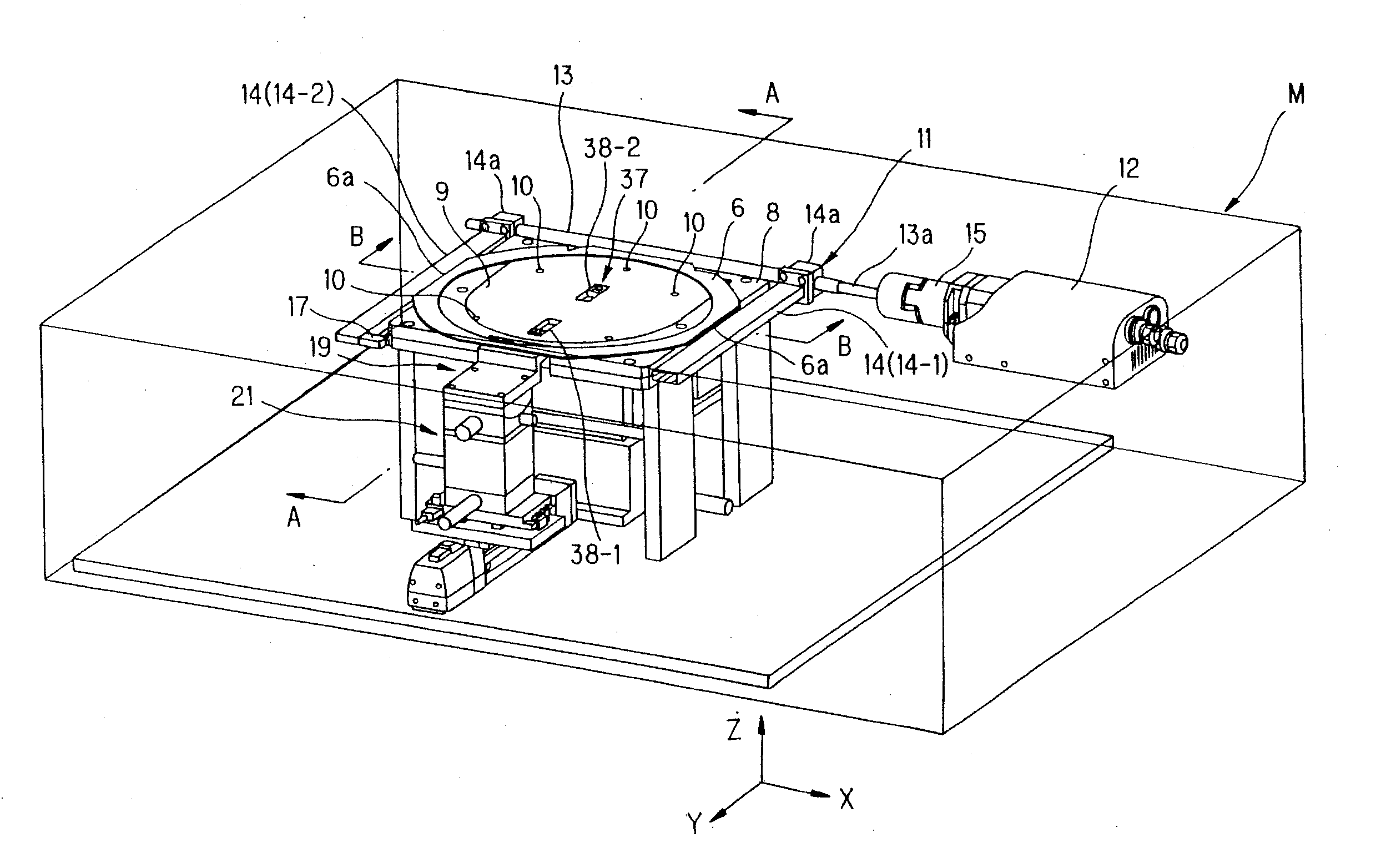

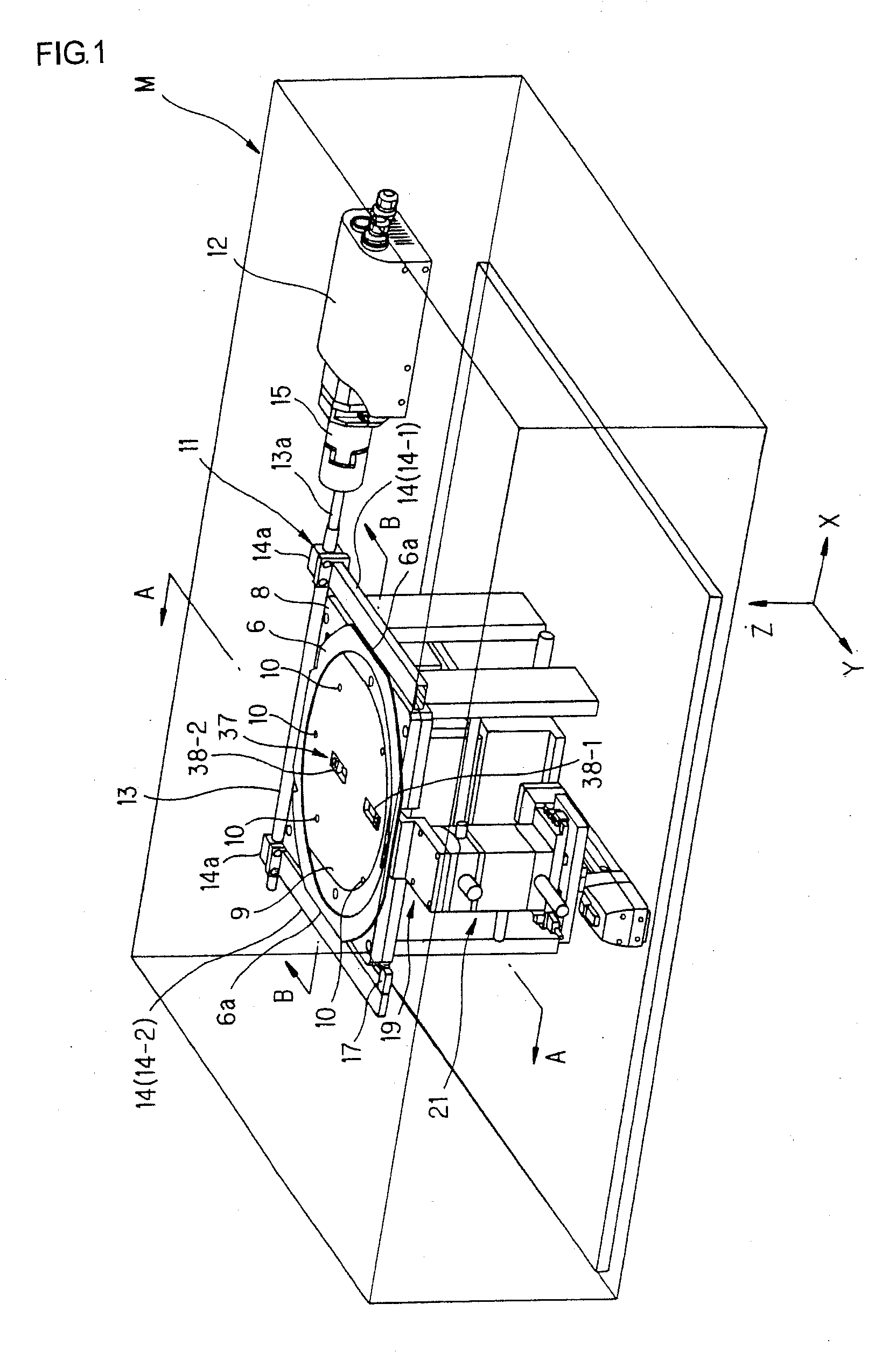

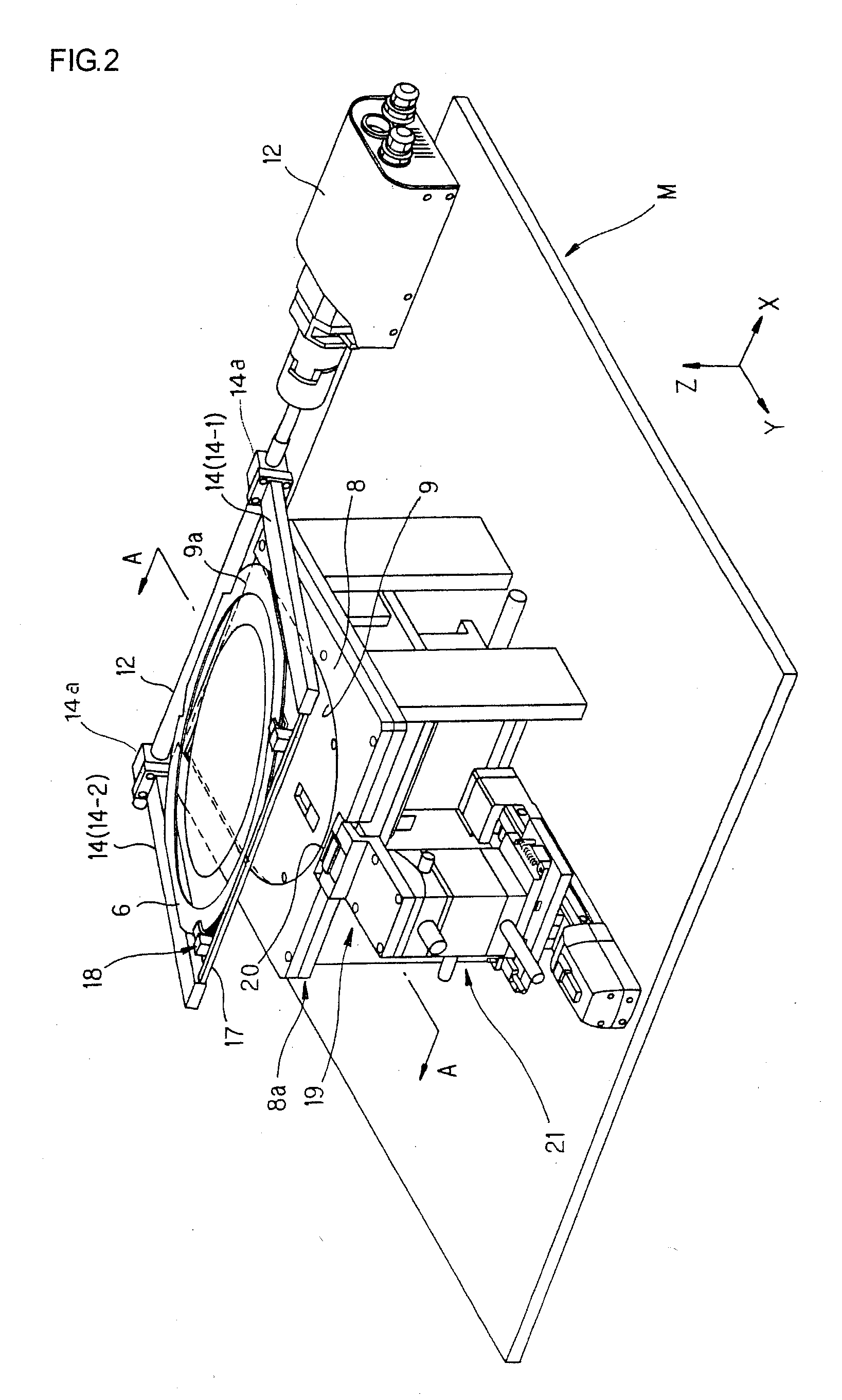

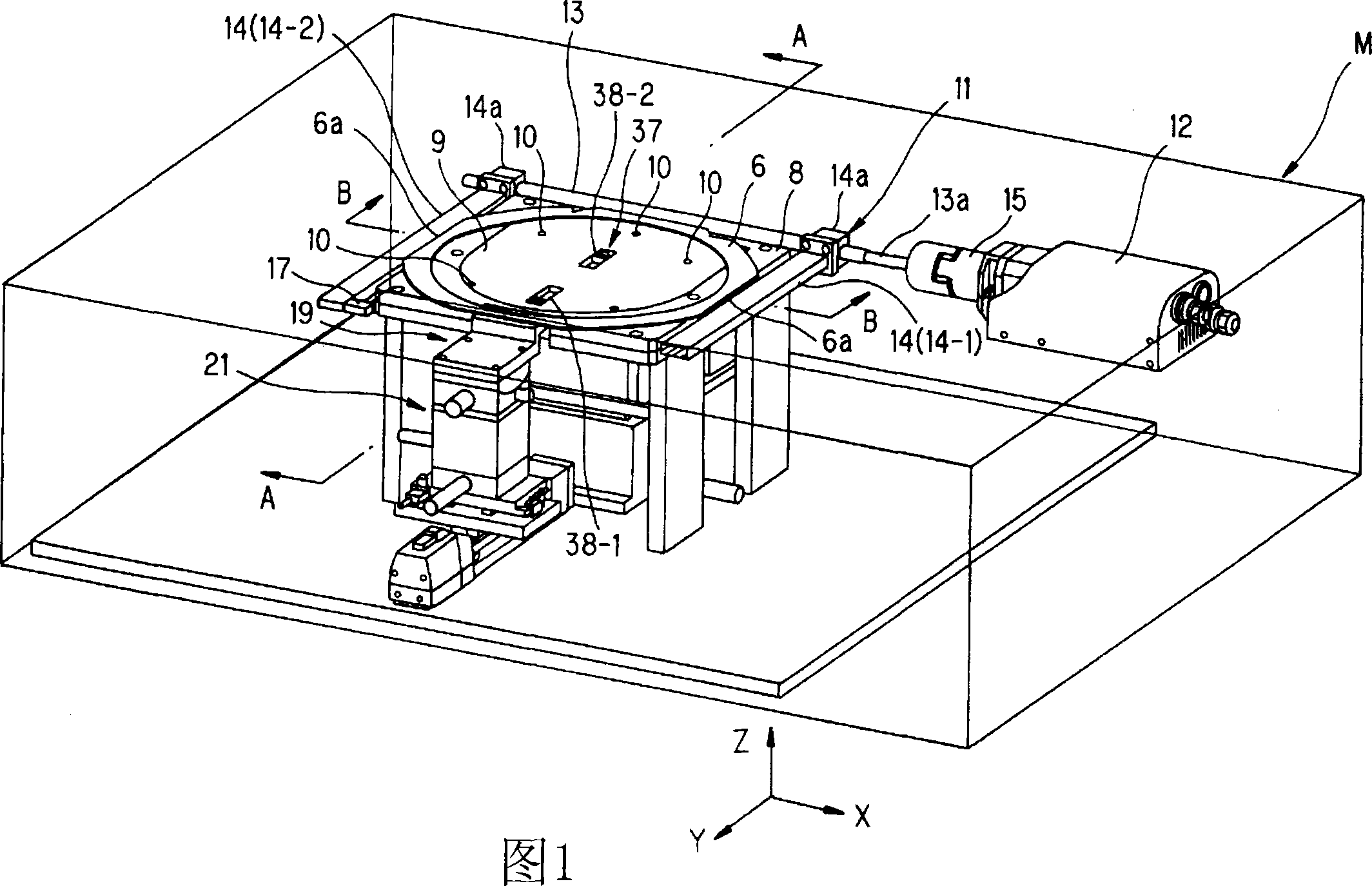

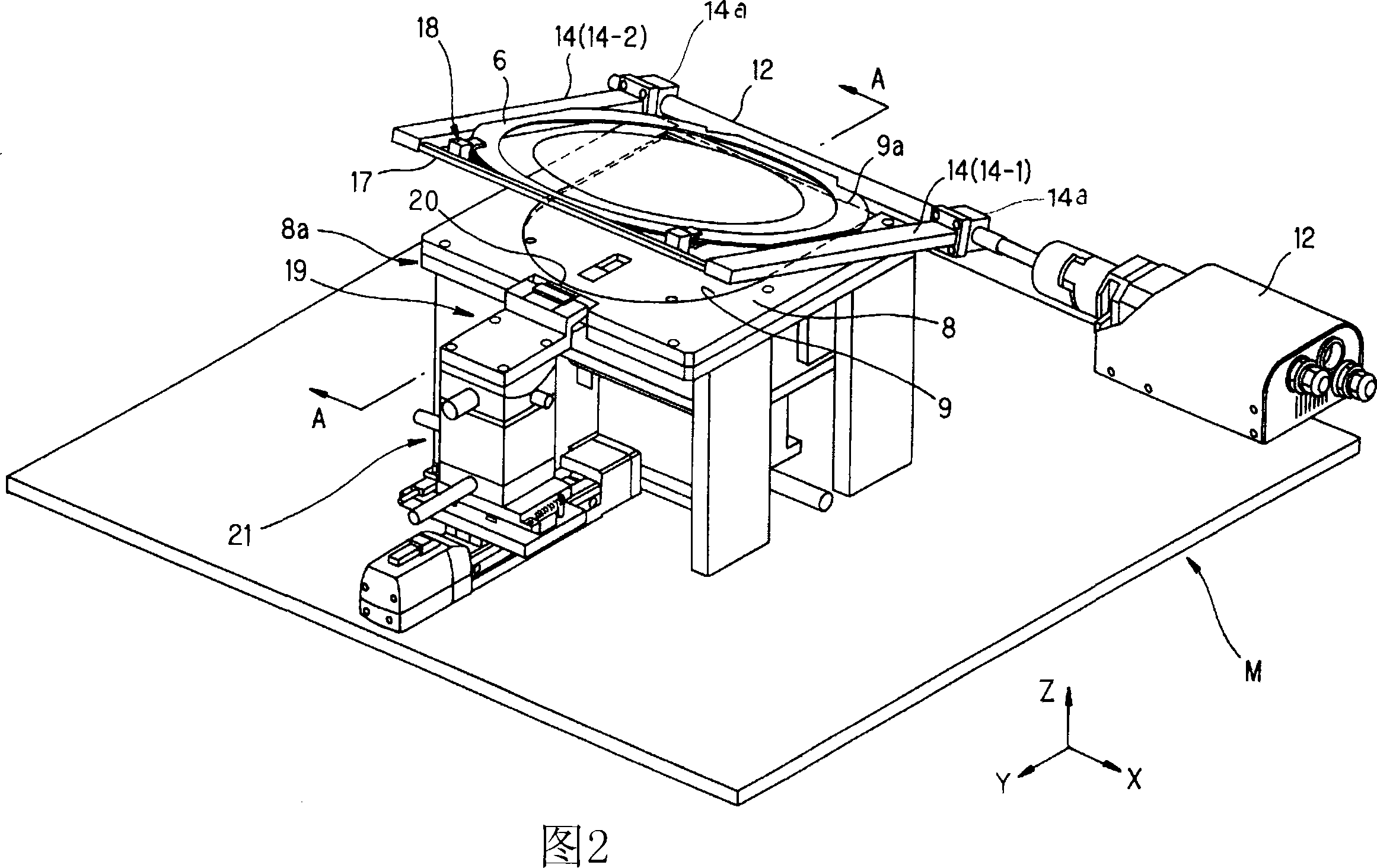

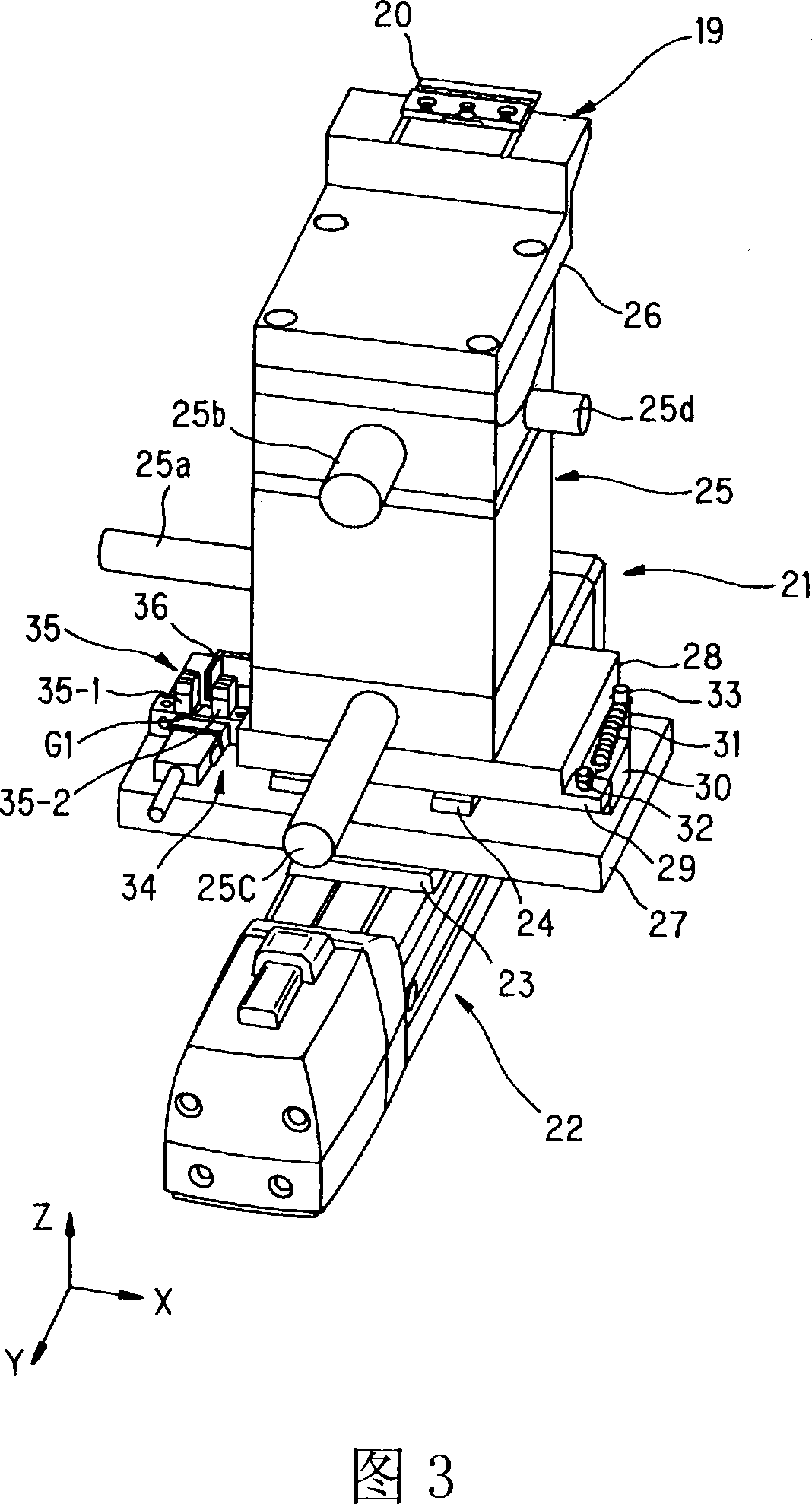

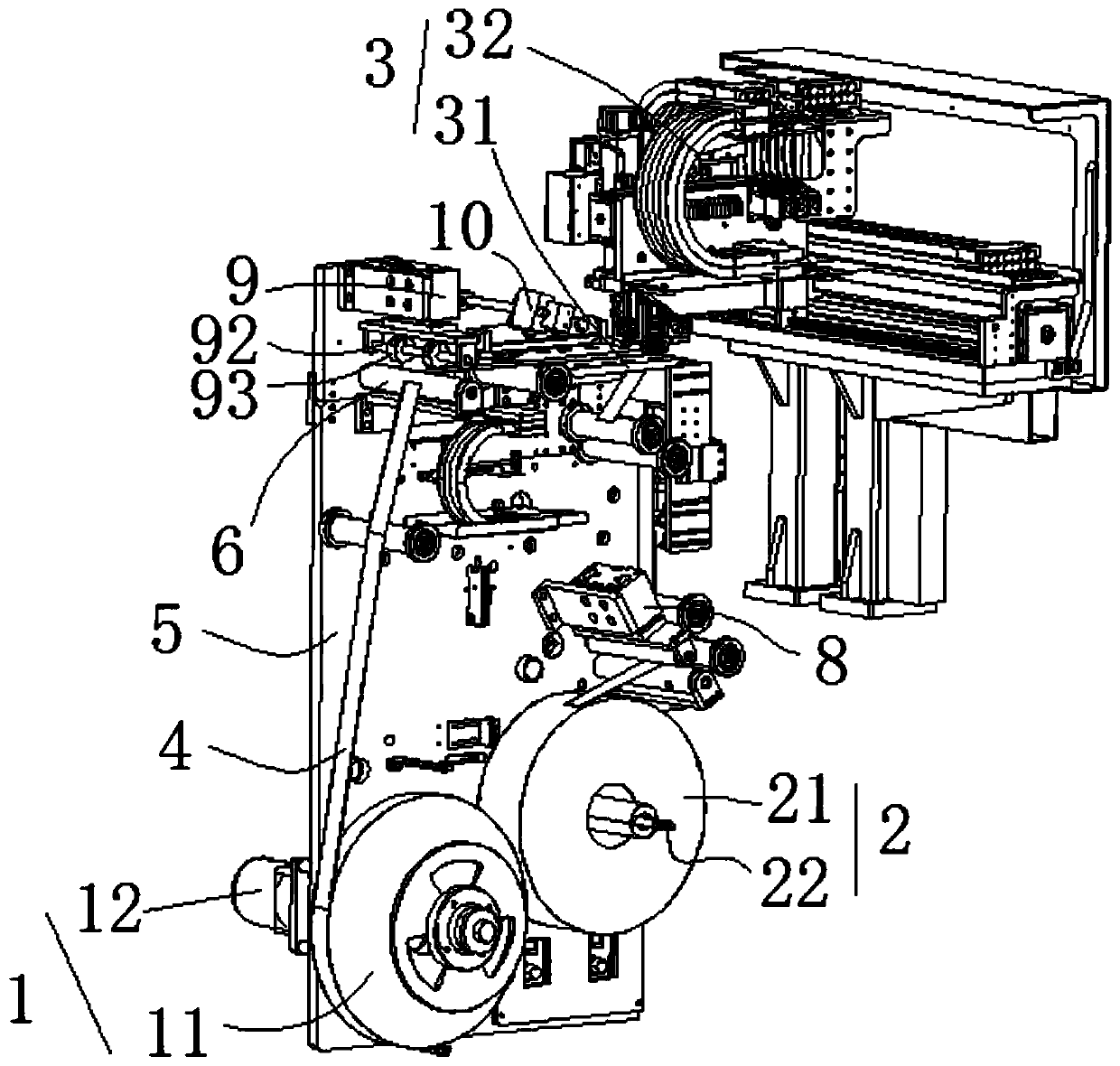

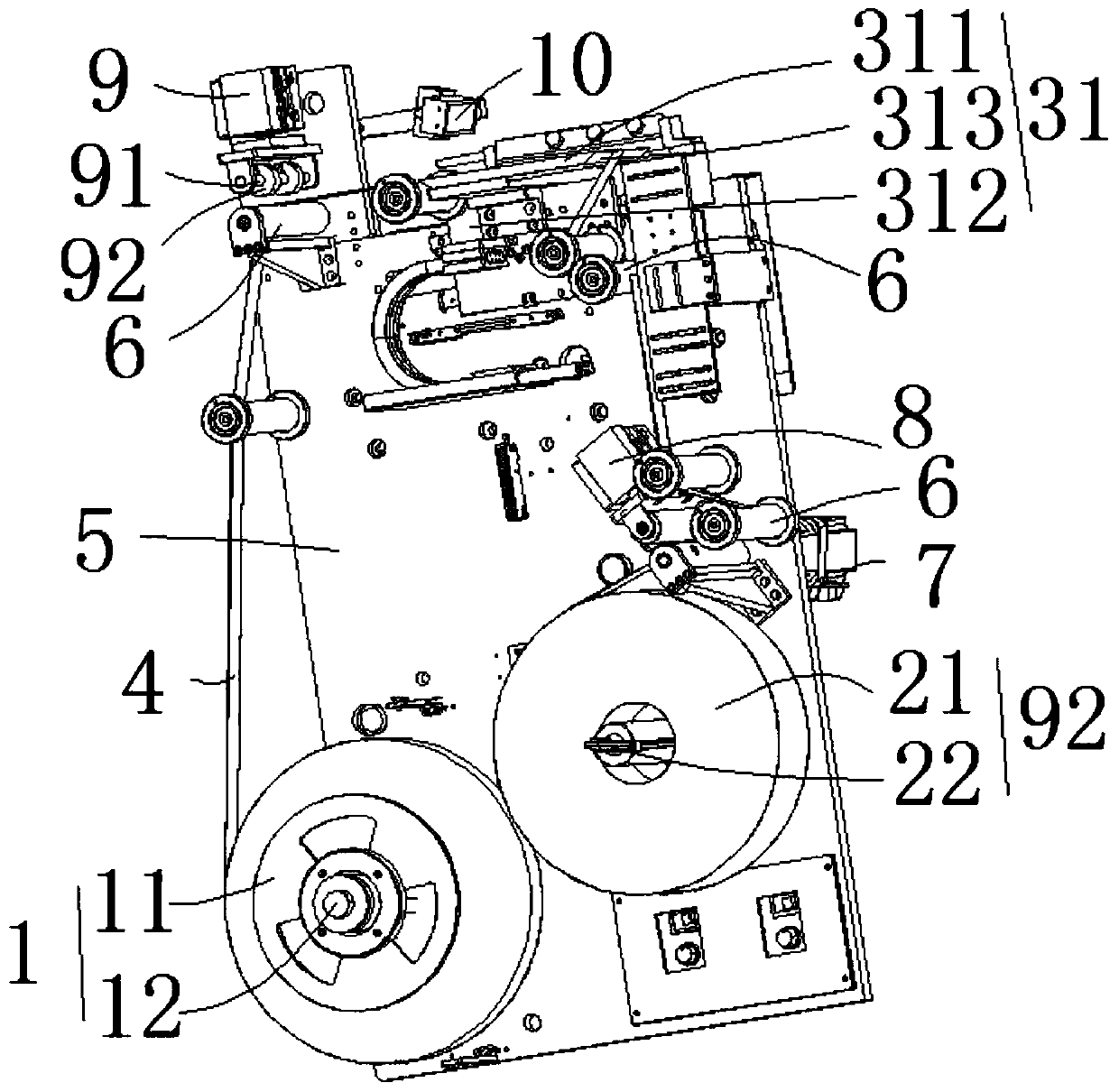

Transferring Apparatus for Brittle Member

InactiveUS20070295458A1Relieve stressLikely can be brokenLamination ancillary operationsSynthetic resin layered productsRotational axisEngineering

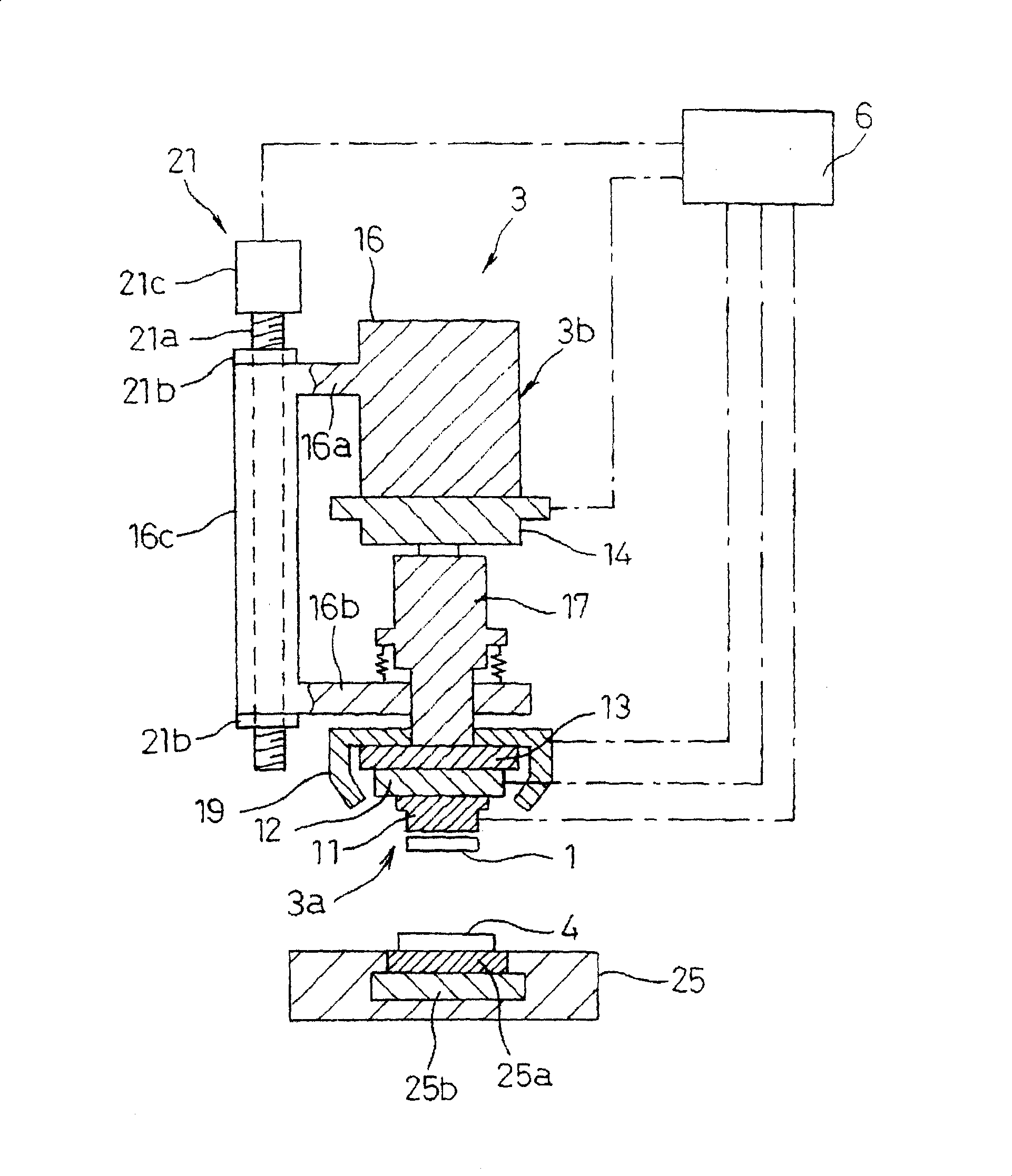

A transferring apparatus for a brittle member capable of peeling a hard member from the brittle member without applying a stress more than required to the brittle member and effectively preventing the brittle member from being damaged by erroneous peeling is provided. When the hard member is peeled off from a stuck structure formed by sticking the brittle member on the top surface of the hard member through a double-sided adhesive sheet to transfer the brittle member onto the adhesive sheet, the adhesive sheet is stuck on the brittle member of the stuck structure to form it integrally with a frame, the hard member side is positioned and fixed onto a table (8), and the frame (6) is raised diagonally upward with respect to the surface of the table with a predetermined torque by a torque control motor (12) with a rotary shaft (13) as a fulcrum. The hard member is peeled off from the brittle member with a force for raising the frame, namely, with the predetermined torque. When the hard member is peeled off, the peeling action is confirmed by peeling confirmation means (37) formed by two reflection type sensors (38-1, 38-2).

Owner:LINTEC CORP

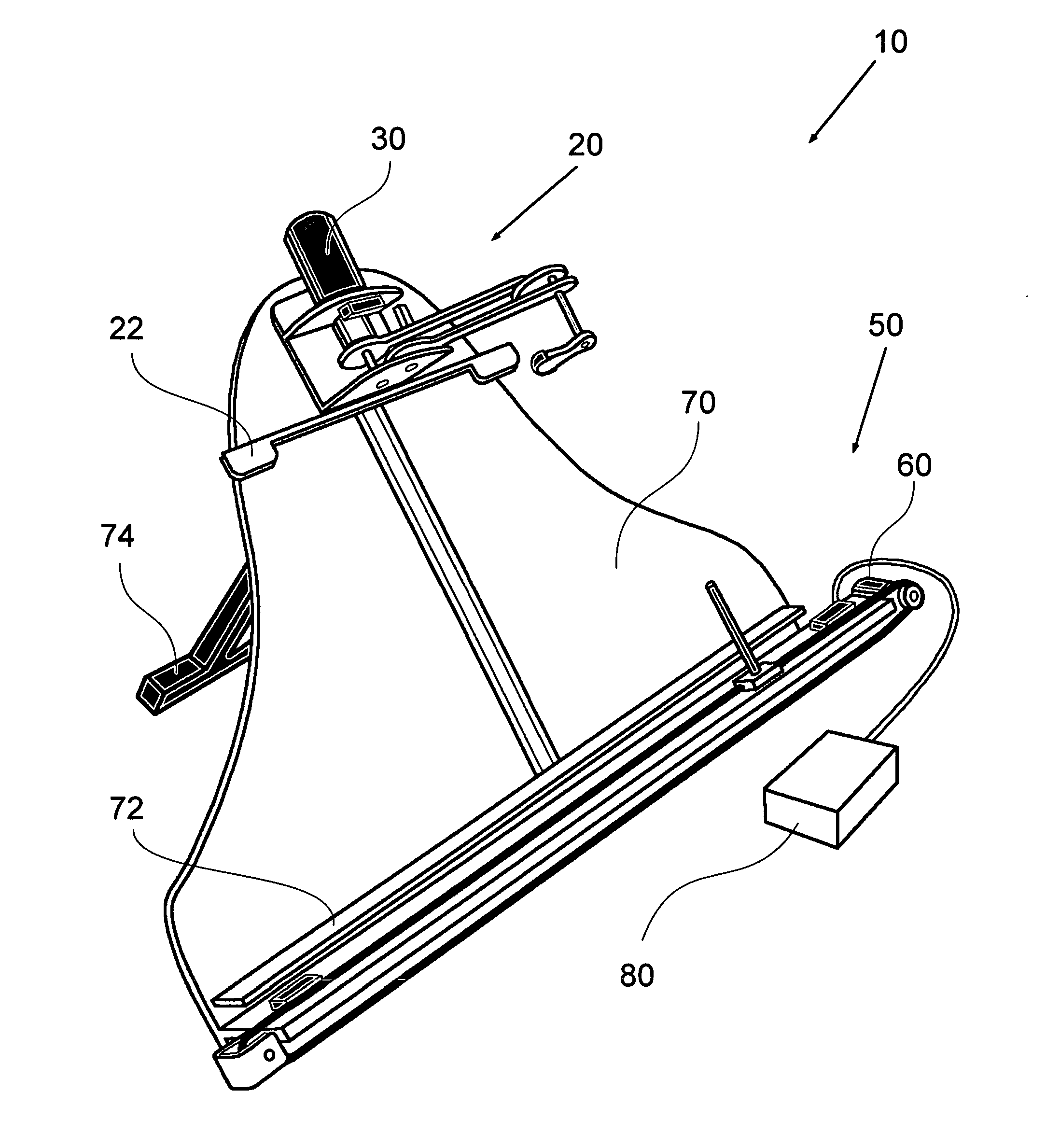

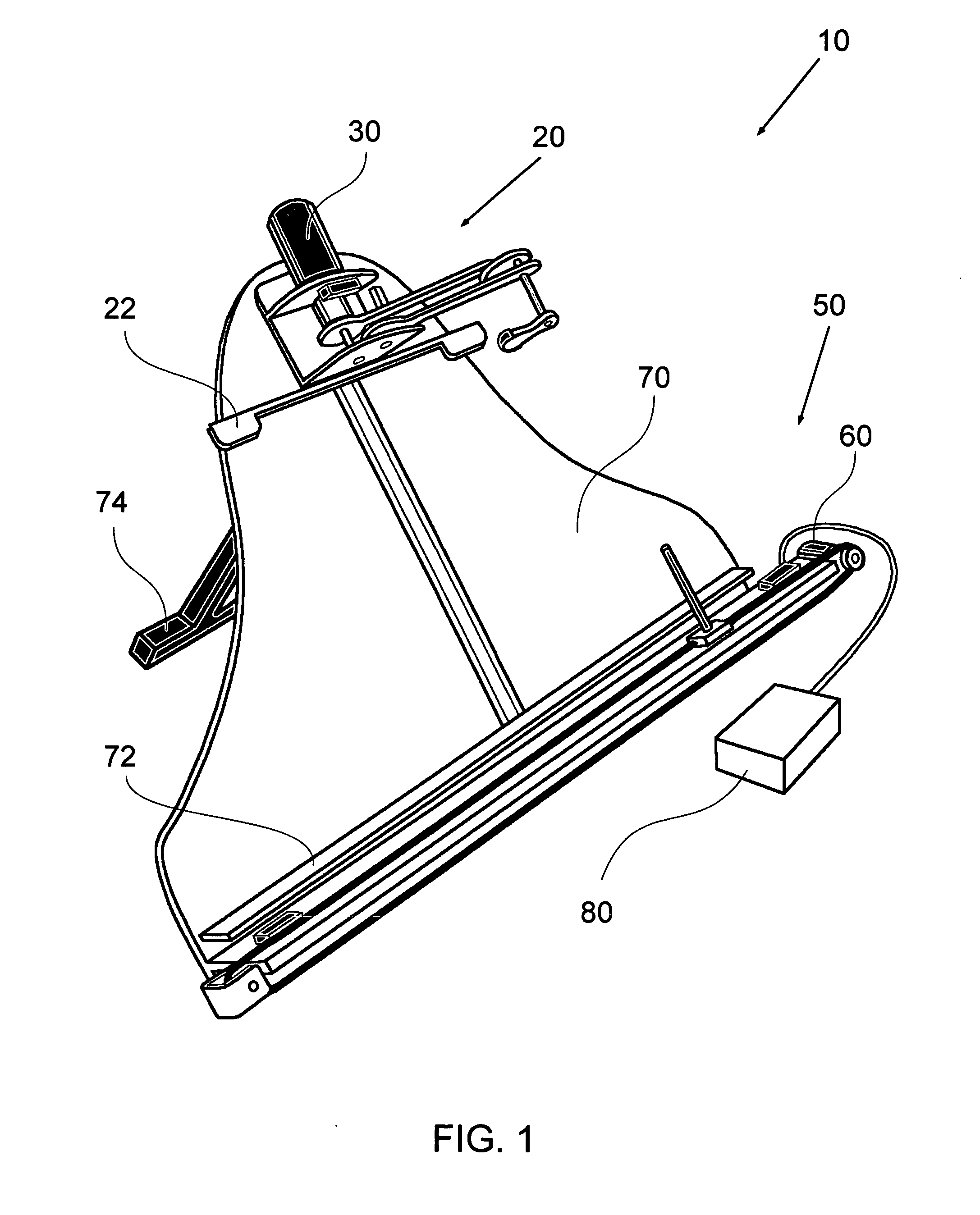

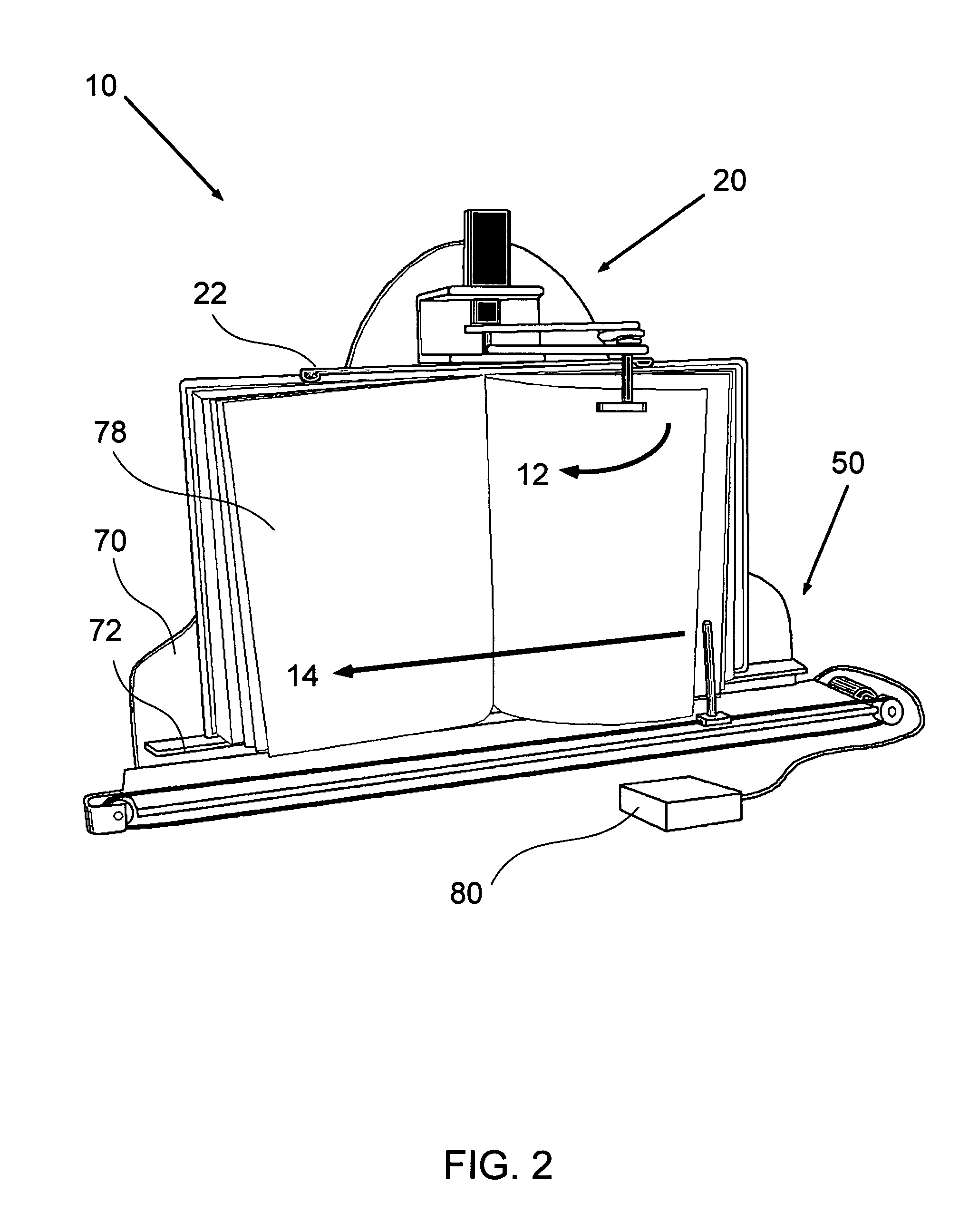

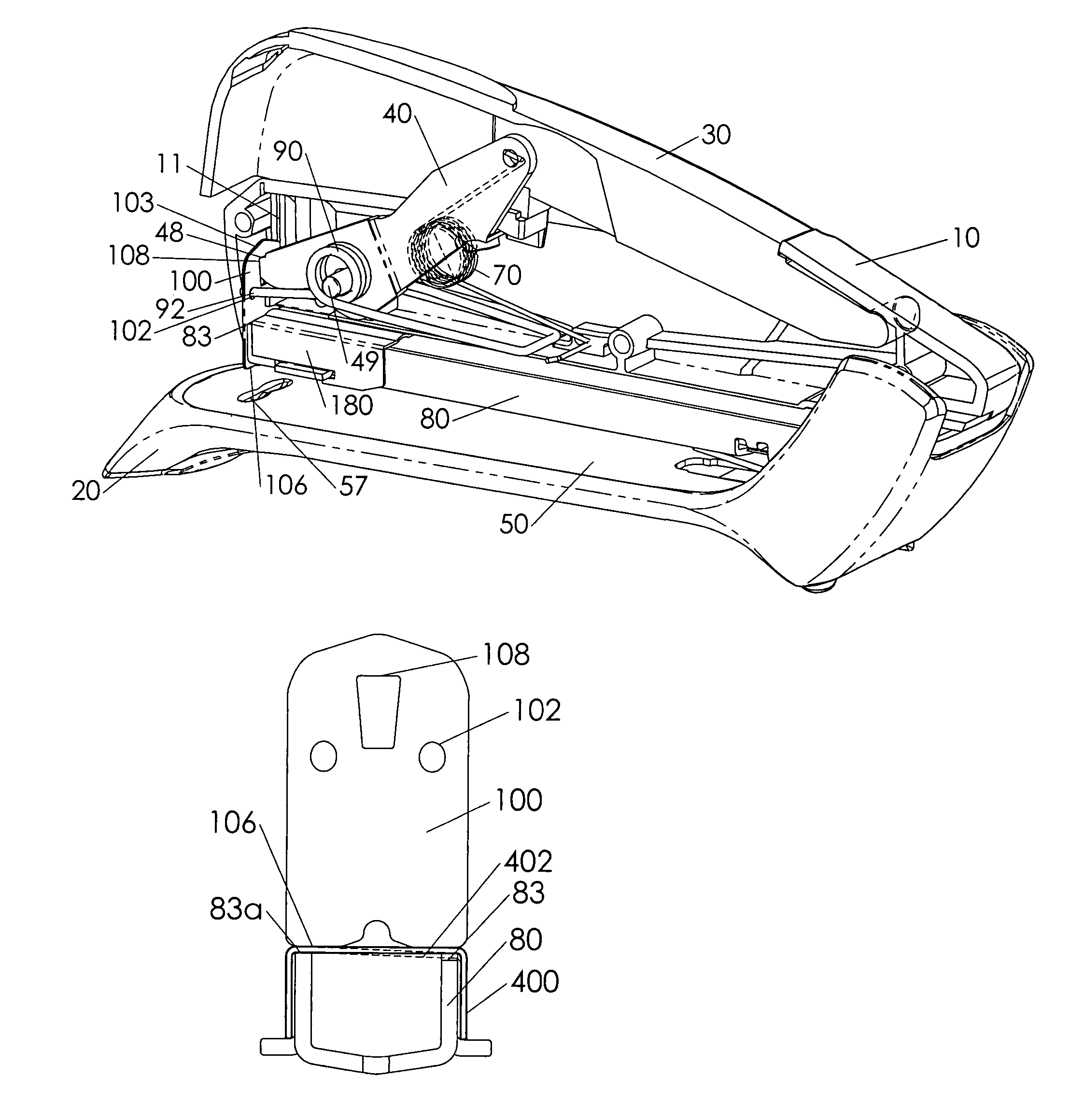

Automated page turner

An automated page turner apparatus for turning the pages of a book either forwards or backwards under the control of a single-switch input. It comprises of a base for book support, a clutch based mechanism for lifting a page with an adhesive head, a shifting mechanism for flipping a page to the opposite side, and an electronic controller for receiving the user input. The lifting mechanism includes a four-bar system for creating a peeling action to separate the adhesive head from the lifted page.

Owner:TILLINGHAST ADAM +8

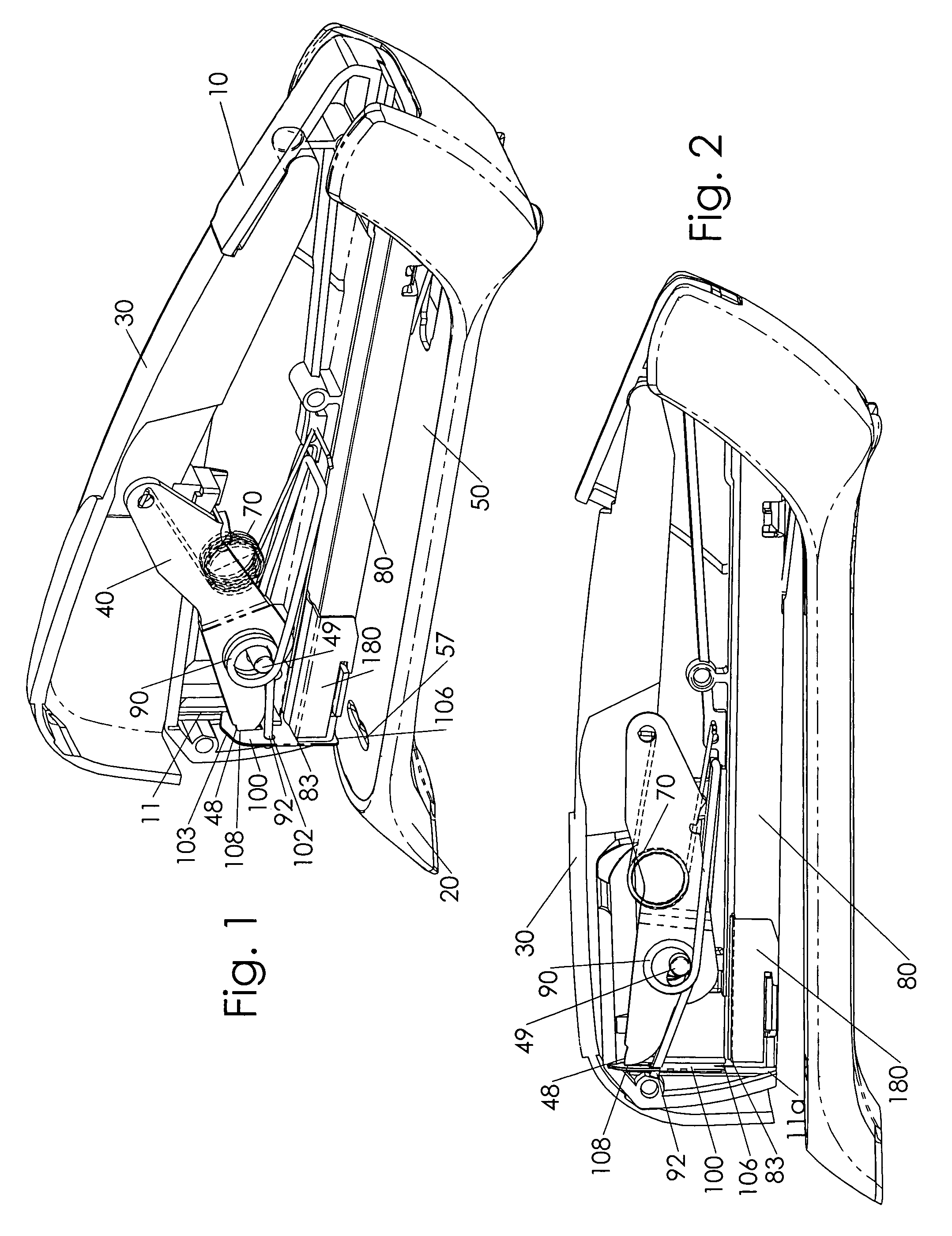

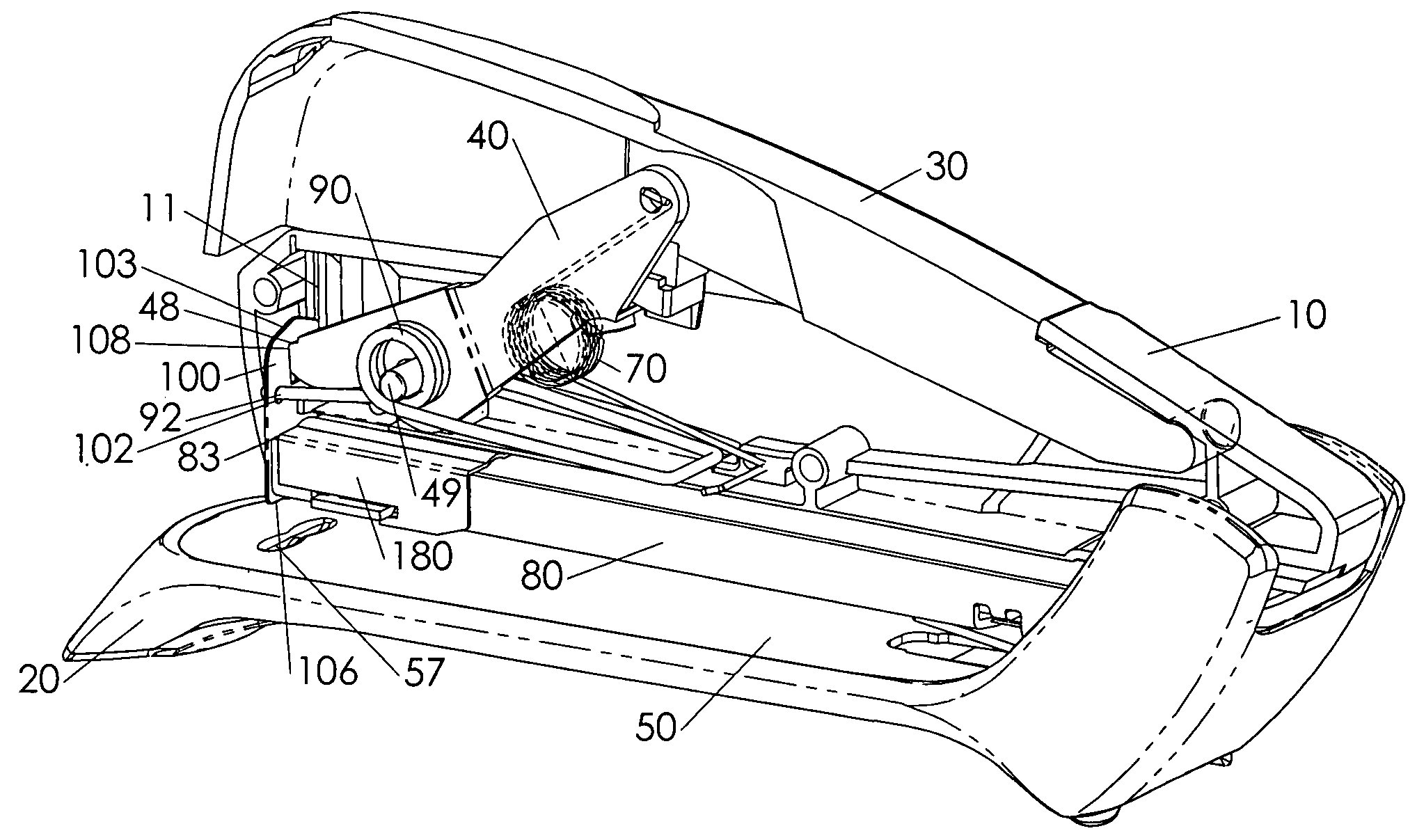

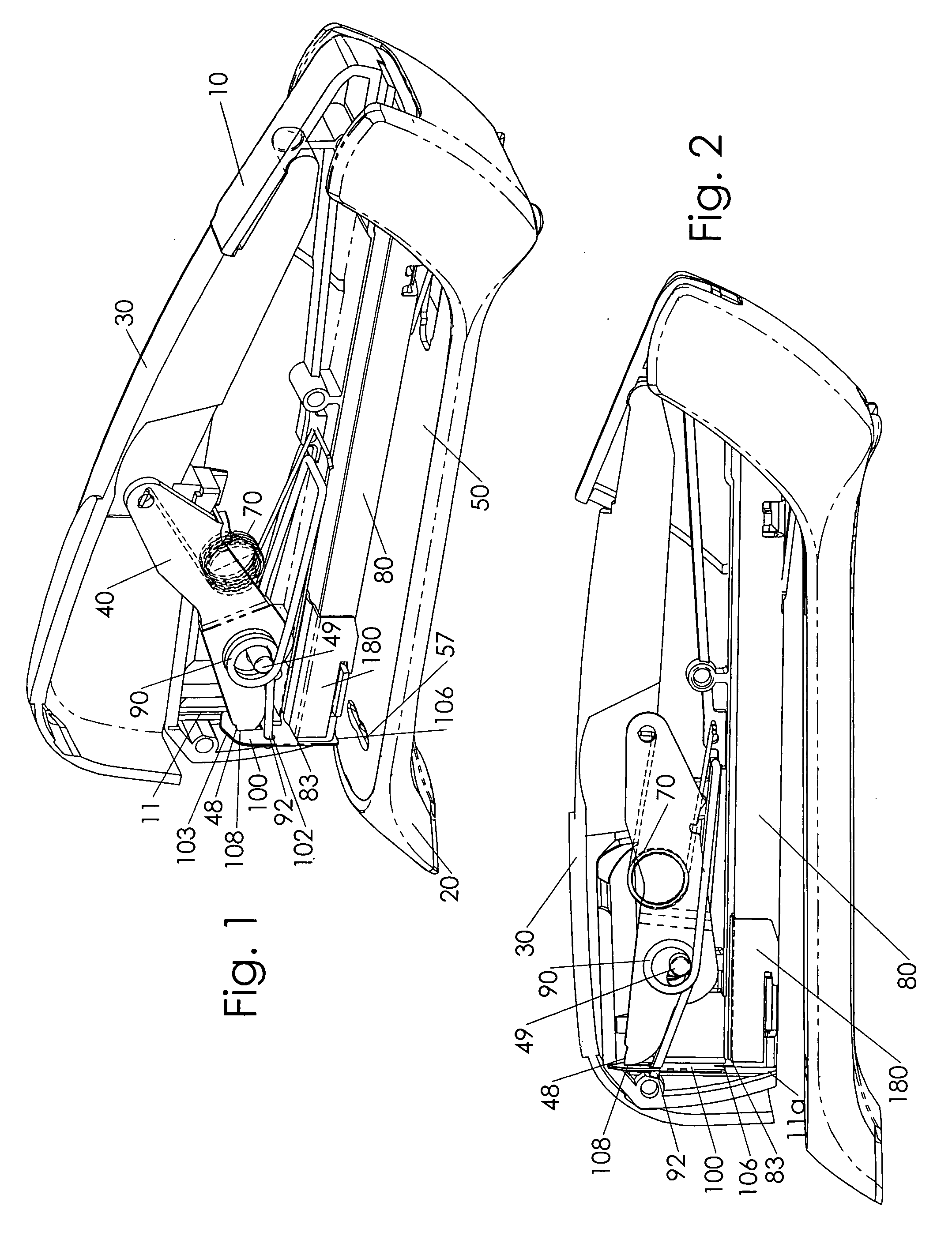

Jam resistant staple holding track for staplers

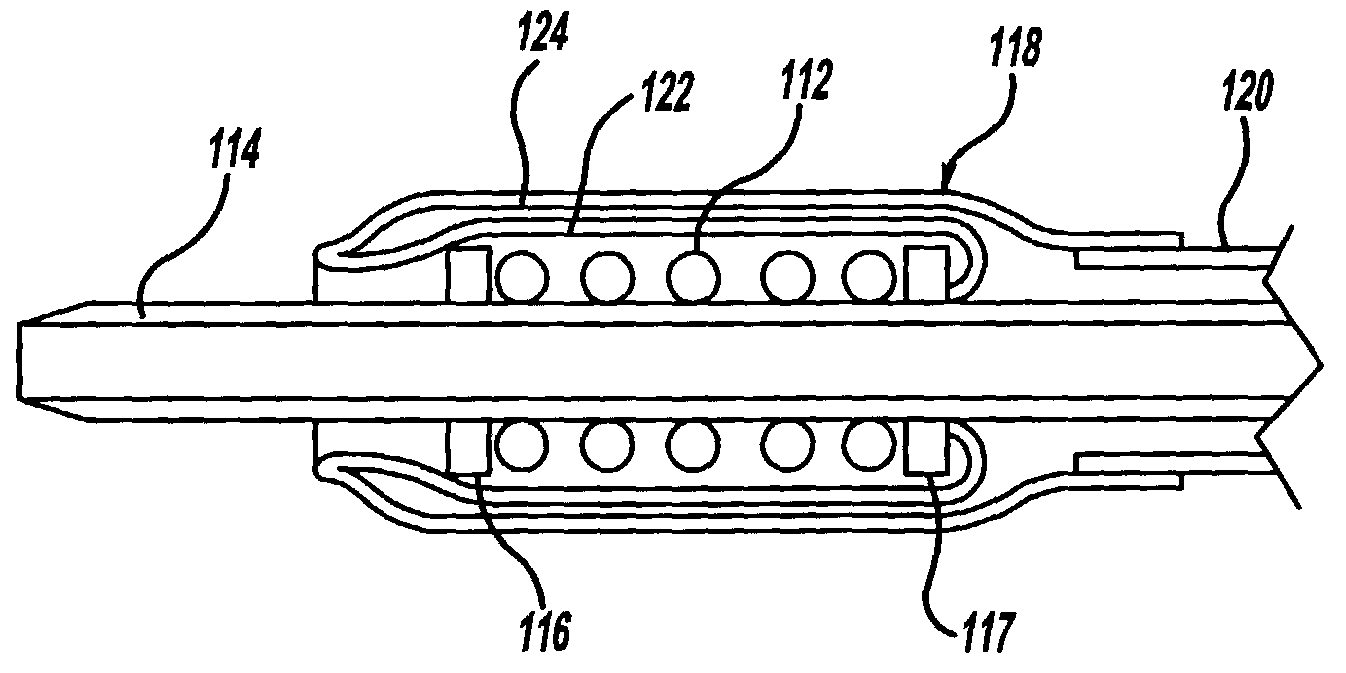

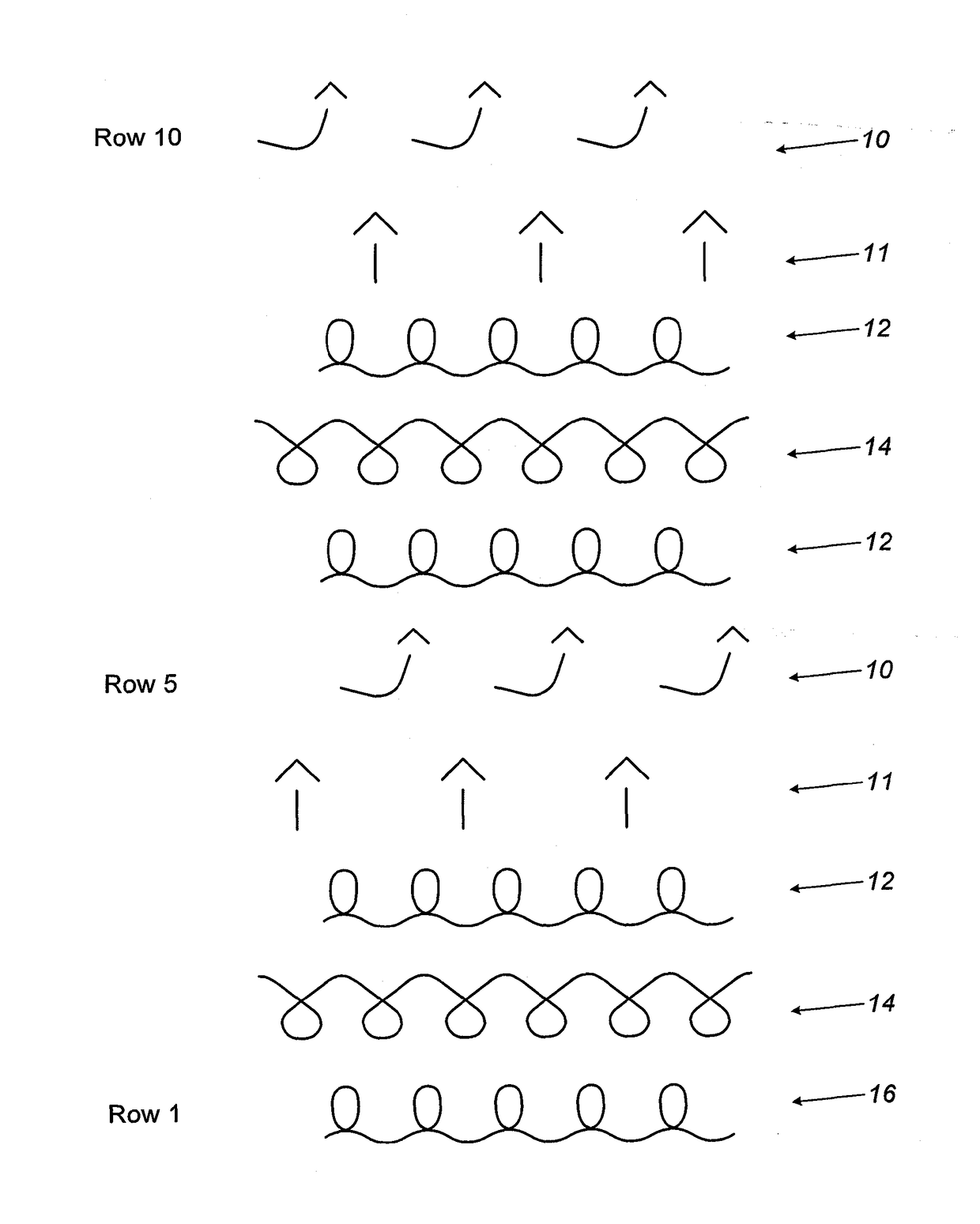

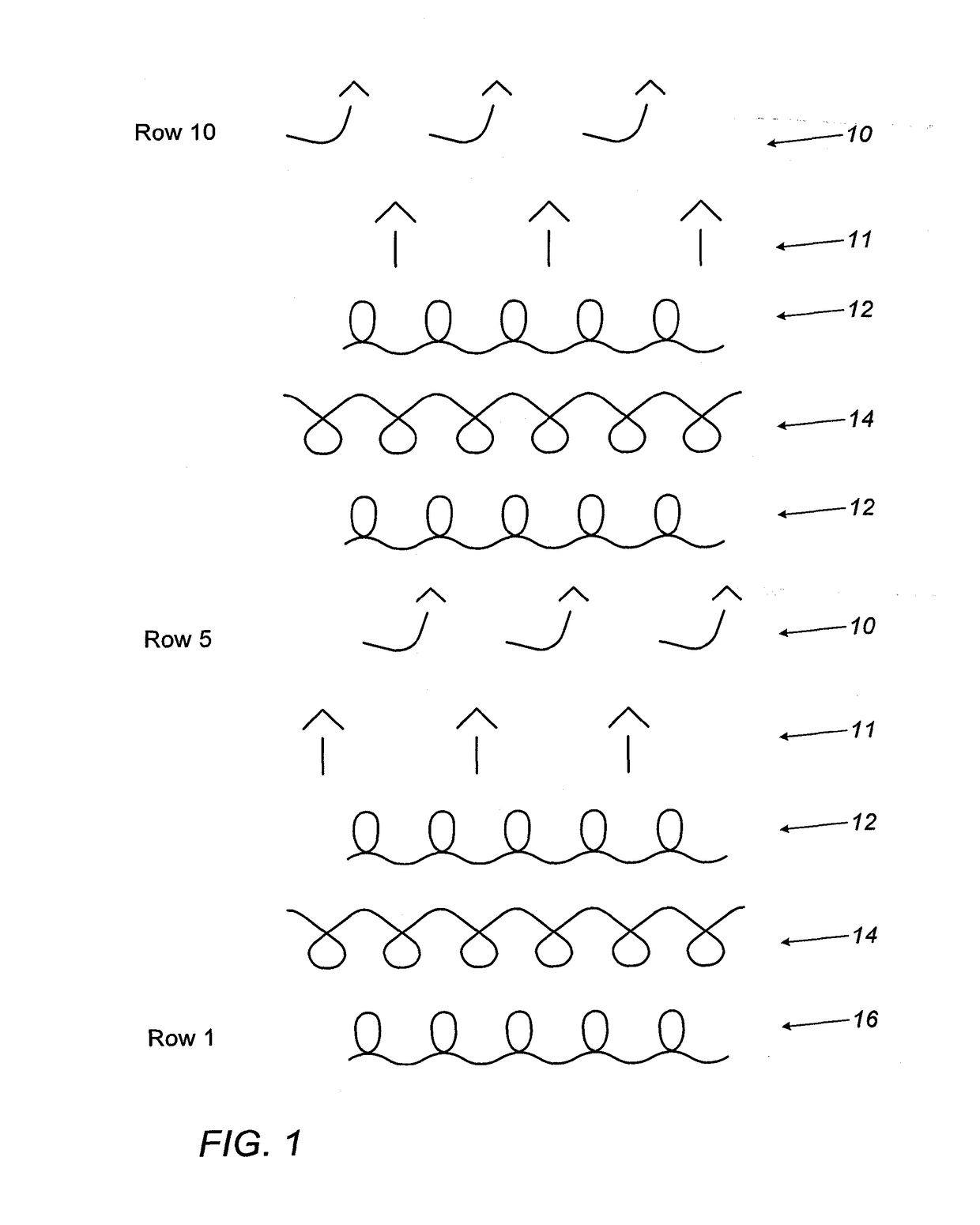

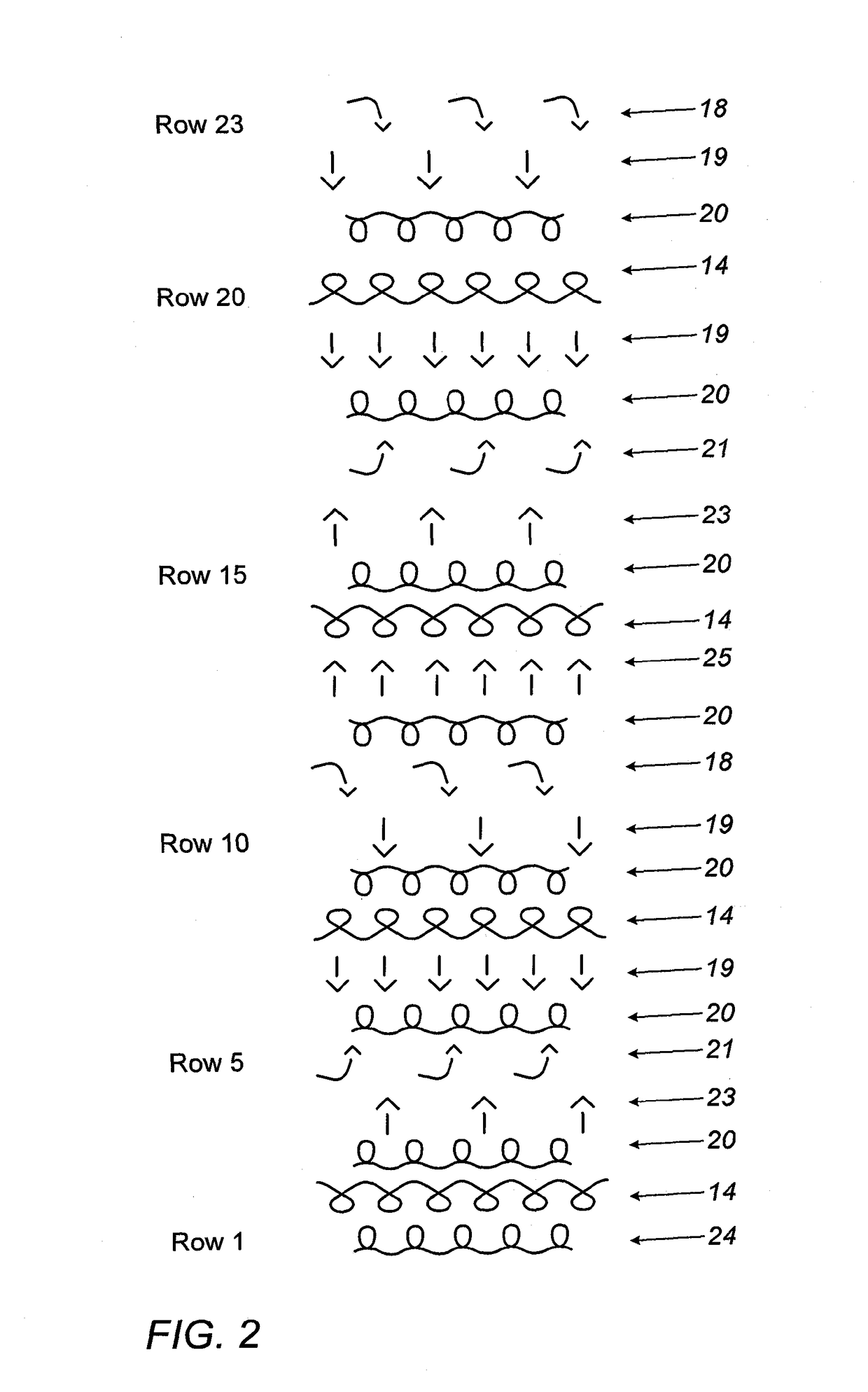

An anti-jamming design for a stapler track provides reduced force to shear a staple from a rack of staples. In stapling, a front staple must be separated from a rack of staples to eject the staple out. Conventional staplers shear the glue that holds the staples together all at once, so the peak force to separate the staple is high. In the present invention the glue that holds staples together in a rack is sheared by a peeling action. Locally progressing sections of glue are peeled as the front staple is sheared from the adjacent second staple. According to one embodiment of the invention progressive shearing is provided by an asymmetric track front end, whereby the front staples are fully supported on one side only so that the staple rack twists as the striker slowly presses down. The striker contacts the supported, higher, side of the staple first and the staple begins to shear from this higher side. When used in a low force spring actuated stapler, the present invention prevents the striker from resting atop the staple in an energized state if the stapling cycle is not properly completed.

Owner:WORKTOOLS

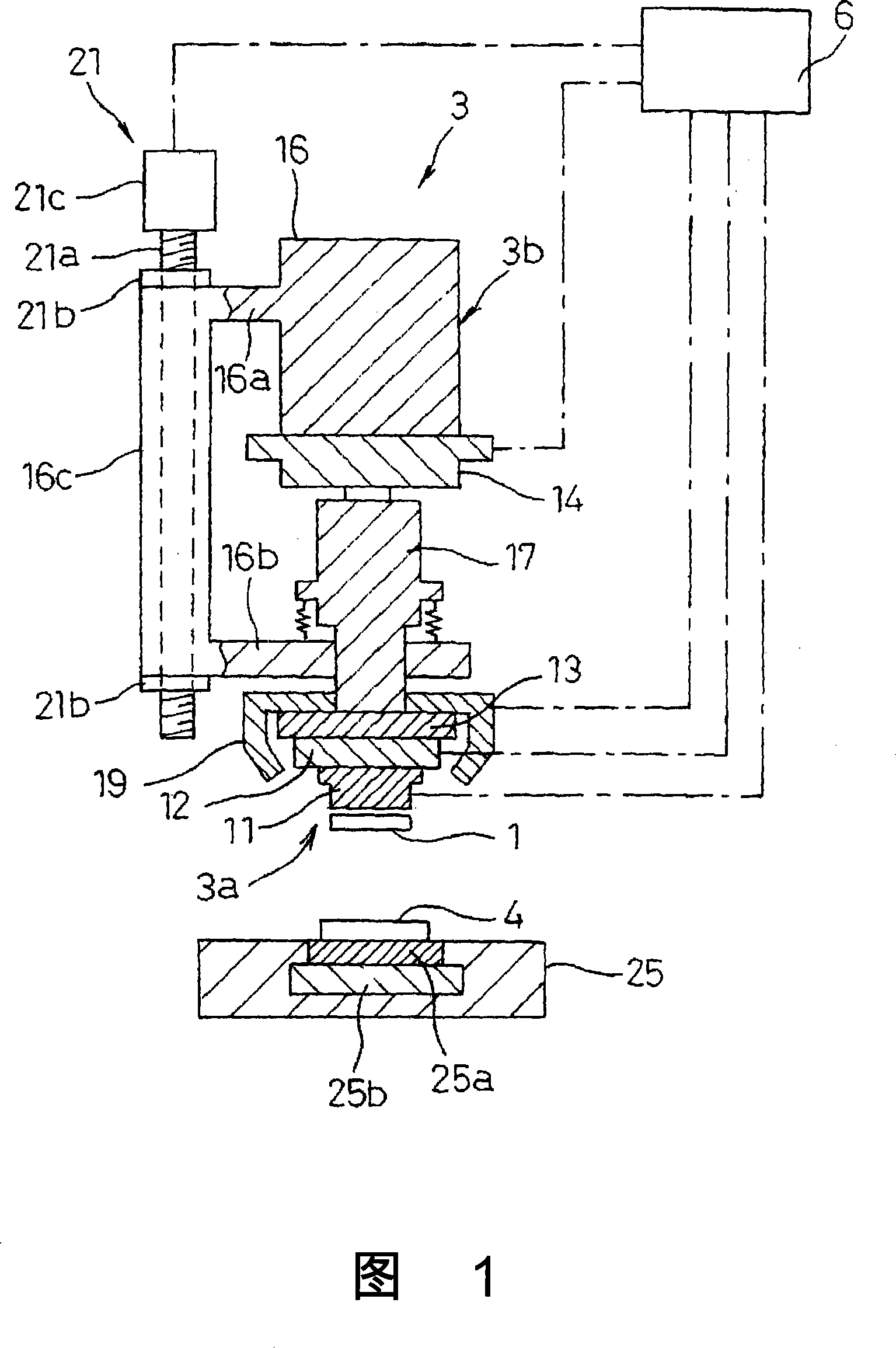

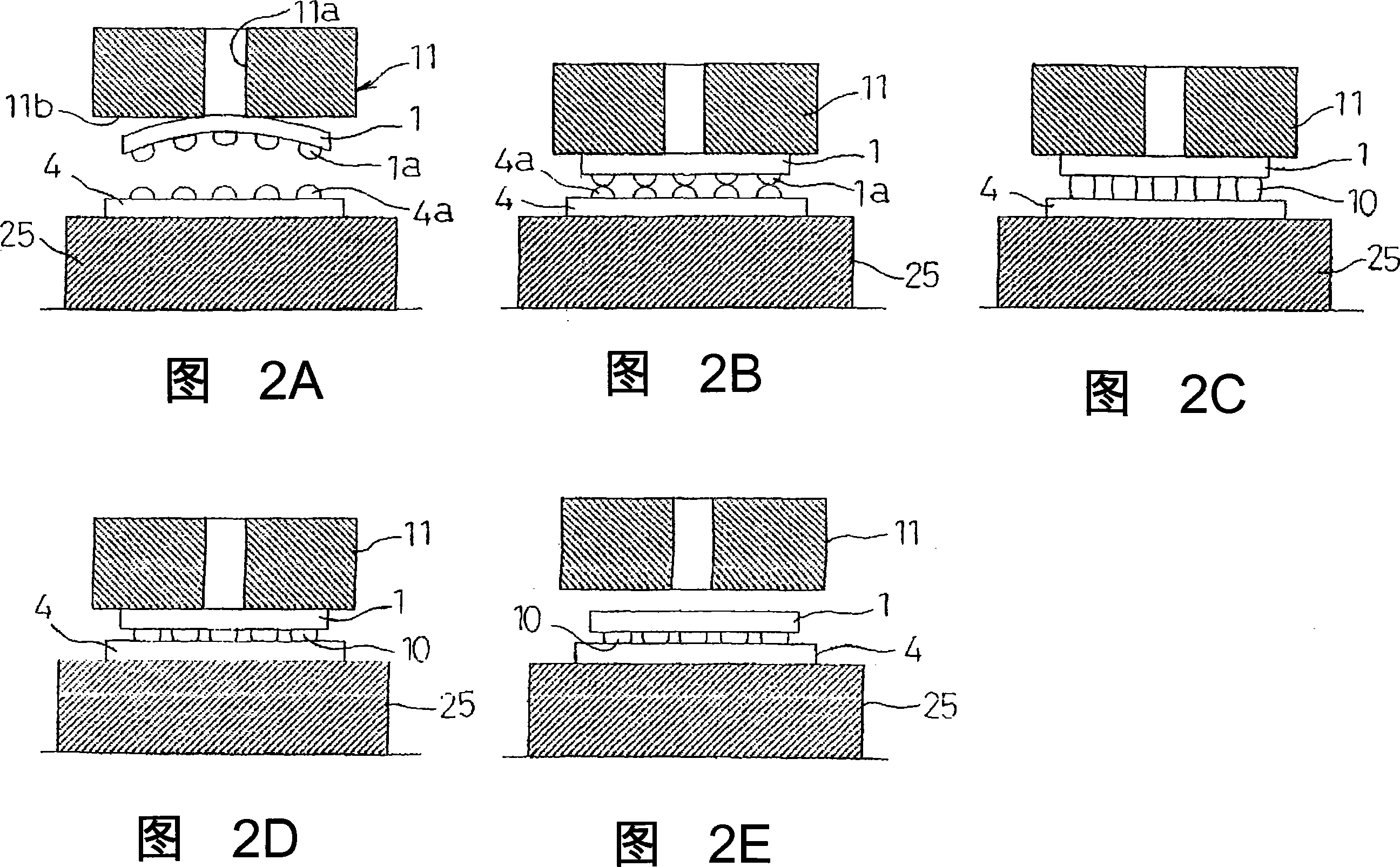

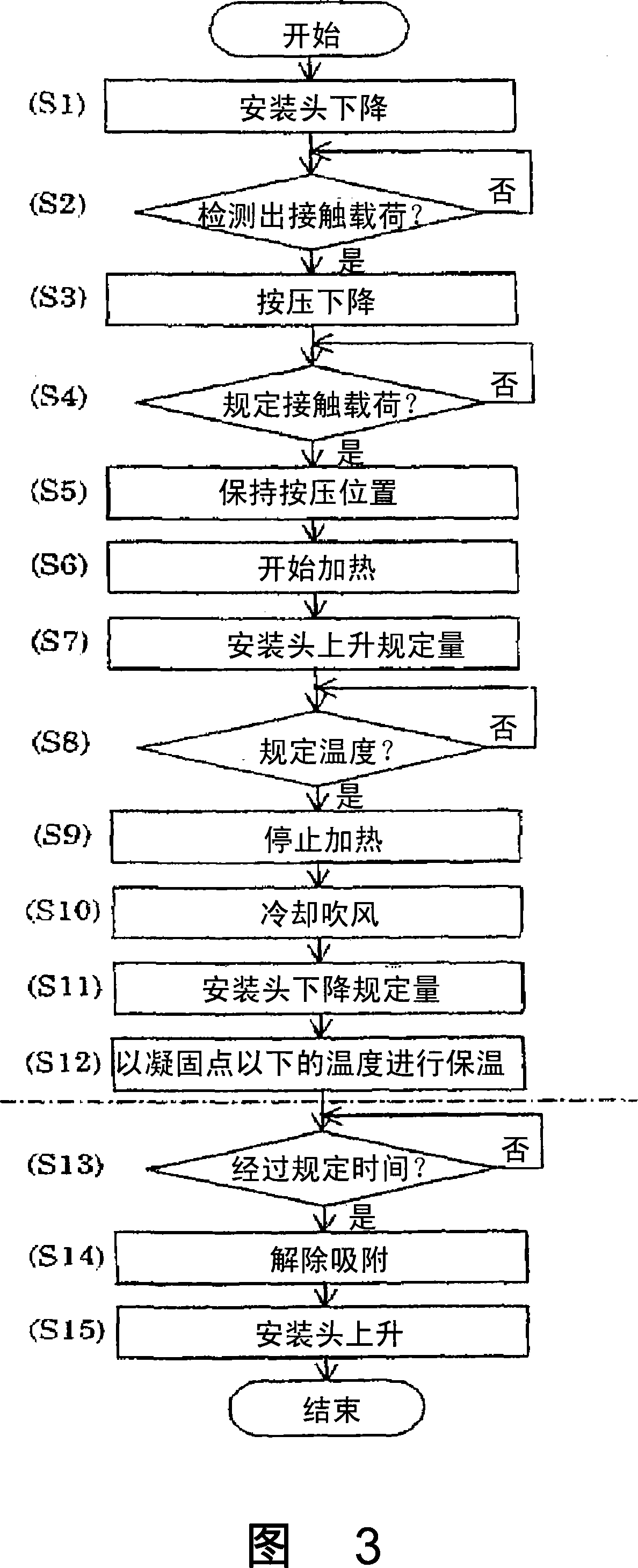

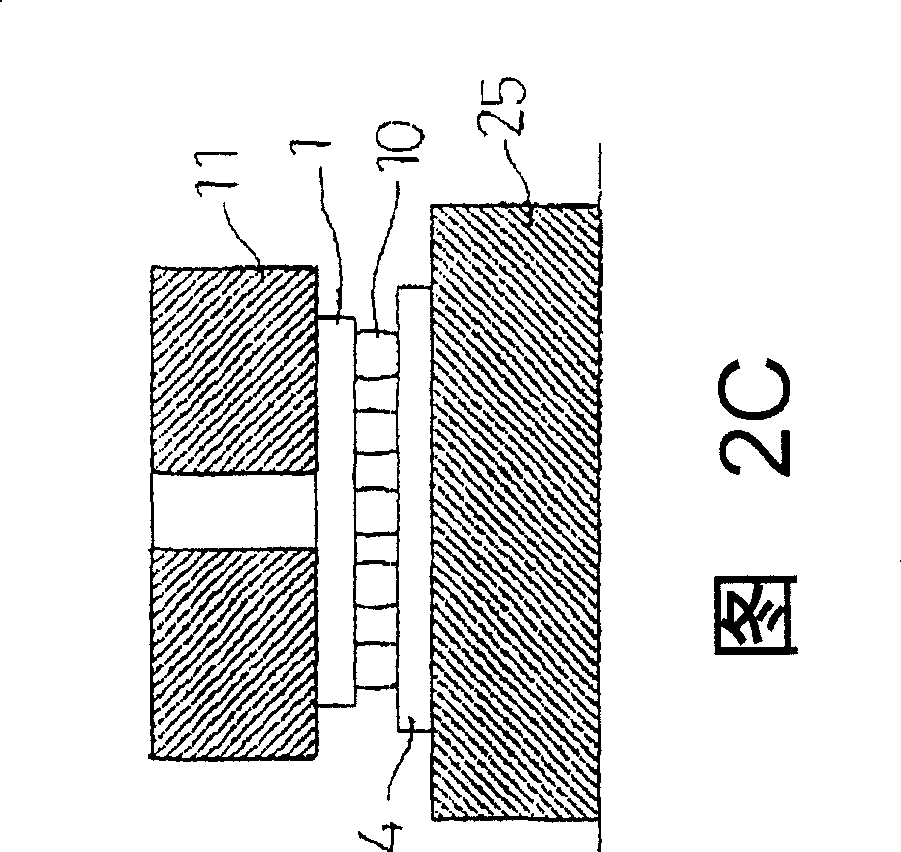

Component mounting method and component mounting apparatus

InactiveCN1965401AAvoid strippingRelative interval increasePrinted circuit assemblingFinal product manufactureEngineeringThermal expansion

There has been a possibility of deteriorating planarity of a thin IC chip due to process distortion and deformation generated when sucking the IC chip by a suction nozzle. The deformation is corrected by pressing the thin IC chip on a board (4) with a prescribed load by a suction nozzle (11) having a suction plane (11b) formed flat. A reduction of a prescribed opposing interval between the IC chip and the board (4), due to thermal expansion caused by heat applied for melting a solder bump (1a) formed on an electrode, is corrected by controlling rising of the suction nozzle (11). A peeling action of the melting part, due to a part which has heat- expanded and contracted by cooling, is corrected by controlling descending of the suction nozzle (11). Thus, an electronic component mounting method and an electronic component mounting apparatus are provided for correctly mounting even the electronic components, such as the thin IC chip easily deformed and the IC chip wherein a multitude of electrodes are formed at a narrow pitch.

Owner:PANASONIC CORP

Jam resistant staple holding track for staplers

ActiveUS20050127129A1Reduce peak forceEasy to peelStapling toolsNailing toolsAnti jammingPeeling action

An anti-jamming design for a stapler track provides reduced force to shear a staple from a rack of staples. In stapling, a front staple must be separated from a rack of staples to eject the staple out. Conventional staplers shear the glue that holds the staples together all at once, so the peak force to separate the staple is high. In the present invention the glue that holds staples together in a rack is sheared by a peeling action. Locally progressing sections of glue are peeled as the front staple is sheared from the adjacent second staple. According to one embodiment of the invention progressive shearing is provided by an asymmetric track front end, whereby the front staples are fully supported on one side only so that the staple rack twists as the striker slowly presses down. The striker contacts the supported, higher, side of the staple first and the staple begins to shear from this higher side. When used in a low force spring actuated stapler, the present invention prevents the striker from resting atop the staple in an energized state if the stapling cycle is not properly completed.

Owner:WORKTOOLS

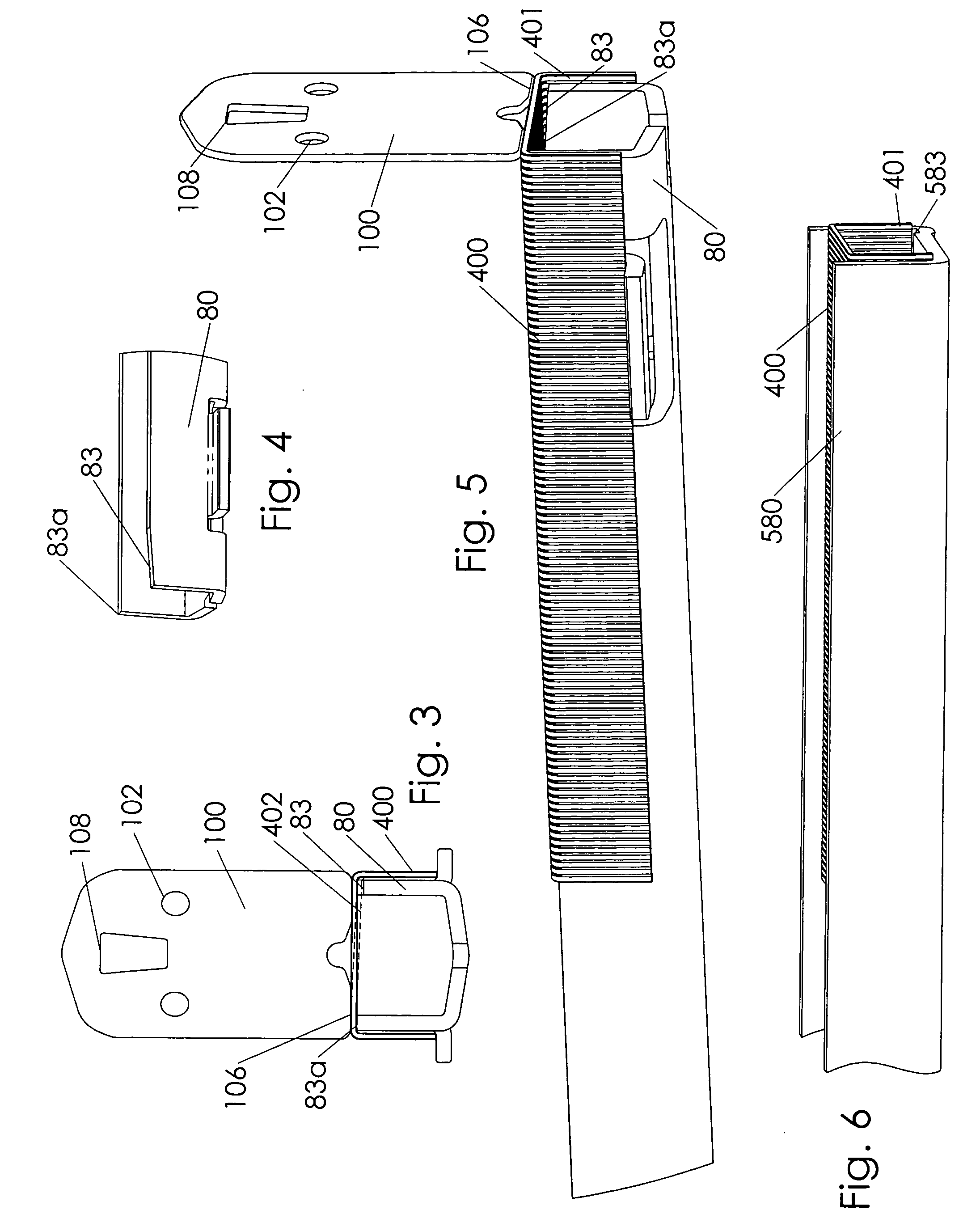

Double blade peeling device for vegetables and fruits

InactiveUS7430958B2Operational securityEasy to operateGrain huskingGrain polishingGear wheelScrew thread

A double blade peeling device for vegetable and fruit comprises a handle attached to a vegetable and fruit retaining member and a body of screw, the handle can drive internal gears to rotate, so as to make the retaining member and the body of screw to rotate as well. The body of screw, which is provided with two screw threads, drives upper and lower blade carriers to move upward and downward oppositely, such that the blades mounted on the upper and lower blade carriers move downward and upward respectively, contact the rotating food frictionally, and peel vegetable or fruit from upside and underside simultaneously. When two blade carriers move to the intermediate position to complete the peeling action, the two blade carriers open through wedge in blade carrier devices, two blades leave the surface of food, the lower blade carrier devices disengage with the body of screw. The body of screw drives upper blade carrier device to press the lower blade carrier device to move downward unceasingly. When the upper and lower blade carrier devices move to bottom, if turning handle, the two blade carrier devices and the body of screw slip on the spot, that is a protective function, and a peeling cycle is completed. The invention can peel a vegetable or fruit conveniently, quickly and exactly, its operation is safe.

Owner:WONG

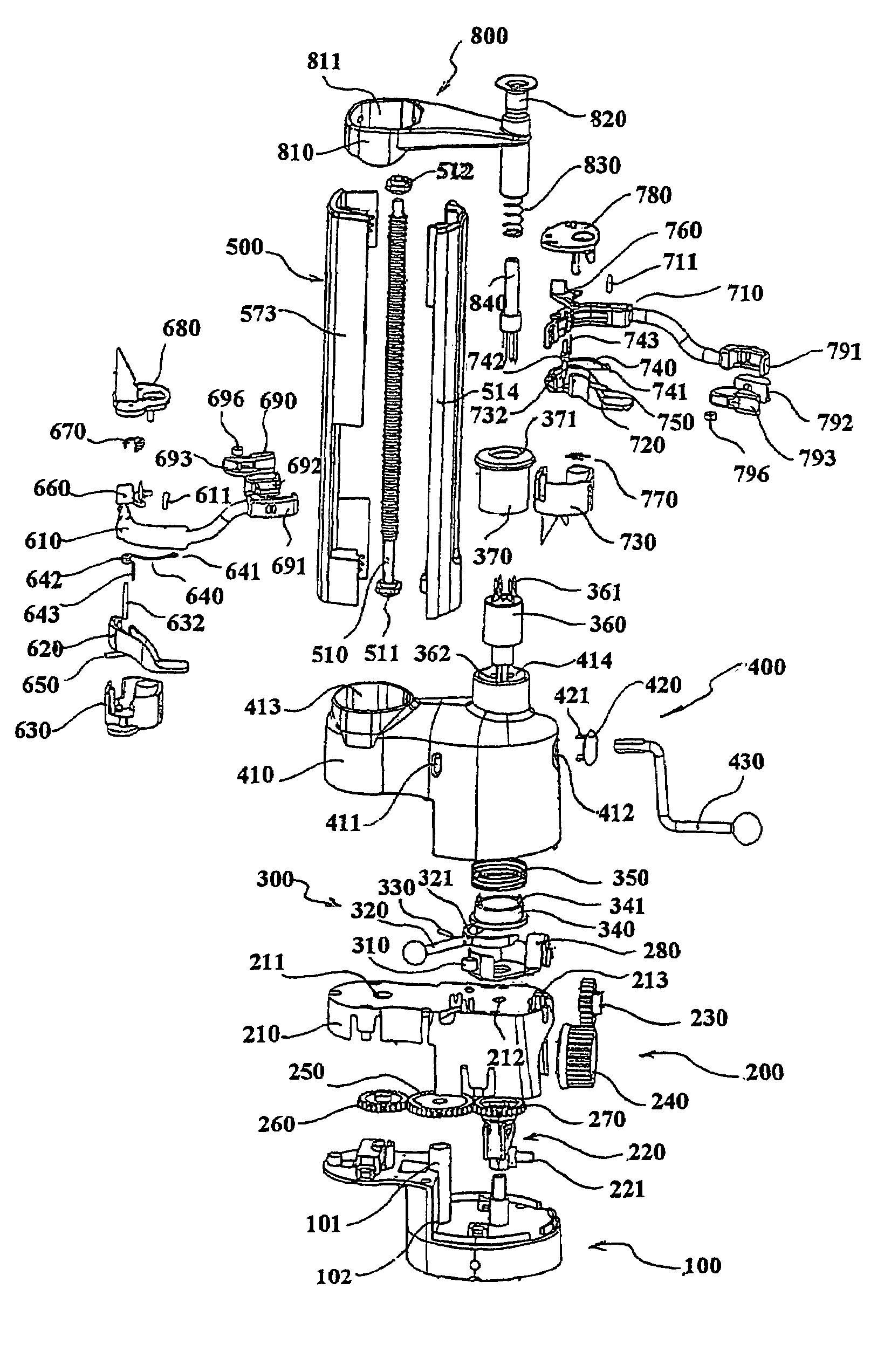

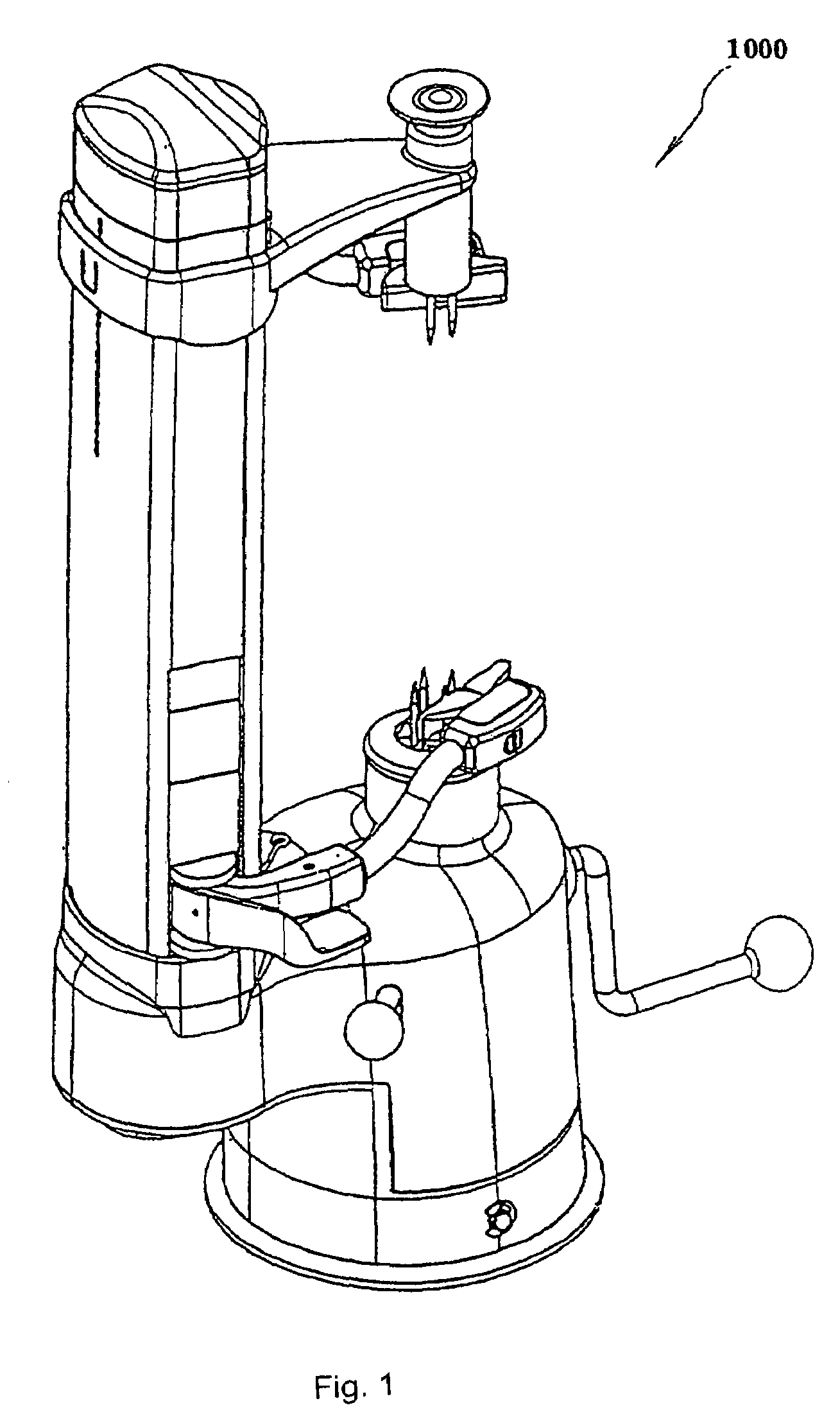

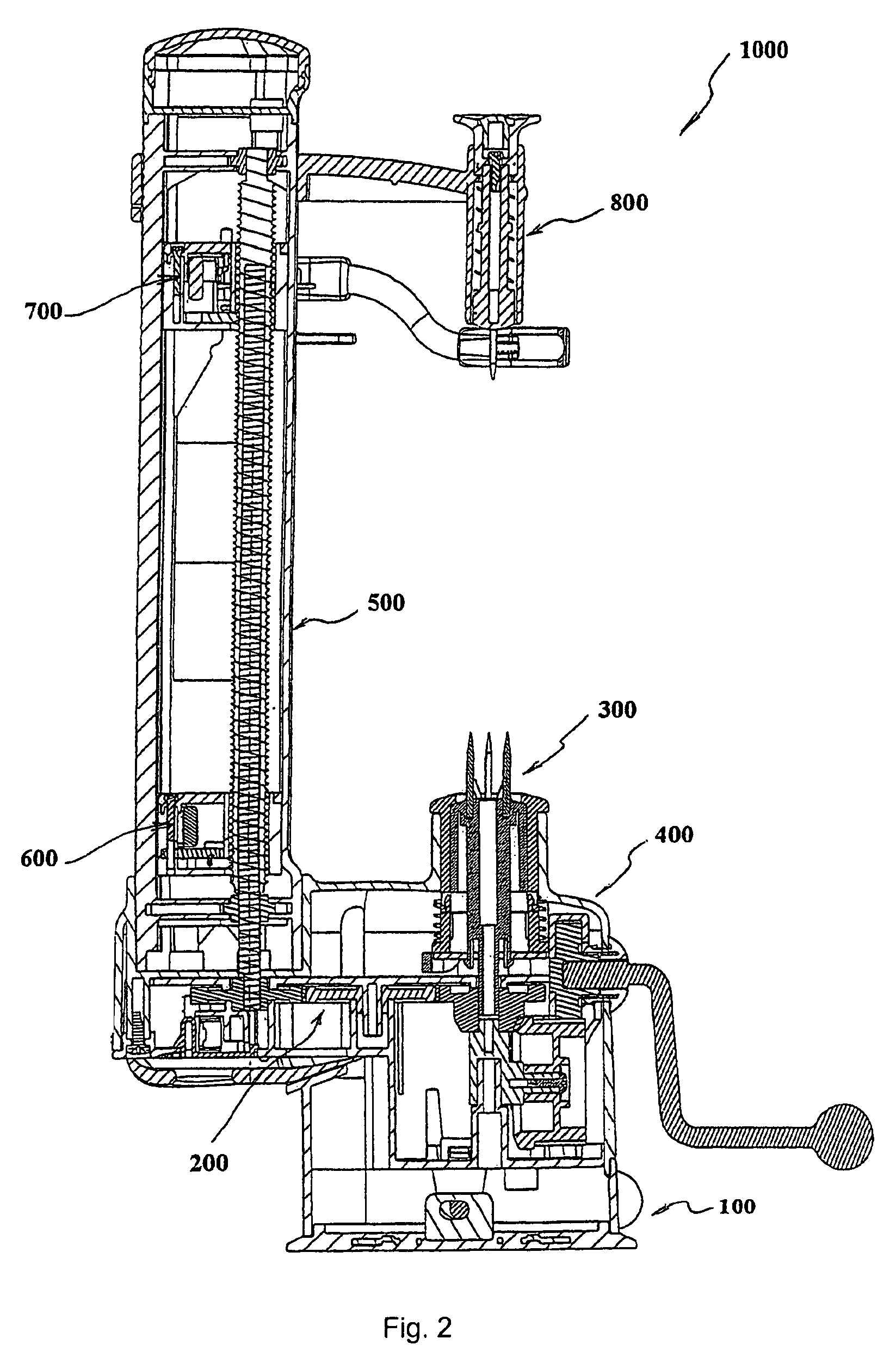

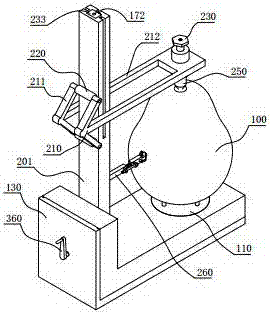

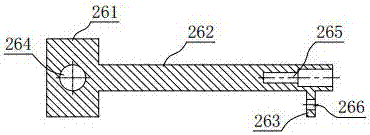

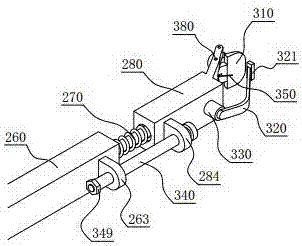

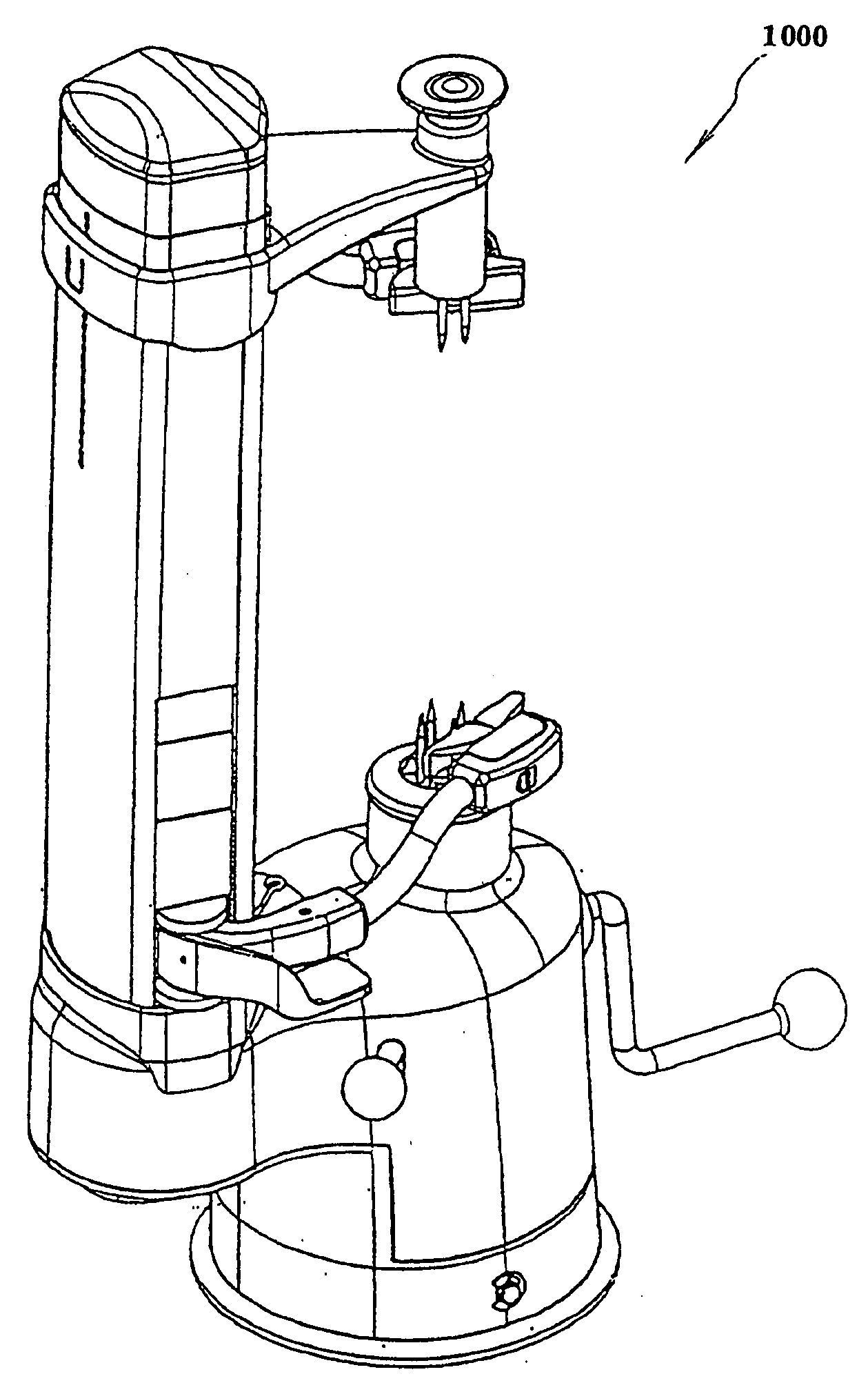

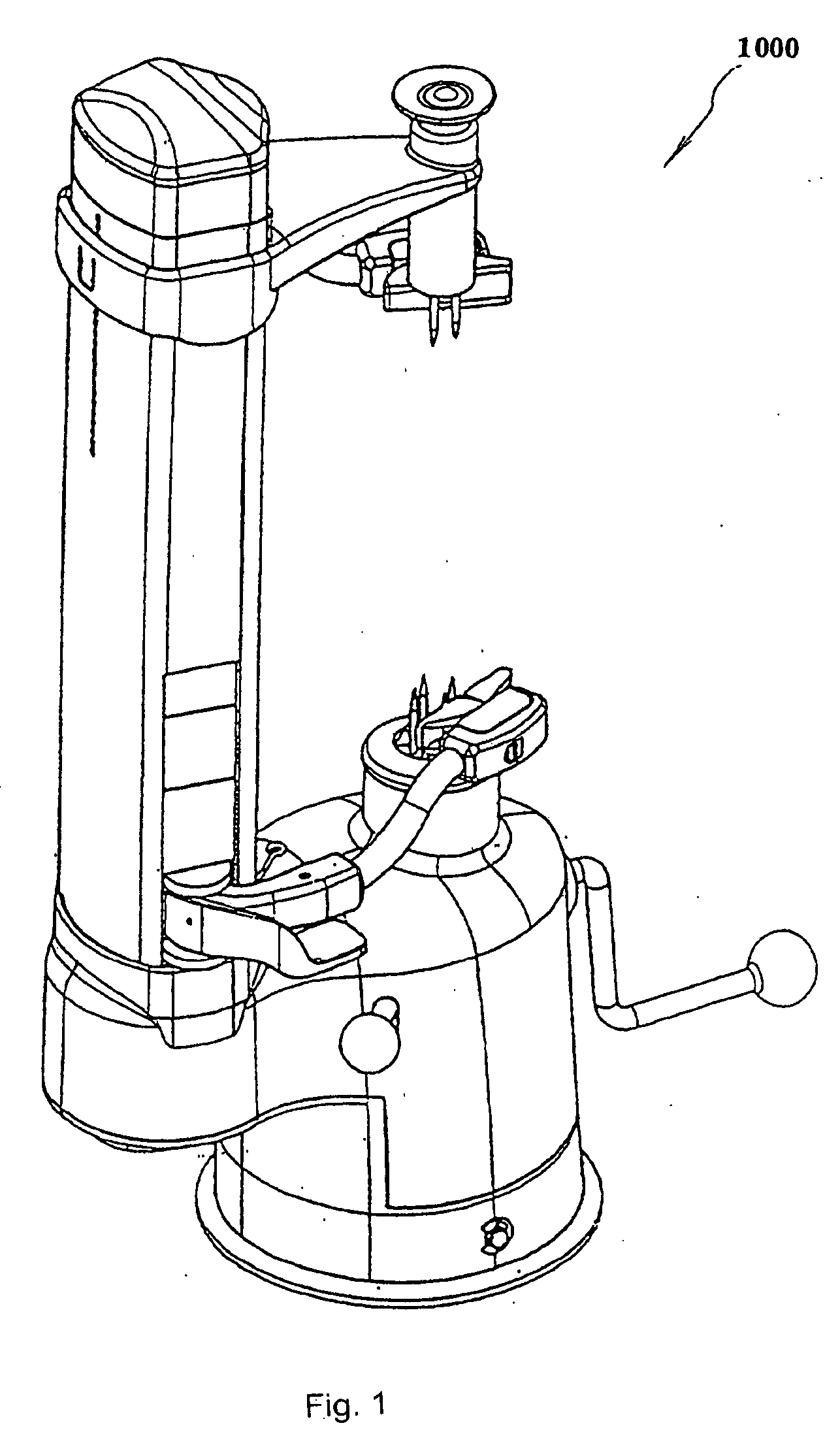

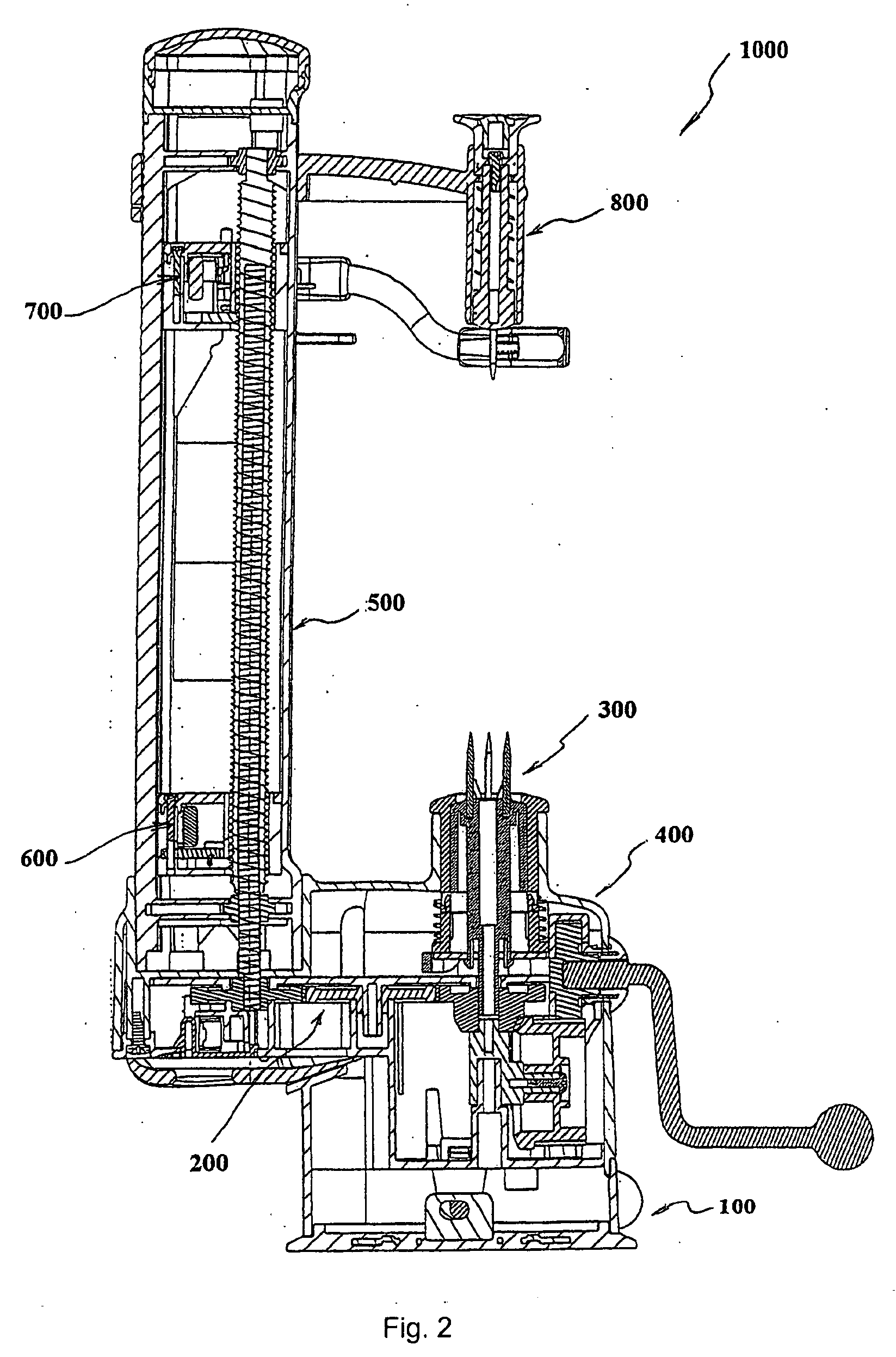

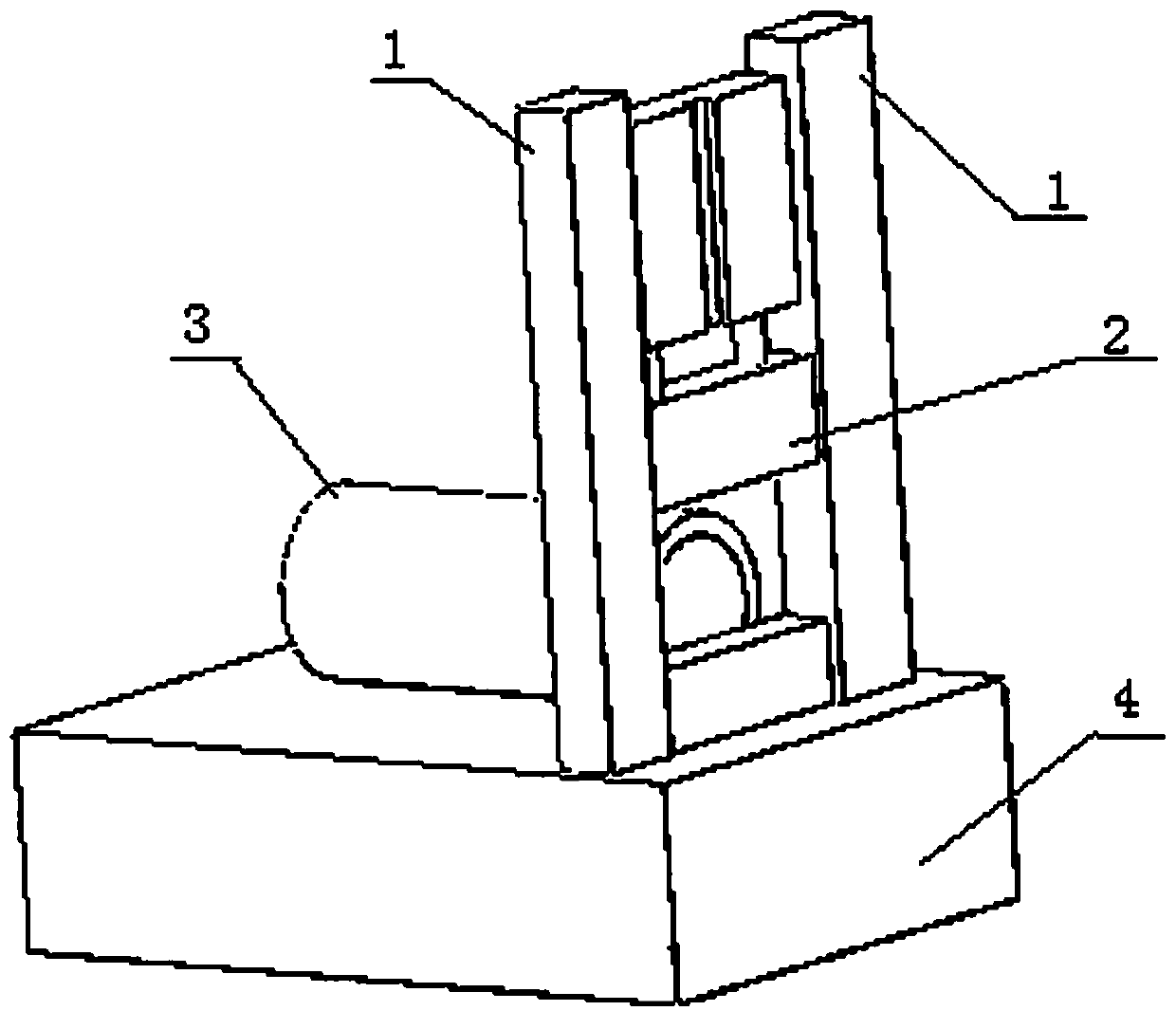

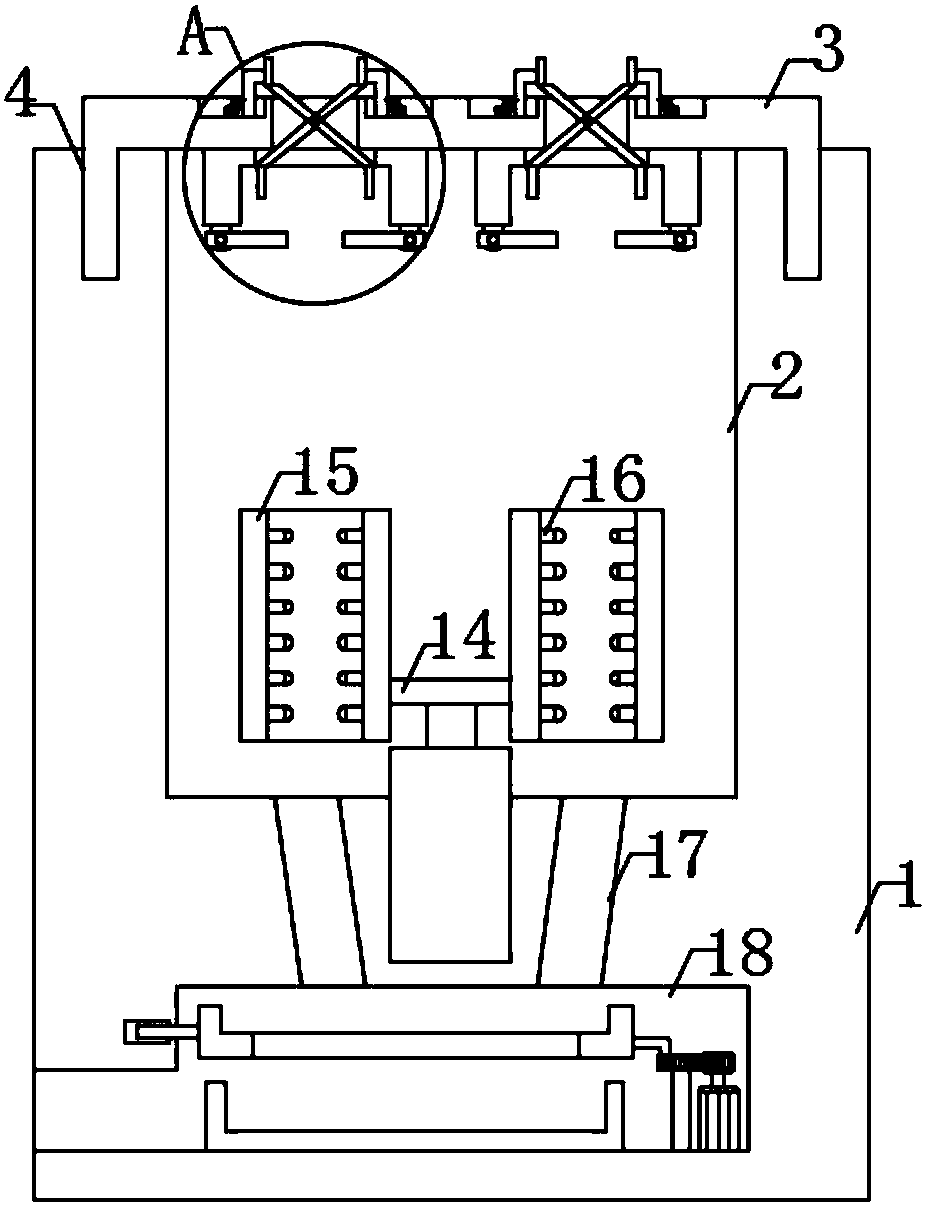

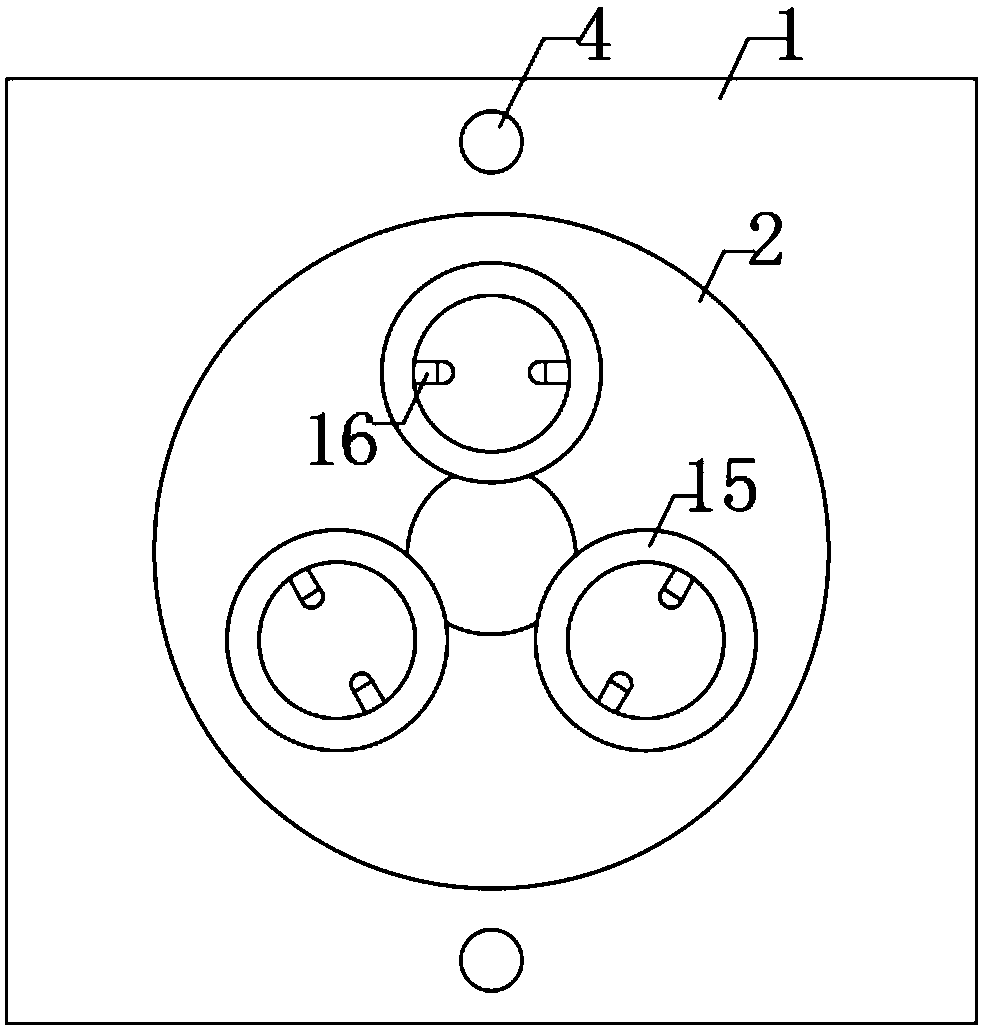

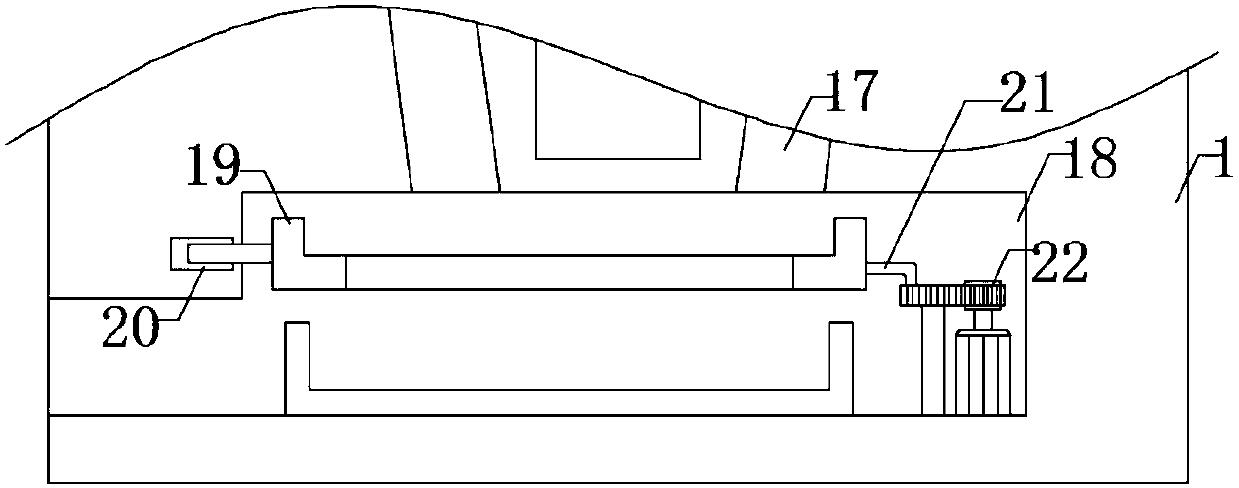

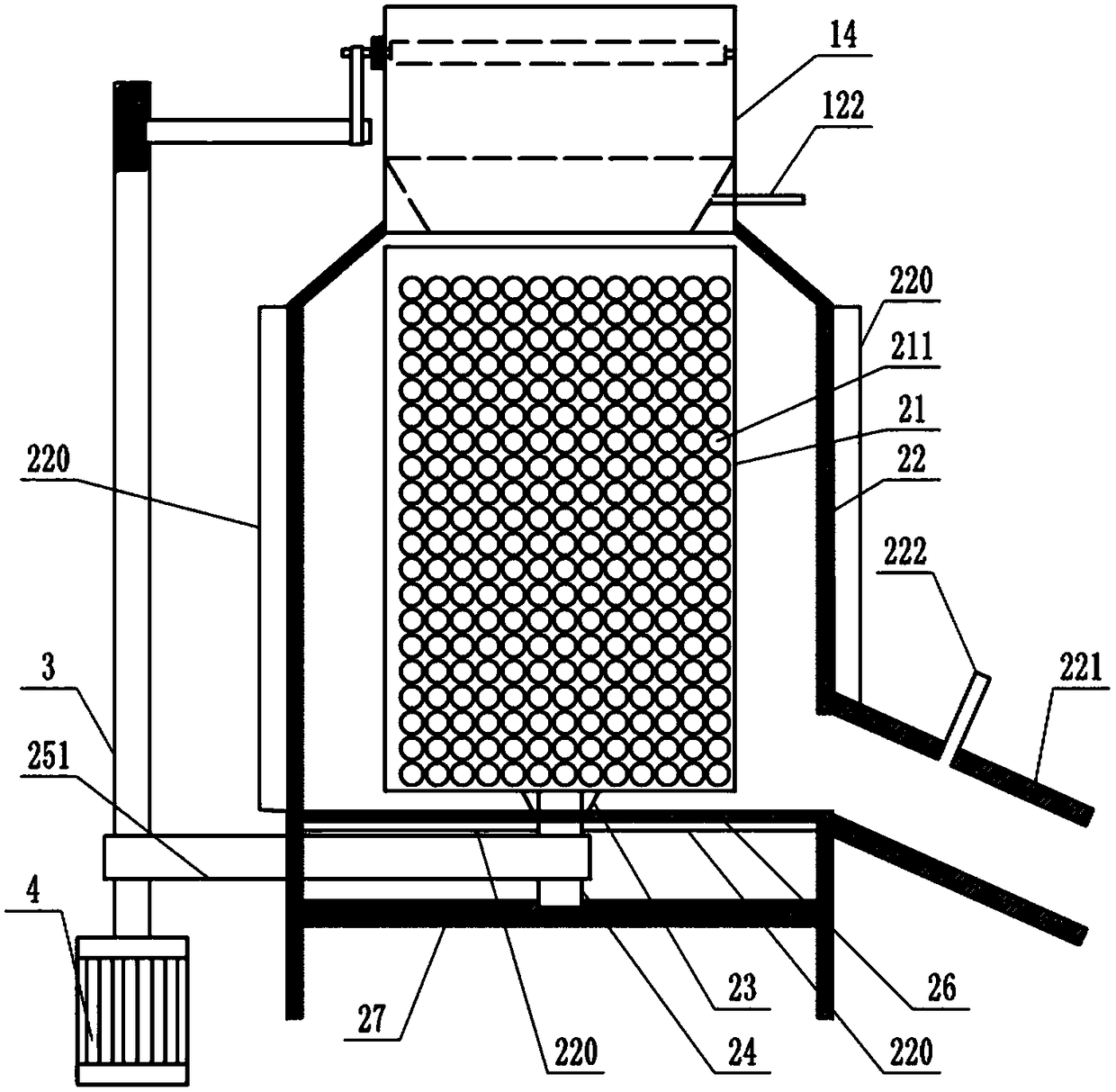

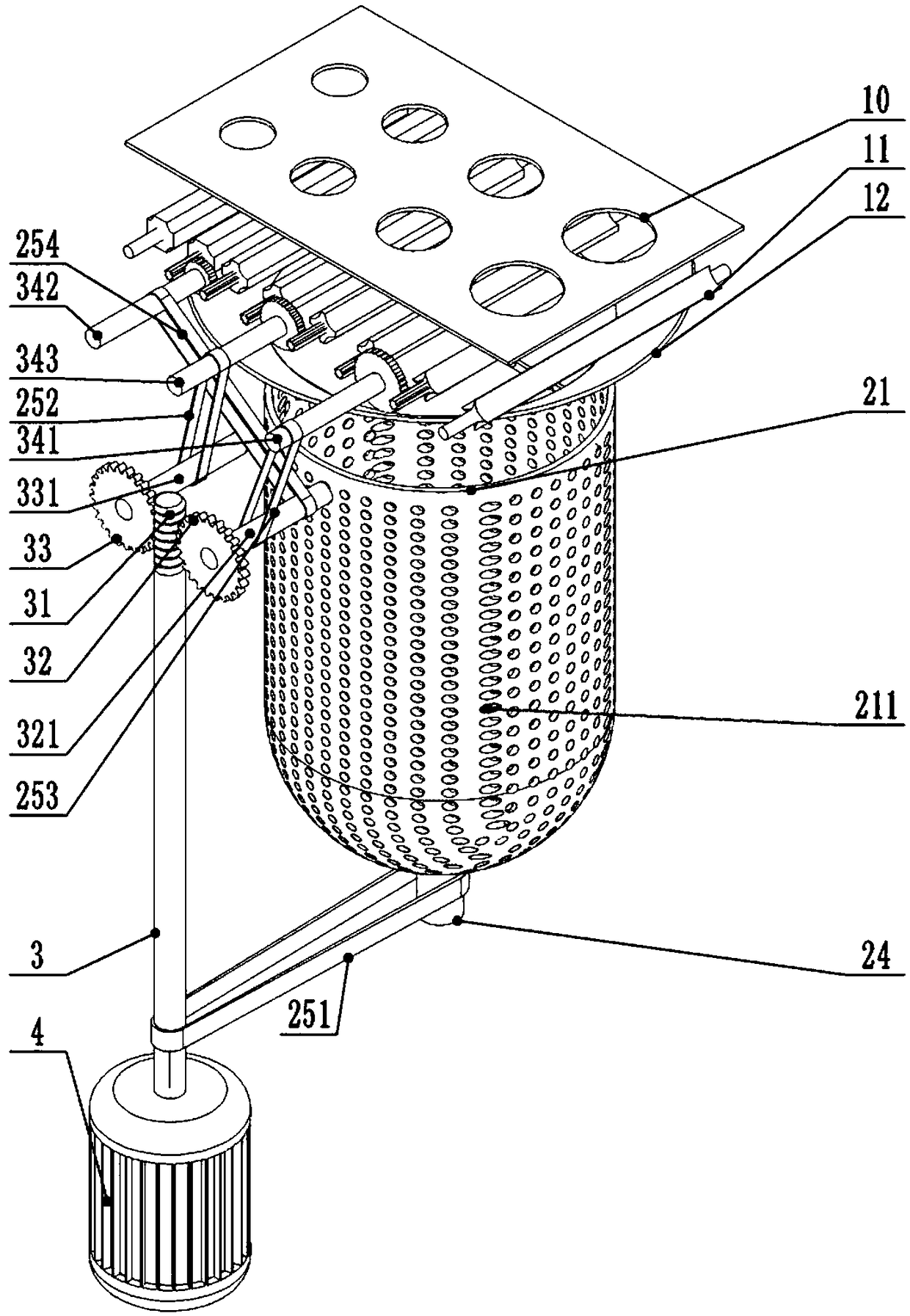

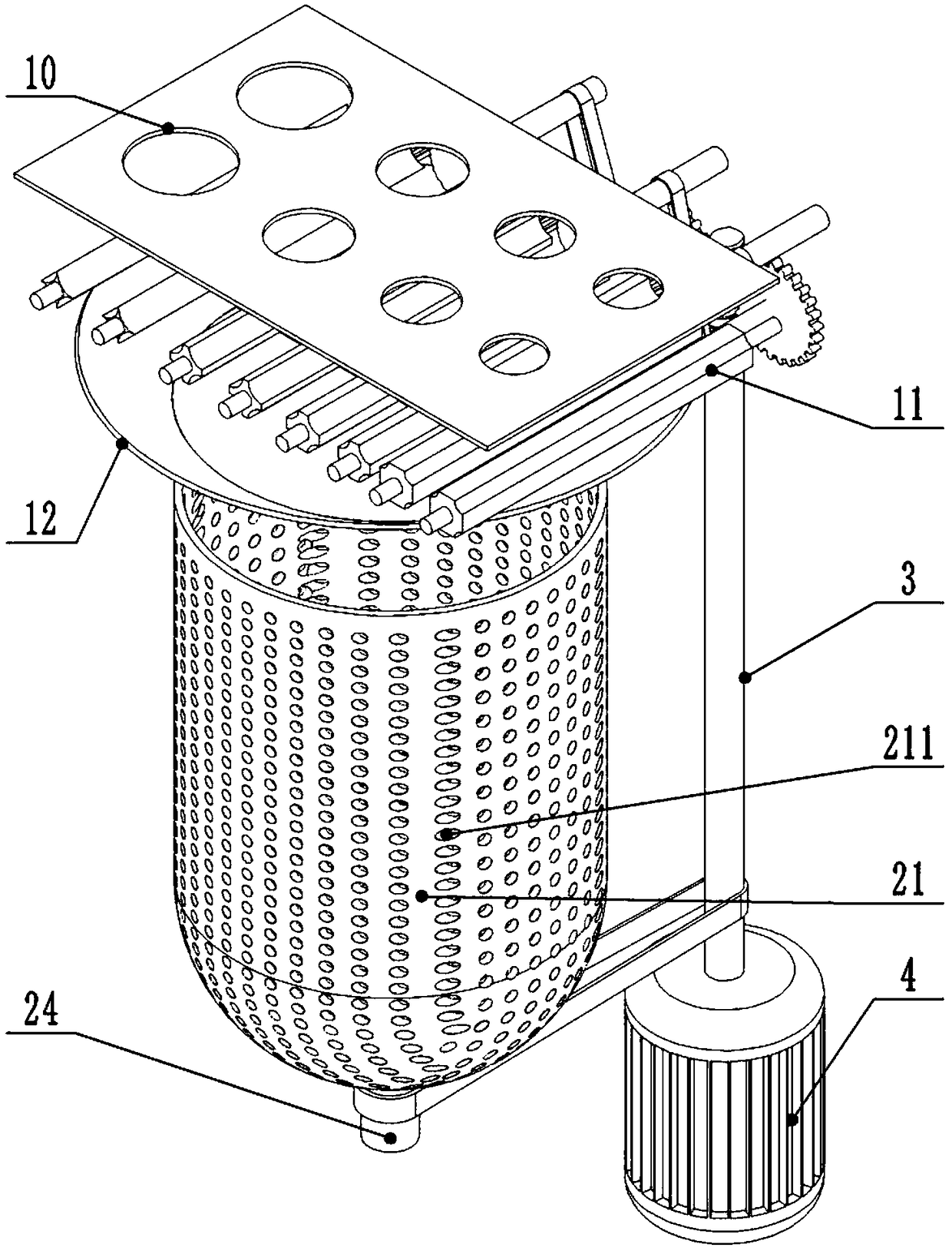

Axisymmetric melon-fruit peeling machine tool and assembling method thereof

The present invention and a peel processing tool, in particular, relate to an axisymmetric melon and fruit peeling tool and its assembly method. The tool box is formed between the machine base shell and the machine cover shell, and a transmission mechanism is arranged in the machine tool box. As an improvement: on the machine cover shell The machine cover column is set, and the machine cover column is provided with the column inner groove and the column outer groove; the machine cover column can slide up and down to fix the knife cutting mechanism and the stabilizing device, and the knife cutting mechanism is also equipped with an adjustment device; the transmission mechanism will be simple The action of the hand crank is converted into the rotation of the axisymmetric melon and fruit and the up and down movement of the peeling blade, which realizes the whole process of peeling, which is convenient and labor-saving; the manual shaking method is used to achieve fast peeling, which is safe It is environmentally friendly, and can adjust the peeling speed in real time according to the needs; the combination of the knife holder guide rod, the guide sub-shaft and the compression spring enables the peeling blade to cling to the surface of the axisymmetric melon and fruit under the elastic force of the compression spring, adapting to different sizes and sizes. Shaped axisymmetric melon and fruit peeler.

Owner:晋江杰雄机电科技有限公司

Double blade peeling device for vegetables and fruits

InactiveUS20060065134A1Operational securityEasy to operateGrain huskingGrain polishingGear wheelEngineering

A double blade peeling device for vegetable and fruit comprises a handle attached to a vegetable and fruit retaining member and a body of screw, the handle can drive internal gears to rotate, so as to make the retaining member and the body of screw to rotate as well. The body of screw, which is provided with two screw threads, drives upper and lower blade carriers to move upward and downward oppositely, such that the blades mounted on the upper and lower blade carriers move downward and upward respectively, contact the rotating food frictionally, and peel vegetable or fruit from upside and underside simultaneously. When two blade carriers move to the intermediate position to complete the peeling action, the two blade carriers open through wedge in blade carrier devices, two blades leave the surface of food, the lower blade carrier devices disengage with the body of screw. The body of screw drives upper blade carrier device to press the lower blade carrier device to move downward unceasingly. When the upper and lower blade carrier devices move to bottom, if turning handle, the two blade carrier devices and the body of screw slip on the spot, that is a protective function, and a peeling cycle is completed. The invention can peel a vegetable or fruit conveniently, quickly and exactly, its operation is safe.

Owner:WONG

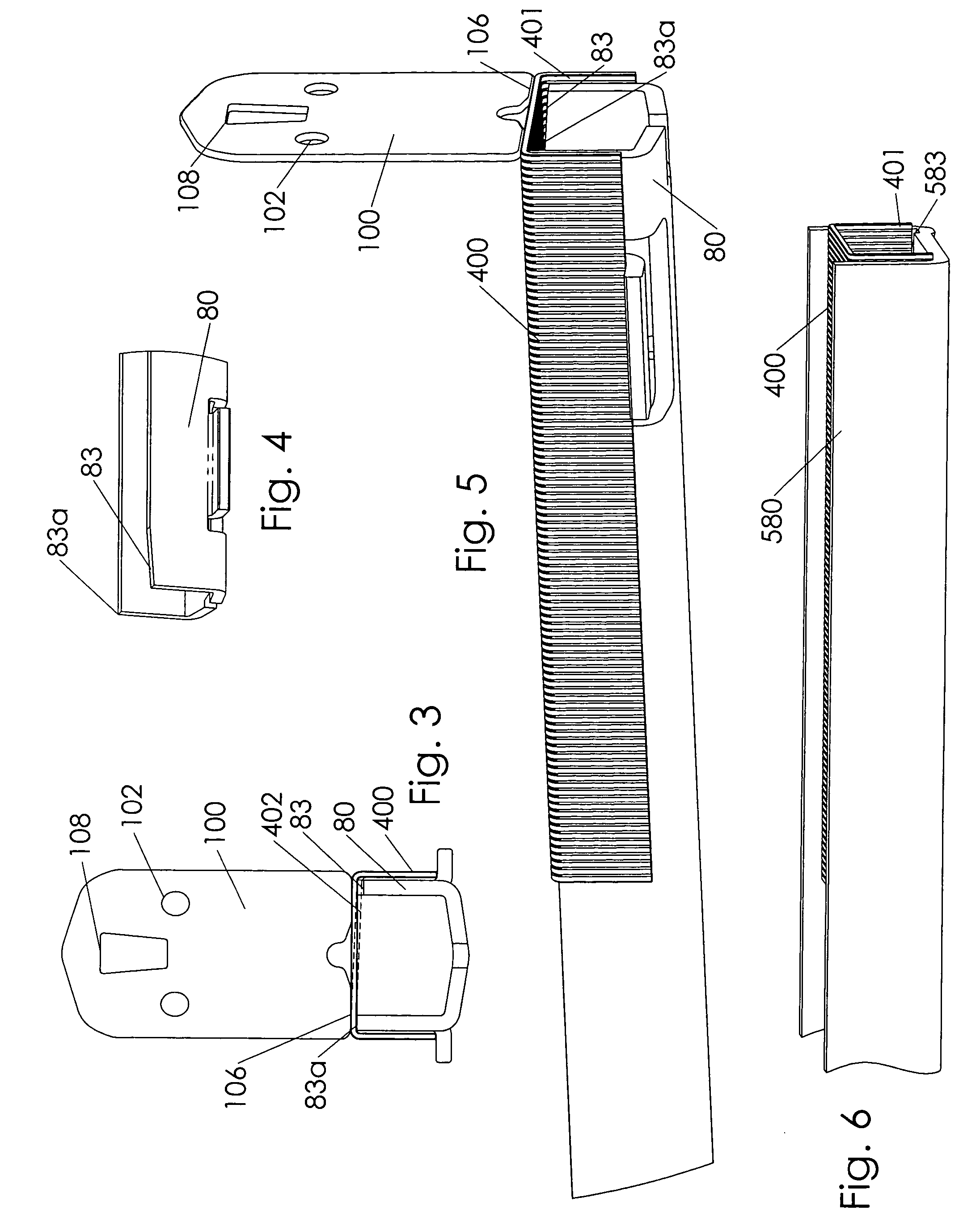

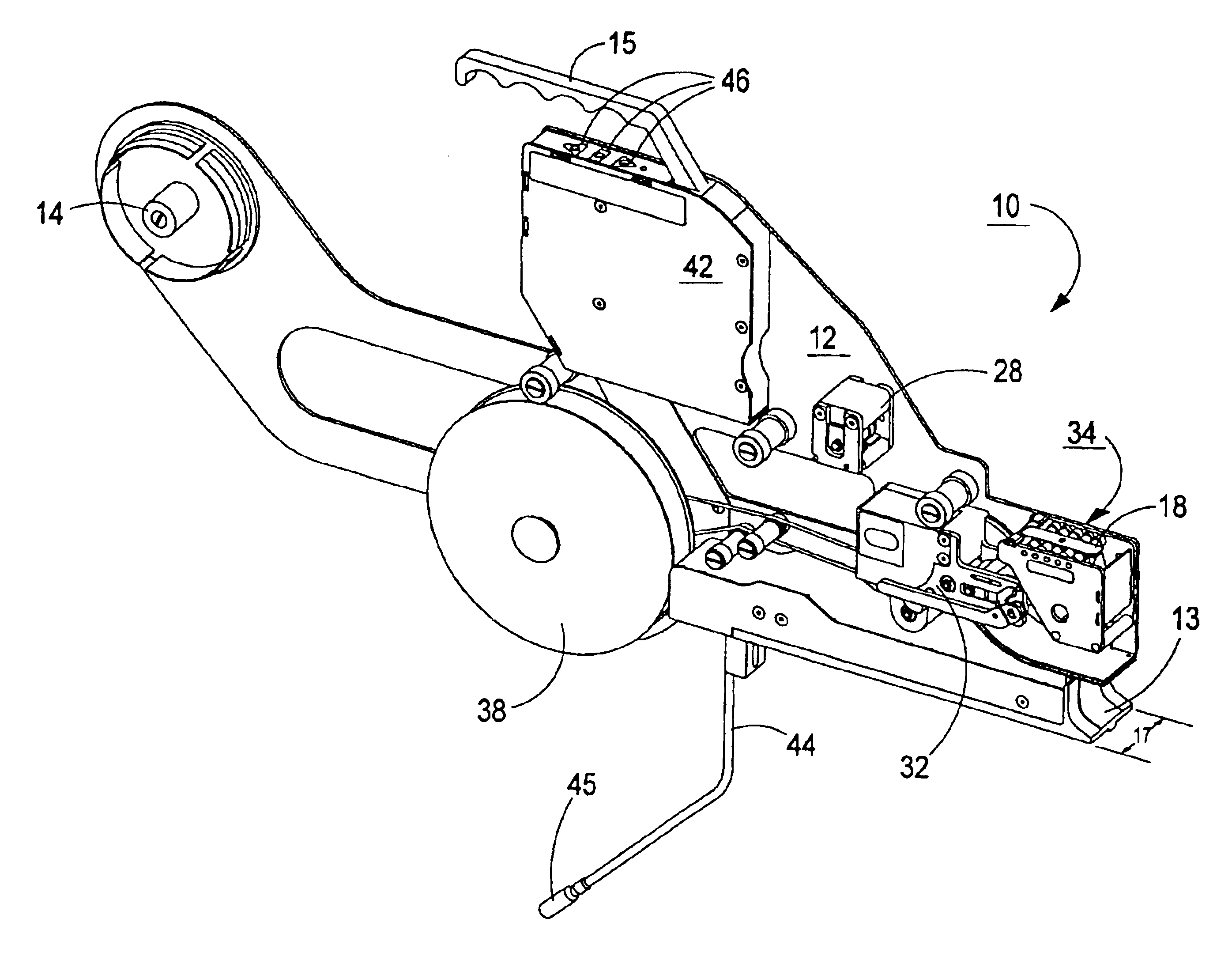

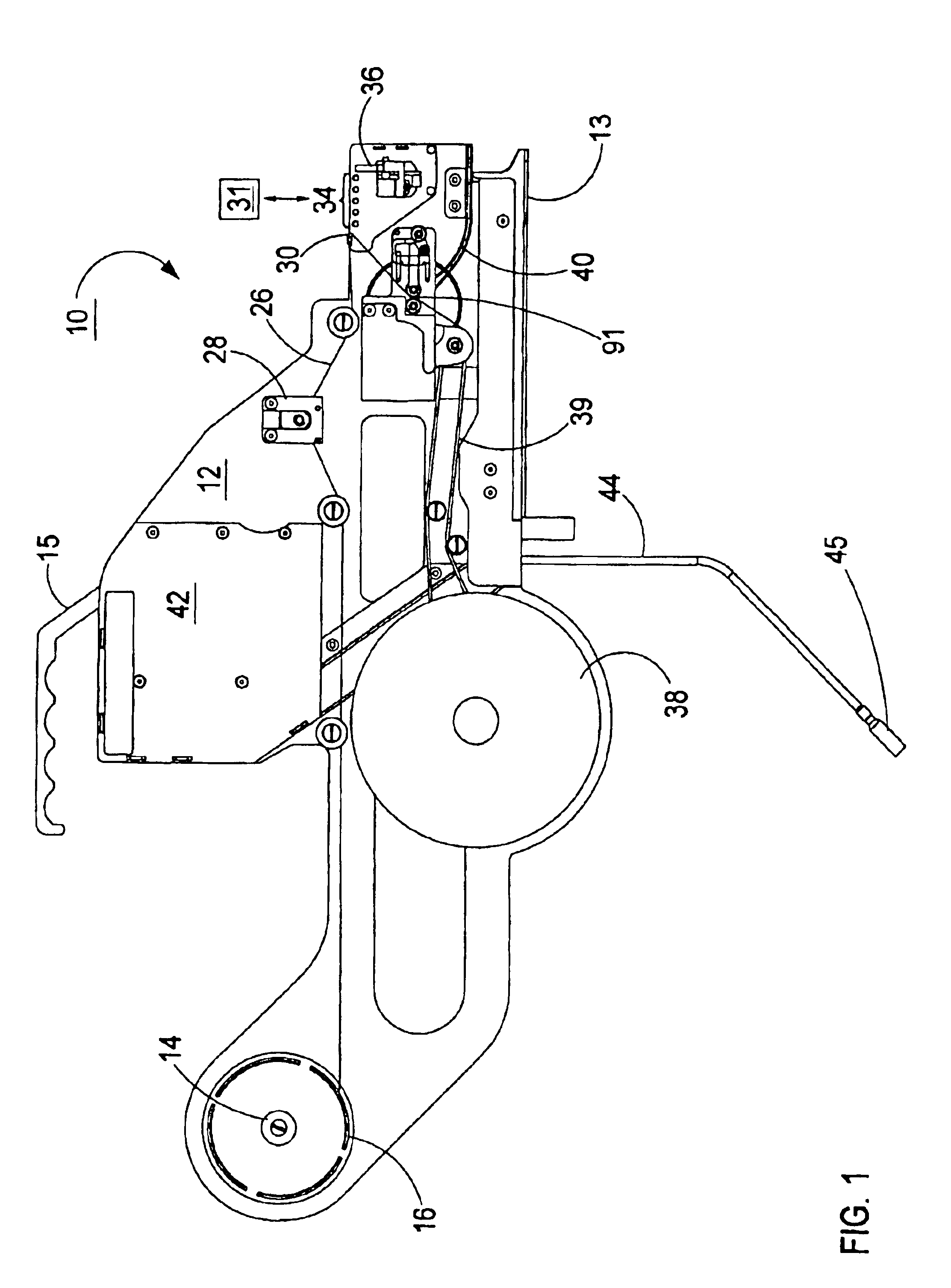

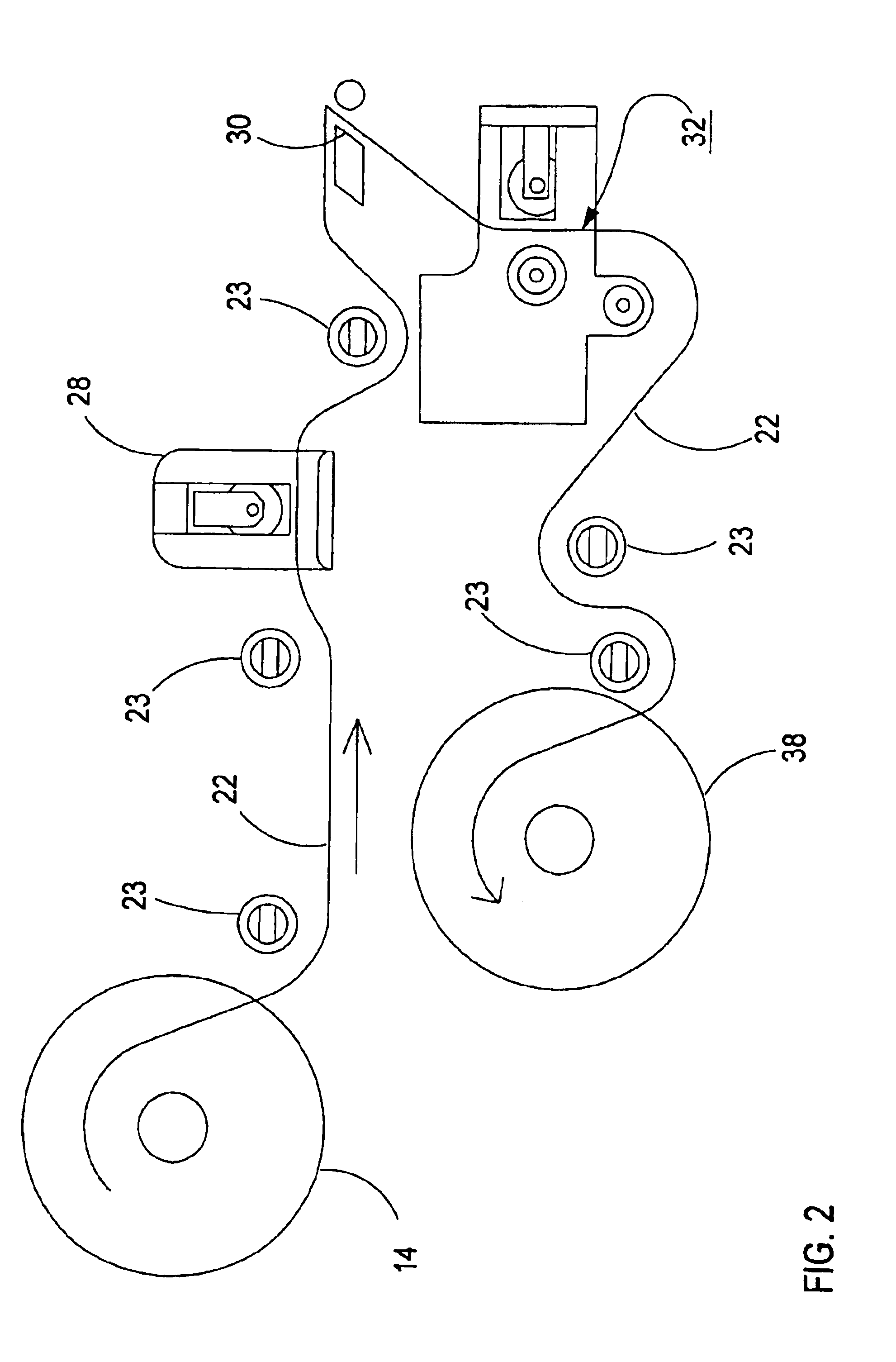

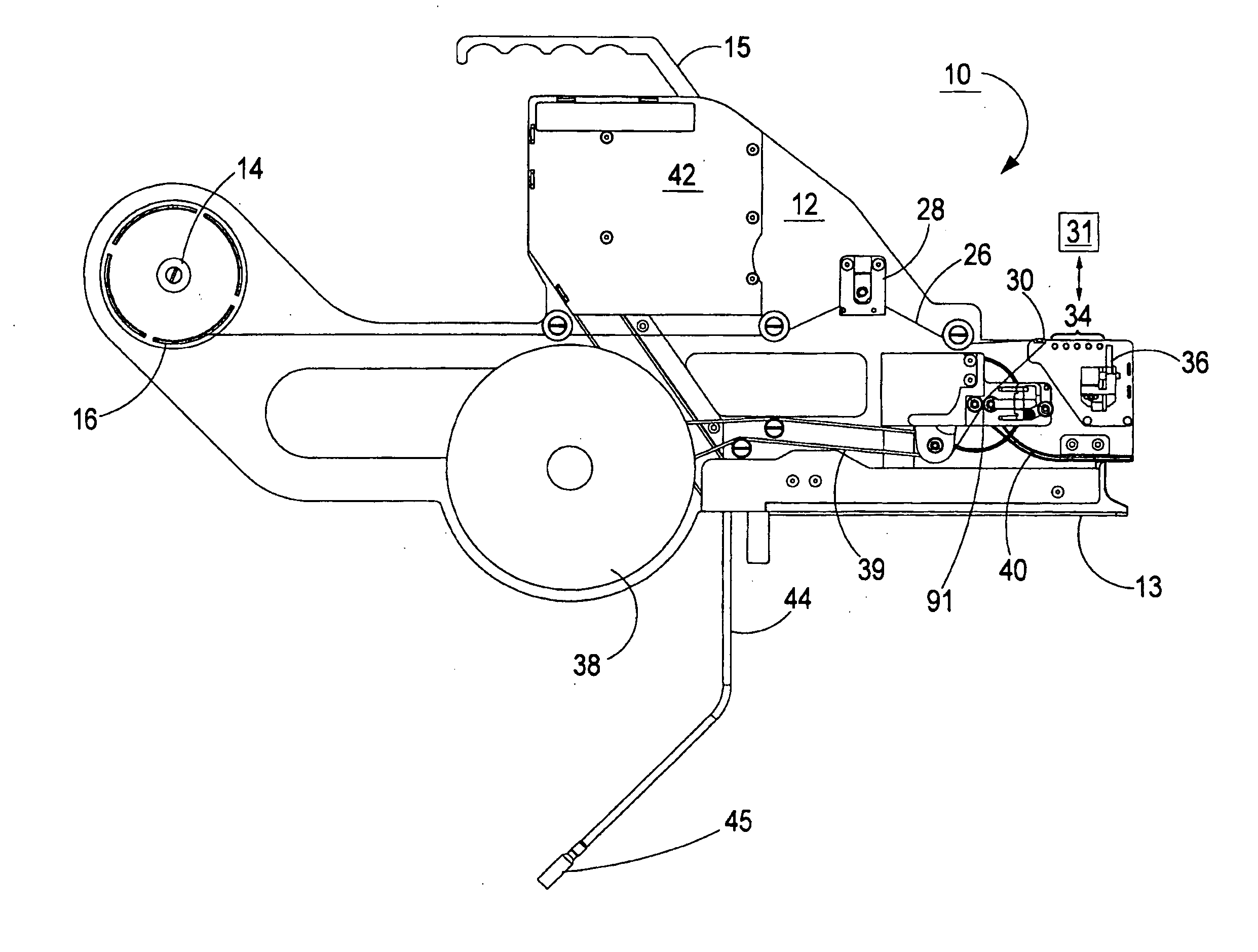

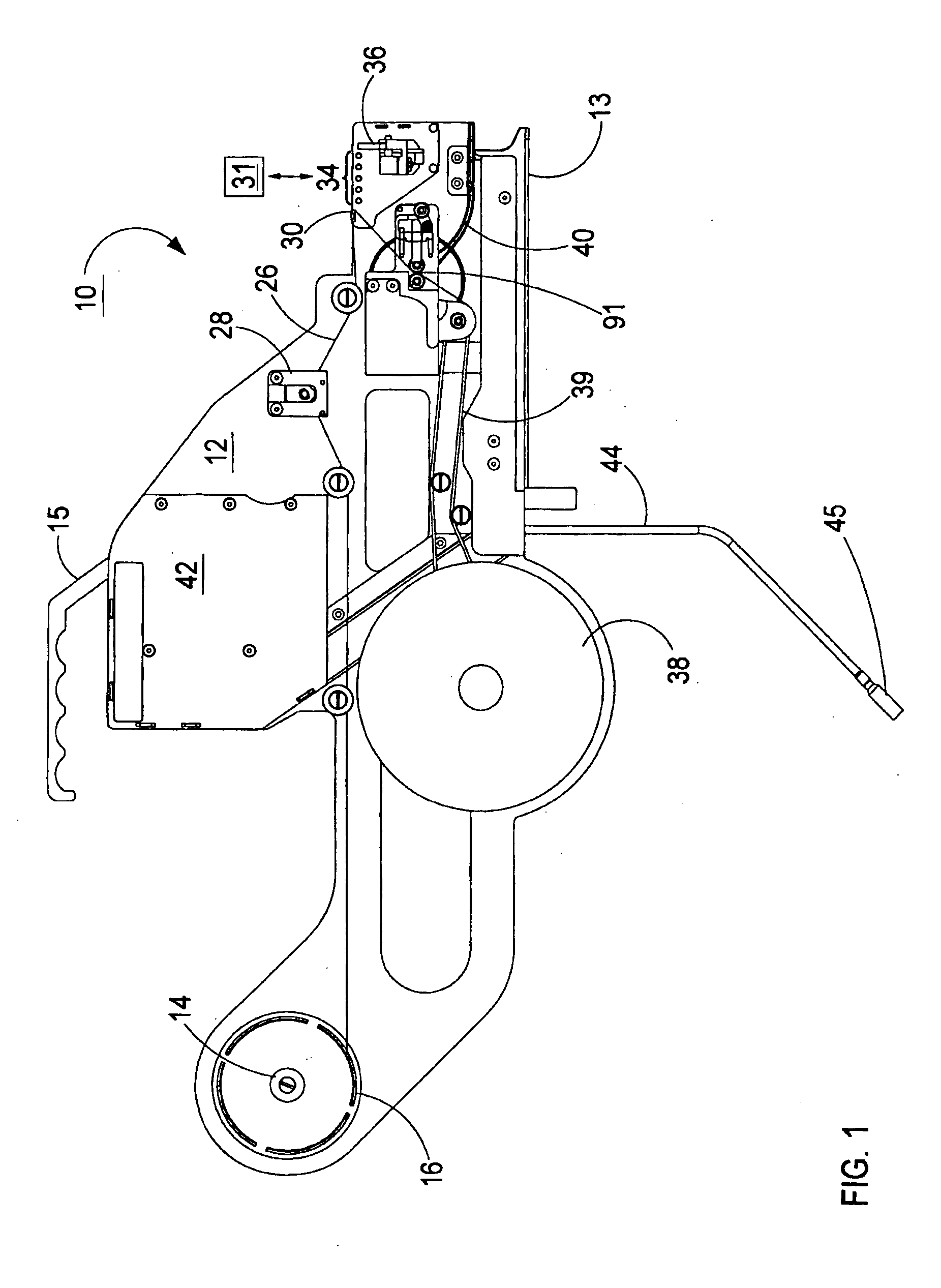

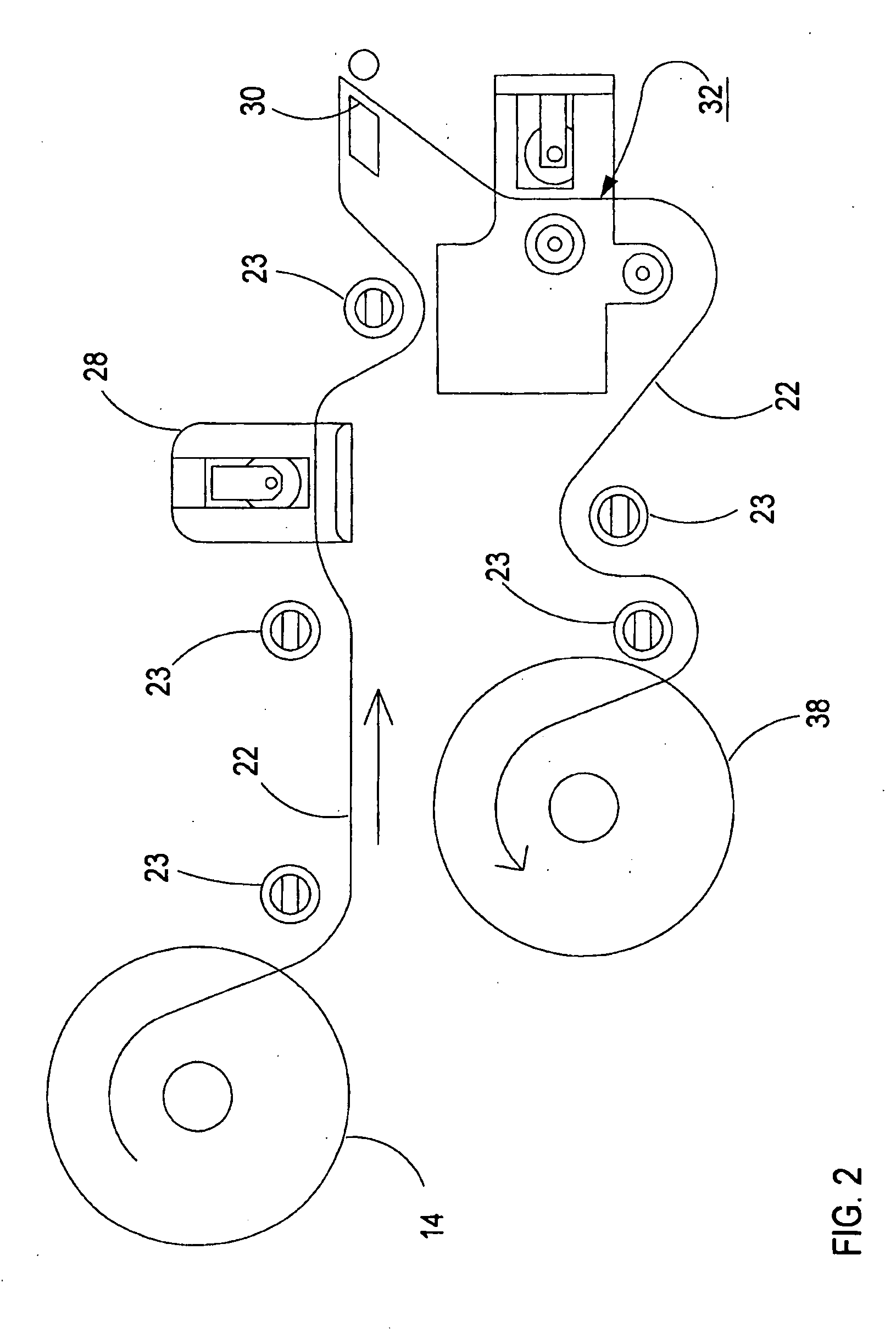

Surface mount assembly system with integral label feeder

InactiveUS6923878B2Enabling useMechanical working/deformationLamination ancillary operationsElectronic controllerAdhesive

The present invention is a method and apparatus conveying a roll of liner stock bearing removably adhered components such as labels. The liner is pulled through the feeder by a capstan drive having opposed fluted nip rollers driven by a stepper motor. Advance of the stepper motor is controlled by a programmable electronic controller. The linered labels are led through a tensioner and around an acute-angle peeler edge which separates the labels from the liner. The peeling action advances a label onto a platform comprising a bed of rollers having an inherently low-adherence surface. Preferably the rollers are undercut to form circumferential ridges and reduce the surface area in contact with the label adhesive and to minimize adherence thereto. When peeling of a label is completed, the label has been advanced onto the roller bed to precisely the proper location for acquisition by a pick-and-place machine. The presence of a label on the platform is confirmed by a sensor that signals the controller to stop further liner advance. The signal also serves to reset the feeder for advance of the next label after the first label is picked from the roller bed.

Owner:UI HLDG

Transferring and bonding device for brittle member

InactiveCN1993821AAvoid damageSemiconductor/solid-state device manufacturingAdhesivesEngineeringPeeling action

A transferring and bonding device for a brittle member capable of peeling off a hard member from the brittle member without adding a stress more than required to the brittle member and effectively preventing the brittle member from being damaged by erroneous peeling. When the hard member is peeled off from a stuck structure formed by sticking the brittle member on the upper surface of the hard member through a double coated adhesive sheet to transfer and bond the brittle member onto the adhesive sheet, the adhesive tape is stuck on the brittle member side of the stuck structure to form it integrally with a frame, the hard member side is fixedly positioned on a table (8), and the frame (6) is raised, about a rotating shaft (13), diagonally upward relative to the surface of the table with a specified torque by a torque control motor (12). The hard member is peeled off from the brittle member with a force for raising the frame, i.e., with the specified torque. When the hard member is peeled off, the peeling action is confirmed by a peeling confirmation means (37) formed of two reflection sensors (38-1, 38-2).

Owner:LINTEC CORP

Surface mount assembly system with integral label feeder

InactiveUS20050252599A1Lamination ancillary operationsDecorative surface effectsElectronic controllerAdhesive

The present invention is a method and apparatus conveying a roll of liner stock bearing removably adhered components such as labels. The liner is pulled through the feeder by a capstan drive having opposed fluted nip rollers driven by a stepper motor. Advance of the stepper motor is controlled by a programmable electronic controller. The linered labels are led through a tensioner and around an acute-angle peeler edge which separates the labels from the liner. The peeling action advances a label onto a platform comprising a bed of rollers having an inherently low-adherence surface. Preferably the rollers are undercut to form circumferential ridges and reduce the surface area in contact with the label adhesive and to minimize adherence thereto. When peeling of a label is completed, the label has been advanced onto the roller bed to precisely the proper location for acquisition by a pick-and-place machine. The presence of a label on the platform is confirmed by a sensor that signals the controller to stop further liner advance. The signal also serves to reset the feeder for advance of the next label after the first label is picked from the roller bed.

Owner:DELAWARE CAPITAL FORMATION INC

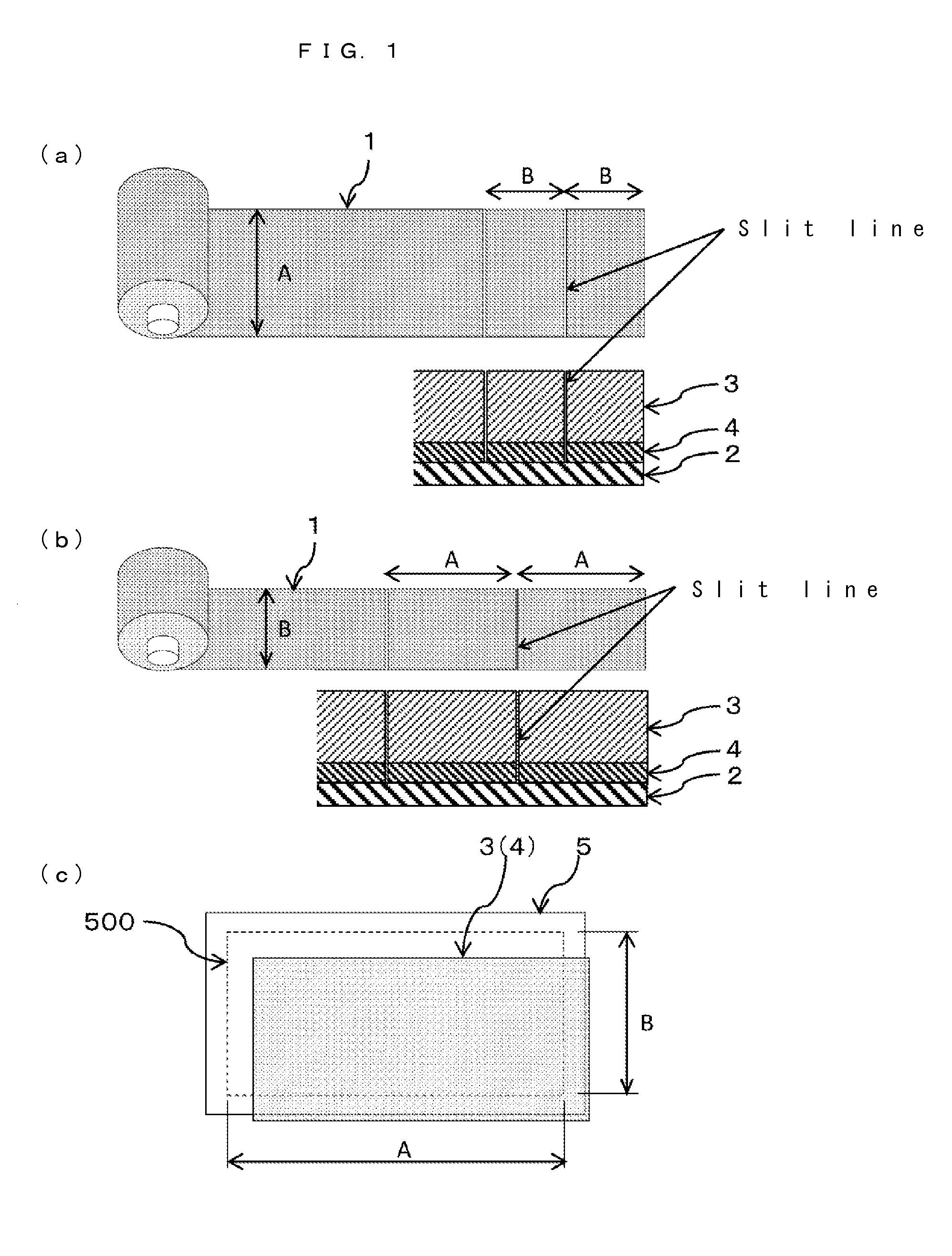

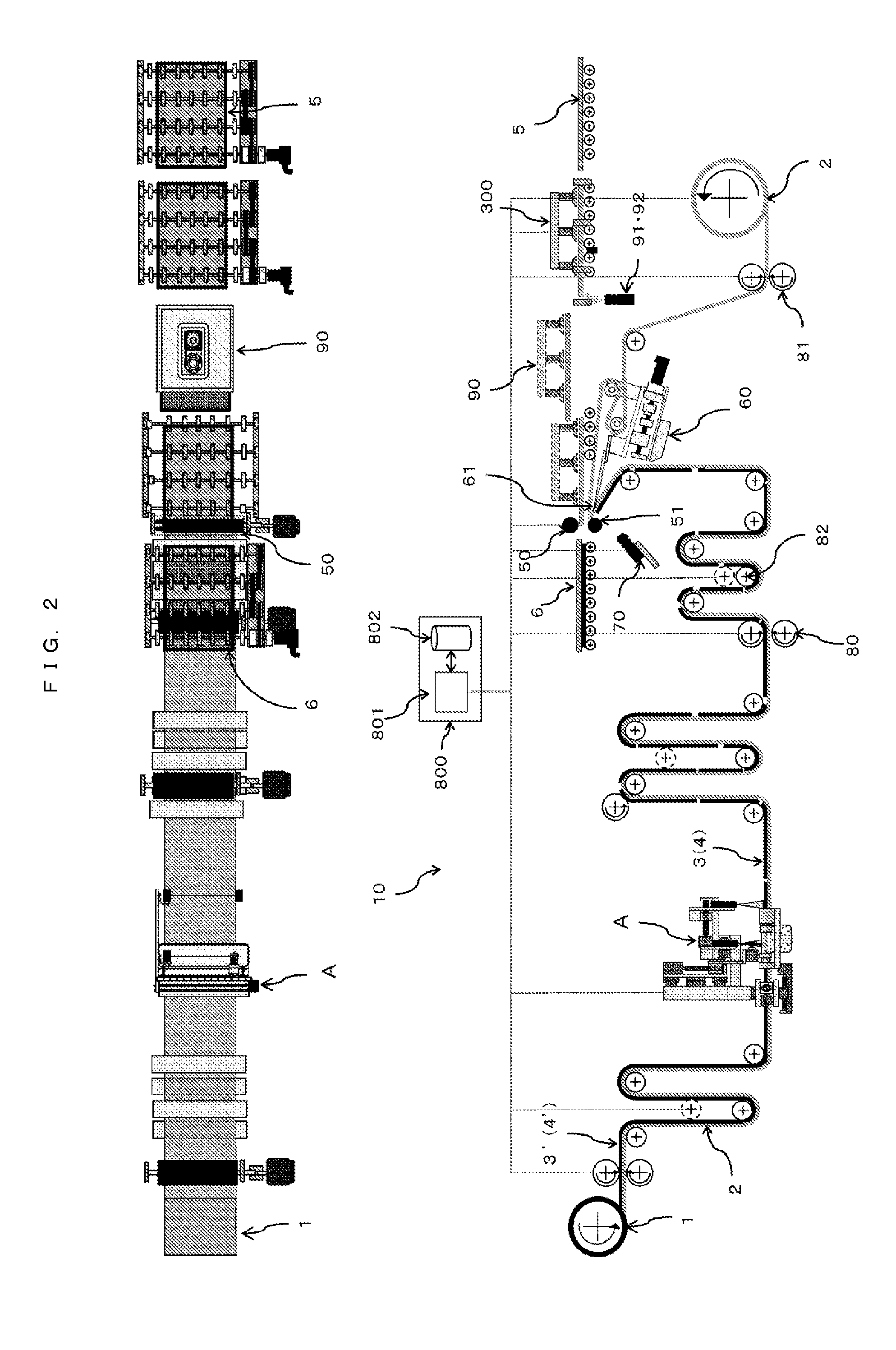

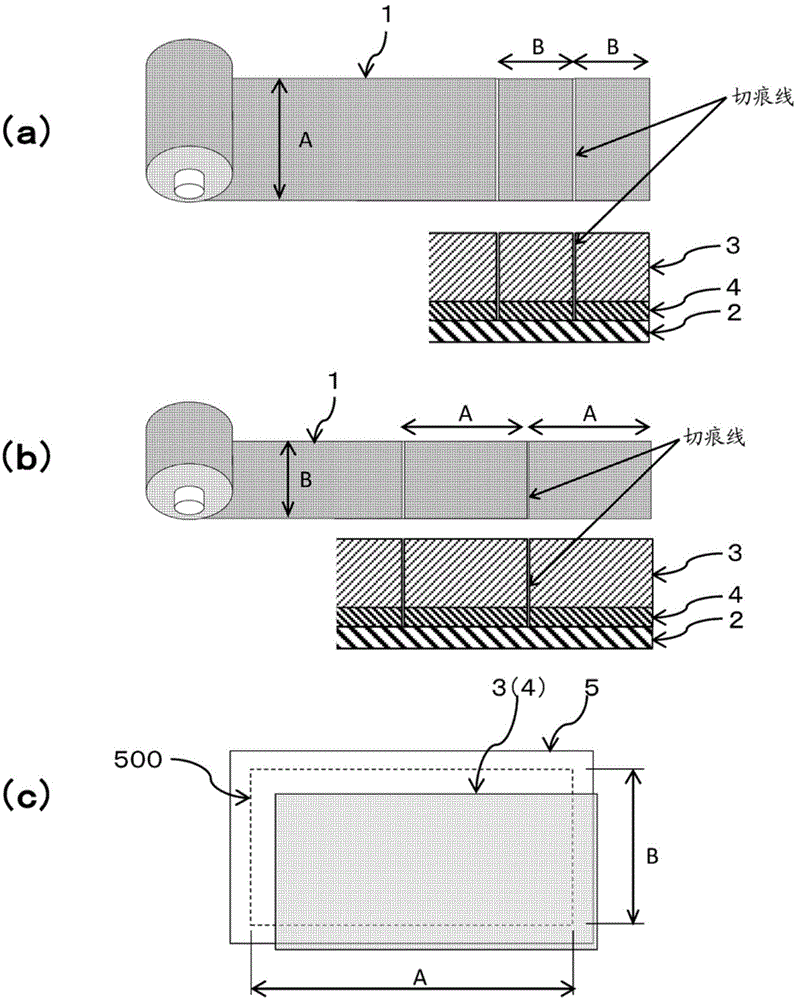

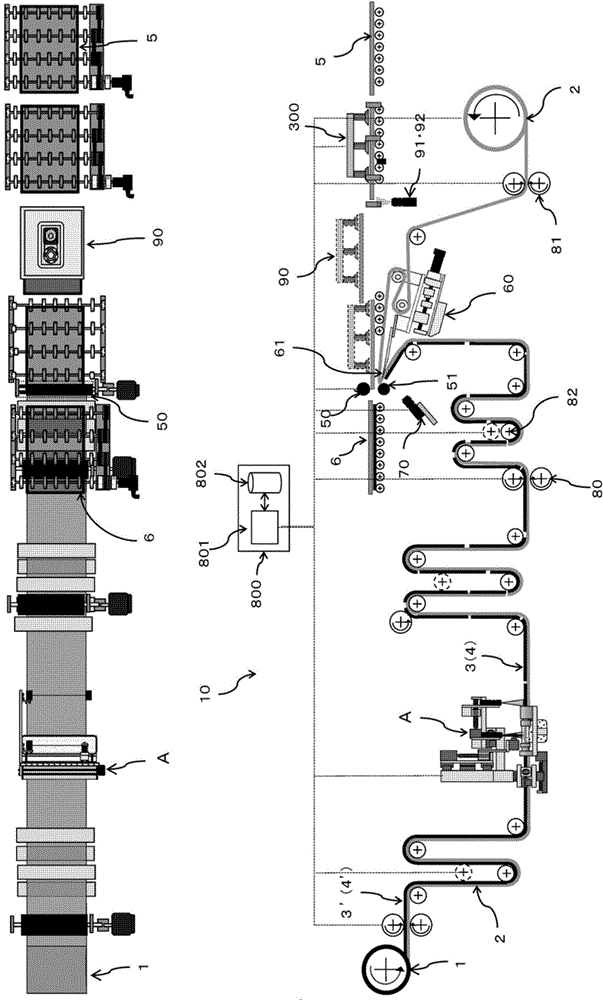

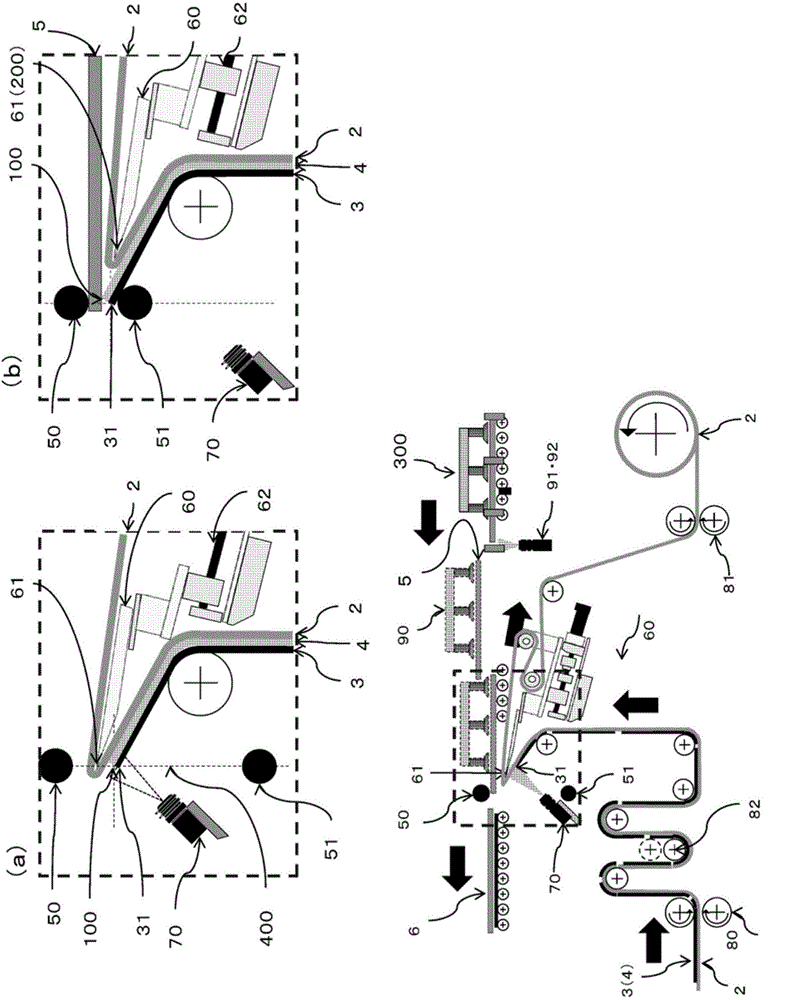

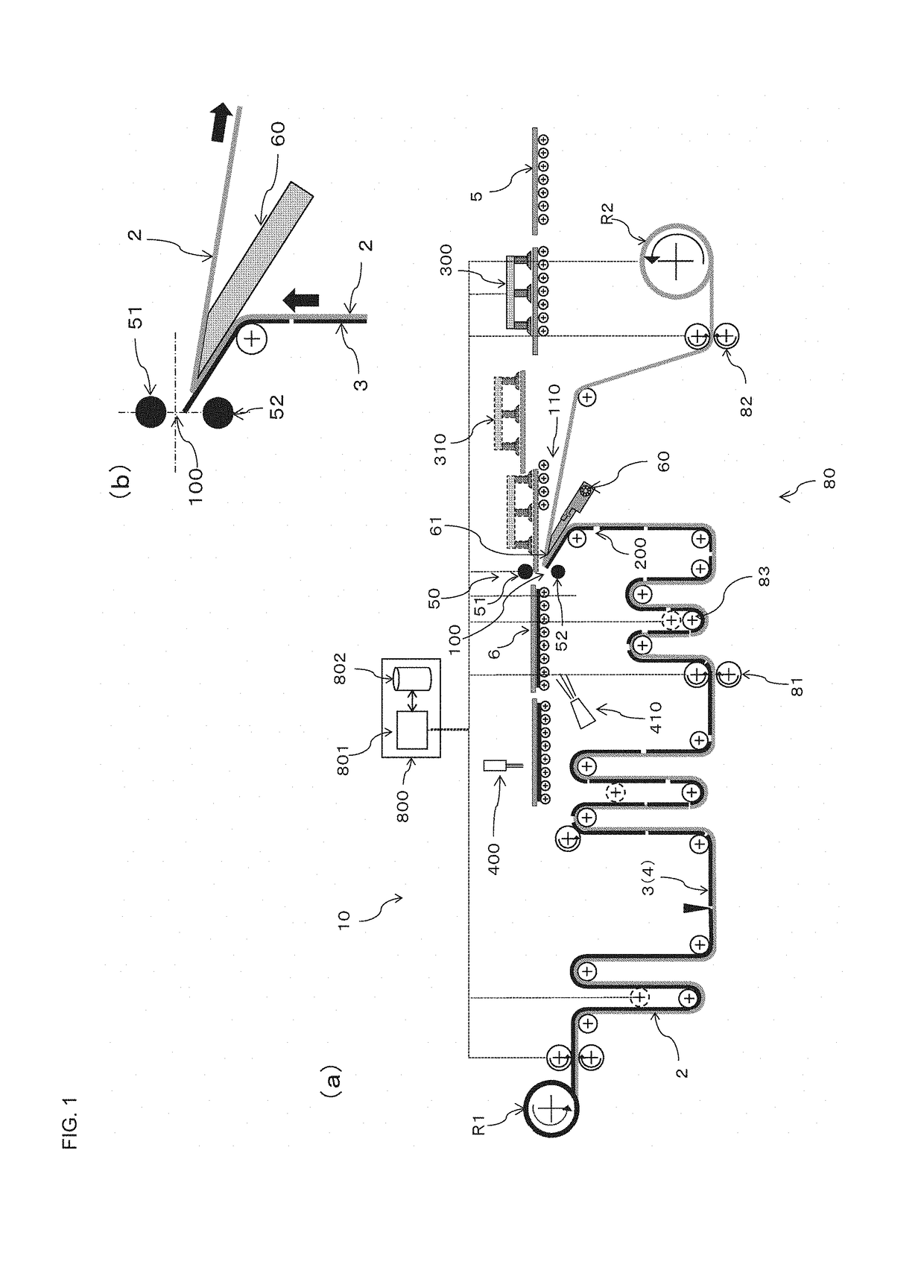

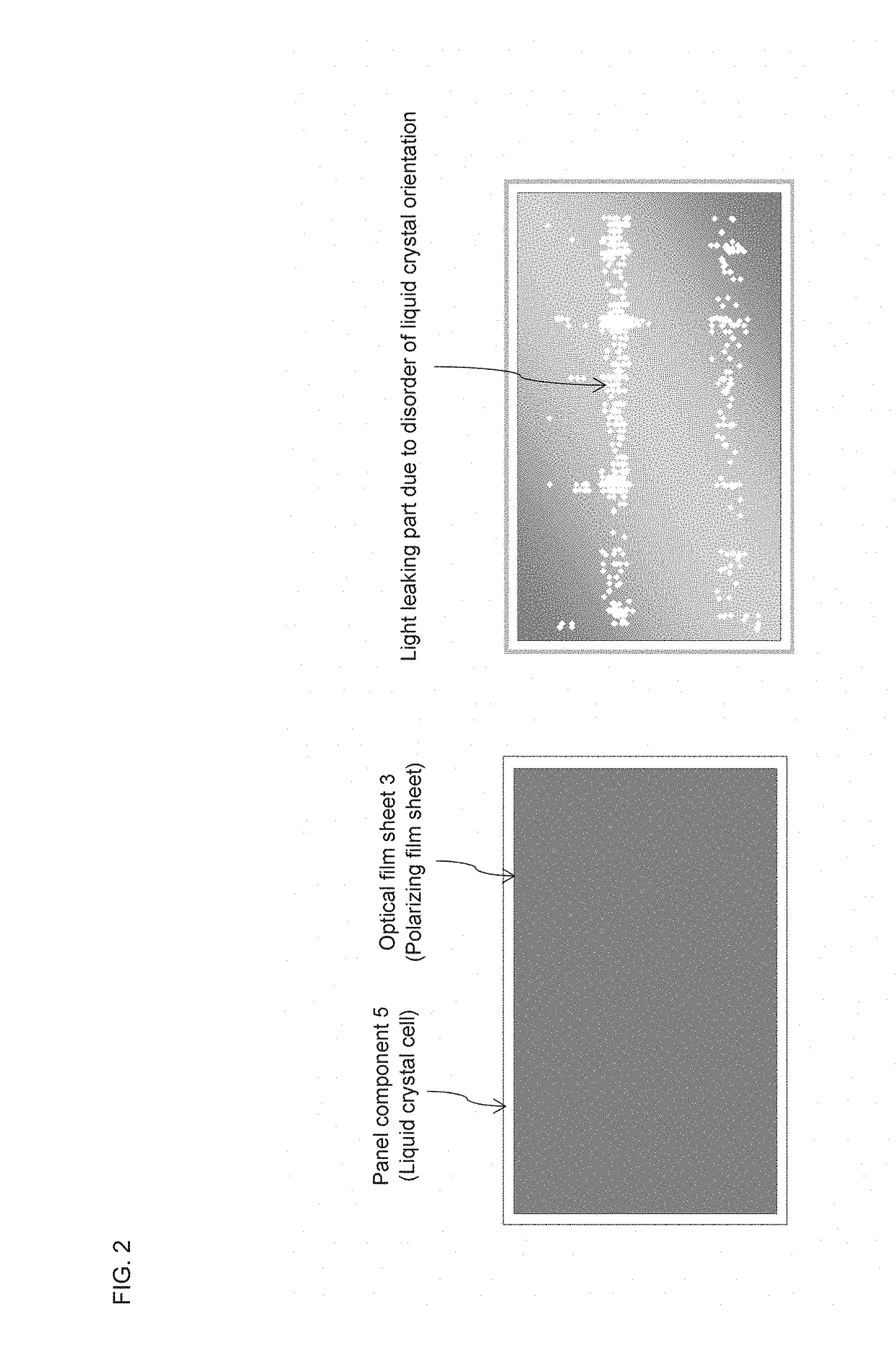

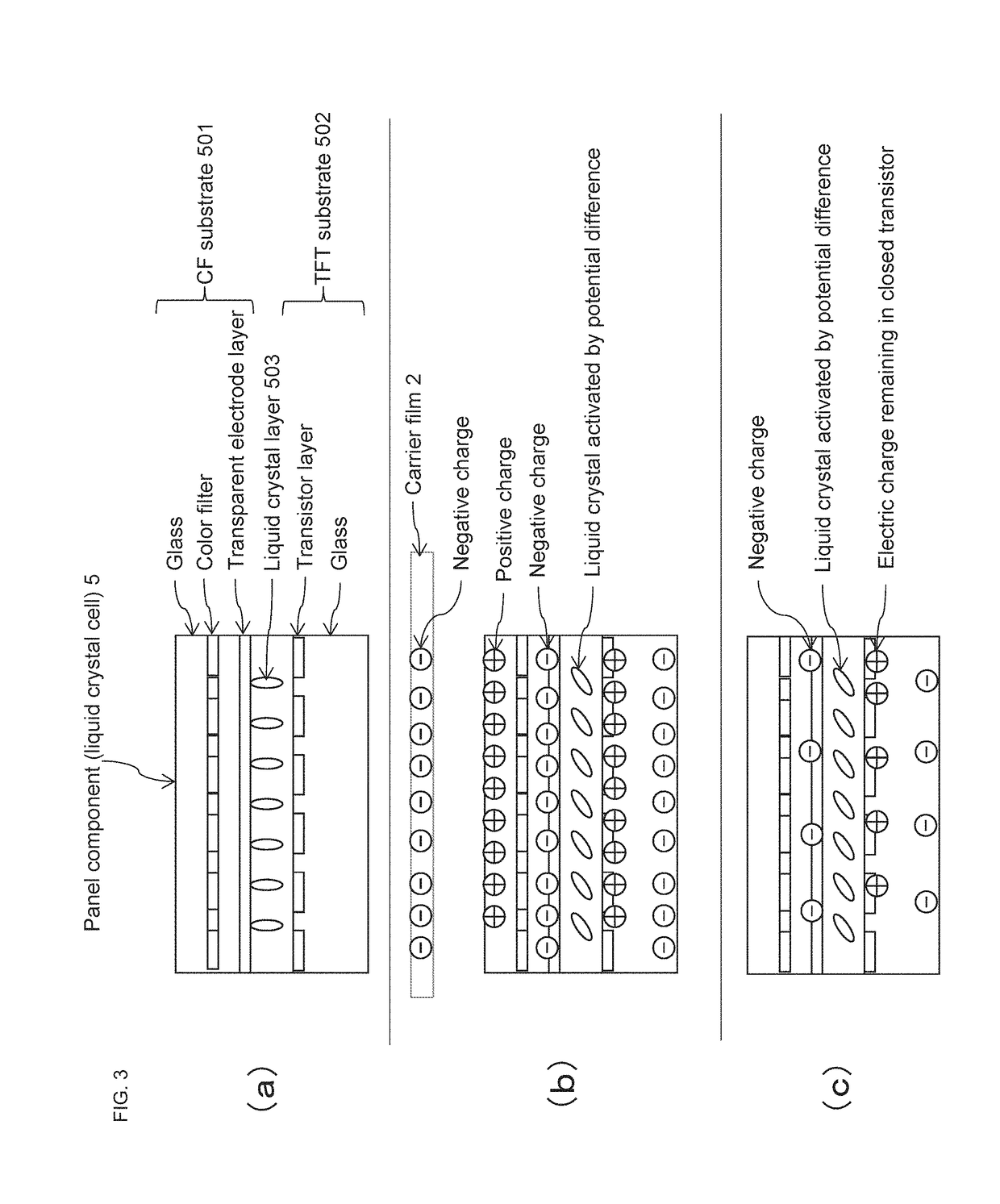

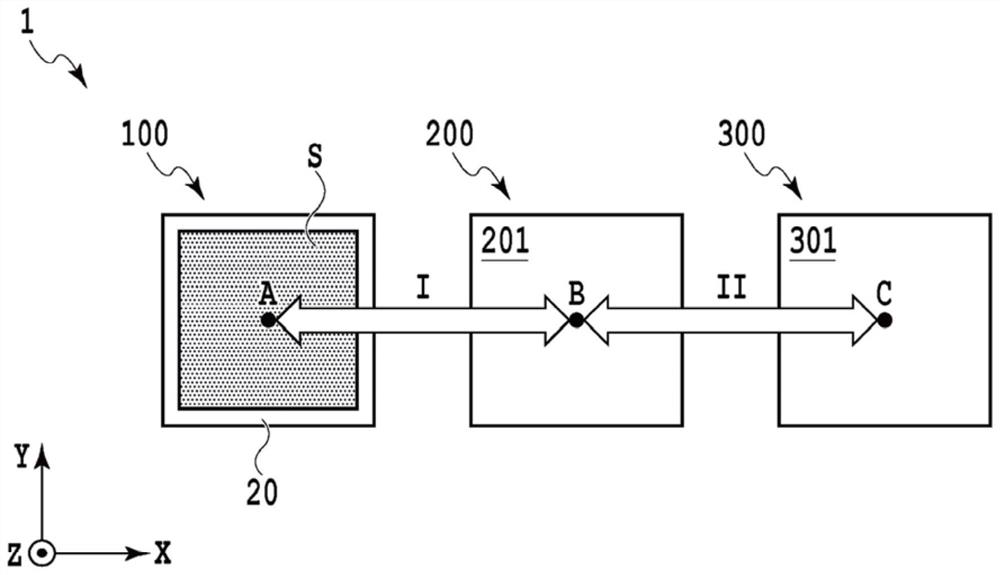

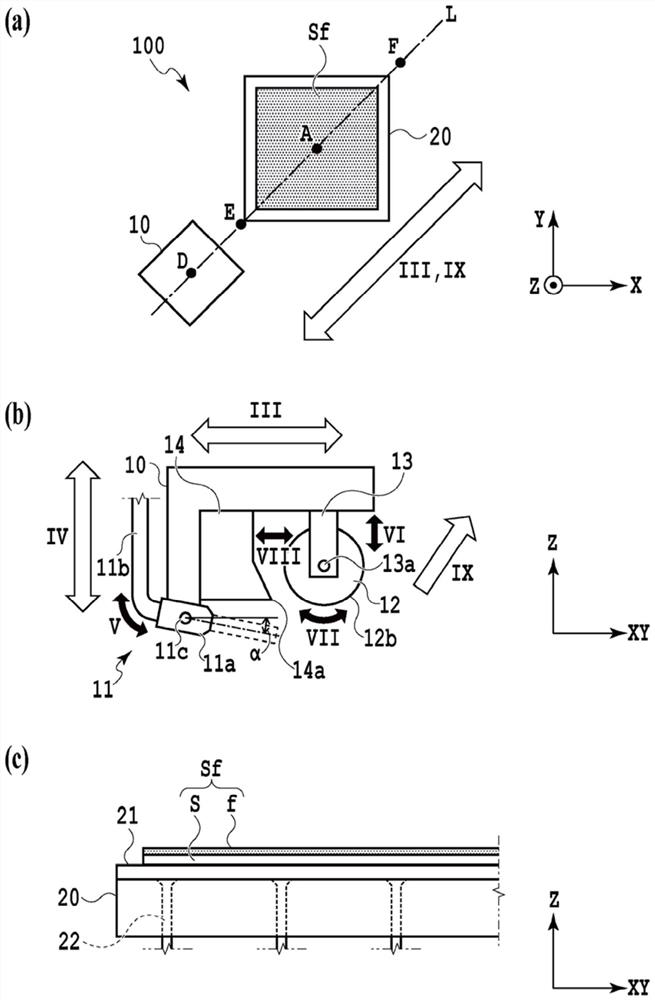

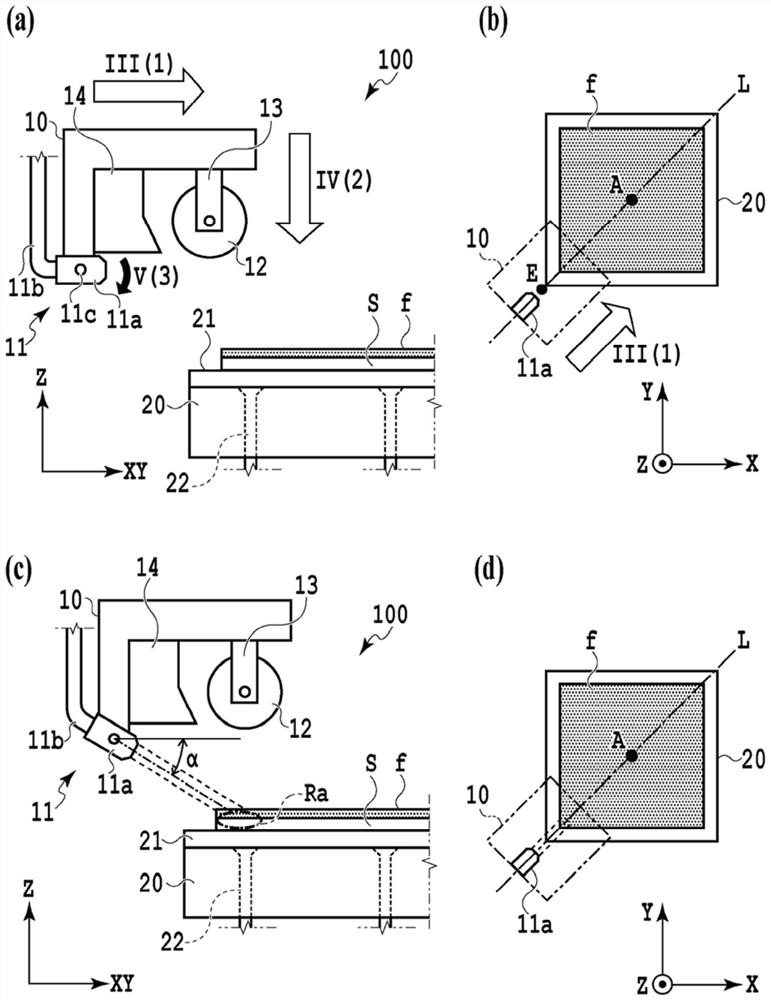

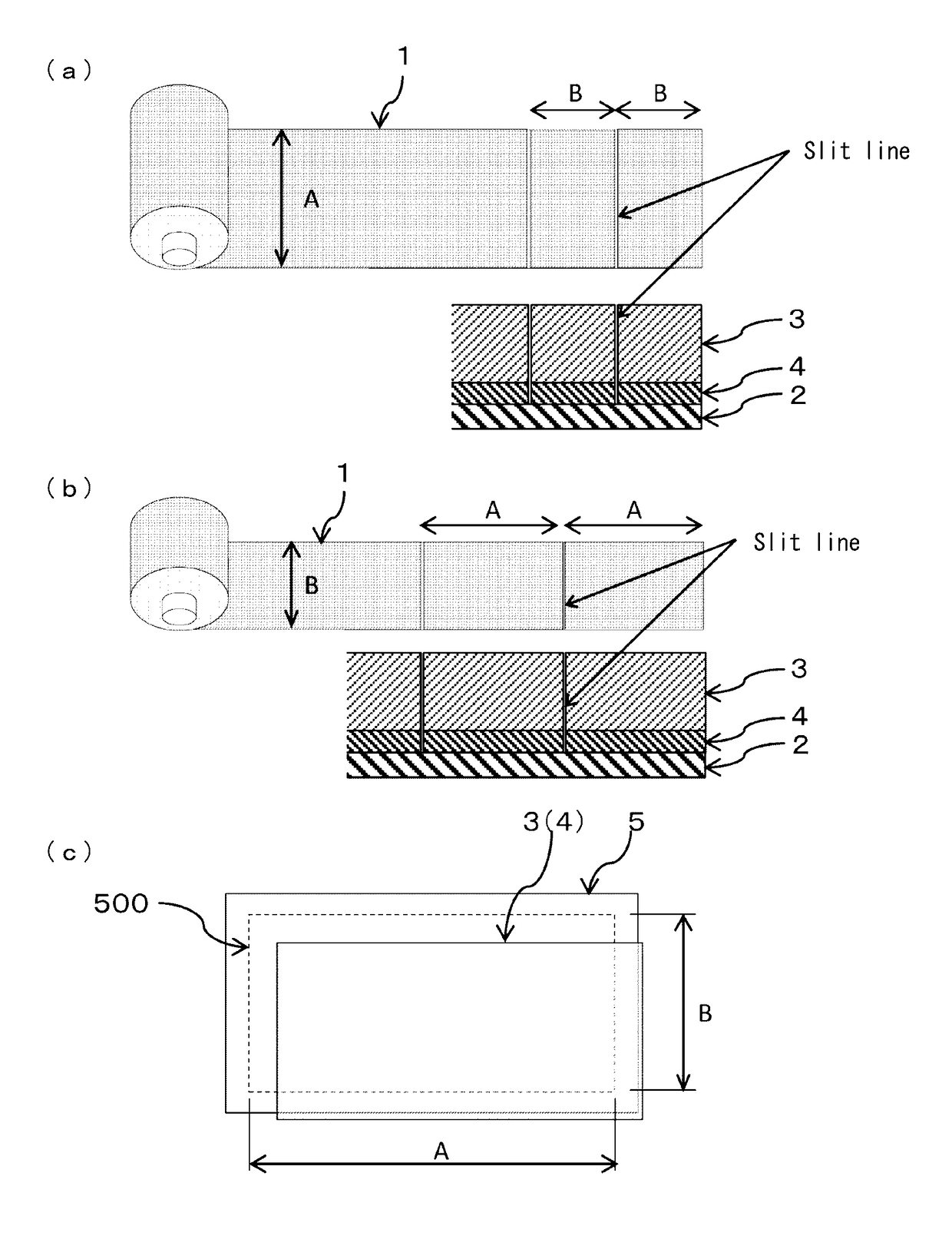

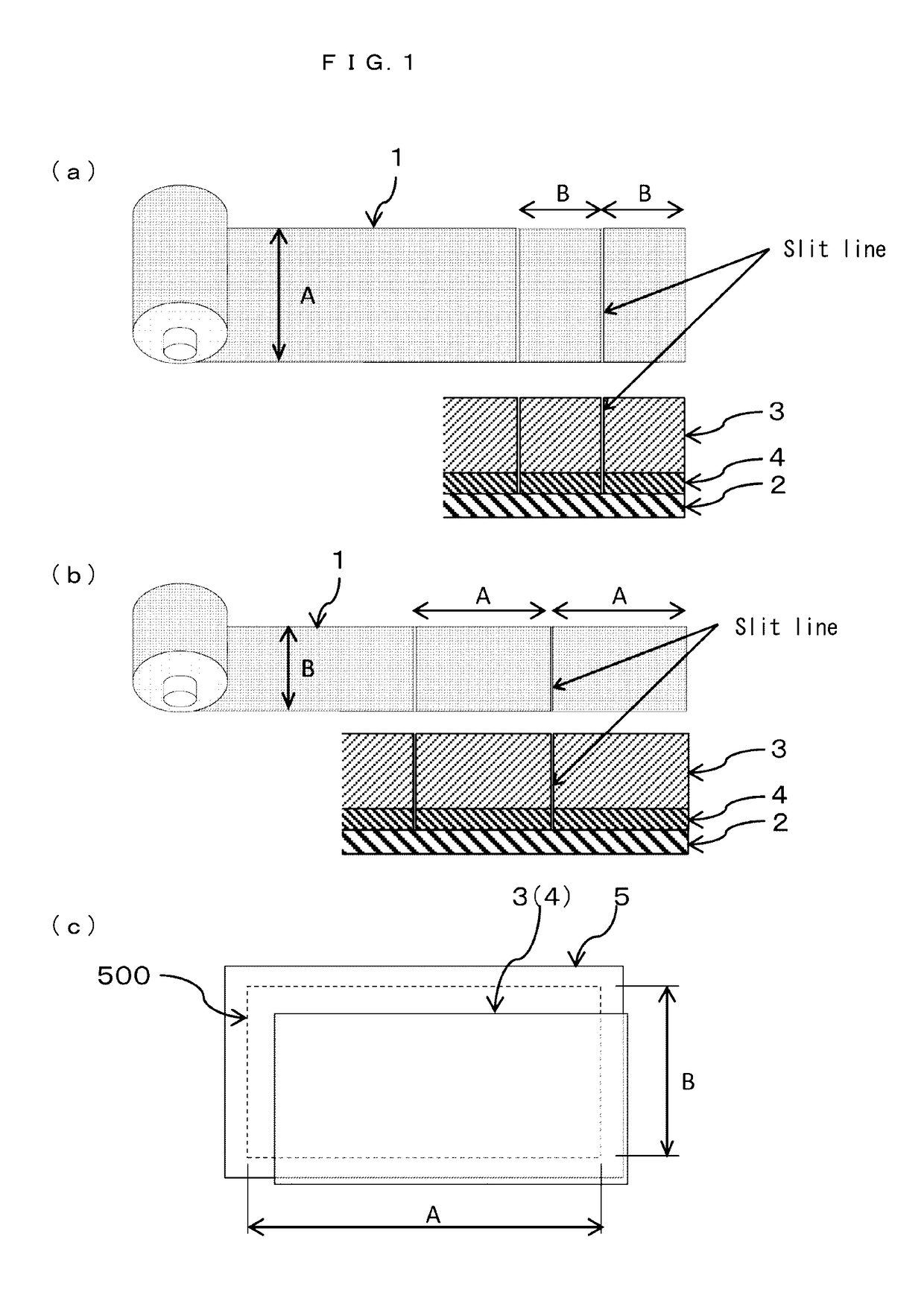

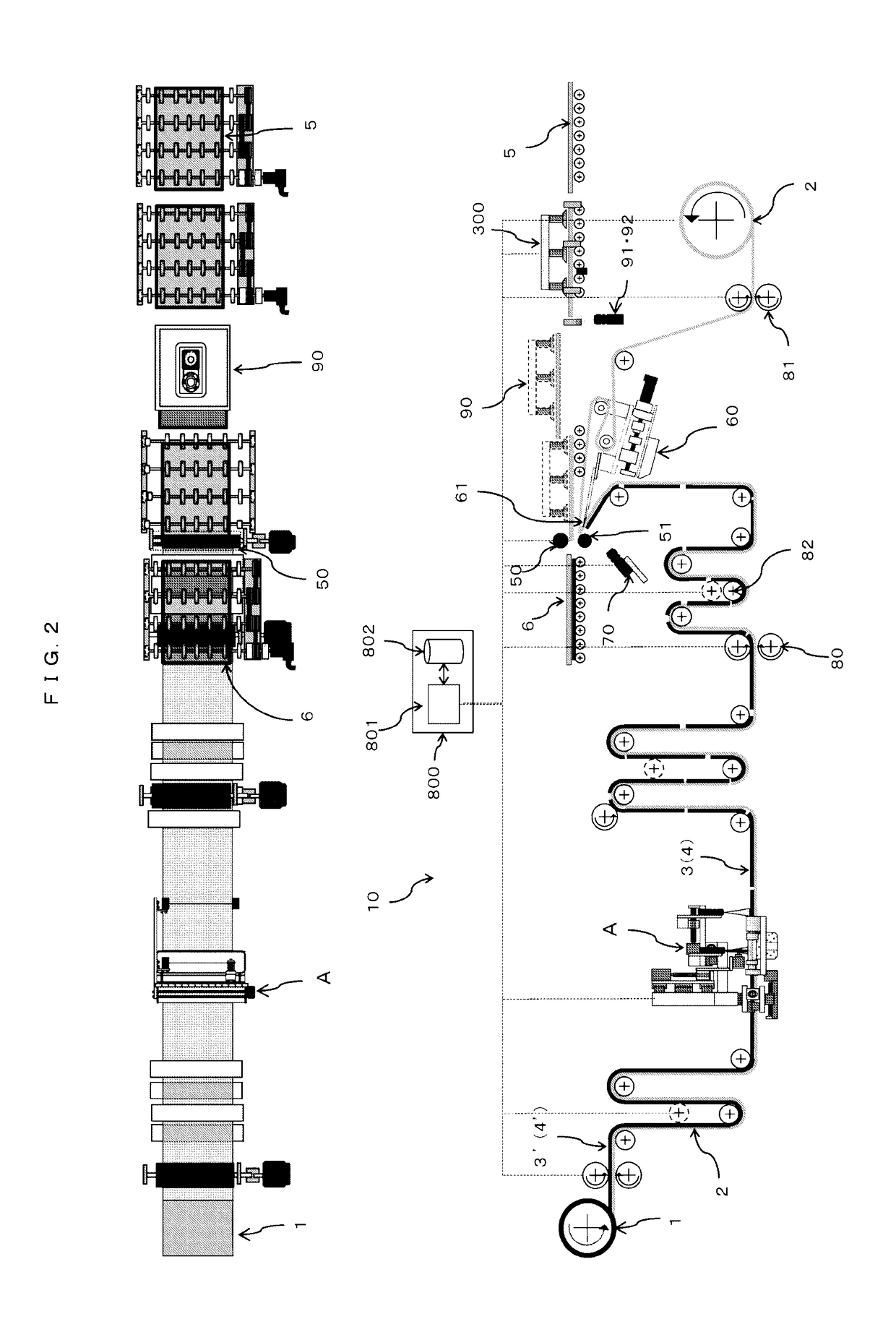

Method and apparatus for manufacturing optical display device

InactiveUS20150277162A1High lamination precisionLamination ancillary operationsLaminationDisplay deviceEngineering

A method for manufacturing an optical display device comprises: sequentially peeling a plurality of optical film sheets continuously supported via an adhesive layer on one of opposite surfaces of a carrier film, together with the adhesive layer from the carrier film under peeling action of the movable peeling member by winding a long web of the carrier film in a state where the other of opposite surfaces thereof being folded to inside at a tip-end of the movable peeling member having the tip-end and passed around the peeling member; and laminating the plurality of optical film sheets to one of opposite surfaces of respective ones of panel components via the adhesive layer under laminating action of the closed lamination rollers.

Owner:NITTO DENKO CORP

Adhesive tape automatic peeling device

InactiveCN110589598AThe peeling process is stable and regularAffect aestheticsArticle deliveryAdhesive beltMobile phone

The invention discloses an adhesive tape automatic peeling device and relates to the field of mobile phone assembling. The adhesive tape automatic peeling device comprises a material discharging mechanism, a material collecting mechanism and an adhesive tape peeling mechanism; the material discharging mechanism discharges an adhesive tape and conveys the adhesive tape to the adhesive tape peelingmechanism; the adhesive tape peeling mechanism peels off an adhesive strip from a release paper of the adhesive tape conveyed to the adhesive tape peeling mechanism; the adhesive tape peeling mechanism comprises an adhesive tape peeling platform and an adhesive peeling platform; the adhesive tape peeling platform is used for placing the adhesive tape to finish the peeling work of the release paper; the adhesive peeling platform adsorbs a protective film and an adhesive strip of the adhesive tape to finish the peeling work of the adhesive strip; and the material collecting mechanism winds the peeled release paper. According to the adhesive tape automatic peeling device, as manual adhesive tape peeling action is simulated to automatically peel off the adhesive tape, manual operation can be replaced so that the production efficiency is enhanced; and moreover, the separated release paper can be recycled to prevent the release paper from being wound on a machine to affect the beauty and safety of equipment; through the adhesive tape peeling platform and the adhesive peeling platform which are separately arranged, the release paper and the adhesive strip are partitioned after being peeled off to guarantee the adhesive peeling effect.

Owner:SHENZHEN JIYIN TECH

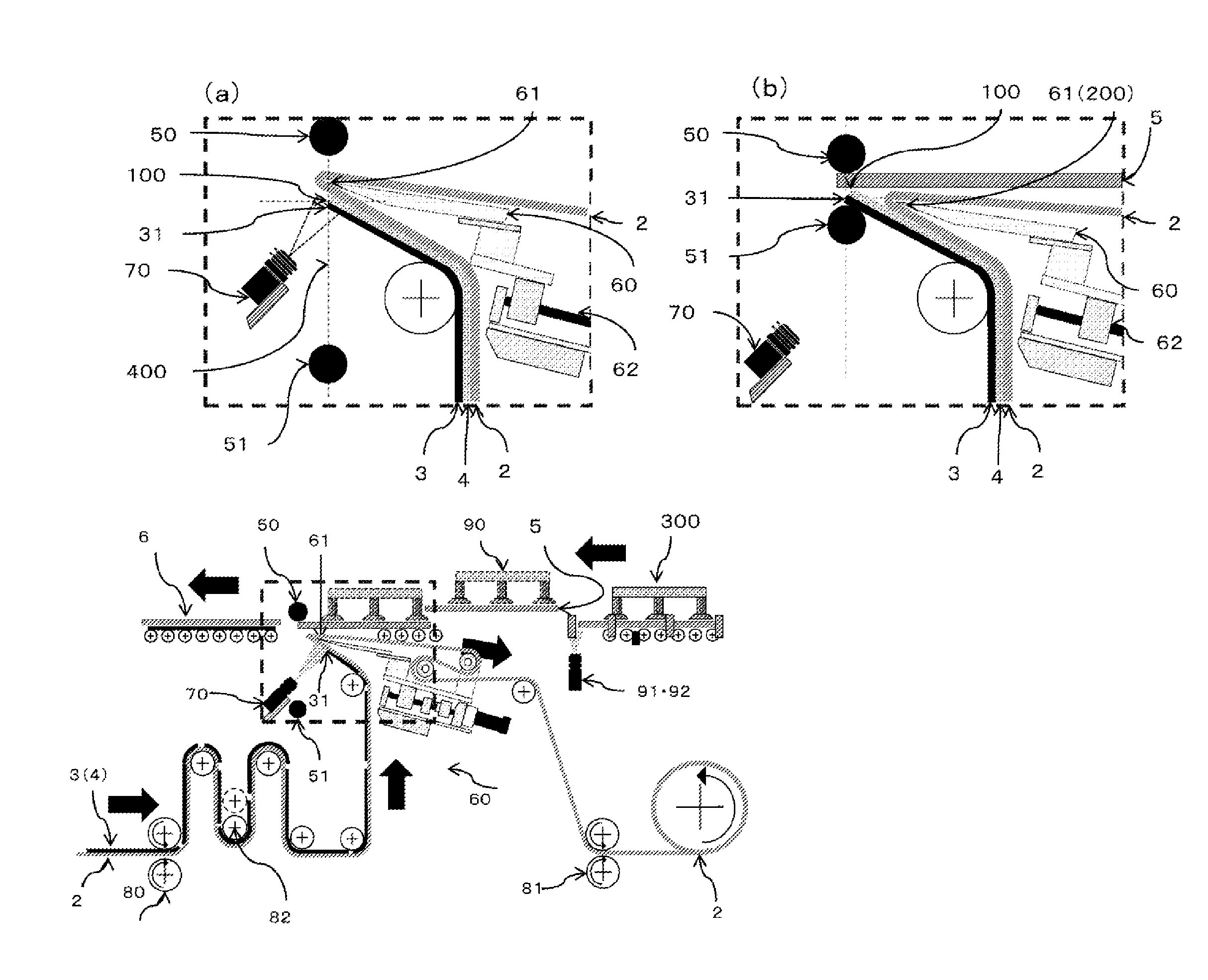

Method and device for manufacturing optical display device

Provided are a method and device for manufacturing an optical display device in which optical sheets are peeled sequentially and bonded to panel members, said optical film sheets being continuously supported on an elongate web-shape carrier film together with an adhesive layer. An optical display device is manufactured using a moveable peeler which is provided with bonding rollers configured to open and close vertically relative to the feed direction of the optical display device, and with a top part that can be inserted between and removed from between the opened bonding rollers. In particular, in manufacturing the optical display device, by winding an elongate web-shape carrier film in a state in which the back surface is folded back inwards by the top part of the moveable peeler and is wound around the moveable peeler, multiple optical film sheets, which are supported continuously on one surface of the carrier film through intermediary of an adhesive layer, are sequentially peeled from the carrier film together with the adhesive layer through the peeling action of the moveable peeler and are bonded, through intermediary of an adhesive layer, to one surface of a panel member through the bonding action of the closed bonding rollers.

Owner:NITTO DENKO CORP

Insulated wire peeling device

InactiveCN110661209AEasy to manageLabor savingApparatus for removing/armouring cablesElectrical connectionControl theory

An insulated wire peeling device comprises a support, a peeling knife, a heating device and a main controller. The support is arranged on the main controller; and the peeling knife and the heating device are connected with the main controller. According to the insulated wire peeling device, the main controller is used for controlling electrical connection and simulating the manual peeling action,and only electricity is needed, so that management is convenient, labor is saved, and the product quality and the working efficiency are improved.

Owner:韦娜诗

Agricultural rapeseed efficient peeling device

The invention discloses a high-efficiency stripping device for agricultural rapeseed, which comprises a stripping device body, an annular stripping chamber and a collection chamber are arranged in the stripping device body, the annular stripping chamber is located in the upper end of the stripping device body, and the annular stripping chamber The upper end of the cover plate is provided with a cover plate, and the lower end of the cover plate is fixedly connected to the upper end of the C-shaped locking ring. The middle part of the upper end of the C-shaped locking ring is provided with a through port, which communicates with the opening, and the middle part of the opening is fixedly connected to the center shaft. One end, the other end of the central axis runs through the middle of the two levers, the lower ends of the two levers extend into the annular stripping cavity and are fixedly connected to one end of the first extension plate, the upper ends of the two levers extend above the opening, and the set The division of labor between the annular stripping chamber and the collection chamber is clear, which makes the overall device more aesthetically pleasing. The set cover plate protects the annular stripping chamber, eliminating potential safety hazards. The C-shaped locking ring is set to fix the rape stalks, and the up and down movement of the stripping sleeve Form a peeling effect on the rape stalk.

Owner:刘园

A self-attaching fabric and methods of manufacturing same

InactiveUS20170181504A1Avoid areaEliminate disadvantagesWarp knittingMulti-ply fabricsHand pressureBiomedical engineering

The invention relates to a fabric which can attach to itself by use of hand pressure, and methods for its manufacture. The invention provides a fabric having at least part of its surface covered with small monofilament loops. The self-attaching fabric having at least part of its surface covered with small monofilament hooks which removably engage each other when the surface is pressed into contact with another similar surface to retain together the two portions of the fabric until they are separated by a peeling action.

Owner:ENFOLD TEXTILES LTD

Sewage purification disinfectant and preparation method thereof

InactiveCN105883988AHas purifying and sterilizing effectMeet the needs of primary treatment disinfectionBiocideSpecific water treatment objectivesChlorine dioxideDisinfectant

The invention discloses a sewage purification disinfectant and a preparation method thereof. The sewage purification disinfectant is prepared from 30-40 parts of chlorine dioxide aqua, 0.1-0.5 part of bromochlorohydantoin, 0.5-1 part of potassium ferrate, 25-35 parts of aluminum sulfate, 15-25 parts of diatomite, 5-9 parts of tannin, 2-4 parts of lactic acid, 1-2 parts of Lactobacillus acidophilusis, 5-10 parts of brown sugar, 1-2 parts of chitosan, 3-5 parts of acetic acid, 2-4 parts of polyethylenimine, 1-3 parts of dodecyldimethylbenzyl ammonium chloride, 2-4 parts of sodium silicate and 120-160 parts of water. The sewage purification disinfectant has the purifying and bactericidal actions on industrial wastewater, is convenient to use, has favorable scale peeling actions, has the functions of flocculation, deoxidization, corrosion inhibition and sterilization, and has the advantages of less preparation equipment, simple production technique and low investment. The product is harmless to the human body in the production and use process, and can sufficiently satisfy the demands for municipal domestic sewage primary disinfection treatment.

Owner:张能力

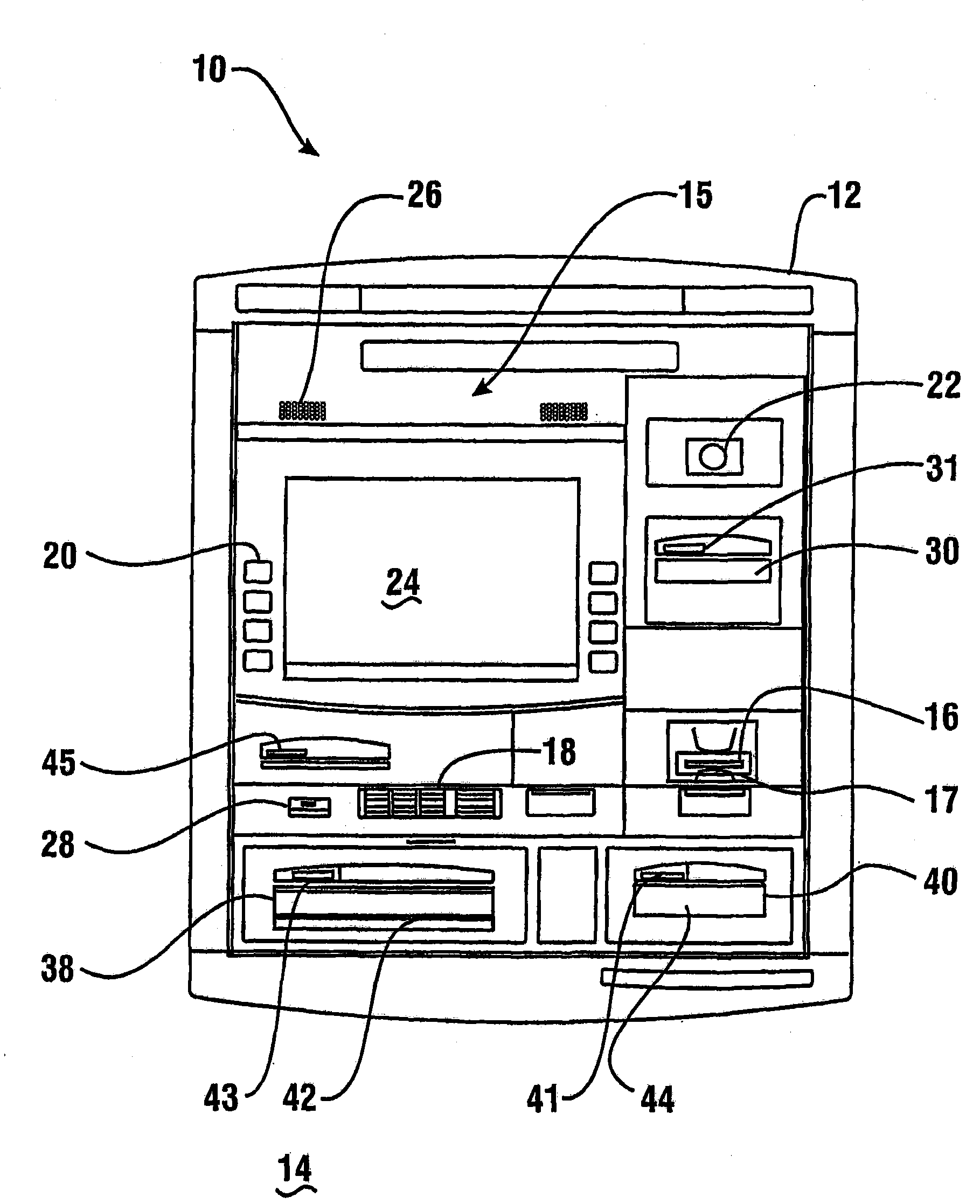

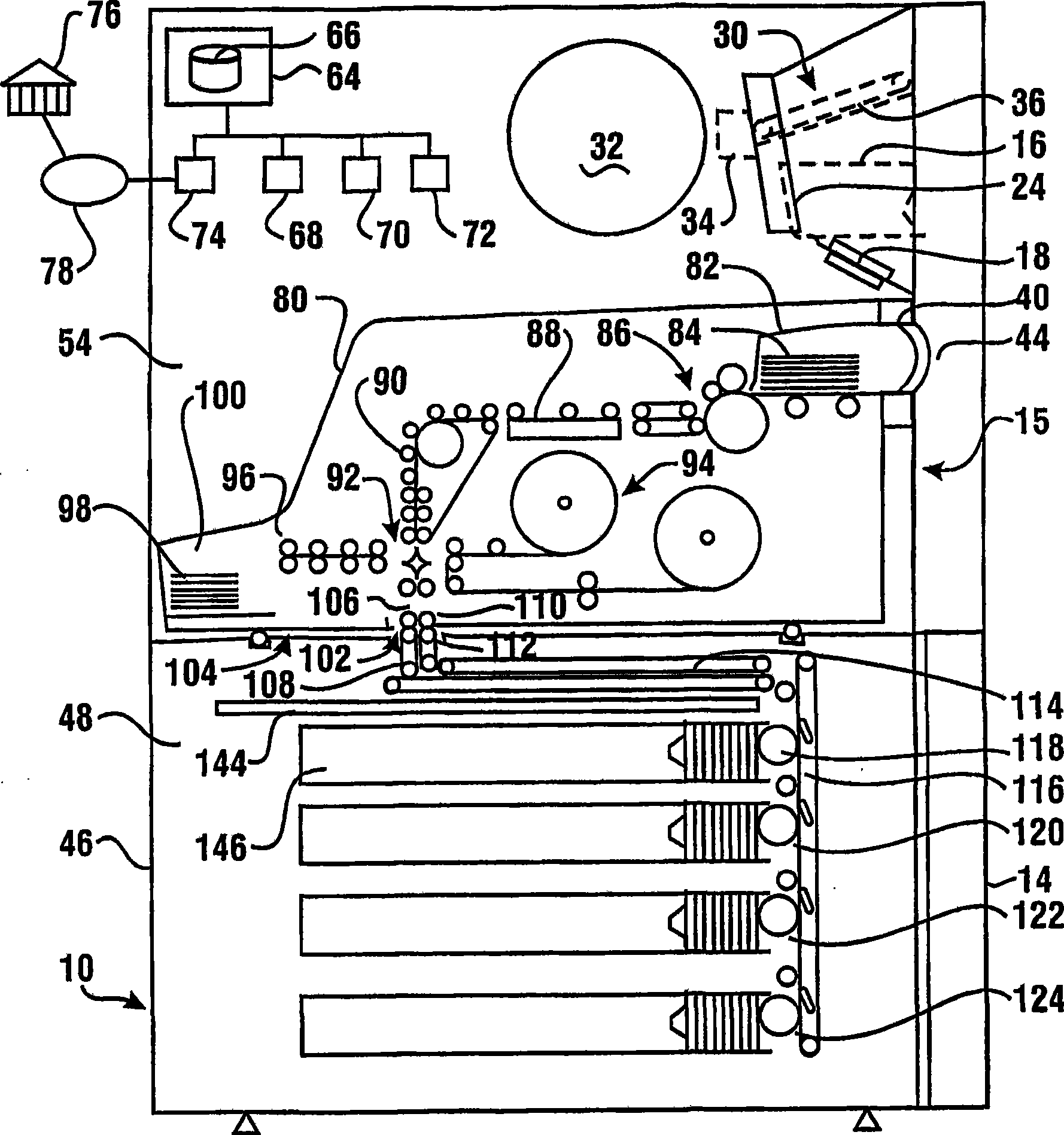

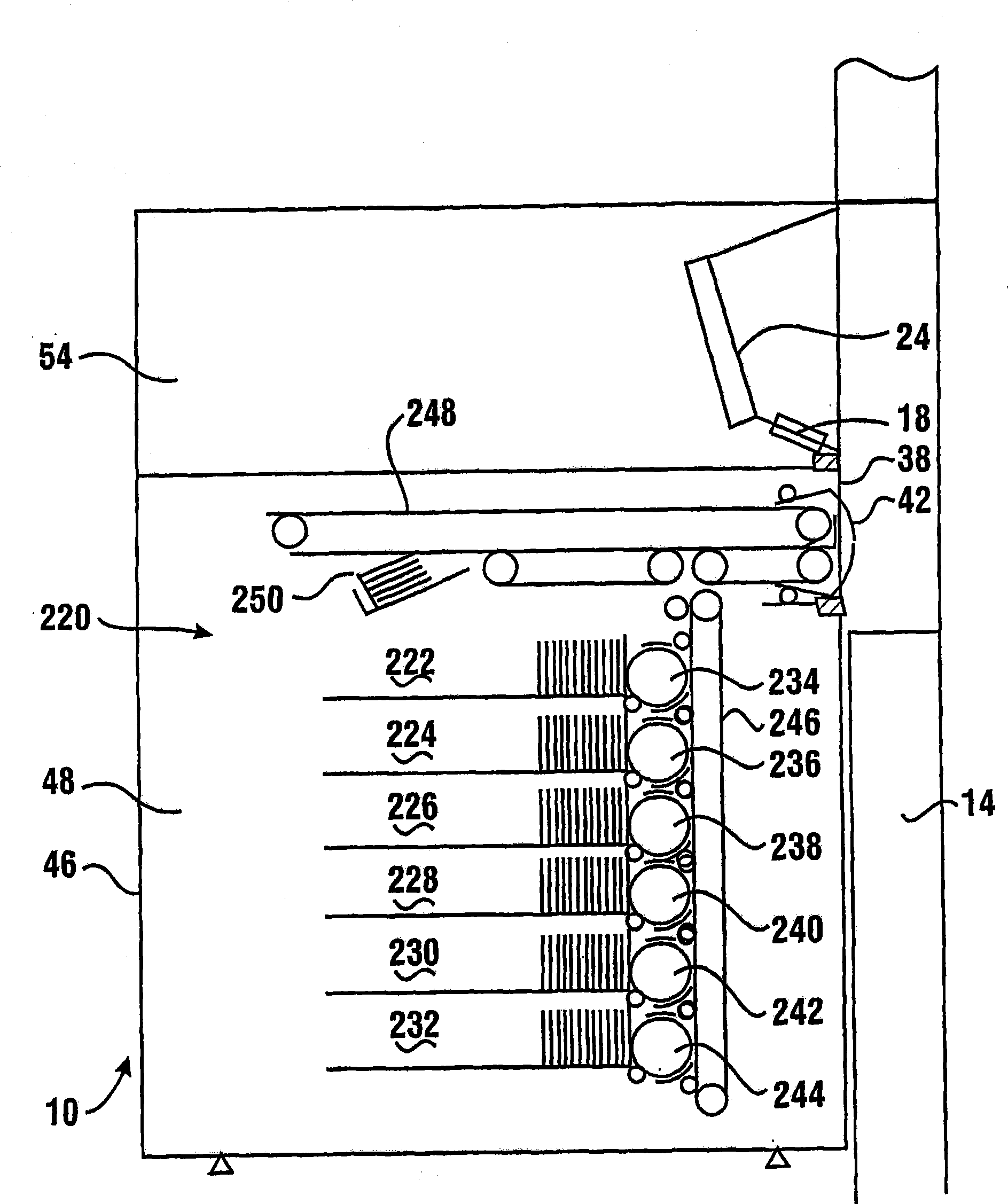

Cash dispensing automated banking machine with note unstacking and validation

An automated banking machine (10) including a user interface (15). The user interface includes a card reader (16), a receipt printing opening (30), a cash dispensing opening (38) and a deposit receiving opening (40). A stack of notes (84) introduced into the machine is separated one by one from the stack by the action of at least one picker (158, 352) and at least one peeler (64, 162, 354). The action of the non-contact peel rollers and the contact peel rollers generally causes the individual sheets to move past the peel member. When the sensors (176, 366) sense that multiple documents have moved past the stripper, the system operates to return those documents for subsequent pick pulls. In some cases, the peel member may be actuated so as to move the notes engaged by the pick member relative to the notes engaged by the pick member in order to reposition the notes to facilitate separation of the notes during subsequent picking events.

Owner:DIEBOLD NIXDORF

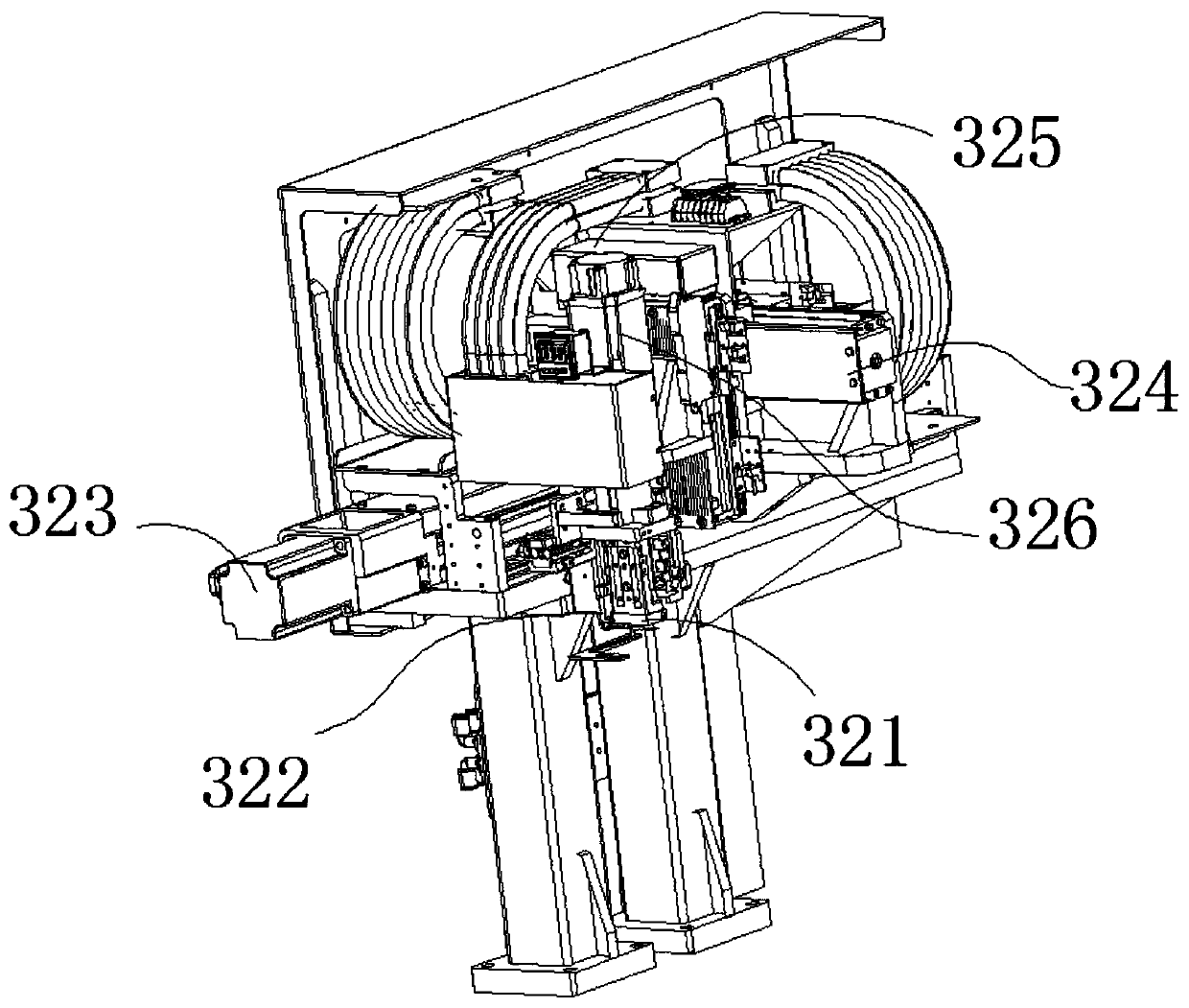

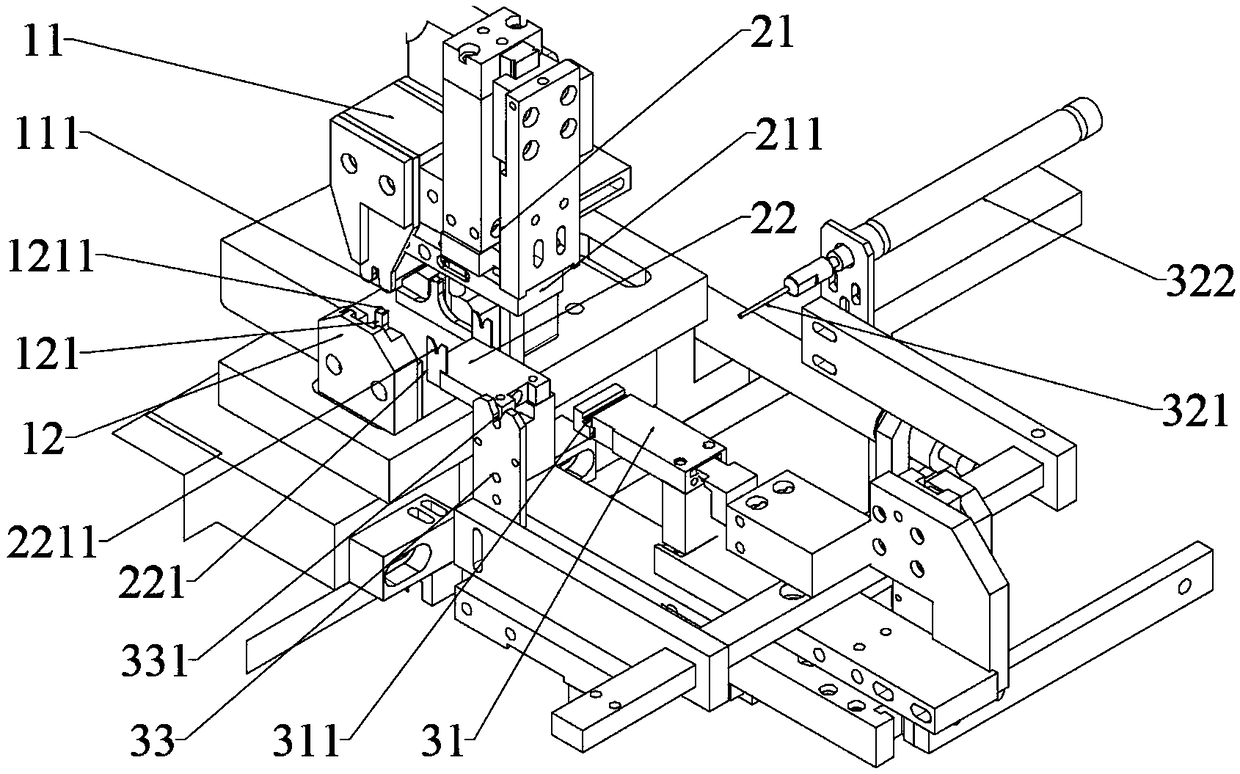

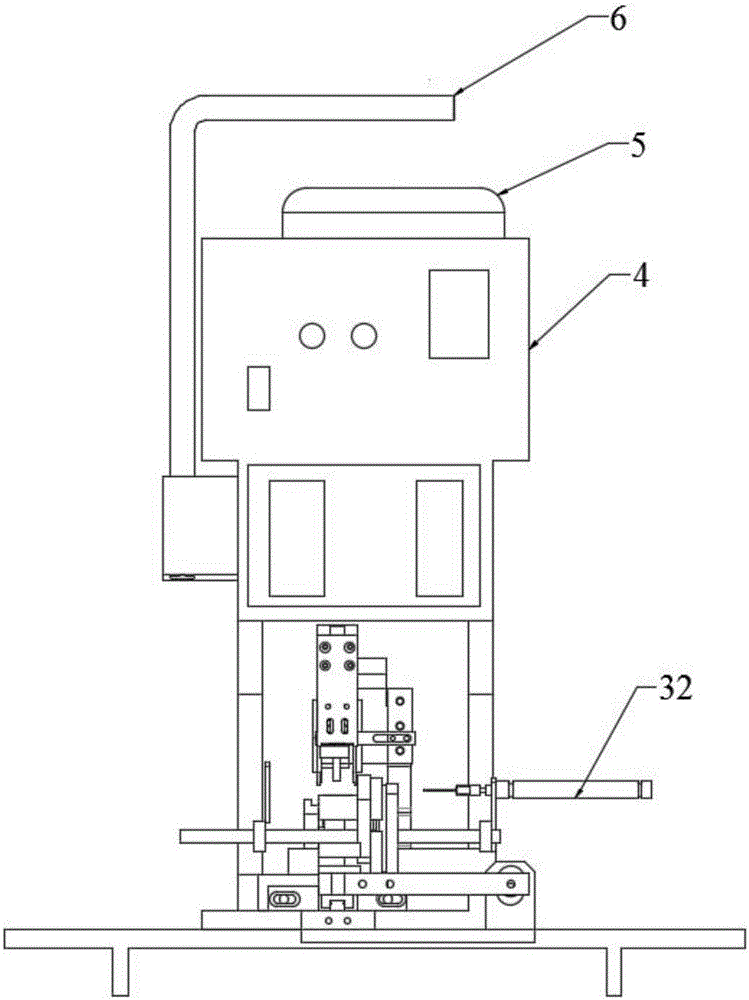

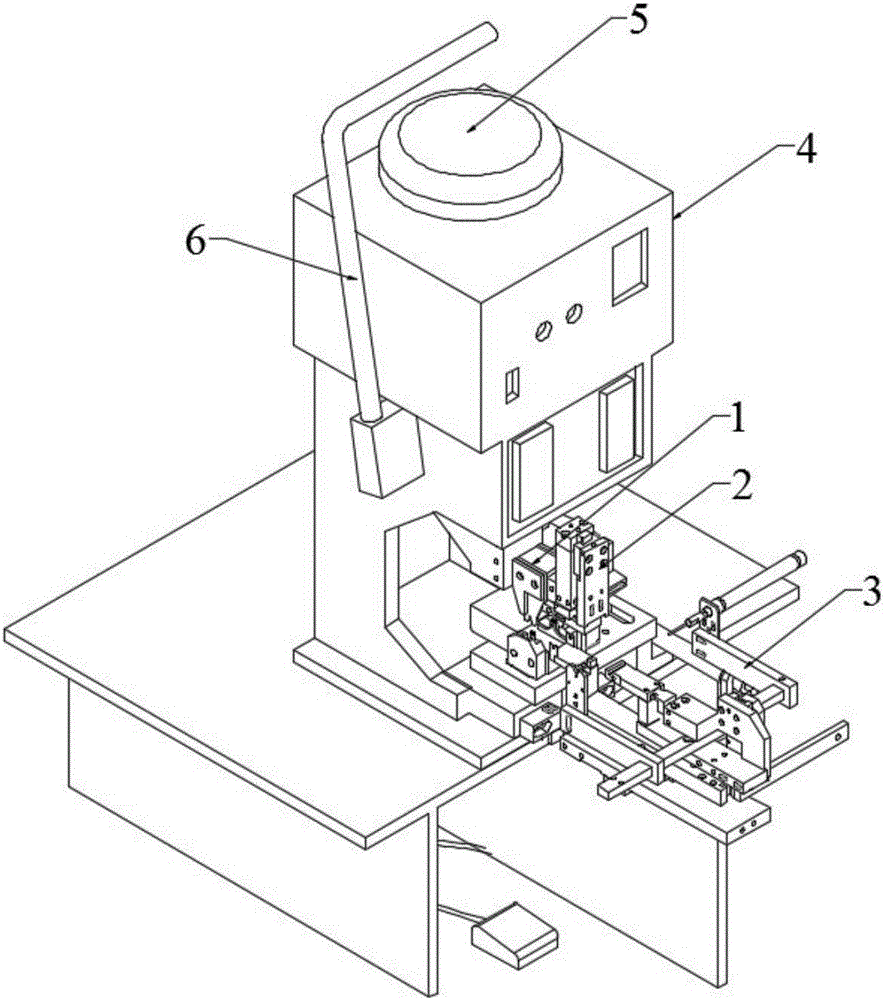

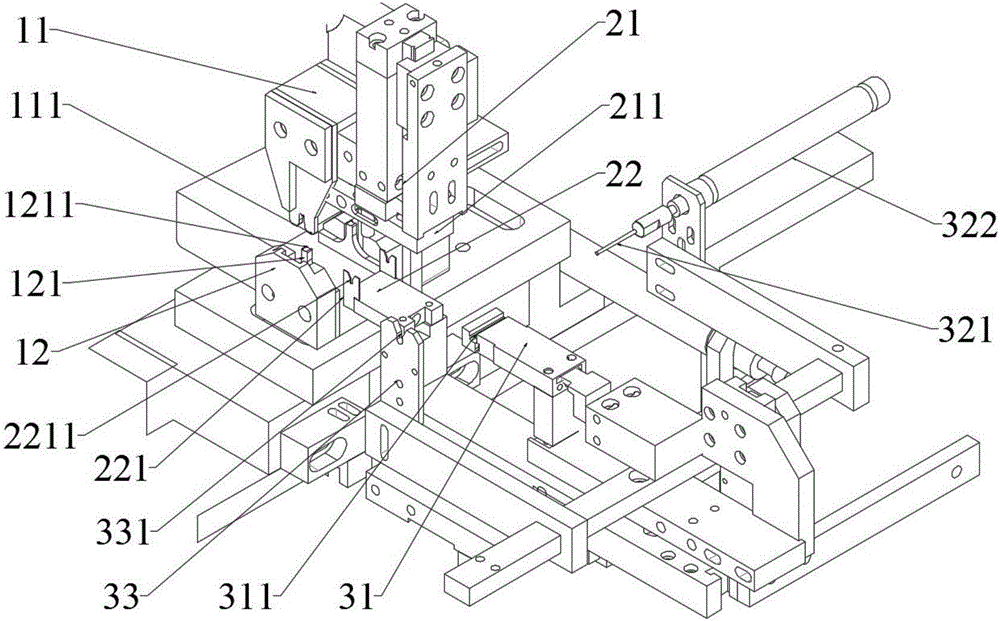

Wire buckle intermediate peeling machine and its use method

ActiveCN106451031BIncrease productivityReduce operating intensityLine/current collector detailsReciprocating motionEngineering

The invention discloses a wire kinking and middle peeling machine and an application method thereof. The wire kinking and middle peeling machine comprises a kinking mold, a cutting mold, a peeling tool, a control device, a first drive device and a second drive device, wherein the kinking mold is located at the lower part of the control device and comprises an upper kinking mold and a lower kinking mold; oppositely arranged punches are arranged at one end, close to the lower kinking mold, of the upper kinking mold; the cutting mold is connected with the kinking mold and comprises an upper cutting mold and a lower cutting mold; a cutting knife is arranged at one end, close to the lower cutting mold, of the upper cutting mold; the first drive device is located on the control device; the peeling tool is located at one side of the cutting mold and is provided with a platform for placing a wire; and the peeling tool is driven by the second drive device to carry out reciprocating motion towards the direction in which the kinking mold and the cutting mold are located. According to the wire kinking and middle peeling machine, kinking and peeling actions can be completed once; the wire kinking and peeling production efficiency is improved; the operation strength of a worker is reduced; and the product size consistency is ensured.

Owner:GUANGDONG BEIBEI ROBOT

Wire kinking and middle peeling machine and application method thereof

ActiveCN106451031AIncrease productivityReduce operating intensityLine/current collector detailsReciprocating motionEngineering

The invention discloses a wire kinking and middle peeling machine and an application method thereof. The wire kinking and middle peeling machine comprises a kinking mold, a cutting mold, a peeling tool, a control device, a first drive device and a second drive device, wherein the kinking mold is located at the lower part of the control device and comprises an upper kinking mold and a lower kinking mold; oppositely arranged punches are arranged at one end, close to the lower kinking mold, of the upper kinking mold; the cutting mold is connected with the kinking mold and comprises an upper cutting mold and a lower cutting mold; a cutting knife is arranged at one end, close to the lower cutting mold, of the upper cutting mold; the first drive device is located on the control device; the peeling tool is located at one side of the cutting mold and is provided with a platform for placing a wire; and the peeling tool is driven by the second drive device to carry out reciprocating motion towards the direction in which the kinking mold and the cutting mold are located. According to the wire kinking and middle peeling machine, kinking and peeling actions can be completed once; the wire kinking and peeling production efficiency is improved; the operation strength of a worker is reduced; and the product size consistency is ensured.

Owner:GUANGDONG BEIBEI ROBOT

Optical film laminate used for continuous lamination to panel component

To provide a continuous web of optical film laminate provided with static electrification prevention function which allows for promptly attenuating static charge of optical film sheet and carrier film electrified by peeling action in RTP lamination method and apparatus. The problem has been solved with a continuous web of optical film laminate for using in RTP lamination method and apparatus, in which static electrification prevention function is provided to optical film sheets and a carrier film configuring the continuous web of optical film laminate, such that sheet resistance of each of the optical film sheets and the carrier film is 1012 Ω / sq or less so as to promptly attenuate static charge of the carrier film to be collected, which is statically electrified by peeling action, and the optical film sheets to be laminated to panel components, which are also statically electrified by peeling action.

Owner:NITTO DENKO CORP

Stripping mechanism and laminating device using same

PendingCN114683673AWon't hurtSmooth peeling actionLamination ancillary operationsLaminationStripping - actionThin membrane

The present invention relates to a peeling mechanism and a laminating device using the peeling mechanism, which can smoothly perform a peeling action without damaging a sheet by easily forming a peeling starting point part, and a laminating device using the peeling mechanism. A peeling mechanism (100) is provided with: a peeling stage (20); a peeling head (10); and a cooling device (11) for cooling a part of the outer peripheral part of the sheet (Sf) with the thin film to form a peeling starting point part (Ra). The peeling head (10) includes film holding devices (12, 14) that peel the film (f) from the sheet (S) by relative movement of the peeling head (10) and the peeling stage (20) while holding the film (f) at the peeling starting point (Ra). Therefore, by easily forming the stripping starting point part, the stripping action can be smoothly performed without damaging the sheet.

Owner:NIKKISO COMPANY

Tomato pulp drink and preparation method thereof

InactiveCN108902571AJuice extractionNatural extract food ingredientsPulp and paper industryAqueous solution

The invention belongs to the technical field of tomato pulp, particularly discloses a tomato pulp drink and a preparation method thereof. The tomato pulp comprises the following components: 10.5 to 11parts of xylooligosaccharide, 60 to 65 parts of tomato raw stock and 17 to 25 parts of water. The equipment used by the preparation method integrates cutting, steam peeling, centrifugal separation, xylooligosaccharide addition and the like into a whole, is compact in structure and uses a power source to supply the most of power. The xylooligosaccharide water solution in the components plays the heat peeling action on the cut tomato, so that the effect of addition in one time and various purposes is realized.

Owner:XINJIANG XIAOCHU FOOD

Method and apparatus for manufacturing optical display device

InactiveUS9645418B2High lamination precisionLamination ancillary operationsLaminationDisplay deviceEngineering

A method for manufacturing an optical display device comprises: sequentially peeling a plurality of optical film sheets continuously supported via an adhesive layer on one of opposite surfaces of a carrier film, together with the adhesive layer from the carrier film under peeling action of the movable peeling member by winding a long web of the carrier film in a state where the other of opposite surfaces thereof being folded to inside at a tip-end of the movable peeling member having the tip-end and passed around the peeling member; and laminating the plurality of optical film sheets to one of opposite surfaces of respective ones of panel components via the adhesive layer under laminating action of the closed lamination rollers.

Owner:NITTO DENKO CORP

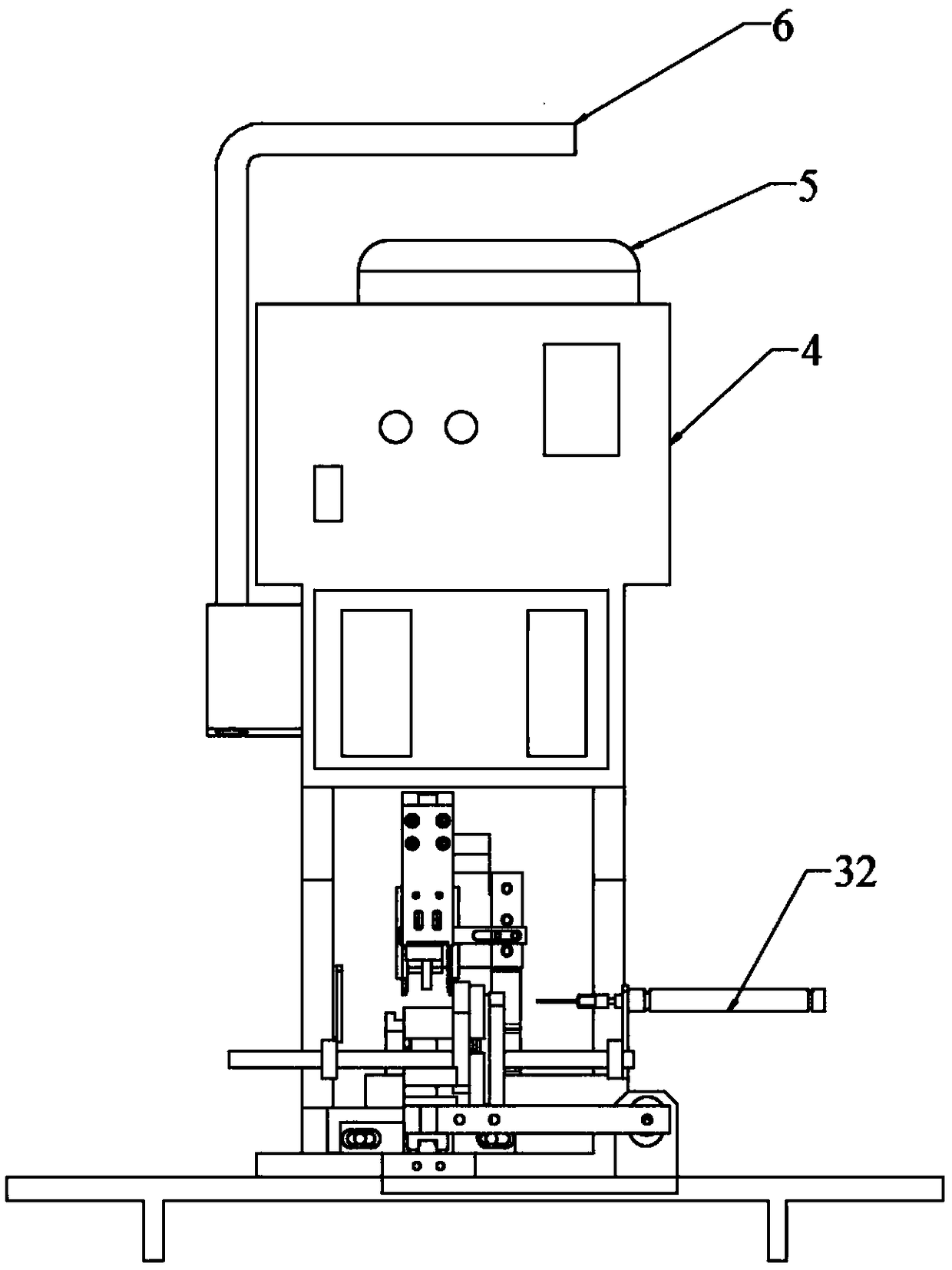

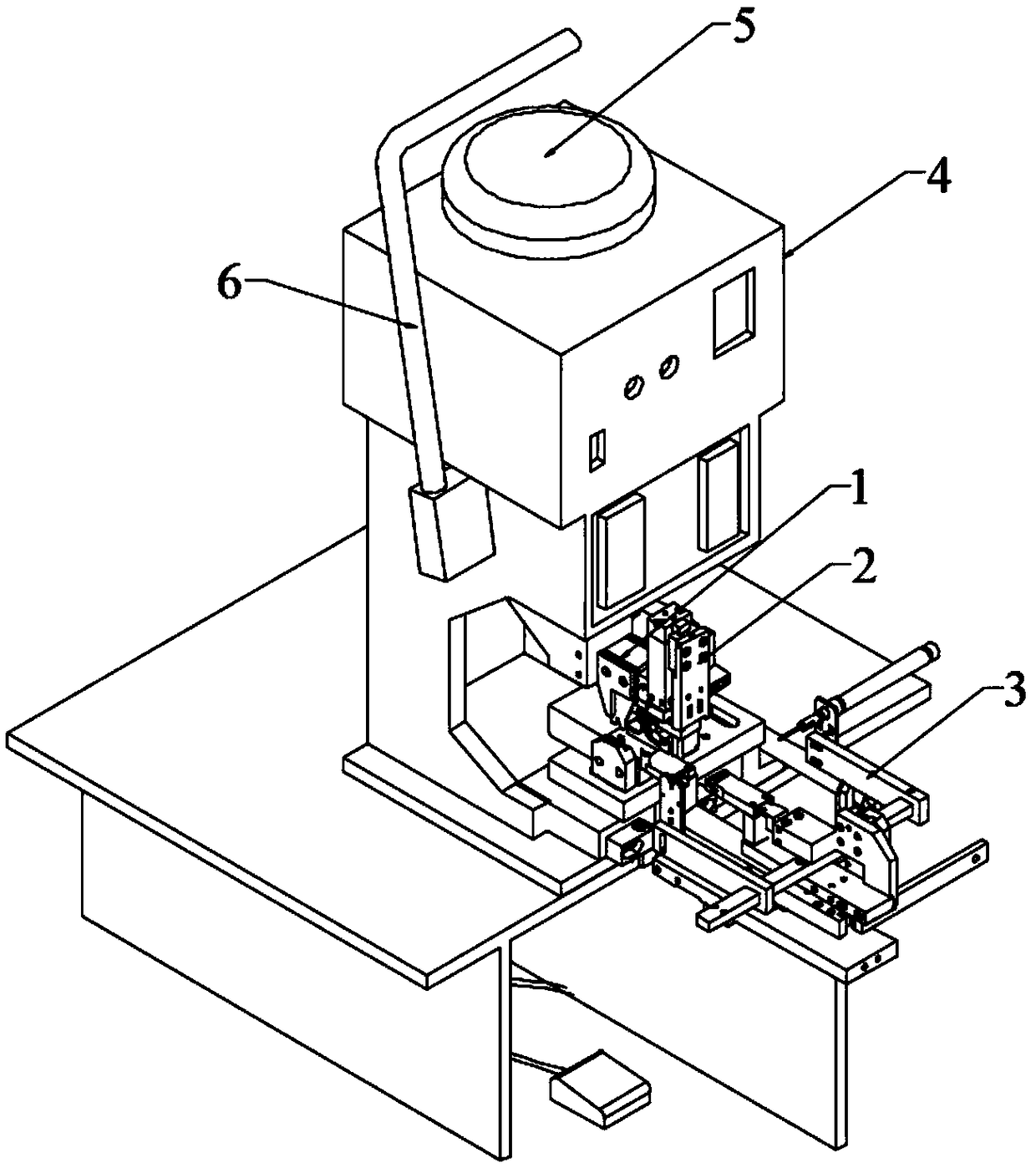

Component mounting method and component mounting apparatus

InactiveCN100461358CAvoid strippingRelative interval increasePrinted circuit assemblingFinal product manufactureEngineeringThermal expansion

There has been a possibility of deteriorating planarity of a thin IC chip due to process distortion and deformation generated when sucking the IC chip by a suction nozzle. The deformation is corrected by pressing the thin IC chip on a board (4) with a prescribed load by a suction nozzle (11) having a suction plane (11b) formed flat. A reduction of a prescribed opposing interval between the IC chip and the board (4), due to thermal expansion caused by heat applied for melting a solder bump (1a) formed on an electrode, is corrected by controlling rising of the suction nozzle (11). A peeling action of the melting part, due to a part which has heat- expanded and contracted by cooling, is corrected by controlling descending of the suction nozzle (11). Thus, an electronic component mounting method and an electronic component mounting apparatus are provided for correctly mounting even the electronic components, such as the thin IC chip easily deformed and the IC chip wherein a multitude of electrodes are formed at a narrow pitch.

Owner:PANASONIC CORP

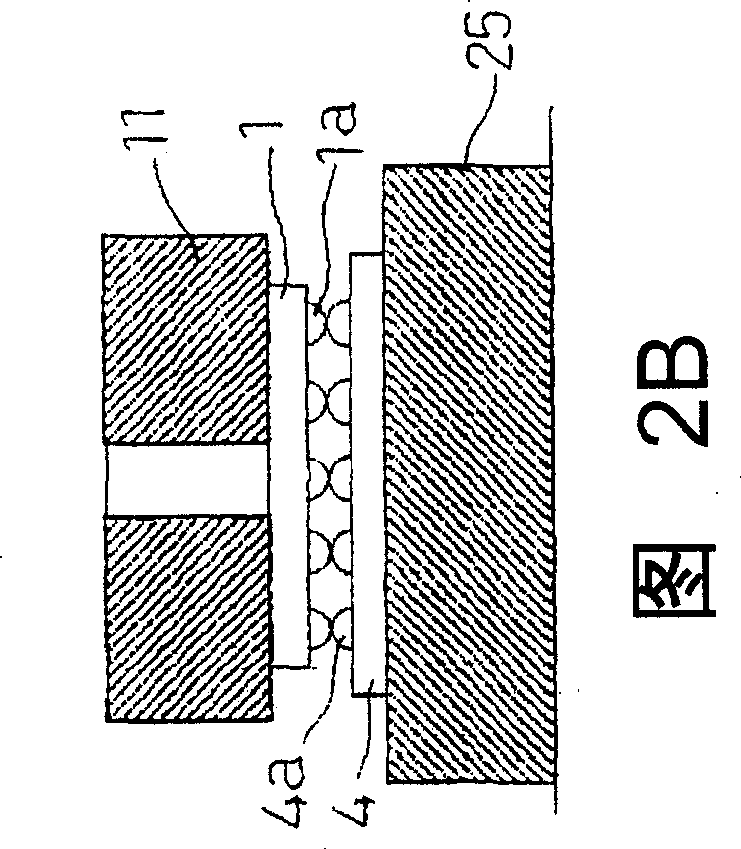

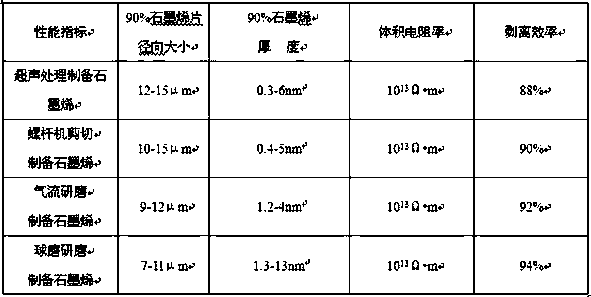

A kind of method and graphene precursor of internal mixer exfoliation preparation graphene precursor

The invention provides a method for preparing a graphene precursor by exfoliating an internal mixer and the graphene precursor. After soaking the graphite in the aqueous dispersion of the excess intercalation agent for a long time, the sugar material is used as the bonding and peeling carrier, and the viscous sugar material is sheared and stretched by the internal mixer to make the graphite in the sugar material Under the action of bonding, the graphene precursor is indirectly stretched and sheared and peeled by the viscous sugar material, which provides a mild shearing method and effectively overcomes the direct action of the huge mechanical shear force in the mechanical peeling process in the prior art Based on the technical defects of graphene and then destroying the layered structure of graphene, the chemical reaction in the prior art is avoided at the same time to destroy the graphene structure, and the technical effects such as high product quality and less pollution to the environment are achieved. The precursor prepared by the invention has stable properties and is easy to exfoliate into graphene.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

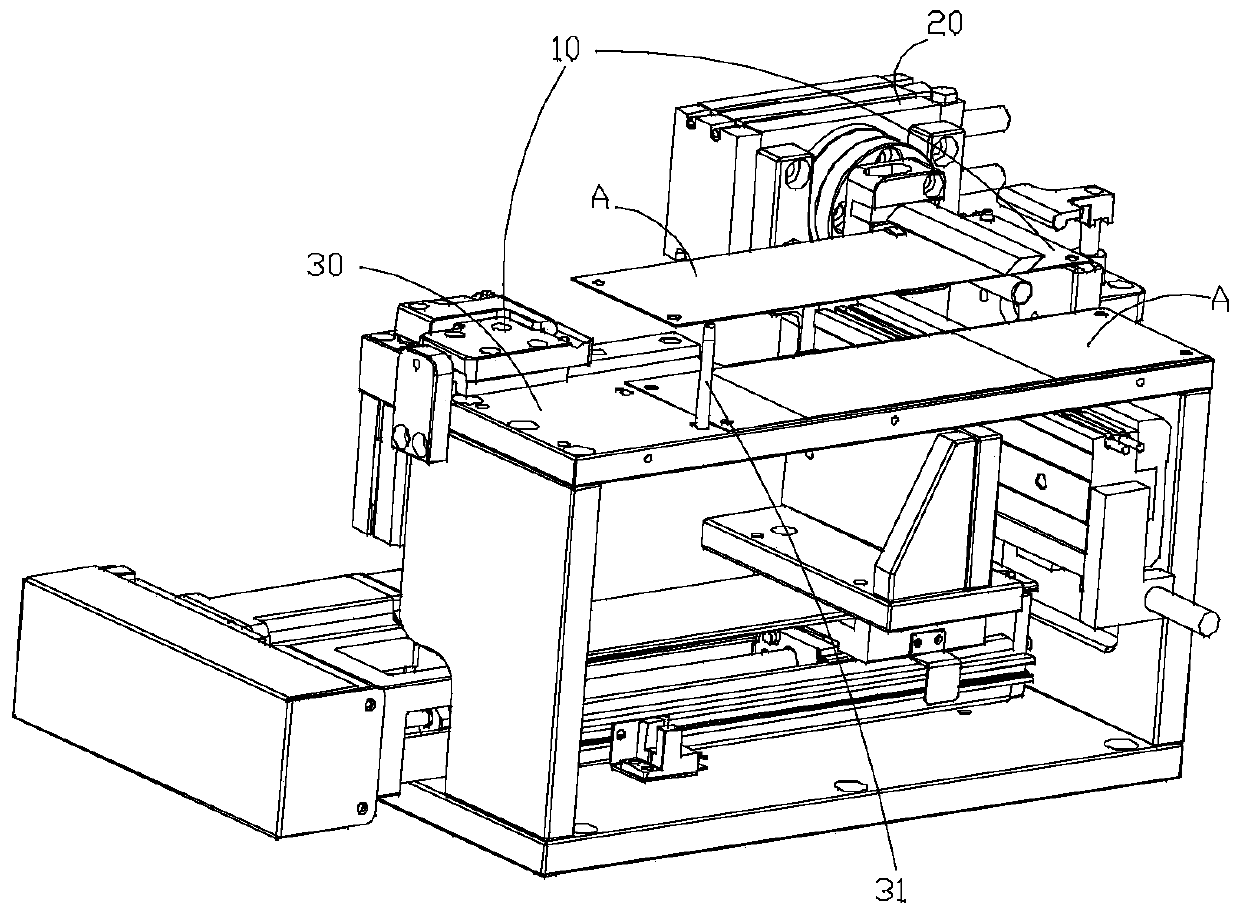

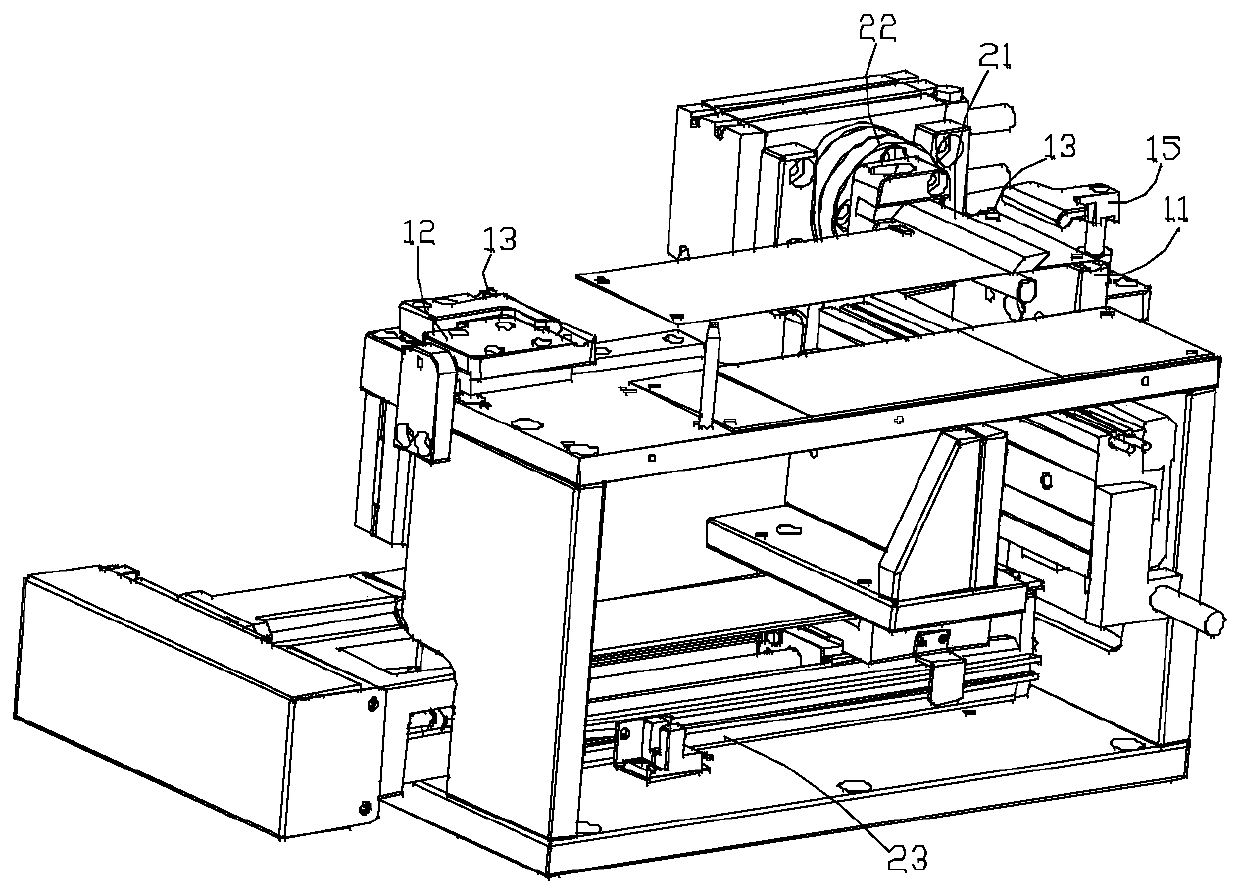

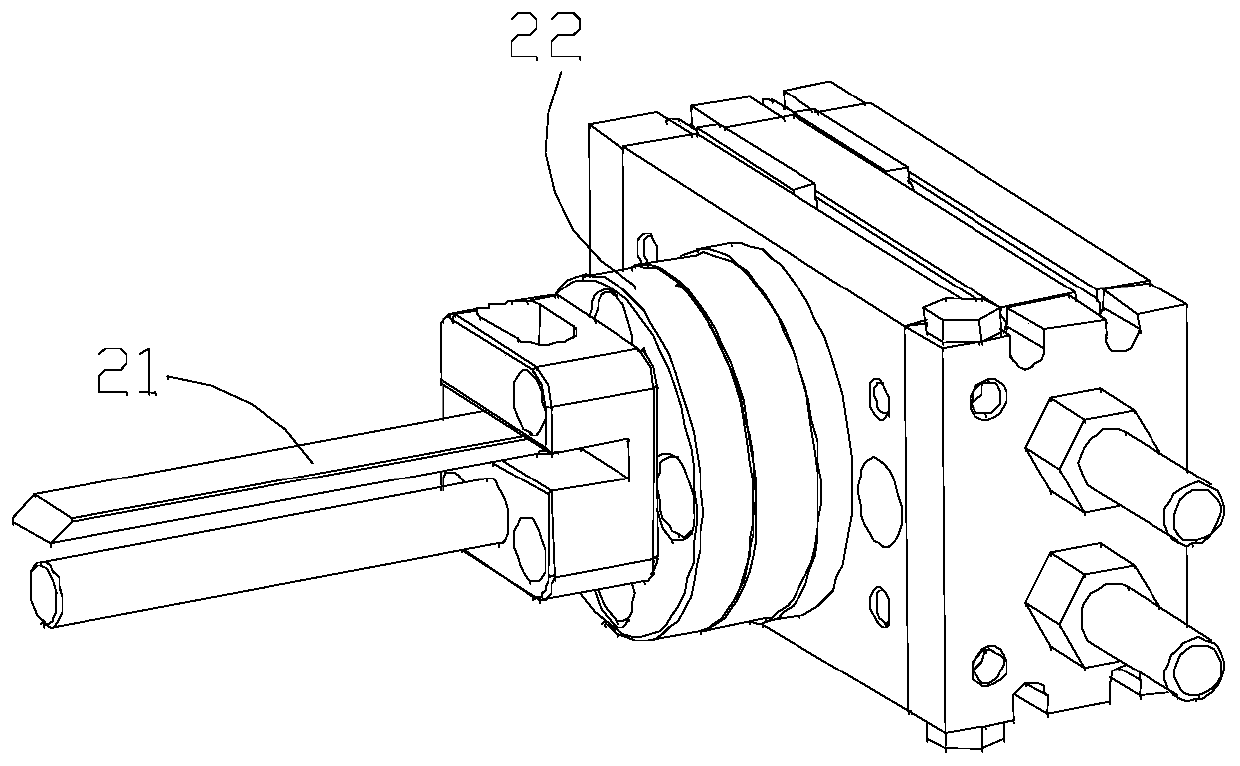

A fully automatic stripping device

ActiveCN107835746BHigh stripping accuracyEasy to operateLamination ancillary operationsLaminationFully automaticBiomedical engineering

A fully automated peeling device, comprising a material loading unit (10) and a peeling unit (20). During use, a material is placed on the material loading unit (10). The material loading unit (10) then secures the material. An action of the peeling unit (20) then completes a material peeling action.

Owner:深圳市佳信新科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com