Insulated wire peeling device

A technology of peeling device and insulated wire, applied in cable installation device, cable installation, equipment for dismantling/armoured cable, etc. Manual, convenient management, fast heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

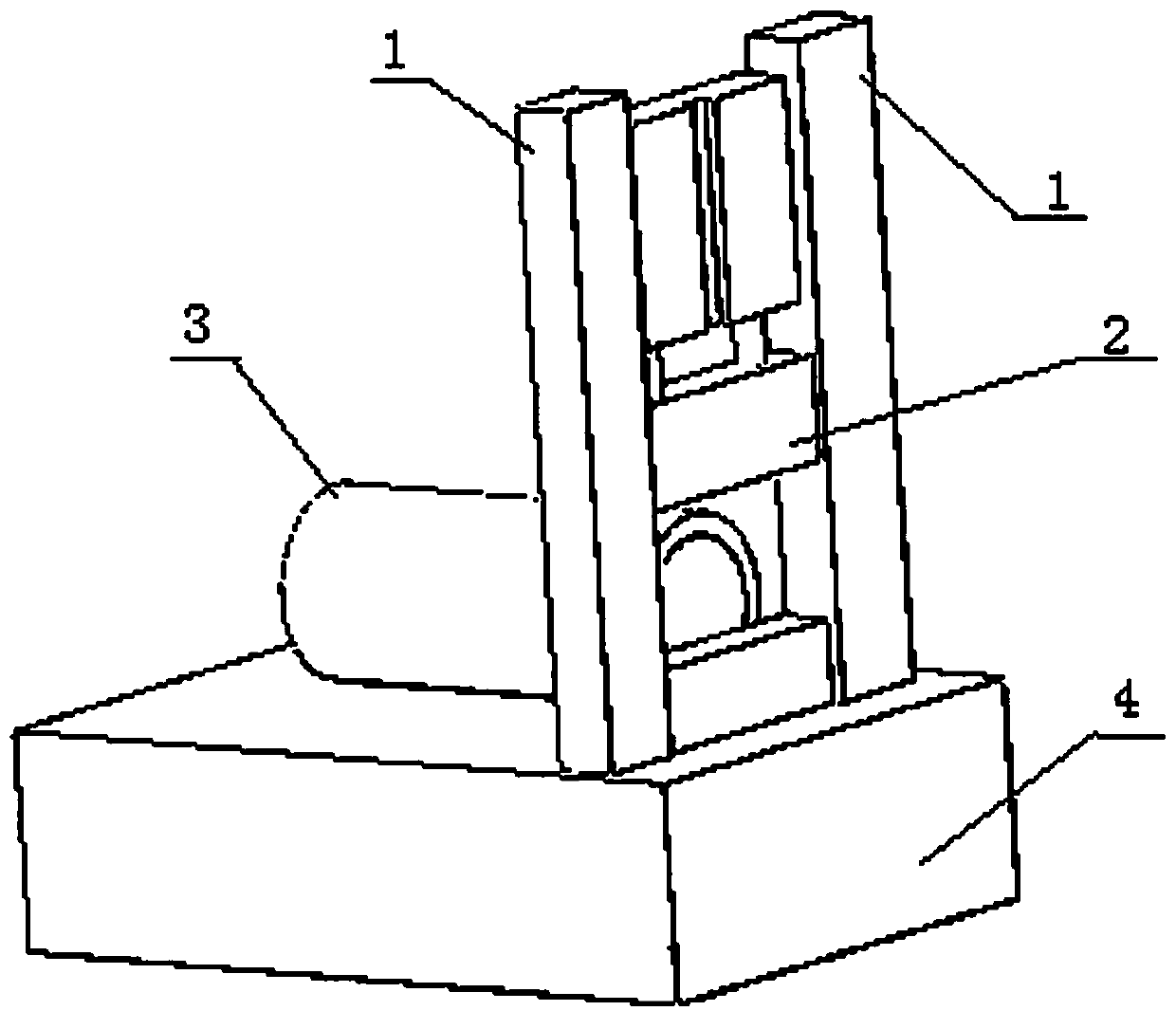

[0030] An insulated wire peeling device includes a support 1, a peeling knife 2, a heating device 3 and a main controller 4, the support 1 is arranged on the main controller 4, and the peeling knife 2 and the heating device 3 are respectively connected to the main controller 4.

[0031] The heating device 3 includes an induction heating power supply and an induction heating coil. The induction heating coil is circular, and the induction heating coil is arranged outside the induction heating power supply. The induction heating power supply provides an alternating current for the induction heating coil. The induction heating coil will be heated by the insulated wire therein, and the peeling knife 2 is pressed down to peel off the insulation.

[0032] The power of the heating device 3 is 1000-1500W.

[0033] The main controller 4 is a PLC controller, a single-chip microcomputer or an integrated circuit.

[0034] The host controller includes a central processing unit, a drive mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com