Transferring and bonding device for brittle member

A transfer device and component technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, adhesives, etc., can solve the problems of brittle component 4 damage, brittle component 4 cannot be peeled off smoothly, and the force of lifting frame 6 is unstable, etc. , to achieve the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS The best mode for carrying out the present invention will be described in detail below with reference to the accompanying drawings.

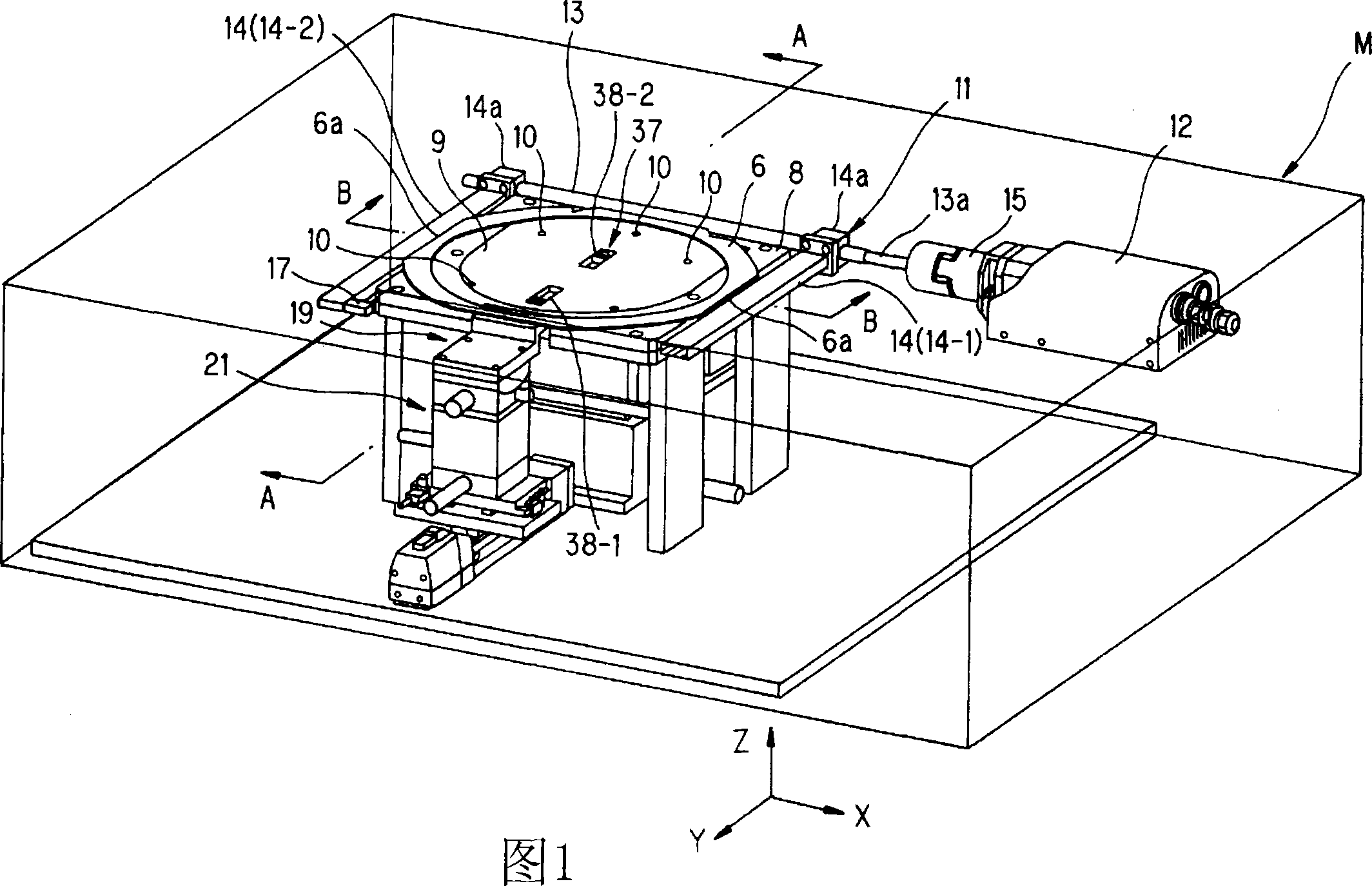

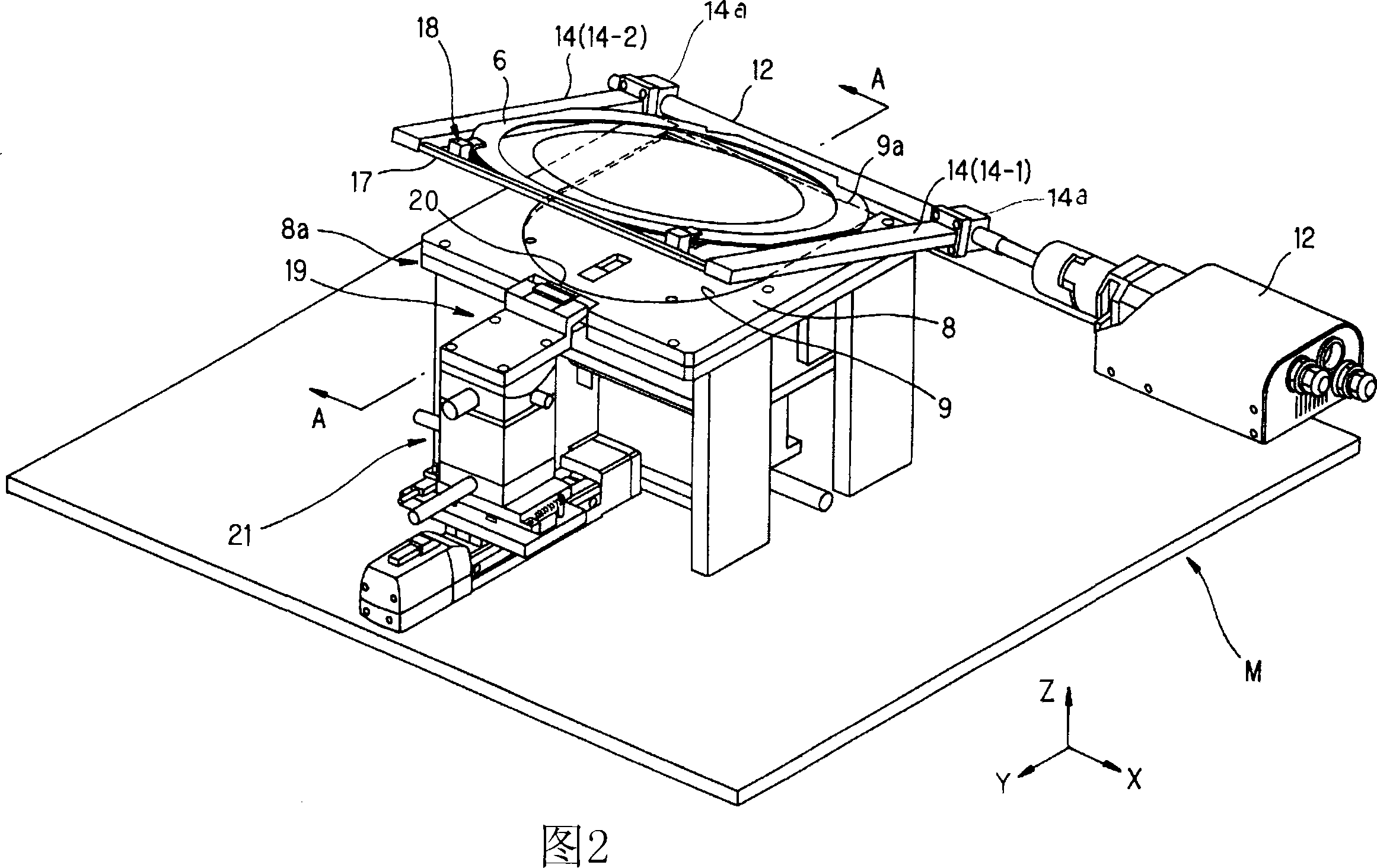

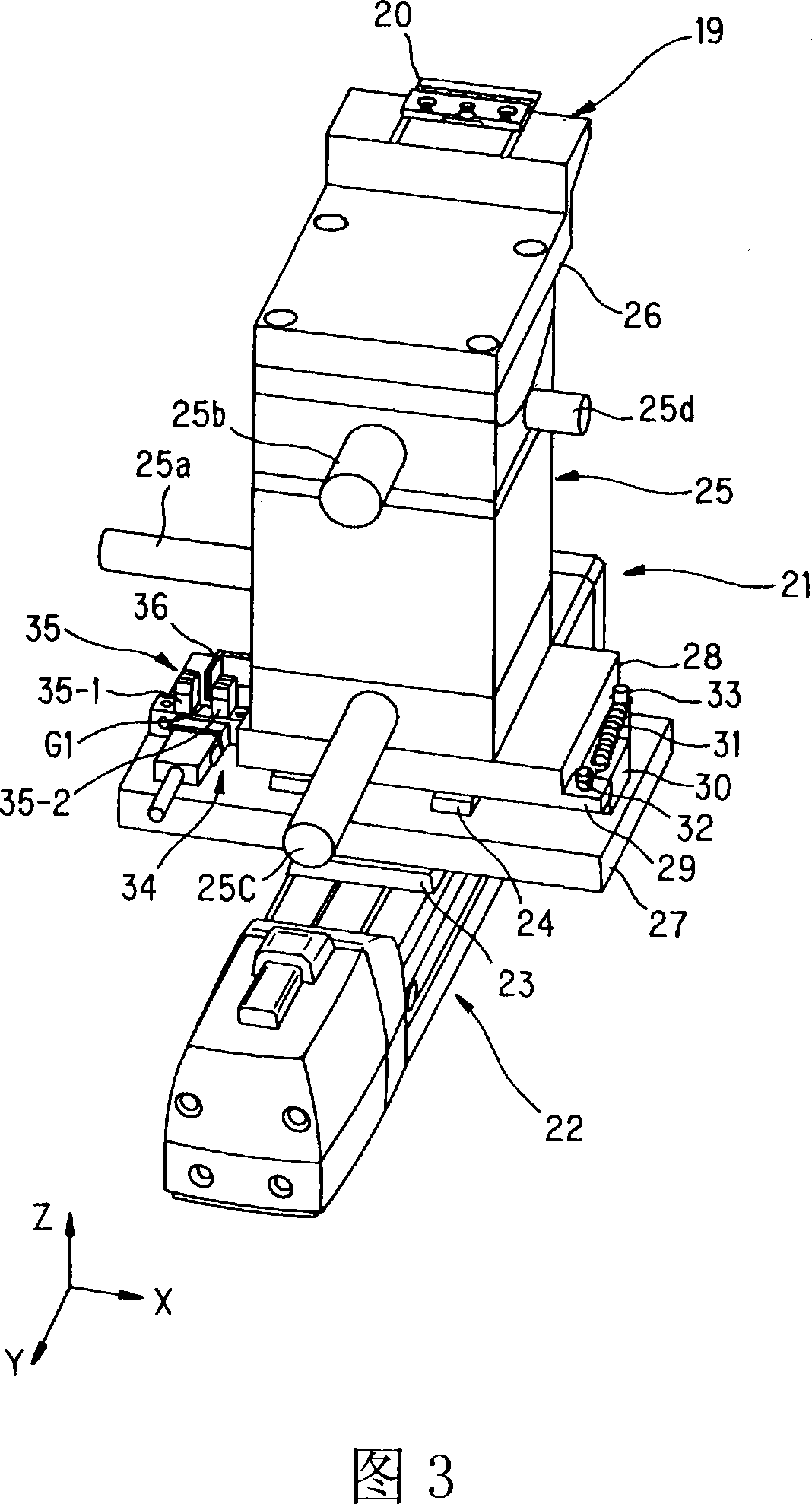

[0083] Fig. 1 is an overall schematic perspective view of the brittle part transfer device according to an embodiment of the present invention; Fig. 2 is a schematic perspective view of the peeling action process in the transfer device shown in Fig. 1; Fig. 3 is a peeling cut that constitutes the transfer device shown in Fig. 1 An enlarged perspective view of the forming mechanism; Fig. 4 is a sectional view of the transfer device taken from the A-A line in Fig. 1; Fig. 5 is a sectional view of the transfer device taken from the A-A line in Fig. 2; Fig. 6 is a sectional view taken from the B-B line in Fig. 1 Figure 11 is a cross-sectional view of the peeling object (a sticking structure integrated with the frame by cutting the adhesive sheet 7) set on the transfer device shown in Figure 1 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com