Component mounting method and component mounting apparatus

An installation method and a technology for installation devices, which are applied in the direction of assembling printed circuits, electrical components, electrical components, etc. with electrical components, can solve problems such as no compensation control, increased electrical positives, poor conduction, etc., and achieve the effect of shortening the installation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

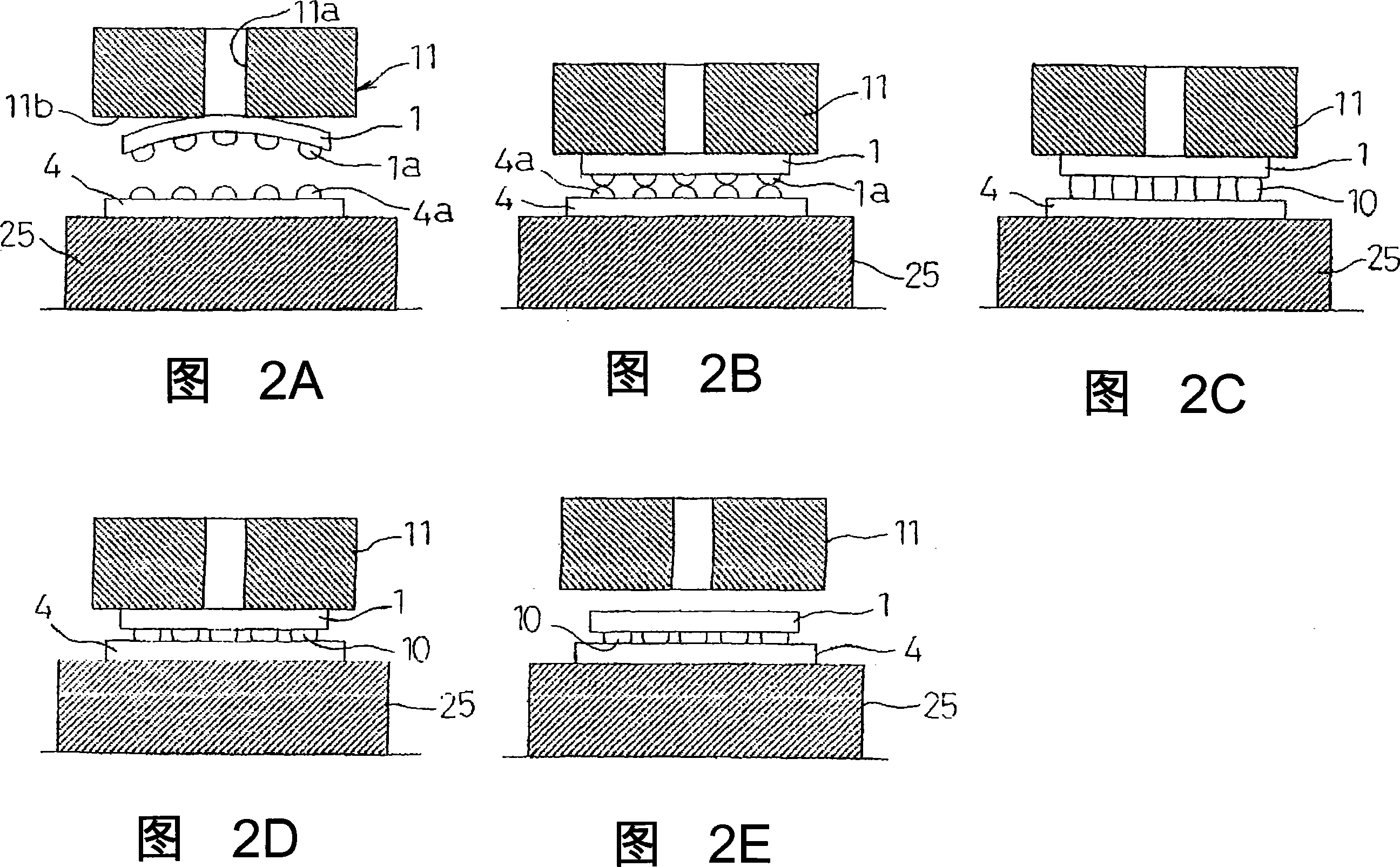

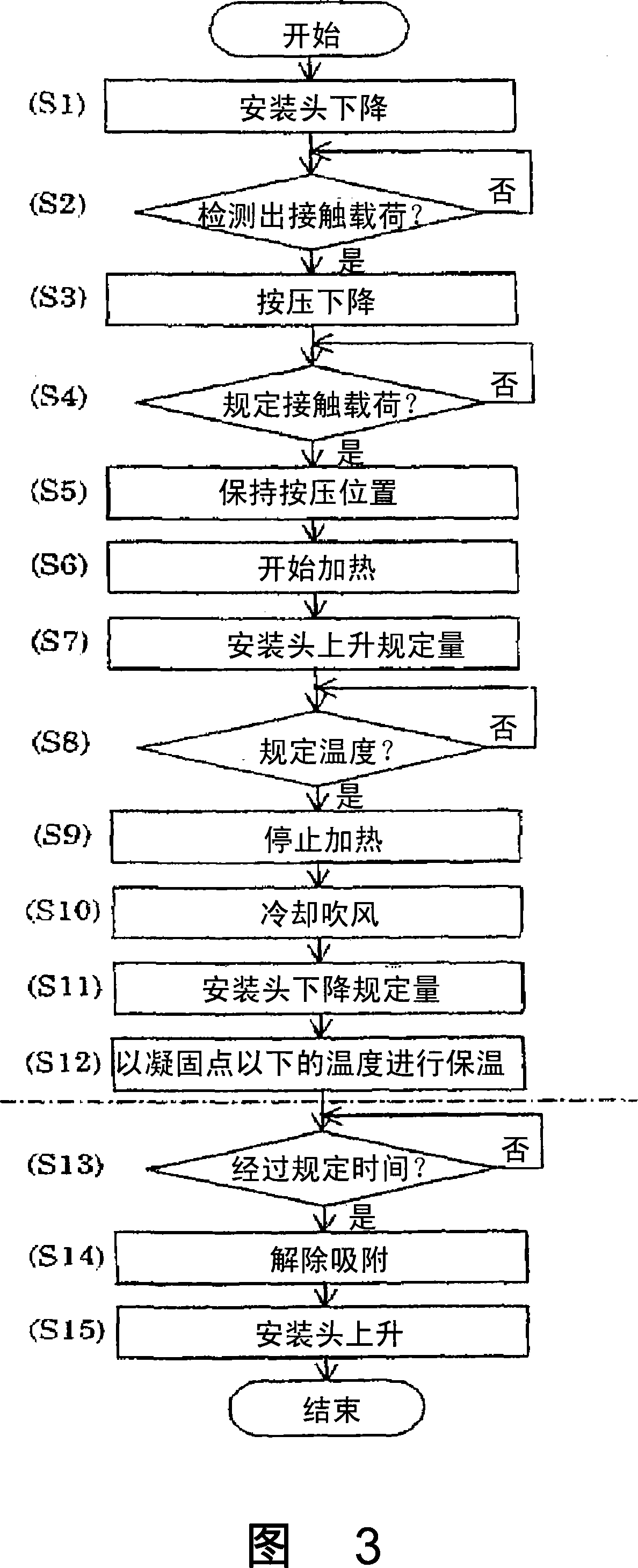

[0046] This embodiment shows how to mount an IC chip on a substrate by fusing and bonding the electrode of an IC chip as an example of an electronic component into a solder bump as a protruding electrode and forming a pad as a substrate electrode with an electrode of a substrate. The component installation method and component installation device on the above. In particular, it is a mounting control method and device thereof capable of mounting with high precision even IC chips whose planarity tends to be impaired due to thinning or IC chips in which a plurality of electrodes are arranged in a row at a narrow pitch. In addition, the object to mount the IC chip is set as the board, but it is not only the circuit board, and in the case of chip-on-chip mounting the IC chip on the IC chip, the IC chip to be mounted is set as the board.

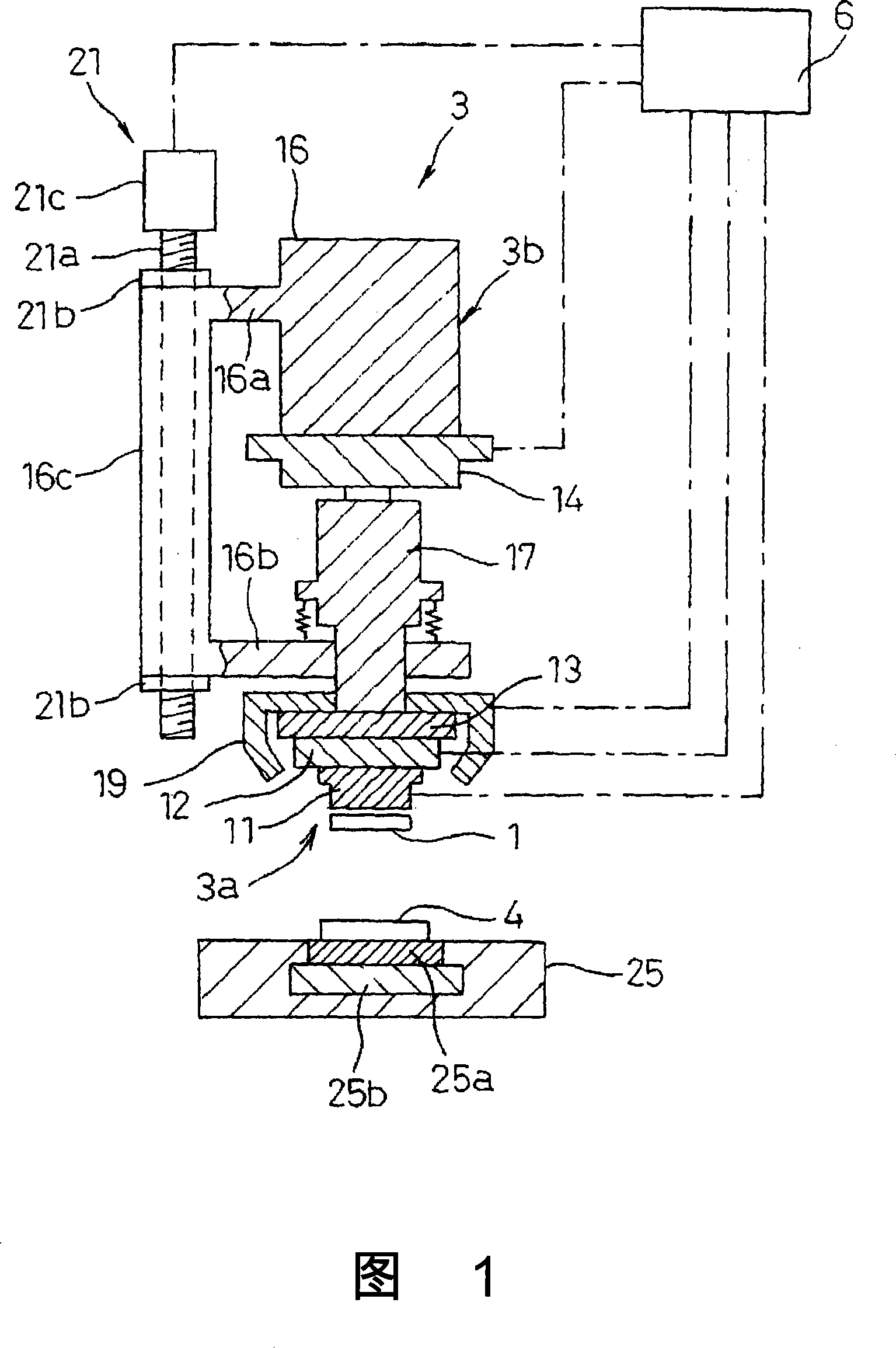

[0047] FIG. 1 shows the main configuration of the mounting device according to the embodiment, and shows the components of the mounting head 3 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com