Amorphous carbon coated graphite composite, preparation method thereof and application of amorphous carbon coated graphite composite serving as lithium ion battery cathode material

A composite material, amorphous carbon technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problem of poor electrochemical performance of amorphous carbon-coated CMS particles, large irreversible capacity and low gram capacity of amorphous carbon materials. and other problems, to achieve the effect of being conducive to rapid diffusion, improving preparation quality and efficiency, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

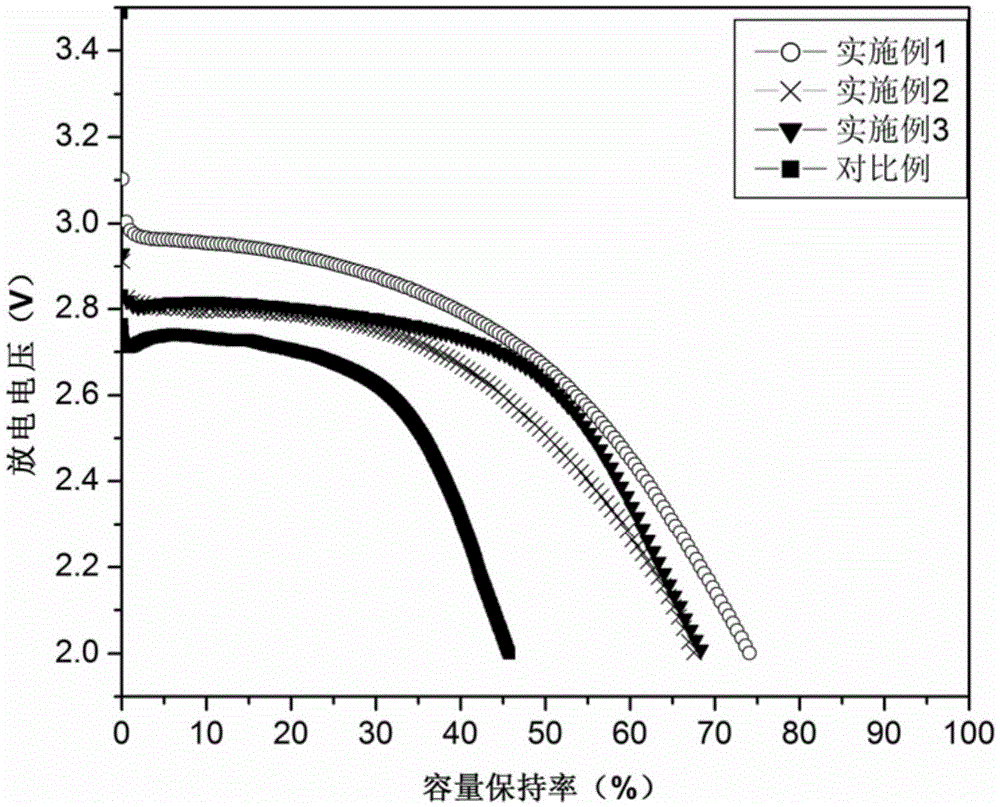

Embodiment 1

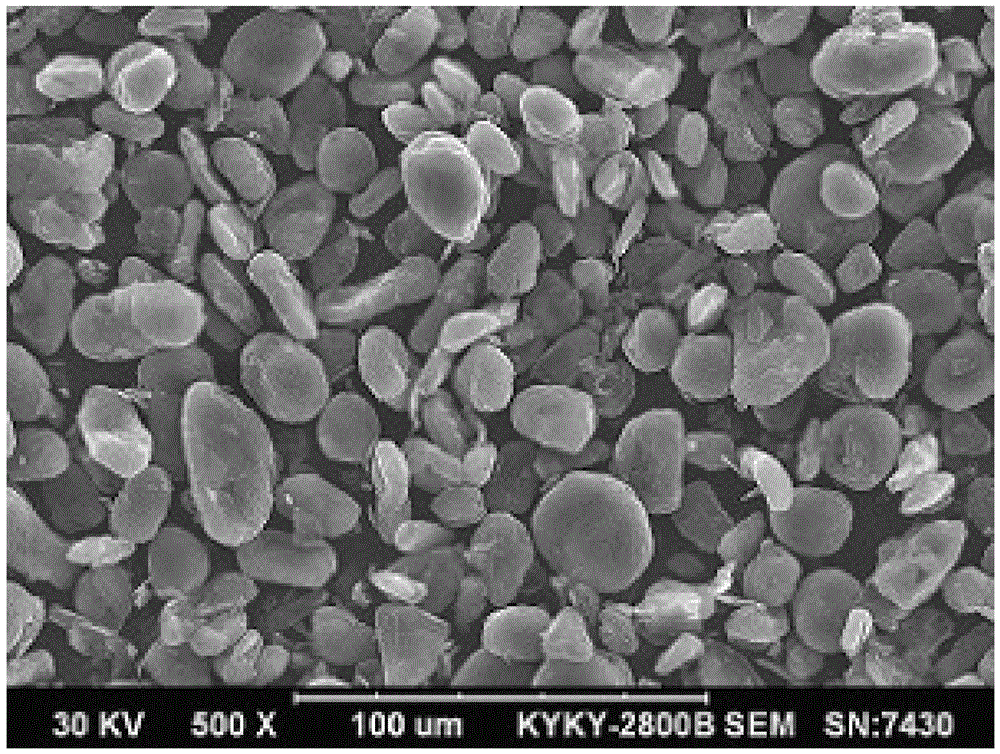

[0041] The amorphous carbon-coated graphite composite material of the present embodiment is prepared by a method comprising the following steps:

[0042] 1) According to the mass ratio of calcium carbonate (template agent) to acrylonitrile monomer of 1:10, take 1.0g of calcium carbonate and 10.0g of acrylonitrile monomer and mix and stir evenly, then add 50g of potassium persulfate and 300g of secondary Distilled water (mass ratio of acrylonitrile monomer, initiator to water: 10:50:300), under nitrogen atmosphere, heat to 60°C and keep warm for 5h to carry out polymerization reaction to polymerize the monomer. After the reaction is completed, cool, wash and dry , to obtain template agent / polyacrylonitrile composite material;

[0043] According to the ratio of graphite, emulsifier and water mass ratio of 1:2:80, put 1.0g of artificial graphite into a three-necked flask, add 80g of distilled water, 2.0g of emulsifier NP9, and ultrasonically disperse for 30min under mechanical st...

Embodiment 2

[0048] The amorphous carbon-coated graphite composite material of the present embodiment is prepared by a method comprising the following steps:

[0049] 1) According to the mass ratio of calcium carbonate (template agent) to acrylonitrile monomer of 1:8, take 1.0g of calcium carbonate and 8.0g of acrylonitrile monomer and mix them evenly, then add 40g of potassium persulfate and 200g of secondary Distilled water (mass ratio of acrylonitrile monomer, initiator to water: 8:40:200), under nitrogen atmosphere, heat to 40°C and keep warm for 10h to carry out polymerization reaction to polymerize the monomer. After the reaction is completed, cool, wash and dry , to obtain template agent / polyacrylonitrile composite material;

[0050] According to the ratio of graphite, emulsifier and water mass ratio of 1:1.5:50, put 1.0g of artificial graphite into a three-necked flask, add 50g of distilled water, 1.5g of emulsifier NP9, and ultrasonically disperse for 30min under mechanical stirri...

Embodiment 3

[0055] The amorphous carbon-coated graphite composite material of the present embodiment is prepared by a method comprising the following steps:

[0056] 1) According to the mass ratio of calcium carbonate (template agent) to acrylonitrile monomer of 1:12, take 1.0g of calcium carbonate and 12.0g of acrylonitrile monomer and mix them evenly, then add 60g of potassium persulfate and 500g of secondary Distilled water (mass ratio of acrylonitrile monomer, initiator to water: 12:60:500), under nitrogen atmosphere, heat to 90°C and keep warm for 1h to carry out polymerization reaction to polymerize the monomer. After the reaction is completed, cool, wash and dry , to obtain template agent / polyacrylonitrile composite material;

[0057] According to the ratio of graphite, emulsifier and water mass ratio of 1:2.5:100, put 1.0g of artificial graphite into a three-necked flask, add 100g of distilled water, 2.5g of emulsifier NP9, and ultrasonically disperse for 30min under mechanical st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com