Patents

Literature

100results about How to "Improve liquid absorption and retention capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

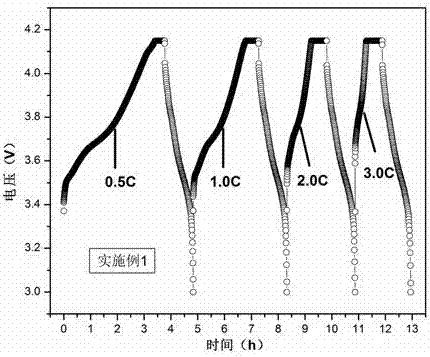

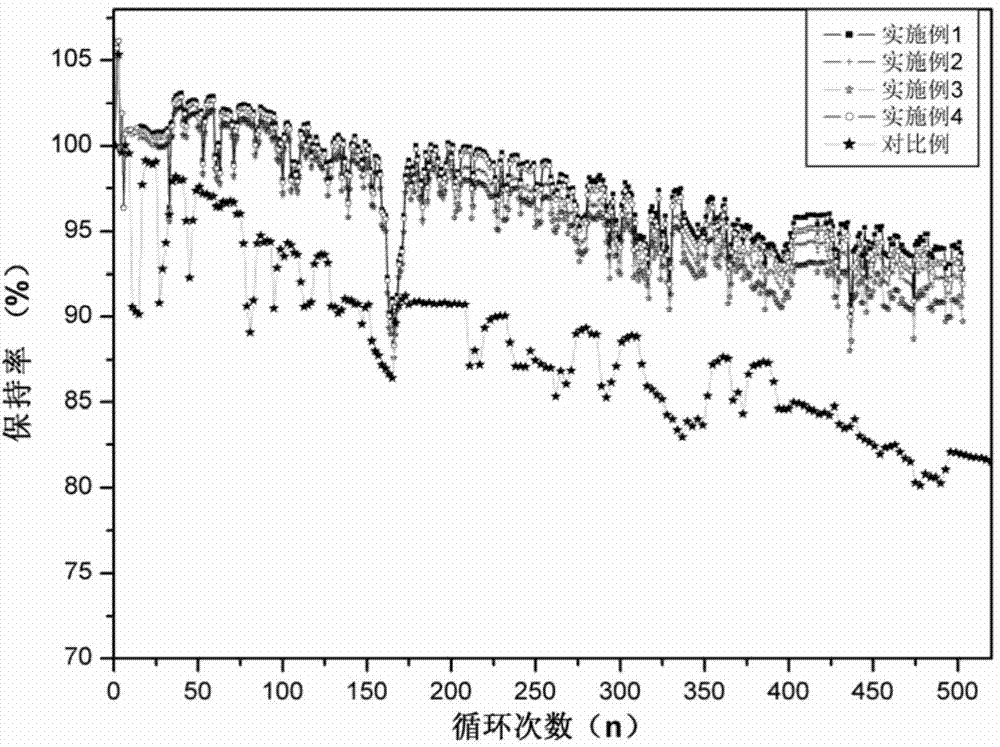

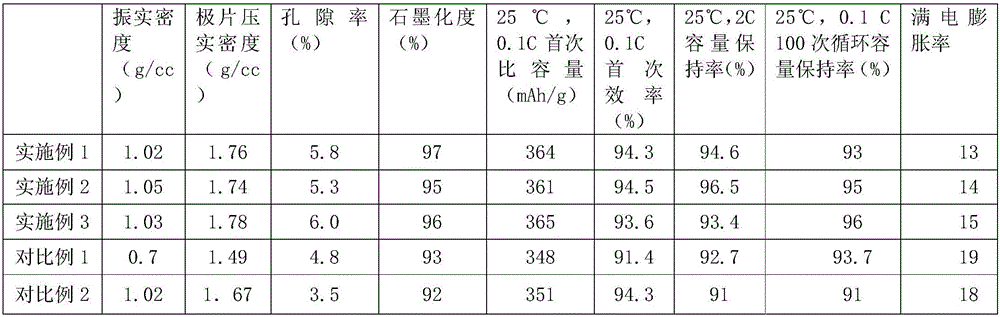

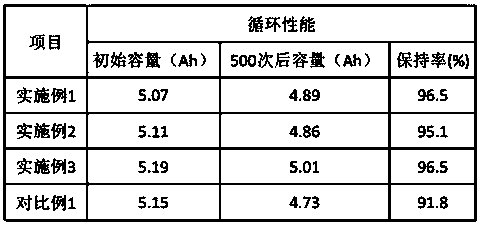

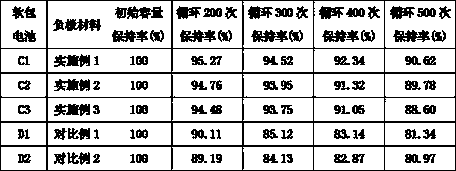

Preparation method of composite graphite, composite graphite and lithium ion battery

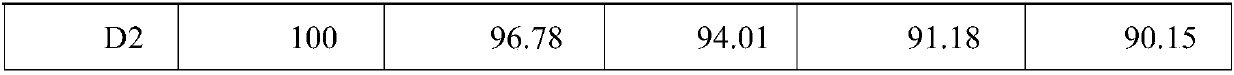

InactiveCN105098184ALow costHomogeneous catalytic effectCell electrodesSecondary cellsLithium electrodeGraphite

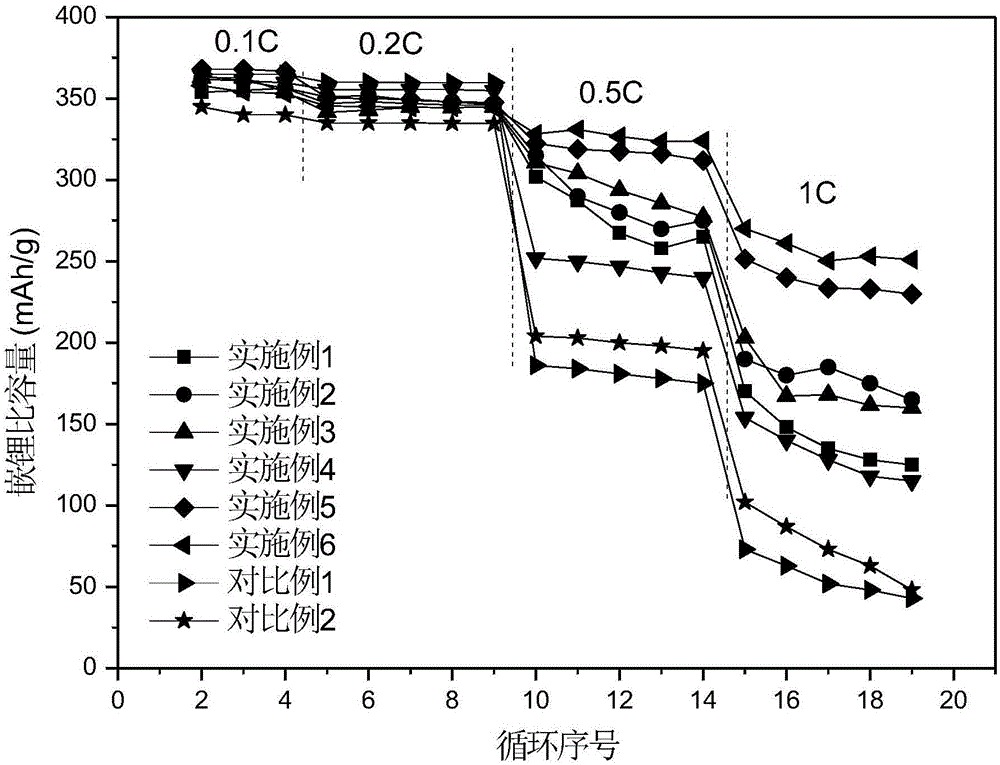

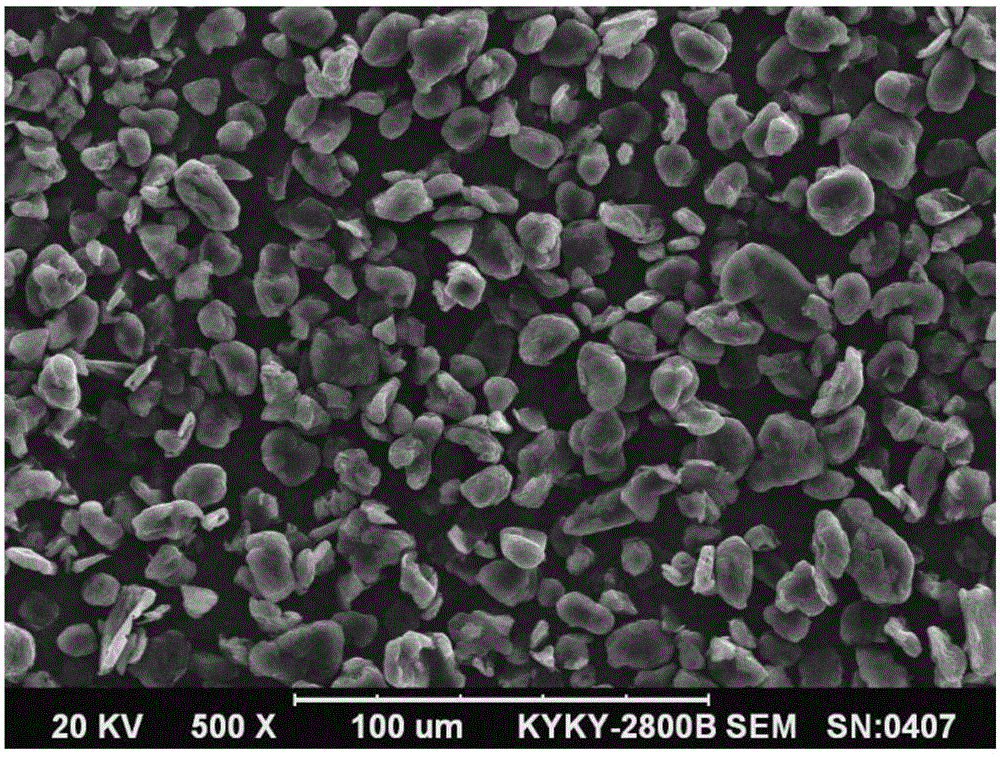

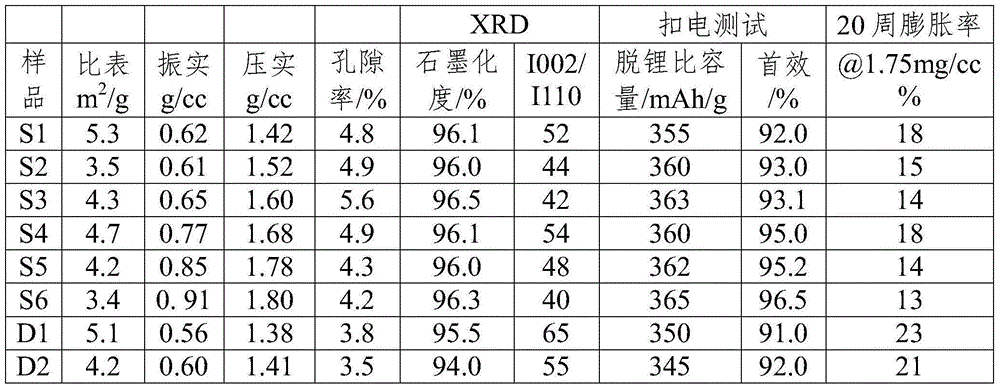

The invention provides a preparation method of composite graphite to overcome the problems that the composite graphite prepared by the method in the prior art is low in energy density, poor in high-rate charge and discharge properties and high in expansion rate in the charging and discharging processes. The preparation method comprises the following steps: (S1) providing ultrafine carbon powder, wherein the ultrafine carbon powder comprises green coke and / or mesophase carbon green microspheres; (S2) mixing the ultrafine carbon powder with a binder to obtain a mixture A, mixing the mixture A with a catalyst to obtain a mixture B, and then carrying out combined treatment on the mixture B to obtain a precursor; (S3) carrying out graphitizing treatment on the precursor to obtain a semi-finished product; and (S4) crushing, spheroidizing, wrapping and sieving the semi-finished product to obtain the composite graphite. Meanwhile, the invention further discloses the composite graphite prepared by the method and a lithium ion battery. The composite graphite provided by the invention is high in energy density, good in liquid absorption and retention properties, good in isotropic property, good in high-rate charge and discharge properties and low expansion rate in the charging and discharging processes.

Owner:BTR NEW MATERIAL GRP CO LTD

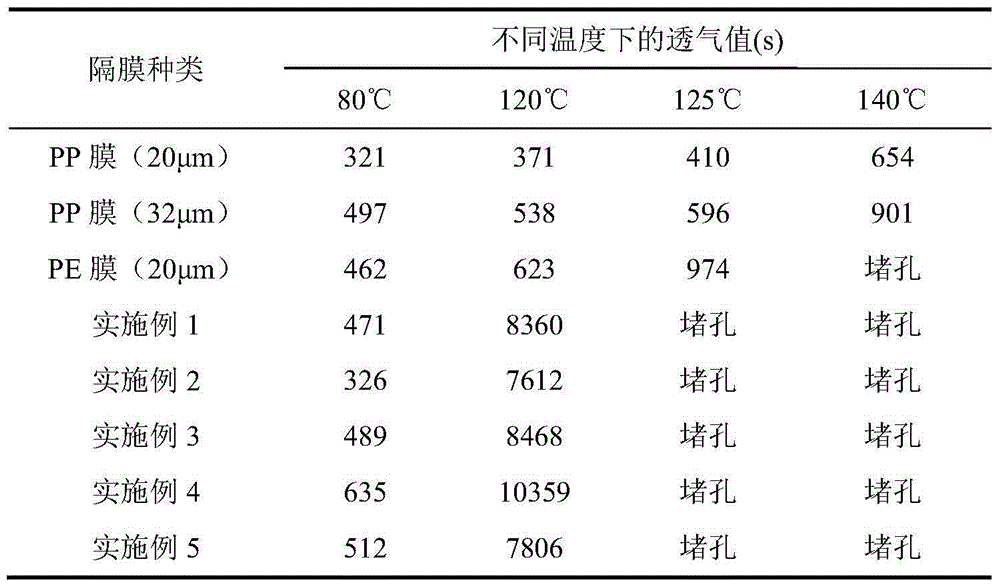

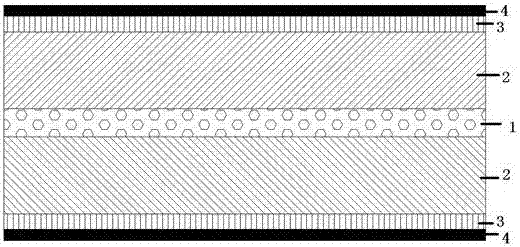

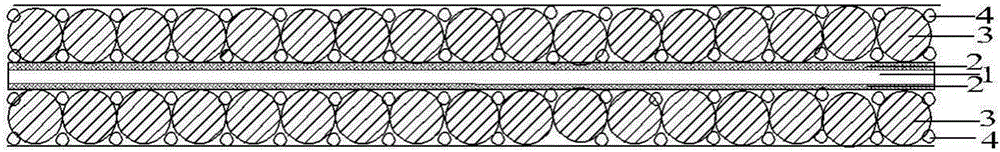

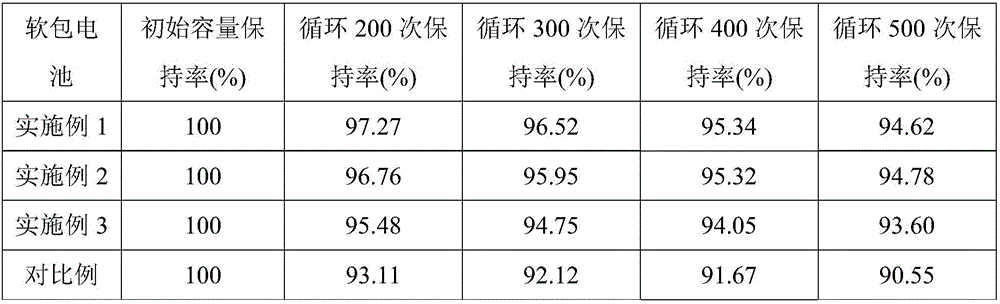

Lithium ion battery composite separator, preparation method thereof, and lithium ion battery

InactiveCN105140450APrevent internal short circuitGood high temperature resistanceCell seperators/membranes/diaphragms/spacersFinal product manufactureLithium electrodeElectrochemistry

The invention relates to a lithium ion battery composite separator, a preparation method thereof, and a lithium ion battery, and belongs to the technical field of lithium ion batteries. The lithium ion battery composite separator comprises a base film; one side of the base film is coated with a hot-melting polymer coating; the other side of the base film is coated with a heat-proof coating; the melting temperature of the hot-melting polymer coating is lower than the hot-melting temperature of the base film; the melting temperature of the heat-proof coating is higher than the hot-melting temperature of the base film; the hot-melting polymer coating comprises the following ingredients by weight: 50 to 98 parts of one or more hot-melt polymer materials, and 2 to 50 parts of one or more agglomerants; the heat-proof coating comprises the following ingredients by weight: 50 to 92 parts of one or more heat-proof polymer materials, and 3 to 20 parts of one or more agglomerants. The lithium ion battery composite separator is favorable in liquid sucking and retention properties, low in heat blocking hole temperature, and high in separator breaking temperature, thereby being capable of obviously improving the safety and the electrochemical property of the battery.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG

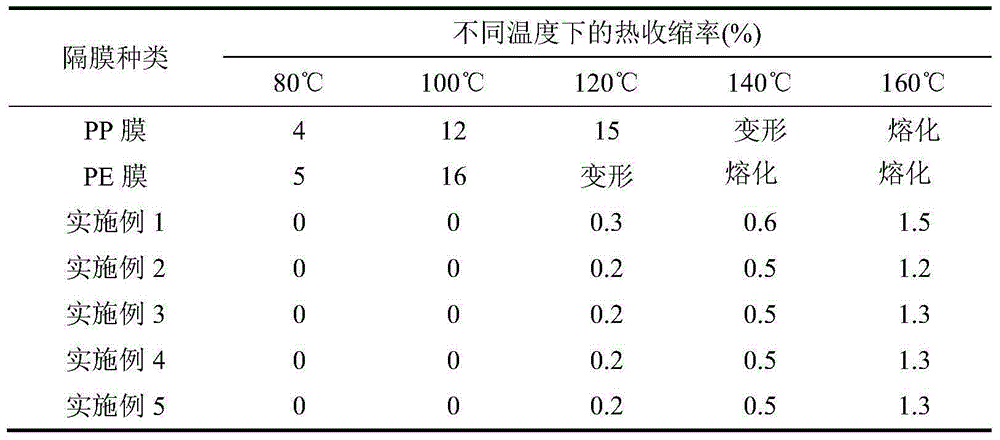

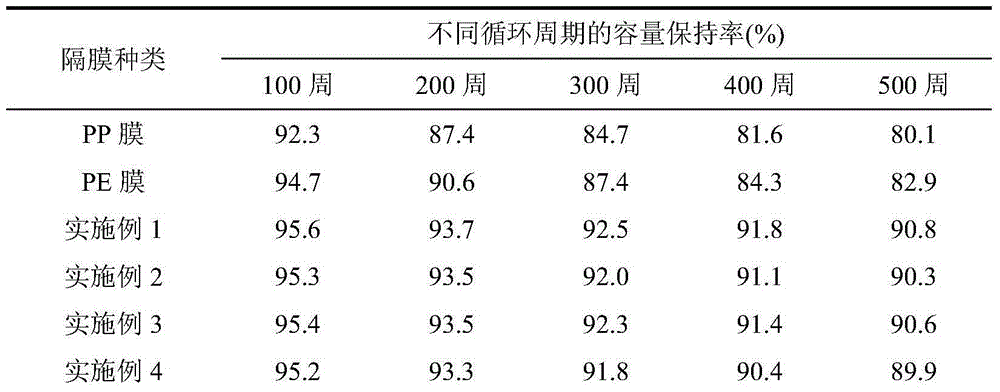

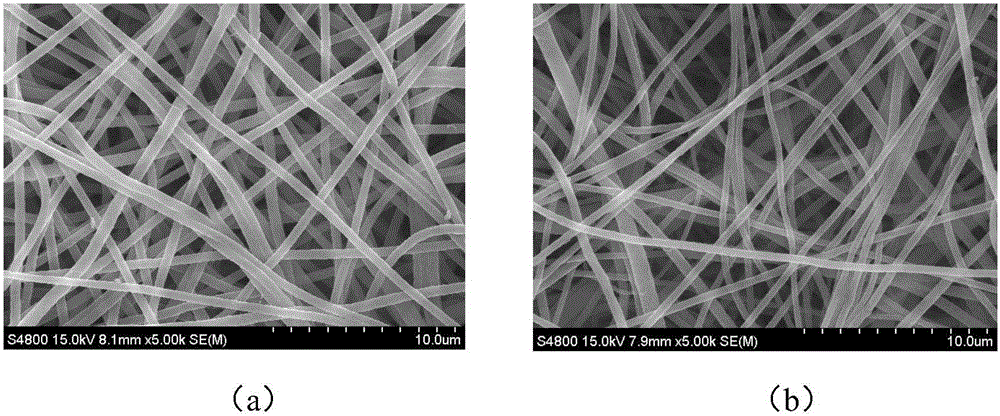

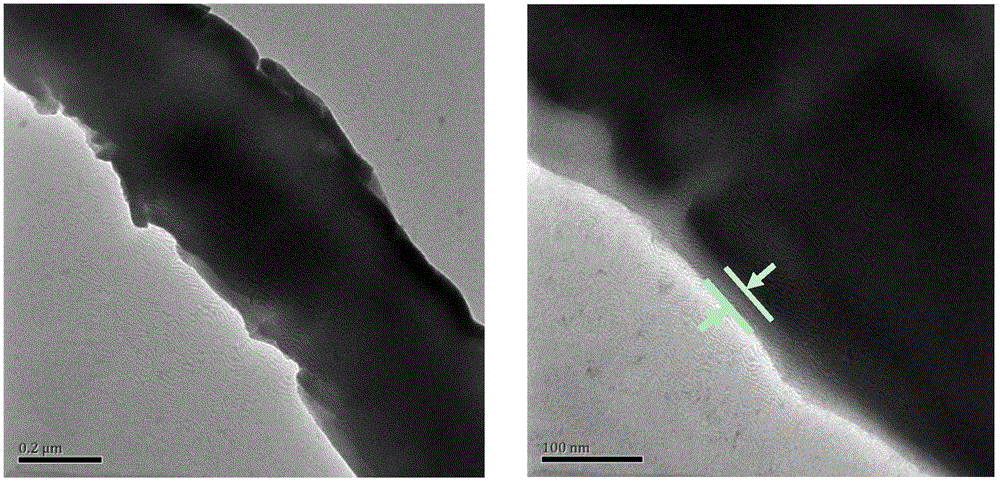

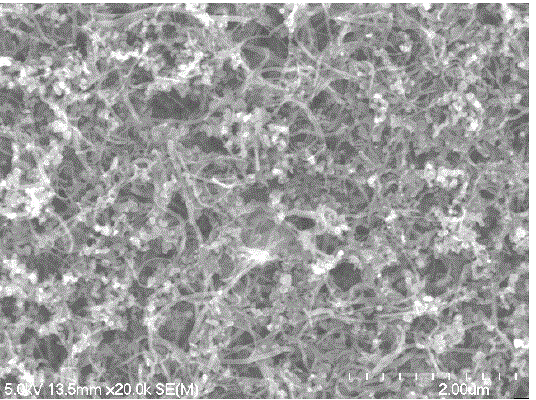

Nonwoven fabric ceramic separator, and preparation method and application thereof

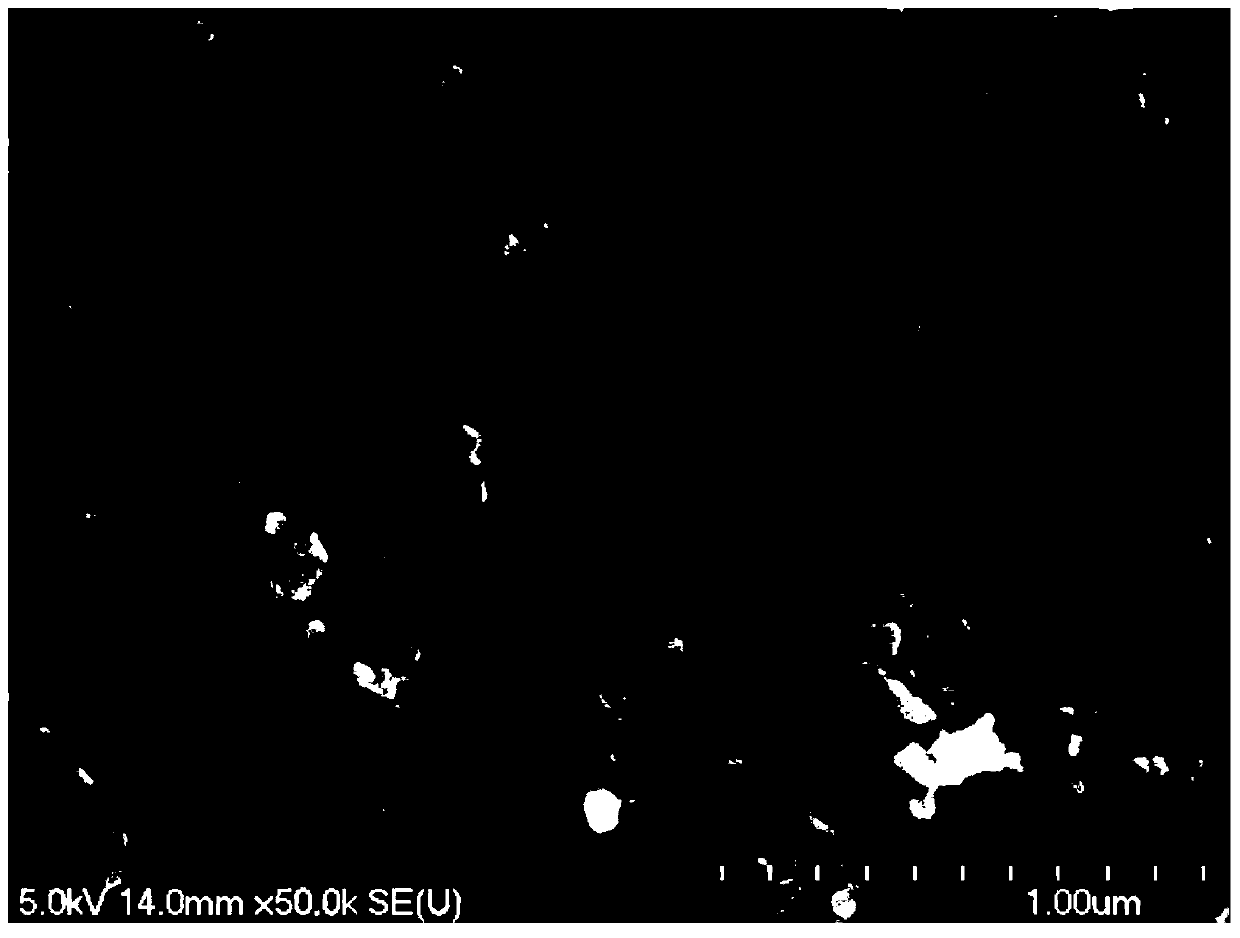

InactiveCN106784539AImprove liquid absorption and retention capacityHigh porosityCell seperators/membranes/diaphragms/spacersSecondary cellsLayer thicknessNonwoven fabric

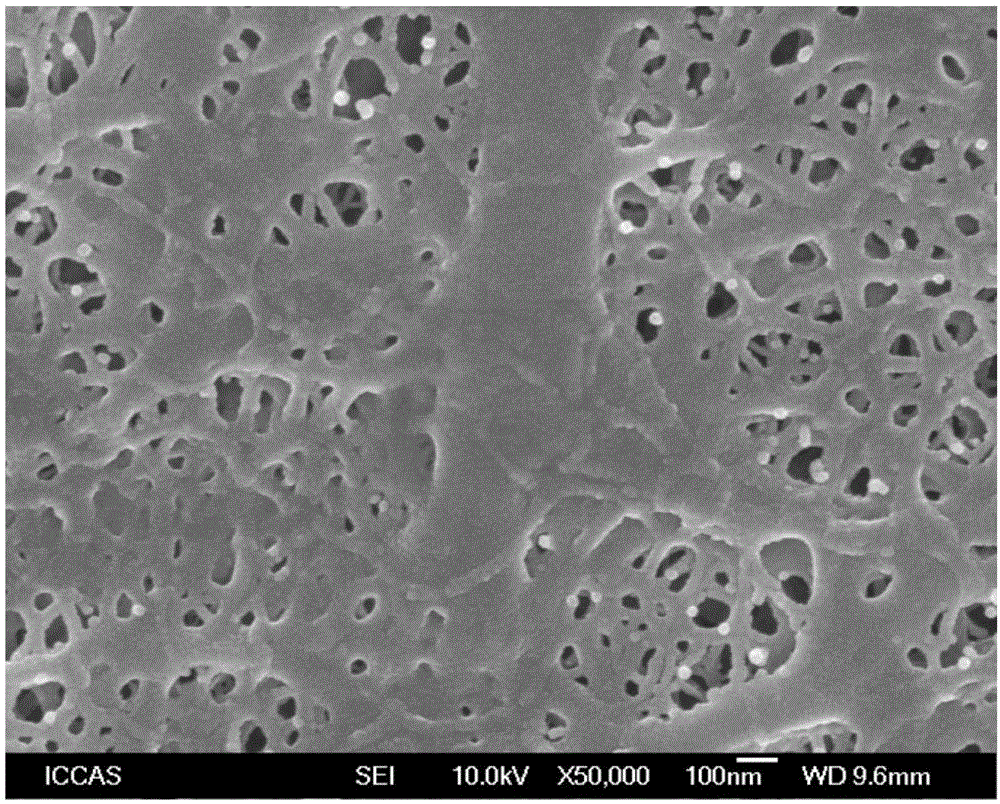

The invention provides a nonwoven fabric ceramic separator, and a preparation method and application thereof. The preparation method specifically comprises the following steps: preparing a nonwoven fabric fiber base membrane through an electrostatic spinning method; and performing atomic layer deposition on the surface through a plasma enhanced atomic layer deposition technology, so that inorganic matters are uniformly coated on the surface of the polymer fiber to form a core-shell structure taking the one-dimensional polymer fiber as the core and the inorganic matters as the shell. The nonwoven fabric ceramic separator is used in a secondary battery. The separator can be further endowed with a thermal shutdown function through a polymer layer compounding method. The nonwoven fabric ceramic separator obtained by the invention has high thermal shrinkage resistance, enhanced mechanical strength, small membrane ceramic layer thickness and favorable uniformity; and an assembled battery has high mass and volume specific energy and high safety. Thus, the separator provided by the invention can be used as a high safety separator material for lithium ion batteries and other secondary batteries.

Owner:XIAMEN UNIV

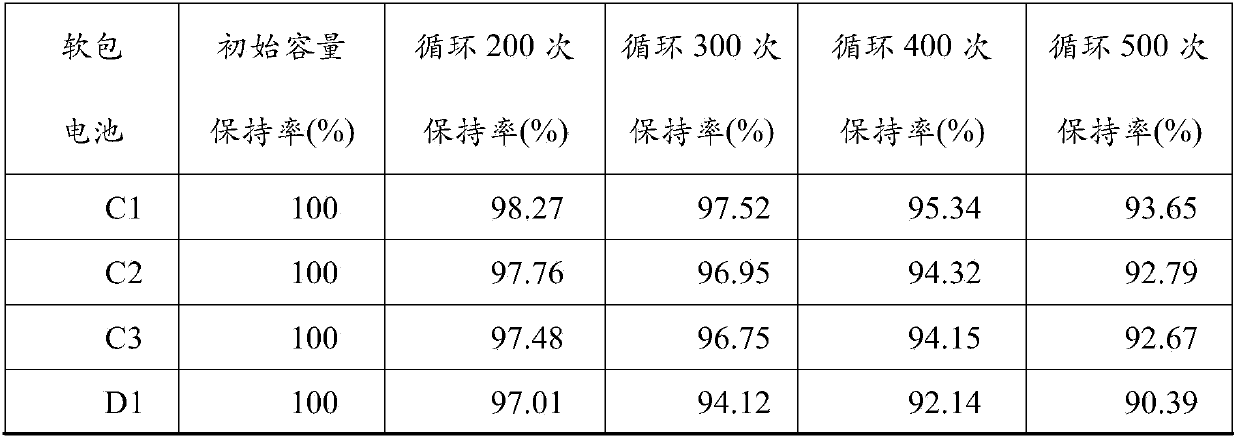

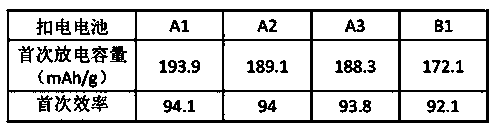

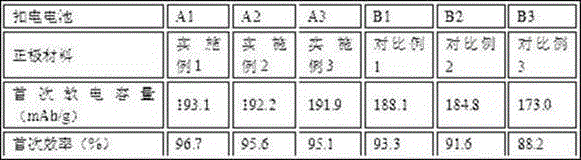

Fast charge ternary material positive pole piece and lithium ion battery comprising same

InactiveCN107068972AShorten the transmission distanceIncrease profitElectrode carriers/collectorsSecondary cellsLithium compoundCarbon nanotube

The invention discloses a fast charge ternary material positive pole piece and a lithium ion battery comprising the same. The fast charge ternary material positive pole piece is characterized in that the positive pole piece is of a laminate structure, wherein a base layer is a mesh aluminum foil current collector, a ternary material composite layer, a lithium supplementary layer and a carbon layer are arranged in turn from inside to outside. The composite positive pole piece provided by the invention utilizes a characteristic of high porosity of the mesh current collector to shorten the transmission distance of lithium ions during charging and discharging processes, lithium compounds in the lithium supplementary layer provide sufficient lithium ions for the charging and discharging processes of batteries, and the rate performance of the material is improved depending on characteristics of high electrical conductivity of graphene and large current carried by the graphene; and in the outermost layer, a carbon nanotube is deposited on the inside and the surface of the lithium supplementary layer by vapor deposition, the transmission rate of electrons is improved, direct contact between the material and electrolytic solution is avoided, and occurrence of side reaction of the material is reduced, so that the first efficiency, the rate performance and the cycle performance of the material are improved.

Owner:江苏元景锂粉工业有限公司

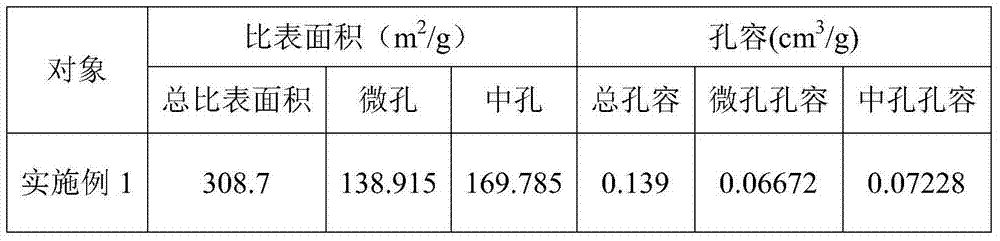

Asphalt-based nanoporous carbon material, negative material thereof, and lithium ion battery

InactiveCN104300150AHas a porous structureLarge specific surface areaMaterial nanotechnologyCell electrodesNanoporous carbonSodium-ion battery

The invention discloses an asphalt-based nanoporous carbon material, a negative material thereof, and a lithium ion battery. The asphalt-based nanoporous carbon material is prepared by mainly using 0.1-10g of asphalt, 3-50g of anhydrous aluminum trichloride, 100-400ml of anhydrous carbon tetrachloride and 200-500ml of a reaction terminating agent, and the amounts of the above raw materials can be freely adjusted in proportion. The asphalt-based nanoporous carbon material is prepared by mainly using asphalt, anhydrous aluminum chloride, anhydrous carbon tetrachloride and the reaction termination agent, and asphalt and anhydrous carbon tetrachloride undergo a Friedel-Crafts crosslinking reaction through a nanometer pore forming technology, so the obtained asphalt-based carbon material has a porous structure and a high specific surface area, and the negative material prepared by using the asphalt-based nanoporous carbon material has the characteristics of strong electrolyte imbibition and retention ability, good processing performance, low price and the like, and can greatly improve the cycle performances of the lithium ion battery.

Owner:HENAN ZHONGLIAN GAOKE NEW ENERGY

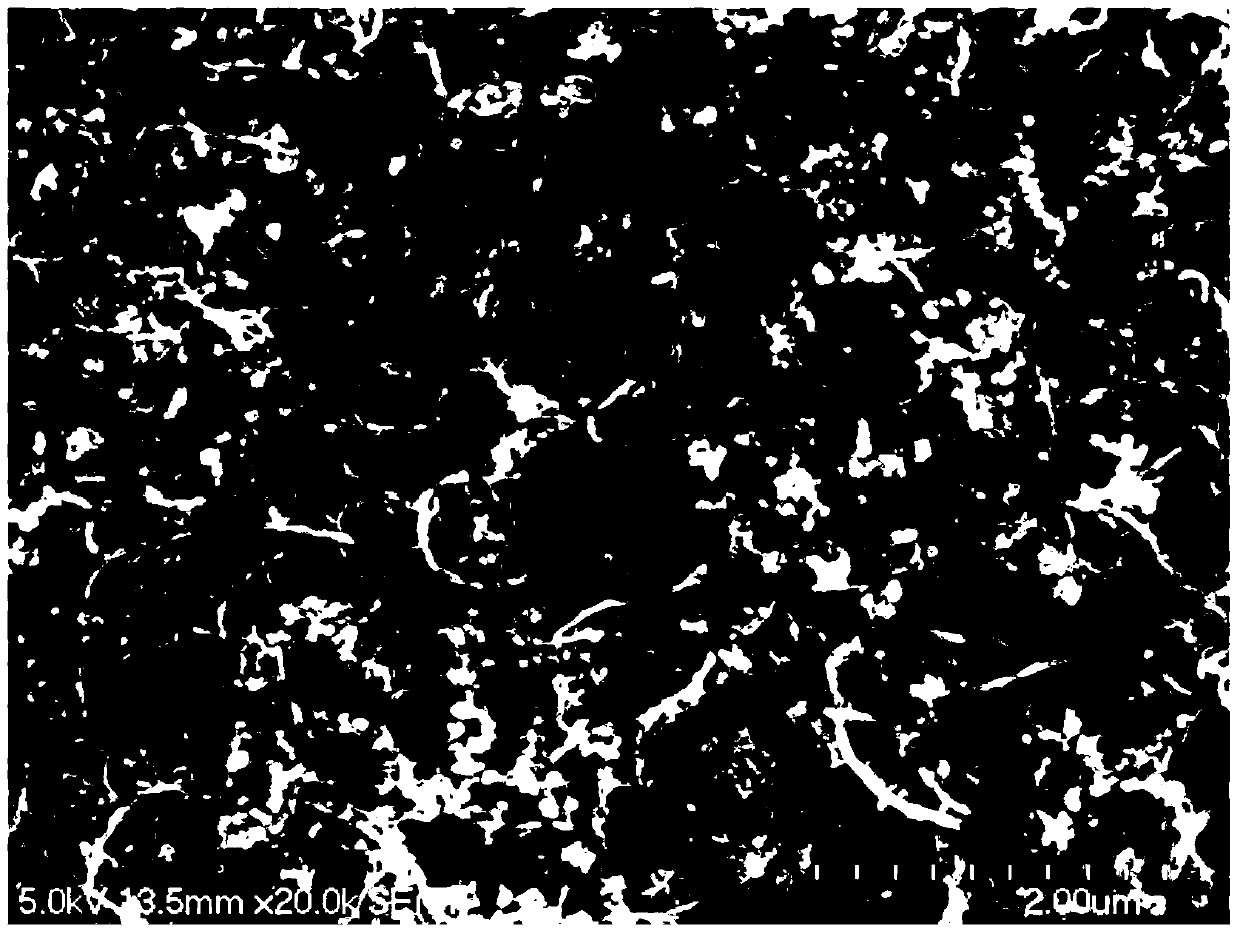

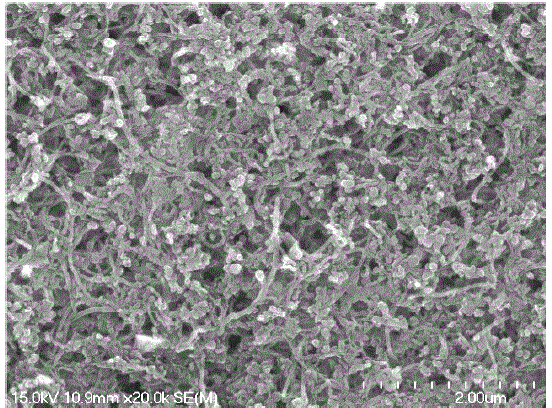

Preparation method of lithium titanate/carbon nano tube composite cathode material

The invention discloses a preparation method of a lithium titanate / carbon nano tube composite cathode material and belongs to the technical field of battery materials. A carbon nano tube grows on the surface of lithium titanate by a chemical vapour deposition method, and has the characteristics of uniform dispersion, high binding force and the like compared with a carbon nano tube directly doped in lithium titanate, the growing carbon nano tube can form a network structure on the surface of lithium titanate, and an important effect is exerted on improving structural stability of the material under the condition of high-rate discharge of a battery. The contact probability of the lithium ion battery with lithium titanate is increased and the internal resistance and polarization are reduced by using high conductivity of the carbon nano tube and the network structure formed by the carbon nano tube, the liquid absorption and keeping ability of the cathode material can be improved due to larger specific surface area of the carbon nano tube, and the high-rate discharge ability and recyclability of the battery are improved.

Owner:RIGHTFUL TECH

Carbon nano tube dispersion liquid and preparation method thereof

ActiveCN103700823AImprove consistencyImprove liquidityCell electrodesSecondary cellsCarbon nanotubeSolvent

The invention provides a carbon nano tube dispersion liquid and a preparation method of the carbon nano tube dispersion liquid. The carbon nano tube dispersion liquid comprises a carbon nano tube, a high conductivity carbon black, a dispersion agent and a solvent. The carbon nano tube dispersion liquid is uniform and stable, and also excellent in consistency, mobility, dispersion and glossiness, the high conductivity carbon black is in the dispersion liquid to further improve the performance of the carbon nano tube dispersion liquid, so that the application of the carbon nano tube dispersion liquid is more extensive. The carbon nano tube dispersion liquid can be dispersed only through being grinded by a regular grinding machine, the preparation of the carbon nano tube dispersion liquid is simpler and more practical, the dispersion is completed only through the cheap grinding machine in the preparation method, in addition, the yield is high, the safety performance is excellent, the operation is simple, the dispersion efficiency is high, the dispersion cost is greatly lowered, the production quality is improved, and the carbon nano tube dispersion liquid is more suitable for batch production as well as large-scale production and application.

Owner:SHENZHEN SSZK NEW MATERIALS CO LTD

Carbon nano tube and carbon black composite dispersing liquid and preparation method thereof

ActiveCN104868125AImprove liquidityGood dispersionCell electrodesSecondary cellsDispersityOrganic solvent

Owner:SHENZHEN SSZK NEW MATERIALS CO LTD

High-performance graphite composite negative electrode material and preparation method thereof

ActiveCN107749472AEvenly distributed dopingIncrease gram capacityNegative electrodesSecondary cellsLithium compoundCore shell

The invention relates to a graphite composite negative electrode material. The graphite composite negative electrode material has a core-shell structure, and comprises a core part and a shell part which coats the core part, wherein the core part is a germanium oxide-graphite composite material composite material, the shell part is an inorganic lithium compound, and the shell part of the graphite composite negative electrode material has a porous structure. The invention also provides a preparation method of the graphite composite negative electrode material.

Owner:乌兰察布市大盛石墨新材料股份有限公司

Lithium ion battery composite separation membrane and preparation method thereof

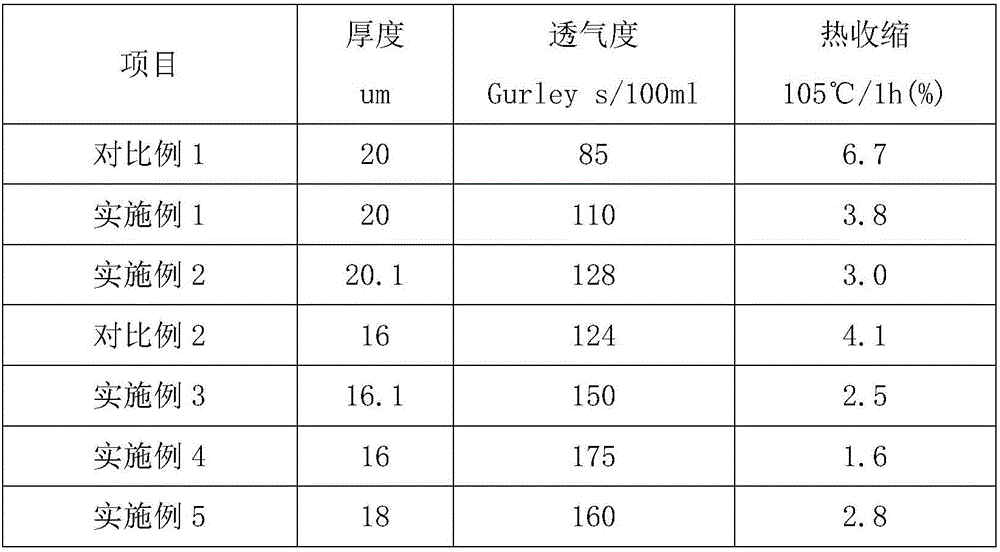

ActiveCN103715384ASimple methodSuitable for large-scale industrial production applicationsCell component detailsPolyolefinCrystallinity

The present invention discloses a lithium ion battery composite separation membrane and a preparation method thereof, and belongs to the technical field of lithium ion batteries, wherein at least a surface of a polyolefin separation membrane is coated with a modified natural rubber polymer coating. According to the invention, the polyolefin separation membrane and the modified natural rubber are combined to form the composite separation membrane, such that mechanical properties of the natural rubber can be improved, and the original pore closing characteristic of the polyolefin separation membrane can be maintained and utilized so as to improve safety of the battery, enhance bonding force between the separation membrane and the positive electrode and bonding force between the separation membrane and the negative electrode, eliminate the interface effect, and improve cycle stability of the battery; and the inorganic nanoparticles are added to the modified natural rubber latex, such that the crystallinity of the polymer can be reduced to a certain extent, the mechanical strength of the separation membrane and the carrier concentration can be increased, the interface compatibility between the separation membrane and the lithium electrode can be effectively improved, and the interface is stable.

Owner:HENAN NORMAL UNIV

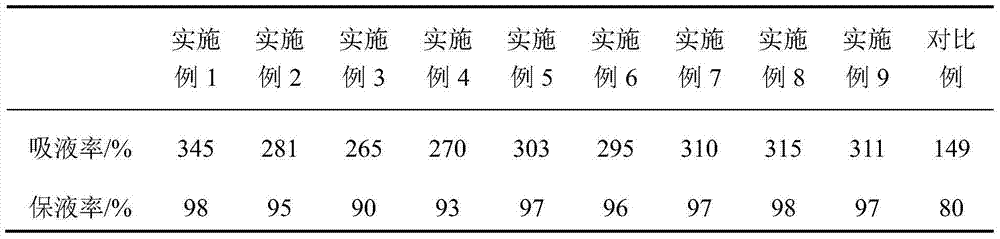

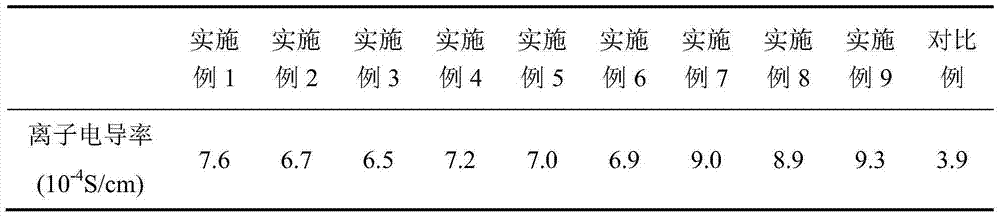

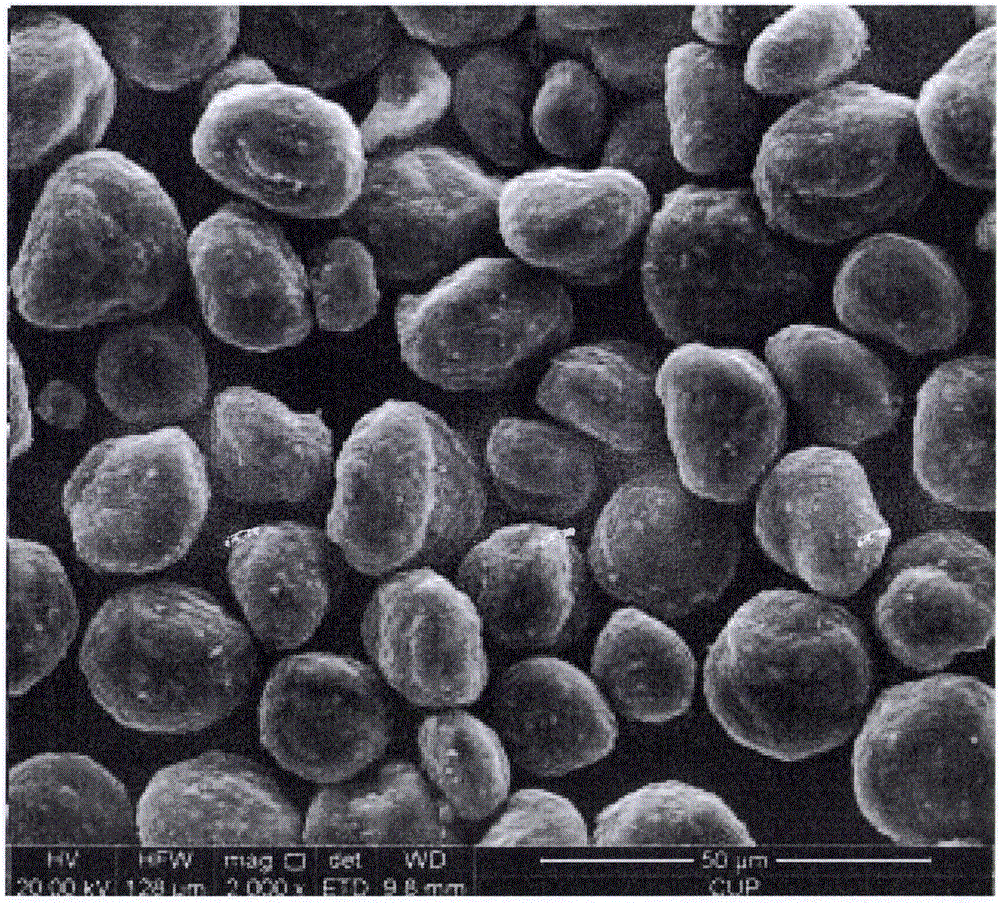

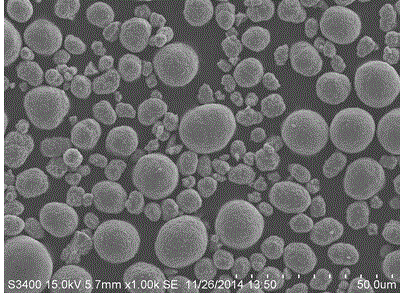

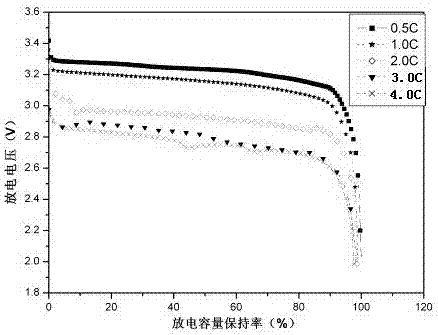

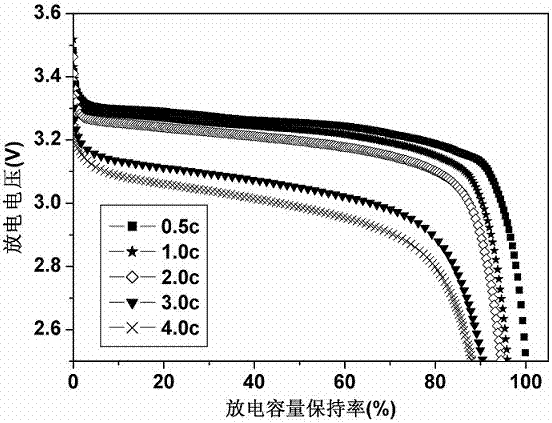

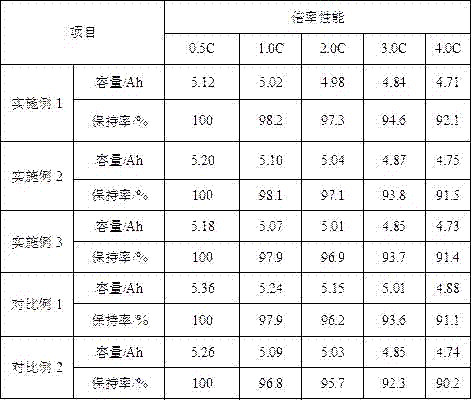

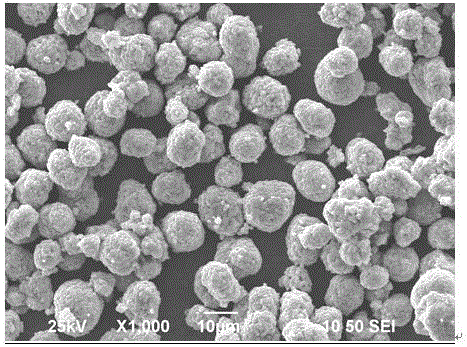

Preparation method of high-performance graphite negative electrode material for lithium ion battery

InactiveCN105789627AEasy to processImprove cycle performanceCell electrodesSecondary cellsHigh rateMass ratio

The invention discloses a preparation method of a high-performance graphite negative electrode material for a lithium ion battery. The method comprises the following steps of 1) collecting petroleum coke micropowder in a shaper and a grinder in normal graphite production, and mixing the petroleum coke micropowder, ground expanded graphite powder, raw mesocarbon microbeads and an adhesive in a mixer for 0.5-3 hours according to a mass ratio of 1 to (0.01-0.3) to (0.7-1.5) to (0.1-0.2) to form a solid-phase coated mixture, wherein the frequency of the mixer is 30-50HZ; and 2) graphitizing the solid-phase coated mixture obtained in the step 1) to obtain the high-performance graphite negative electrode material for the lithium ion battery. The method is simple and feasible; micropowder wastes in a dust collector are recycled, so that the cost is reduced; the method is easy for large-scale industrial production; and the obtained graphite negative electrode material has the characteristics of high energy density, good liquid absorption and retention performance, good cycle performance, good isotropic performance, good high-rate charge / discharge performance and low expansion rate in a charge / discharge process.

Owner:FUJIAN XFH NEW ENERGY MATERIALS CO LTD

Method for preparing composite cathode material by modification of graphite

InactiveCN105932320AImprove conductivityLarge specific surface areaCell electrodesSecondary cellsComposite cathodeOrganic solvent

The invention discloses a method for preparing a composite cathode material by the modification of graphite. The method comprises four processes of preparation of a solution A, preparation of a solution B, preparation of a solution C and preparation of the composite cathode material, wherein during the preparation process of the solution A, a polymer matrix, a pore forming agent, a conductive agent, an inorganic additive and an organic solvent are used; during the preparation process of the solution B, pitch and an organic solvent are used; during the preparation process of the solution C, the solution A and the solution B are used; and during the preparation process of the composite cathode material, the graphite, the solution C and a three-dimensional mixer are used. According to the method, the graphite is modified by the pore-forming technology and doping modification technology, the composite cathode material with high capacity, high specific surface area and good conductivity can be prepared, and liquid protection capabilities, rate performance and cycle performance of the composite cathode material in the lithium ion battery are improved, and the requirement of high-energy-density lithium ion battery on the cathode material is met.

Owner:赵晓锋

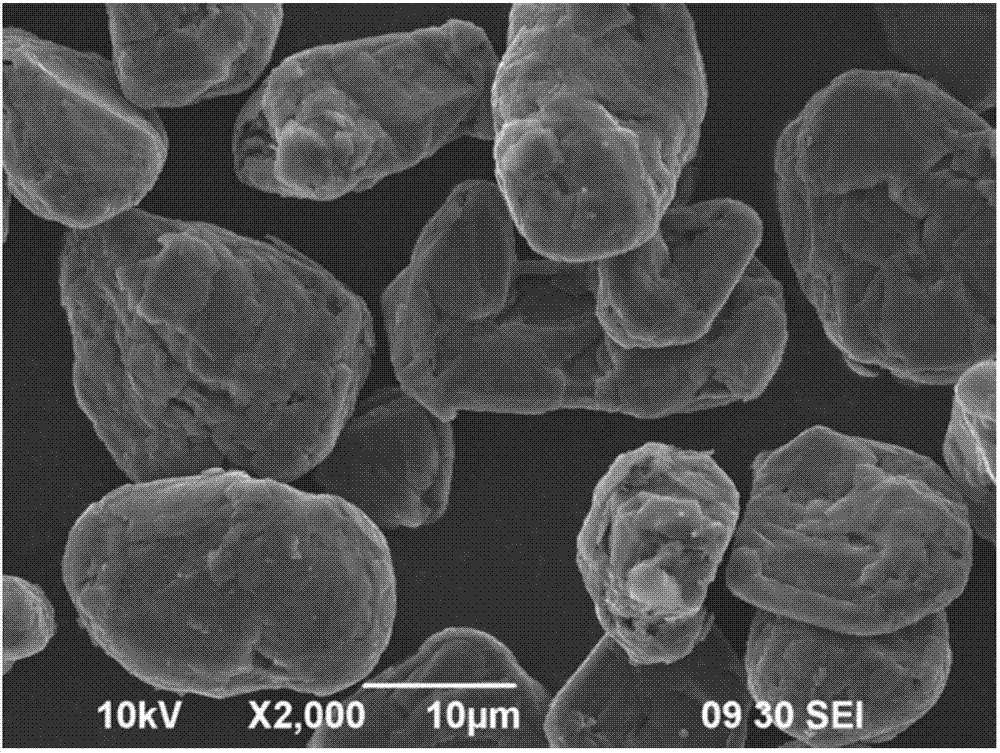

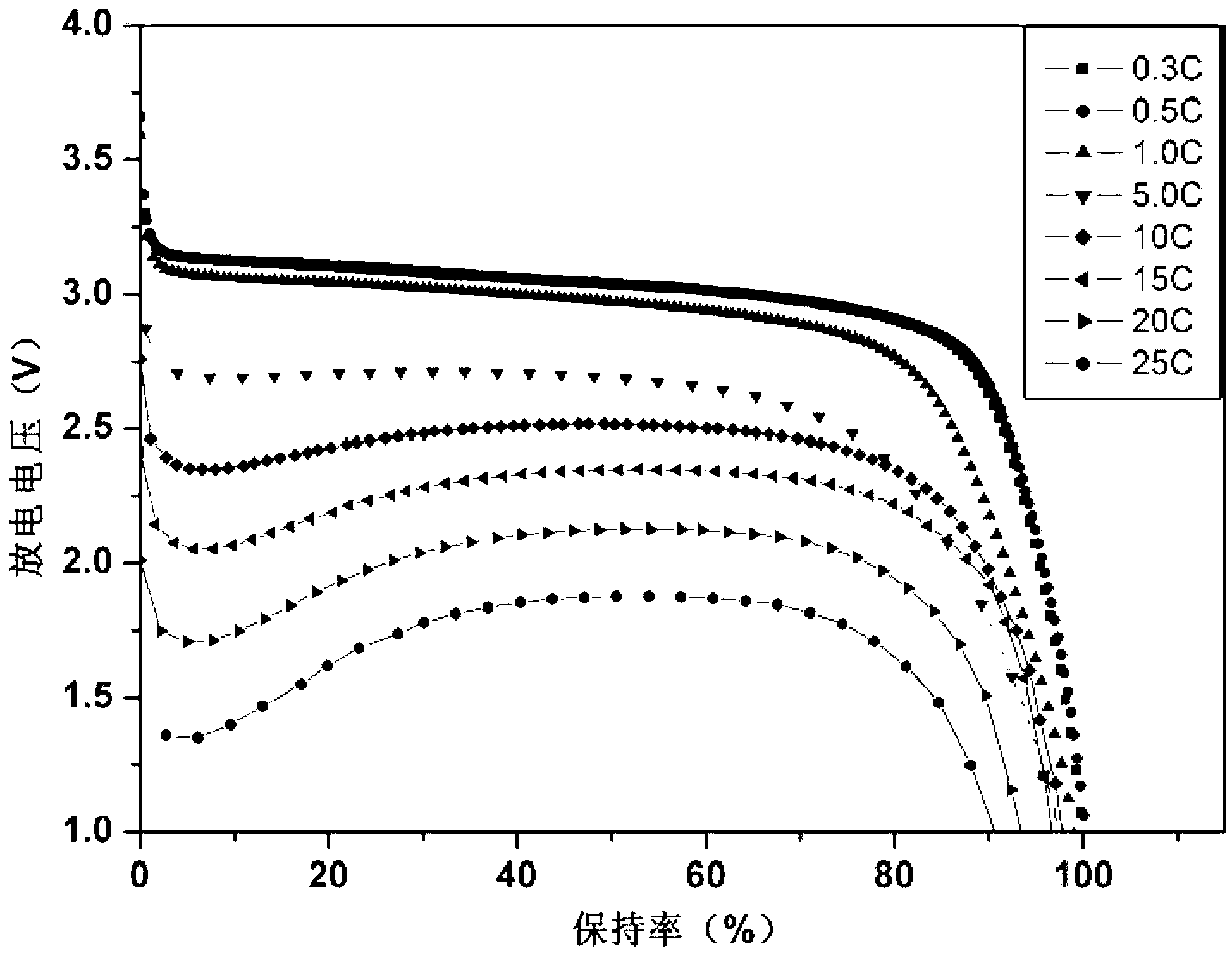

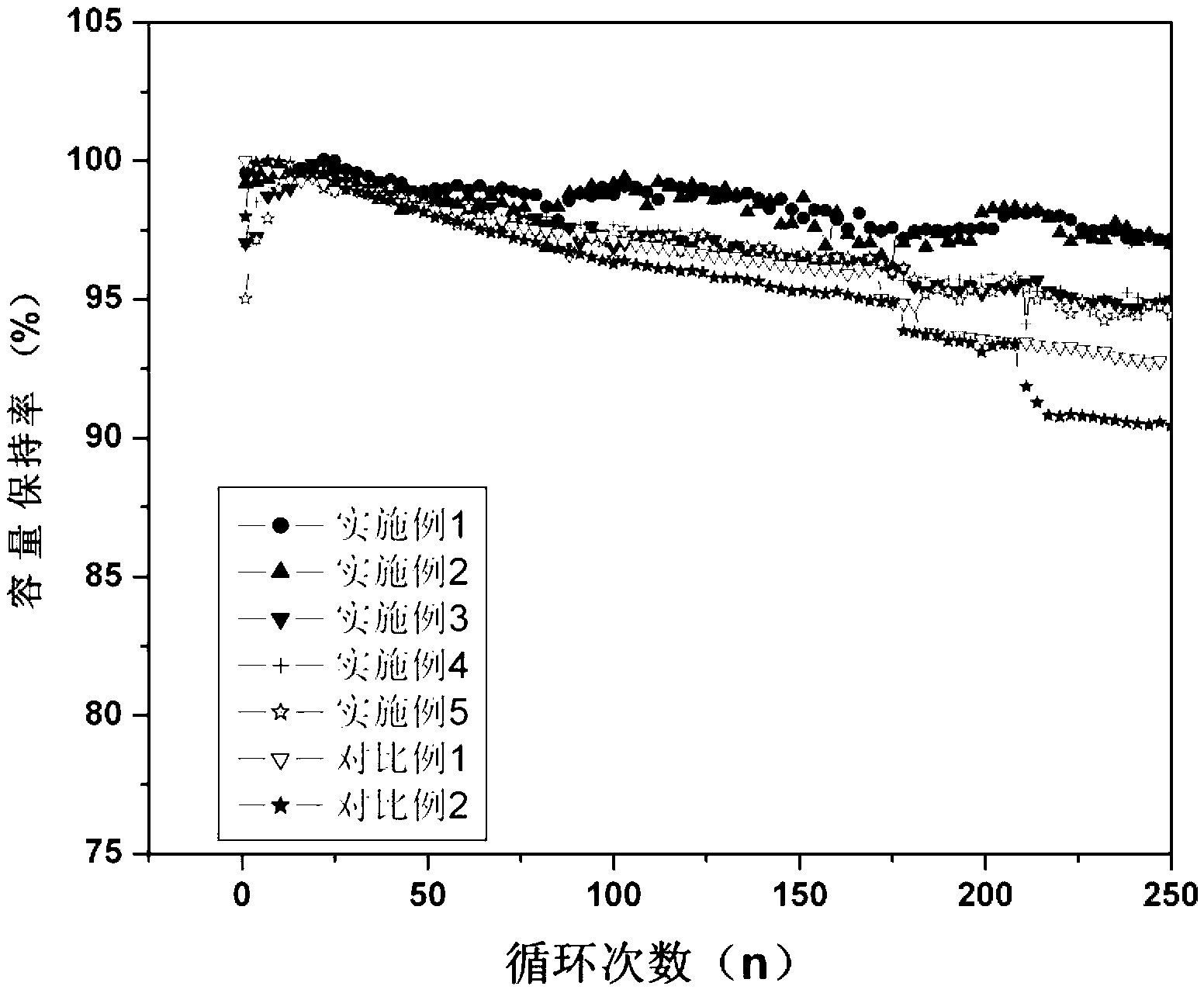

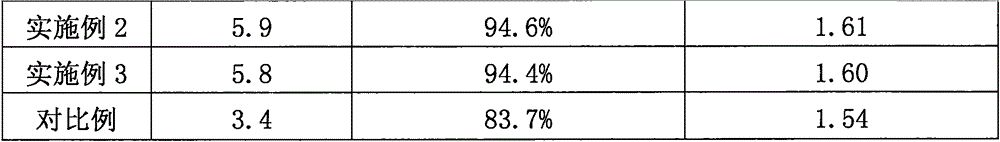

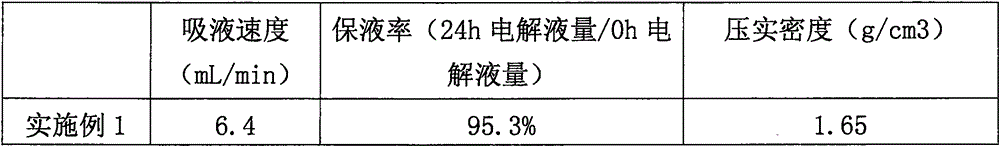

Negative pole material for lithium ion power and energy storage battery, as well as preparation method and battery thereof

InactiveCN103943860AHigh specific surface areaImprove liquid absorption and retention capacityCell electrodesSecondary cellsCarbonizationGraphite

The invention belongs to the field of preparation processes of lithium batteries and particularly relates to a negative pole material for a lithium ion power and energy storage battery, as well as a preparation method and a battery thereof. Based on the insufficiencies in modification of the negative pole material in the prior art, a mixed solution of a binder and a catalyst is firstly configured, and graphite-like materials with different structures are uniformly mixed to form a graphite mixed body with different graphite structure types and close combination; then a porous coated carbon material is prepared by Friedel-Crafts cross-linking reaction, and coating, carbonization, crushing and other treatment are performed on the graphite mixed body, thus the negative pole material with high compaction density, strong liquid absorption capability, excellent rate performance and good cycling performance is finally prepared.

Owner:JIAOZUO JUNENG ENERGY TECH

Wiping cloth with multilayered structure and processing method for wiping cloth

The invention discloses wiping cloth with a multilayered structure and processing method for the wiping cloth. An upper layer and a lower layer of the wiping cloth are made of ultrathin polyester fibers and common polyester fibers; a middle layer of the wiping cloth is made of common polyester fibers; the filament number of the ultrathin polyester fibers is 0.1-0.4dtex; the filament number of the common polyester fibers is 0.5-1.2dtex; the common polyester fibers are projected out of the upper surface and the lower surface of the wiping cloth; and the occupied area of the common polyester fibers are lower than the superficial area of the upper and lower surfaces of the wiping cloth. After the wiping cloth is purified, cut off and washed, the generation rate of particles with the diameters smaller than or equal to 0.5 micrometer in air can reach 16-2000 per m (2) (the diameters of the particles are smaller than or equal to 0.5 micrometer), and the generation rate of the particles in liquid can reach 1-1000 per cm (2). The wiping cloth has firm handfeel, and is excellent in liquid suction property and liquid retainability, excellent in wiping performance, simple in processing procedure and low in cost; and the wiping cloth does not have additional impurities.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

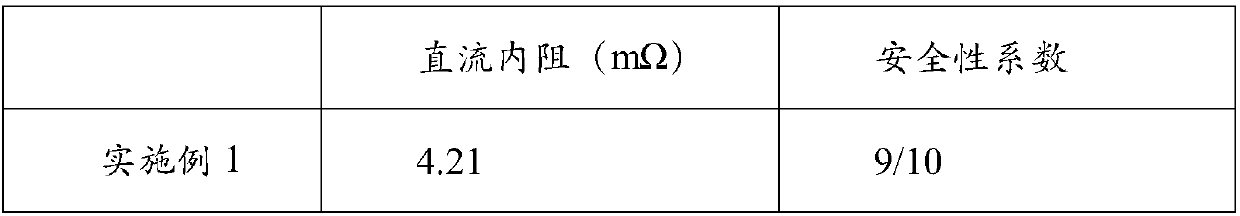

Preparation method of high-nickel ternary material used for lithium ion battery

A preparation method of a high-nickel ternary material used for a lithium ion battery. The ternary material is Li(Ni<0.6>Co<0.2>Mn<0.2>)O<2>, of which gram volume is not less than 180 mAh / g and service life retention rate after 2000 circulations is not less than 80%. The preparation method includes following steps: (1) preparation of a precursor solution; and (2) mix-calcination. During the preparation process, because an organic solution can reduce particle aggregation, a complexing agent can control the appearance and the compatibility between a titanium dioxide enhancing material and electrolyte, the ternary material is high in the gram volume (not less than 180 mAh / g) and is good in the service life retention rate after 2000 circulations (not less than 80%). The ternary material is easy to control in appearance, is simple in process and is suitable for industrialized production.

Owner:JIANGSU LENENG BATTERY INC

Composite positive pole piece for lithium ion battery, preparation method of composite positive pole piece and lithium ion battery

ActiveCN107317037AImprove liquid absorption and retention capacityHigh porosityElectrode carriers/collectorsSecondary cellsPorosityMicrowave method

The invention provides a composite positive pole piece for a lithium ion battery, a preparation method of the composite positive pole piece and the lithium ion battery. The composite positive pole piece for the lithium ion battery is of a laminated structure, and comprises an inner layer, a middle layer and an outer layer, wherein the inner layer is a current collector, the middle layer is a positive active substance layer, and the outer layer is a spraying layer. Trilithium hexafluoroaluminate is contained in the spraying layer of the composite positive pole piece, the spraying layer is sprayed on the surface of the pole piece, the purpose that lithium ions are supplemented by the pole piece is reached, and sufficient lithium ions are provided for high-rate charging and discharging process and long cycle process of the lithium ion battery. In the preparation method of the composite positive pole piece for the lithium ion battery provided by the invention, the porosity and adhesive power of the pole piece are improved through a liquid nitrogen and microwave method, the flexibility and adhesive force of the pole piece are improved through a hot rolling technology, and the rebounding rate of the pole piece is reduced.

Owner:惠州博磊达新能源科技有限公司

Preparation method of oily polymer coated diaphragm

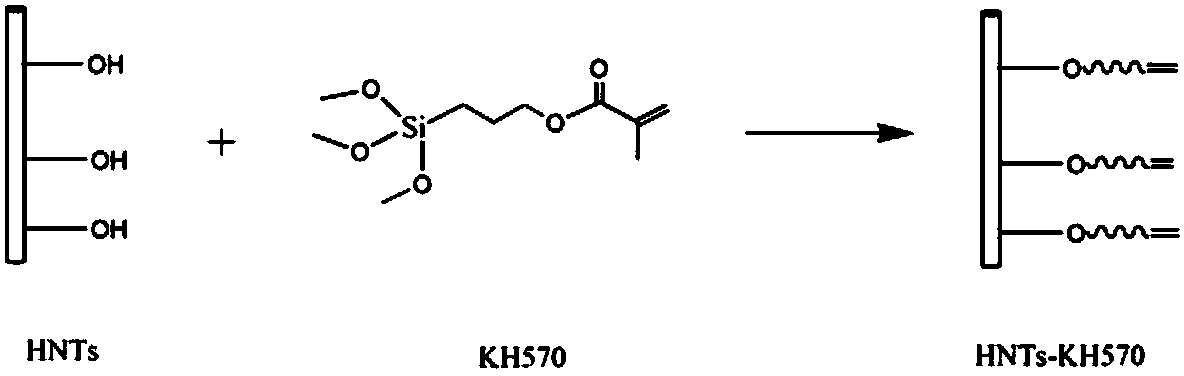

InactiveCN110379981AHigh mechanical strengthImprove liquid absorption and retention capacitySecondary cellsCell component detailsPolymer modifiedPolymer science

The invention discloses a preparation method of an oily polymer coated diaphragm, and belongs to the technical field of preparation of lithium ion battery diaphragms. The method comprises the following steps: 1, preparation of oily mixed slurry: firstly, uniformly mixing and stirring an oily solvent and ceramic powder, then adding modified PMMA and performing uniform stirring, adding PVDF and a PVDF copolymer and performing uniformly stirring, and then carrying out ball milling for 0.5-1 hour to obtain the oily mixed slurry, adding a pore-forming agent into the uniformly mixed slurry for 2 hours, and performing uniform stirring to obtain final oily polymer slurry; 2, coating: coating one side or two sides of a base film with the oily mixed slurry prepared at the step 1 in a dip-coating, intaglio coating, spraying and spot-coating manner to form an oily coating, and carrying out drying in a drying oven at the temperature of 40-90 DEG C to obtain the polymer modified PMMA / PVDF and the copolymer ceramic coated diaphragm thereof. The method is simple in process, high in production efficiency and compatible with existing production equipment, and the large-scale production can be achieved.

Owner:高芳

Lithium ion battery diaphragm and preparation method thereof

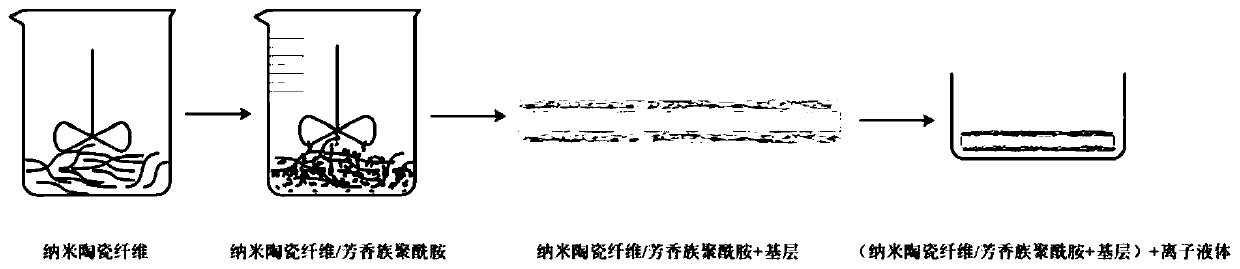

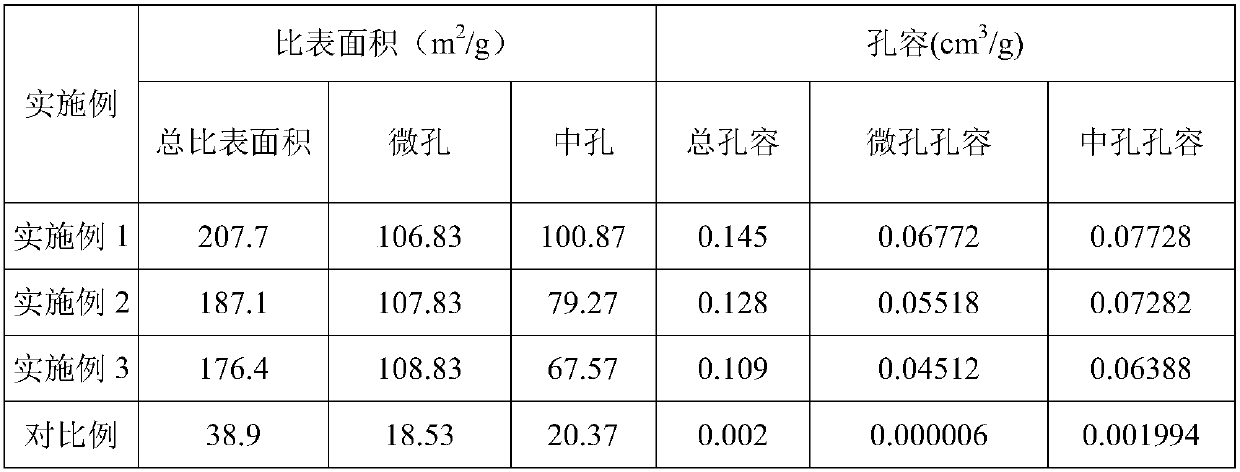

InactiveCN111477816AEvenly dispersedAvoid reunionSecondary cellsCell component detailsFiberDiaphragm structure

The invention relates to a lithium ion battery diaphragm and a preparation method thereof, and belongs to the technical field of batteries. The diaphragm is a multi-layer composite diaphragm, and comprises a base material and a coating layer formed by coating a single surface or double surfaces of the base material with mixed slurry of nano ceramic fibers and aromatic polyamide, and after ionic liquid modification, a composite diaphragm structure taking the coating layer as a three-dimensional fiber space network framework and taking the base material as a diaphragm thermal shutdown is formed.The preparation method comprises the following steps: 1) performing in-situ polymerization in uniformly dispersed nano ceramic fibers to form aromatic polyamide to obtain mixed slurry; 2) coating thesurface of a base material with the mixed slurry; 3) carrying out drying and water washing on the coated composite diaphragm, placing the composite diaphragm in an ionic liquid, and carrying out vacuum impregnation; and 4) drying the impregnated composite diaphragm to obtain the lithium ion battery composite diaphragm. The lithium ion battery diaphragm provided by the invention has a three-dimensional fiber space network structure skeleton, has good electrolytic solution absorption and retention capability, and is beneficial to improvement of battery safety, cycle and rate capability.

Owner:华鼎国联四川动力电池有限公司

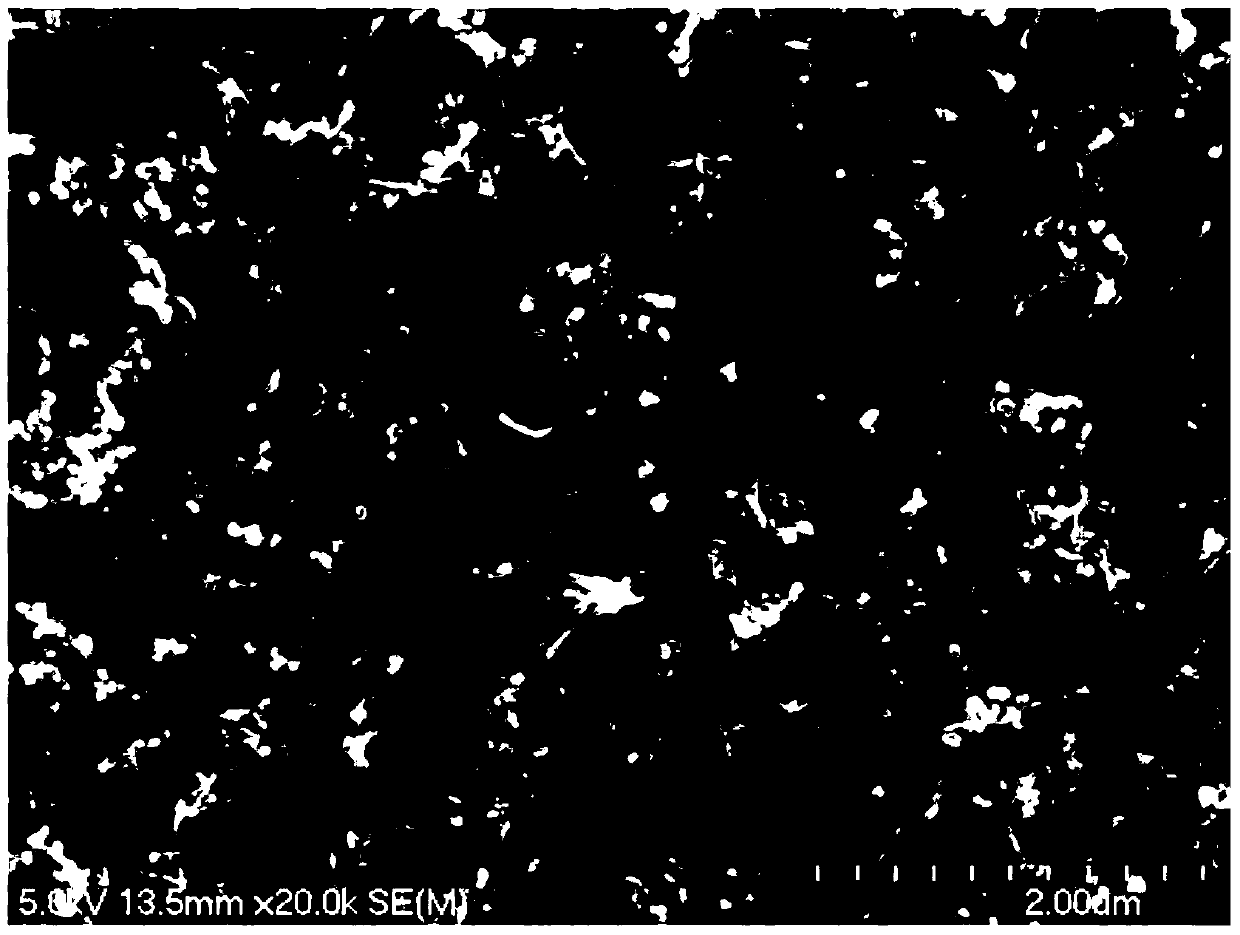

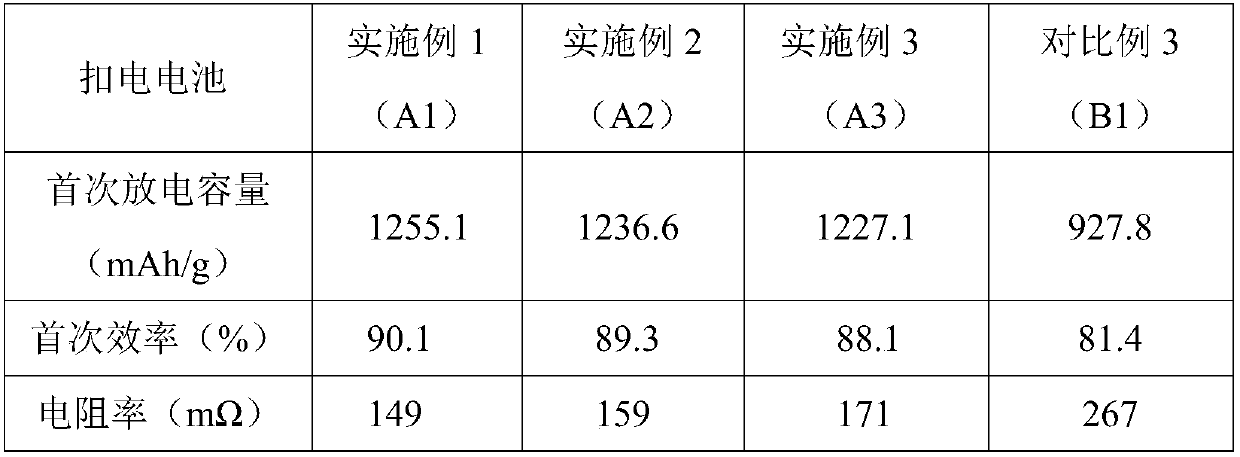

Graphene/silicon composite material, preparation method thereof and lithium ion battery

ActiveCN107946562AImprove liquid absorption and retention capacityImprove liquid retention capacityCell electrodesSecondary cellsSilane compoundsMass ratio

The invention relates to a graphene / silicon composite material, a preparation method thereof and a lithium ion battery, and belongs to the field of preparation of a lithium ion battery material. The preparation method of the graphene / silicon composite material comprises the following steps of 1) performing reaction of a silane compound, a graphene oxide solution and a nitrogen source for 1-6 hoursunder 120-150 DEG C to obtain hydrogel A, wherein the mass ratio of the silane compound, the graphene oxide solution and the nitrogen source is (10-30):(1-10):(1-5); 2) performing vacuum freezing anddrying on the hydrogel A to obtain a material B; and 3) performing heat preservation on the material B for 1-6 hours under an inert atmosphere, and performing heat preservation for 1-6 hours at 800-900 DEG C, and performing cooling, thereby obtaining the graphene / silicon composite material. In the graphene / silicon composite material obtained by the preparation method, the tap density and the specific area are obviously improved, and the graphene / silicon composite material has a good application prospect in the field of lithium battery preparation.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG

Carbon nano-tube net/Ni(OH)<2>/PPY composite electrode, preparation method and application

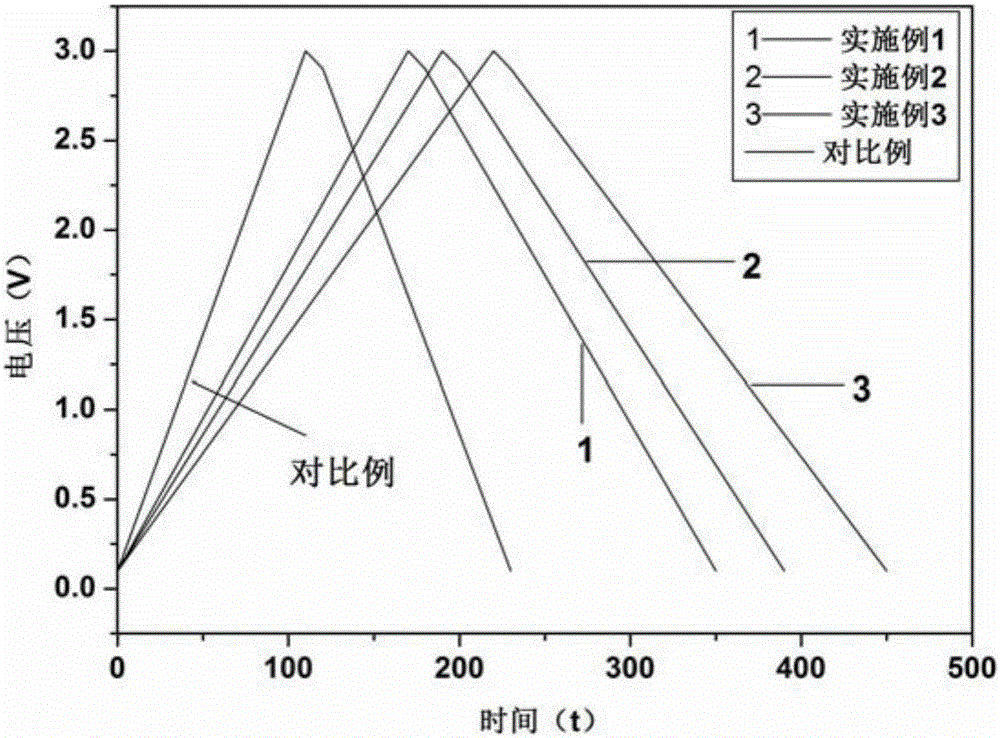

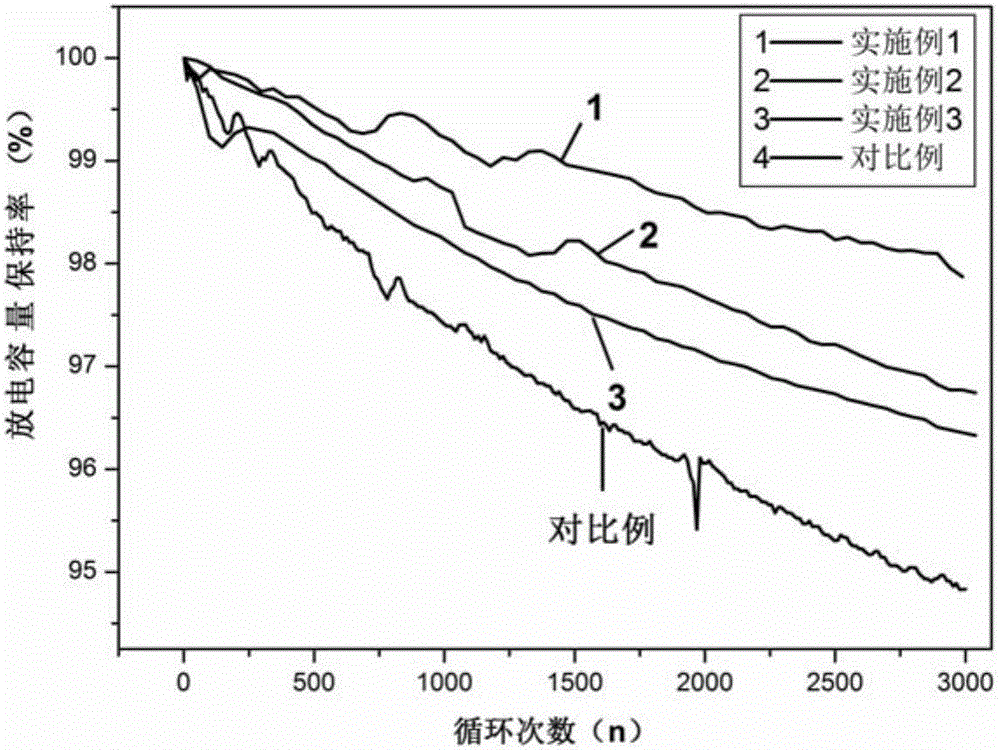

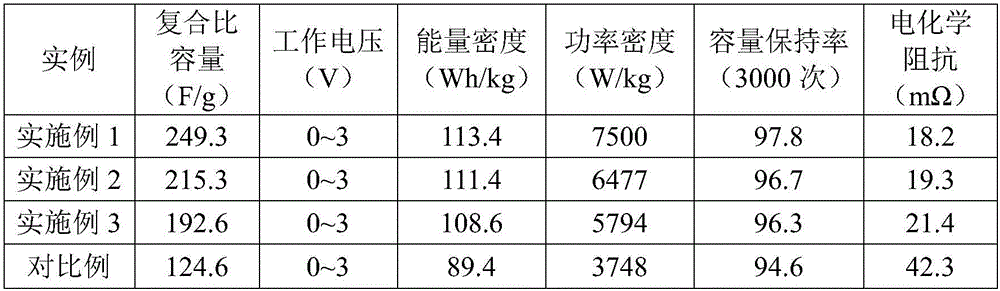

InactiveCN106169377AImprove specific energy density characteristicsHigh specific energy density characteristicsMaterial nanotechnologyHybrid capacitor electrodesCapacitanceHigh rate

The invention discloses a carbon nano-tube net / Ni(OH)<2> / PPY composite electrode, a preparation method and application, belonging to the technical field of super capacitors. The carbon nano-tube net / Ni(OH)<2> / PPY composite electrode is a core-shell structure; a core is composed of Ni(OH)<2> and a carbon nano-tube net doped therein; and a shell is uniform and compact PPY formed through an electrochemical deposition method. The composite electrode exerts a double-electrode-layer effect by utilizing the carbon nano-tube net having high specific surface area; with the help of the pseudocapacitance characteristic of the nano metallic oxide Ni(OH)<2>, the specific capacity is increased; simultaneously, depending on the high electric conductivity and the high specific energy density of the polymeric conductive polymer PPY, the discharge capability of the super capacitors under a high rate can be improved; the carbon nano-tube net with a connection point in a composite pole piece is doped in Ni(OH)<2>; therefore, the electric conductivity and the liquid sucking and keeping capability of the material are easily improved; and furthermore, the structural stability of the material can be improved through a net type structure.

Owner:深圳博磊达新能源科技有限公司

Preparation method of high-voltage ternary composition material

InactiveCN108390034APromote circulationImprove liquid absorption and retention capacityCell electrodesSecondary cellsCvd grapheneUrea

The invention belongs to the field of lithium ion battery material preparation, and particularly relates to a preparation method of a high-voltage ternary composition material. The preparation methodcomprises the steps of adding a ternary material precursor, a lithium salt, a vanadium salt and a manganese salt into a three-dimensional mixing machine, and performing uniform stirring and sinteringto obtain a material A; and adding the material A into urea and a graphene ion liquid mixed solution thereof, performing heating and heat preservation after uniform stirring, and performing spray drying to prepare the ternary composition material. A surface of the Ni-Co-Mn ternary positive electrode material is coated with the vanadium salt and the manganese salt, the voltage platform is improved,meanwhile, the conductivity of the material is improved by conductivity of graphene, the coating quality is improved by a special effect in the urea, a layer of uniform coating film is formed, and the cycle property and the rate performance of the material under a high-voltage condition are improved.

Owner:SHANDONG FENGYUAN CHEM CO LTD

Negative pole piece of lithium-ion battery and preparation method of negative pole piece and lithium-ion battery

ActiveCN105914378AImproved magnification performanceImprove cycle performanceElectrode carriers/collectorsSecondary cellsCalcium bicarbonateGraphene

The invention discloses a negative pole piece of a lithium-ion battery and a preparation method of the negative pole piece and the lithium-ion battery. The negative pole piece comprises a current collector, wherein the surface of the current collector is sequentially provided with a nano inorganic material layer and an active substance layer along the direction far away from the current collector; the nano inorganic material layer comprises the following components: nano calcium carbonate or calcium bicarbonate and graphene at the mass ratio of (60-80) to (10-20); the active substance layer comprises a silicon-carbon negative electrode material and hollow carbon spheres; and the mass ratio of the silicon-carbon negative electrode material to the hollow carbon spheres is 100: (10-20). By the negative pole piece of the lithium-ion battery, the expansion rate of the pole piece when the lithium-ion battery is full can be effectively reduced; meanwhile, the compaction density and the liquid absorption and retention capabilities of the negative pole piece are improved; and the cycle performance of the lithium-ion battery is improved.

Owner:深圳博磊达新能源科技有限公司 +1

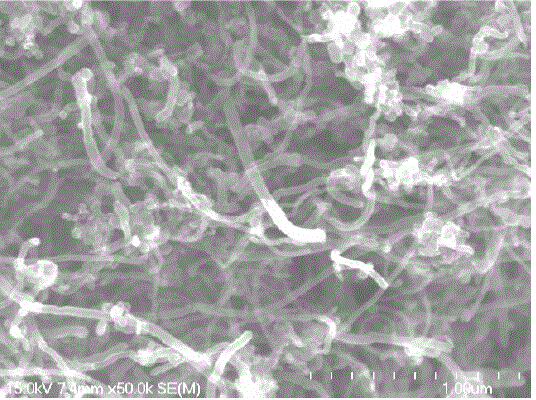

Lithium ion battery, diaphragm and preparation method thereof

ActiveCN108807813AHigh affinityPrevent retraction deformationMaterial nanotechnologySecondary cellsLithium-ion batteryNanotube

The invention discloses a lithium ion battery, a diaphragm and a preparation method thereof. The diaphragm comprises a base material and a coating arranged on the surface of the base material in a coating manner, wherein the material of the coating comprises polyacrylate modified hollow ceramic nanotubes.

Owner:欣旺达惠州动力新能源有限公司

Silica-graphene composite negative electrode material and preparation method thereof

ActiveCN107732187AImprove bindingImprove uniformityCell electrodesSecondary cellsOrganic solventOxide composite

The invention relates to a preparation method for a silica-graphene composite negative electrode material. The preparation method comprises the following steps: (1) dissolving organosilicate in an organic solvent to obtain a first mixed solution; (2) adding an oxidant, a pore-forming agent and a graphene oxide solution into the first mixed solution and carrying out mixing to obtain a second mixedsolution; (3) placing the second mixed solution in a high-pressure reactor, carrying out a reaction at a temperature of 150 to 200 DEG C and then carrying out drying to obtain a porous silica / grapheneoxide composite; and (4) mixing the silica / graphene oxide composite with a binder, coating the surface of a copper foil with the obtained mixture, and carrying out heat treatment in a reducing atmosphere so as to obtain the silica-graphene composite negative electrode material. The invention also provides the silica-graphene composite negative electrode material.

Owner:乌兰察布市大盛石墨新材料股份有限公司

Lithium-rich ternary composite material and preparation method thereof

InactiveCN106711428AImprove first-time efficiencyImprove gram capacityCell electrodesSecondary cellsHigh rateLithium electrode

The invention belongs to the field of lithium ion battery material preparation, and particularly relates to a lithium-rich ternary composite material and a preparation method thereof. The preparation method comprises the steps of firstly preparing lithium powder externally coated with a polymer, then adding the lithium powder into a ternary material, uniformly mixing the lithium powder and the ternary material, soaking in a lithium metaaluminate solution, and drying to prepare the ternary composite material with a core-shell structure. The prepared material utilizes the lithium powder coated with the ternary material for providing sufficient lithium ions during a charge-discharge process, so that the first-time efficiency and the rate capability thereof are improved; meanwhile, the lithium-ion transmission rate under the high-rate condition is improved by depending on the lithium ions in the lithium metaaluminate solution on the outermost layer; meanwhile, an outer shell layer has better compatibility with an electrolyte solution, so that the cycle performance is improved.

Owner:江苏元景锂粉工业有限公司

Composite super capacitor diaphragm material with good isolation performance

InactiveCN106128793AHigh tensile strengthGood chemical stabilityHybrid capacitor separatorsHybrid/EDL manufacturePolyesterPolyvinyl alcohol

The invention discloses a composite super capacitor diaphragm material with good isolation performance. The composite super capacitor diaphragm material is prepared from the following raw materials in parts by weight: 35-40 parts of polyvinyl alcohol fibers, 33-35 parts of polypropylene fibers, 10-13 parts of polyacrylonitrile powder, 30-32 parts of acetone, 72-75 parts of N,N-dimethyl formamide, 8-10 parts of water-soluble PVA fibers at 70 DEG C, 4-5 parts of cationic starch, 4-5 parts of glass wool, 2-3 parts of liquid paraffin, 1.5-2 parts of dimethylsiloxane, 9-11 parts of clay, 2-3 parts of palmitic acid and 3-4 parts of polyester adhesive powder. The ingredients of the glass wool, the clay and the like are also added to preparation of a product through a series of modified additives, so that the breathability is good; the mechanical strength of the product is improved; the high-temperature tolerance is improved; the super capacitor material can also keep a good isolating state at a high temperature; and the service lifetime of a super capacitor is prolonged.

Owner:ANHUI JIANGWEI PRECISION IND

Supercapacitor composite separator material of high mechanical strength

InactiveCN105990036AHigh tensile strengthGood chemical stabilityHybrid capacitor separatorsNon-woven fabricsPolyvinyl alcoholSlurry

The invention discloses a supercapacitor composite separator material of high mechanical strength. The supercapacitor composite separator material is prepared by the raw material of the following parts by weight: 35-40 parts of polyvinyl alcohol fiber, 33-35 parts of mekralon, 10-13 parts of polyacrylonitrile powder, 30-32 parts of acetone, 72-75 parts of N,N-dimethyl formamide, 8-10 parts of water soluble PVA fiber of 70 DEG C, a moderate amount of water, 13-15 parts of calcium carbonate, 5-7 parts of glass fiber, 7-9 parts of mica powder, 2-3 parts of oxidized polyethylene wax, 1-1.2 parts of sodium dodecyl benzene sulfonate, 2-3 parts of waterborne polyurethane emulsion, 3-4 parts of animal glue and 1-1.5 parts of polydimethylsiloxane. The processed calcium carbonate, the glass fiber and the mica powder are added in the preparation process of nonwoven fabric and evenly dispersed in slurry so that the mechanical strength of the prepared product can be further enhanced, the product is enabled to be anti-tensile and is not liable to fracture, and thus the supercapacitor composite separator material of high mechanical strength is the supercapacitor used composite separator material of excellent performance.

Owner:ANHUI SUREPHON CAPACITOR CO LTD

Anode material for lithium-ion power battery and preparation method of anode material

PendingCN108134087AReduce expansionImprove cycle performanceCell electrodesCarbon compositesSilver carbonate

The invention discloses an anode material for a lithium-ion power battery and a preparation method of the anode material, and relates to the field of preparation of battery materials, in particular tothe field of preparation of the anode materials of lithium batteries. The anode material is characterized by being prepared from porous silicon dioxide and coating compound asphalt, wherein porous silicon dioxide is prepared from raw materials as follows: polycrystalline silicon powder, hydrochloric acid, silver carbonate, hydrofluoric acid and hydrogen peroxide; the compound asphalt is preparedfrom materials as follows: nano calcium carbonate, asphalt, graphene, sodium hydroxide, a binder and distilled water; after porous silicon dioxide and the compound asphalt are mixed uniformly in a ratio being 5:(3-5), a mixture is carbonized, and a silicon-carbon anode material is prepared. The prepared silicon-carbon composite material has the effect of improving rate performance and safety performance while the transfer number of lithium ions is increased and stacking of the lithium ions is reduced, further has advantages of high gram volume, excellent cycle performance, high liquid absorption and retaining capability, low cost and low expansion rate, and is particularly suitable for meeting demands of high-energy-density batteries for the anode material.

Owner:内蒙古欣源石墨烯科技股份有限公司

Silicon-based thin-film composite pole piece and manufacturing method thereof, and lithium ion battery

ActiveCN109546089AHigh densityReduce consumptionElectrode carriers/collectorsSecondary cellsSilicon monoxideOxide composite

The invention belongs to the technical field of lithium ion batteries, and specifically relates to a silicon-based thin-film composite pole piece and a manufacturing method thereof, and a lithium ionbattery. The manufacturing method of the silicon-based thin-film composite pole piece comprises the following steps: (1) uniformly mixing organosilane lithium, a film-forming additive and an ionic liquid, to obtain an electrolyte; (2) using graphene oxide as a working electrode and silicon as a counter electrode, and saturated calomel as a reference electrode, depositing silicon dioxide on the surface of the working electrode by an electrochemical deposition method in the electrolyte obtained in the step (1), to obtain a silica / graphene oxide composite material; (3) under a reducing atmosphere, heating the silica / graphene oxide composite material to 600-800 DEG C and keeping warm for 1 to 6 h, and then cooling to obtain a silicon-monoxide / graphene composite material, that is, a silicon-based thin-film composite pole piece. A lithium ion battery in which the silicon-based thin-film composite pole piece obtained by the method is a negative electrode has advantages of high specific capacity, excellent cycle performance, and excellent rate capacity.

Owner:CALB CO LTD +1

Preparation method of lithium battery membrane

InactiveCN106299199AImprove wettabilityIncreasing the thicknessCell component detailsElectrolytic agentPhysical chemistry

The invention provides a preparation method of a lithium battery membrane. The preparation method includes: adding a precursor compound, a structure directing agent and hydrochloric acid into a first mixed solution, stirring, and allowing alcoholysis reaction to obtain sol; coating the sol on the surface of a porous membrane, washing, and using hot air to dry to obtain the lithium battery membrane. The porous membrane is used as a base membrane, tetraethoxysilane, tetramethyl orthosilicate, silicon tetrachloride, titanium tetrachloride and tetrabutyl titanate are used as precursors, segmented copolymer is used as the structure directing agent, and an inorganic compound resistant to high temperature is coated among pores of the porous membrane, so that heat resistance of the membrane is improved effectively. Wettability of the membrane coated among the pores to electrolyte is improved obviously, and liquid absorbing and retaining performance is improved greatly; increase in thickness and weight of the lithium battery membrane prepared by utilizing an inter-porous coating method is small, and increasing of volumetric specific energy of batteries is facilitated. Experiment results show that the lithium battery membrane has high heat resistance and wettability to the electrolyte and is small in thickness.

Owner:SHENZHEN SENIOR TECH MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com