Silica-graphene composite negative electrode material and preparation method thereof

A graphene composite and silicon dioxide technology, applied in the field of lithium ion batteries, can solve the problems of high expansion rate of silicon-carbon multi-component composite negative electrode materials, poor doping uniformity, low tap density, etc., so as to improve liquid absorption and liquid retention. capacity, improve cycle performance, improve the effect of tap density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The invention provides a method for preparing a silicon dioxide-graphene composite negative electrode material, which comprises the following steps:

[0022] S1, dissolving organosilicate in an organic solvent to obtain a first mixed solution;

[0023] S2, adding an oxidizing agent, a pore forming agent and a graphene oxide solution to the first mixed solution, and mixing to obtain a second mixed solution;

[0024] S3, placing the second mixed solution in a high-pressure reactor, reacting at a temperature of 150°C to 200°C, and drying to obtain a porous silica / graphene oxide composite material, wherein during the reaction process The organosilicate decomposes to form silicon dioxide, and at the same time, a plurality of first pore structures are formed on the surface of the graphene oxide under the action of an oxidizing agent; and

[0025] S4, mixing the silica / graphene oxide composite material with a binder, coating it on the surface of copper foil, and performing he...

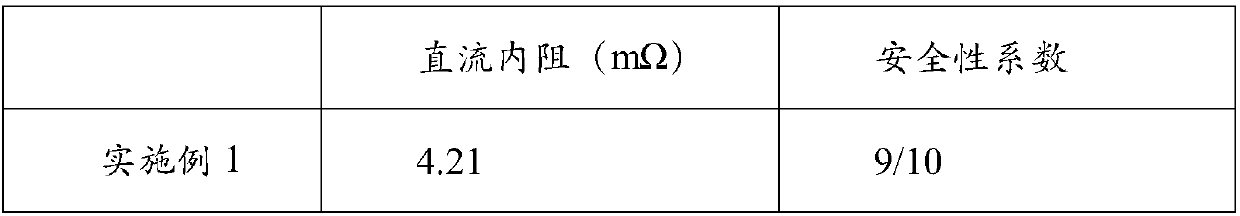

Embodiment 1

[0047] Step 1. Add 2g of isopropyl silicate to 10ml of N-methylpyrrolidone organic solvent and dissolve evenly;

[0048] Step 2: Add 3mL of 10% hydrogen peroxide, 3g of nano-potassium carbonate with a particle size of 500nm, and then add 2000mL of graphene oxide solution with a concentration of 5mg / mL, and disperse uniformly by ultrasonic to obtain the second mixed solution;

[0049] In step 3, the second mixed solution is transferred to an autoclave, reacted at 180°C for 3h, then filtered, and dried at 50°C for 24h to obtain a porous silica / graphene oxide composite material;

[0050] In step 4, 90g of silica / graphene oxide composite material, 10g of polyvinylidene fluoride binder and 150mL of double distilled water were mixed into a sticky paste and coated on the surface of copper foil. Then transfer to a tube furnace, feed ammonia and argon mixed gas with a volume ratio of 1:1, heat to 350°C for 3h, then raise the temperature to 850°C for 3h at a heating rate of 5°C / min, and...

Embodiment 2

[0052] Step 1. Add 1 g of bis(sec-butanol) orthosilicate triethyl orthosilicate aluminum salt to 10 mL of N,N-dimethylformamide organic solvent, and dissolve evenly;

[0053] Step 2: Introduce 10 mL of chlorine gas, 1 g of calcium oxide with a particle size of 0.5 μm, and then add 1000 mL of graphene oxide solution with a concentration of 10 mg / mL, and disperse evenly by ultrasonic to obtain a second mixed solution;

[0054] In step 3, the second mixed solution is transferred to a high-pressure reactor, and the temperature is 150° C. for 6 hours, then filtered, and dried at low temperature to obtain a porous silica / graphene oxide composite material;

[0055] In step 4, mix 90g of silica / graphene oxide composite material, 10g of vinylidene fluoride, and 150mL of double distilled water into a sticky paste and apply it on the surface of copper foil. Then transfer to a tube furnace, feed ammonia and argon mixed gas with a volume ratio of 1:1, heat to 300°C for 6 hours, then raise ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com