Preparation method of composite graphite, composite graphite and lithium ion battery

A composite graphite and natural graphite technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as inability to improve orientation, and achieve high catalyst utilization, guaranteed specific capacity, and good liquid absorption and retention performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of composite graphite provided by the invention comprises the steps:

[0031] S1. Provide ultra-fine carbon powder; the ultra-fine carbon powder includes raw coke and / or mesocarbon microspheres;

[0032] S2, mixing ultrafine carbon powder with a binder to obtain a mixture A, mixing the mixture A with a catalyst to obtain a mixture B, and then performing a composite treatment on the mixture B to obtain a precursor;

[0033] S3, performing graphitization treatment on the precursor to obtain a semi-finished product;

[0034] S4, crushing, spheroidizing, covering and sieving the semi-finished product to obtain the composite graphite.

[0035] According to the present invention, the ultrafine carbon powder contains at least raw coke and / or mesocarbon microspheres. Among them, raw coke can be one or more of needle coke raw coke, pitch coke raw coke, homogeneous coke raw coke.

[0036] In the present invention, by preparing composite graphite on the b...

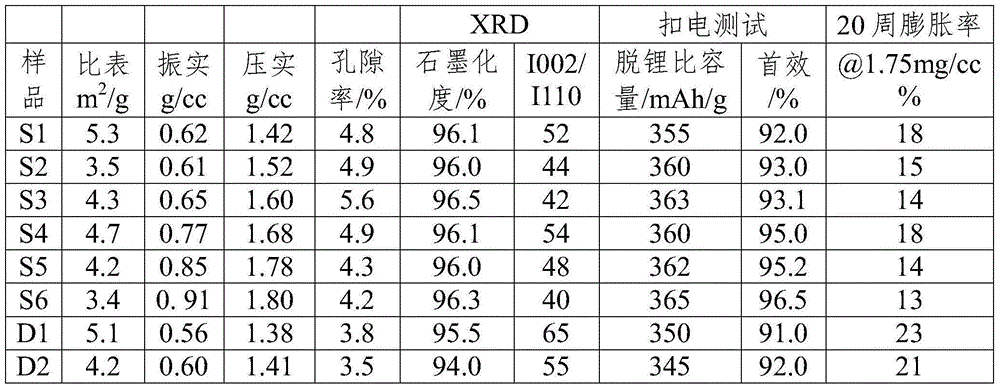

Embodiment 1

[0076] This example is used to illustrate the preparation method of the composite graphite disclosed in the present invention.

[0077] Step 1. Mix the raw coke of the same sex coke and the cooked coke of the needle coke, and use mechanical pulverization and jet pulverization to D 50 4-5μm, get superfine carbon powder.

[0078] Step 2. Add the superfine carbon powder obtained in step 1 to the kneader according to the ratio of homogeneous coke raw coke: needle coke cooked coke: ferric oxide = 30:70:15, heat to 200°C, and dry powder according to mixture A: low temperature Asphalt=100:20 Add molten low-temperature asphalt, knead it for 1 hour, take it out and perform compression molding to obtain a precursor.

[0079] Step 3. Graphitizing the bulk precursor obtained in Step 2 to obtain a semi-finished product.

[0080] Step 4, the semi-finished products obtained in step 3 are sequentially mechanically crushed and sieved to obtain D 50 Composite graphite finished product of 12-...

Embodiment 2

[0083] This example is used to illustrate the preparation method of the composite graphite disclosed in the present invention.

[0084] Step 1. Mix raw homogeneous coke, green needle coke and cooked needle coke raw materials, and use mechanical pulverization and jet pulverization to D 50 4-5μm, get superfine carbon powder.

[0085] Step 2. Add the ultra-fine carbon powder obtained in step 1 into the kneader according to the ratio of homogeneous coke raw coke: needle coke raw coke: needle coke cooked coke: boron trioxide = 30:40:30:15, and heat to 200 ℃, according to the dry powder of mixture A: low-temperature pitch = 100:10, add molten low-temperature pitch, knead for 1 hour, take it out and perform compression molding to obtain a precursor.

[0086] Step 3. Graphitizing the bulk precursor obtained in Step 2 to obtain a semi-finished product.

[0087] Step 4, the semi-finished products obtained in step 3 are sequentially mechanically crushed and sieved to obtain D 50 Compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| D50 | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com