Silicon-based thin-film composite pole piece and manufacturing method thereof, and lithium ion battery

A silicon-based film and pole piece technology, applied in battery electrodes, secondary batteries, electrode carriers/current collectors, etc., can solve the problems of unguaranteed silicon monoxide uniformity, weak adhesion, etc. The effect of improving fluid capacity, improving stability, and improving cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

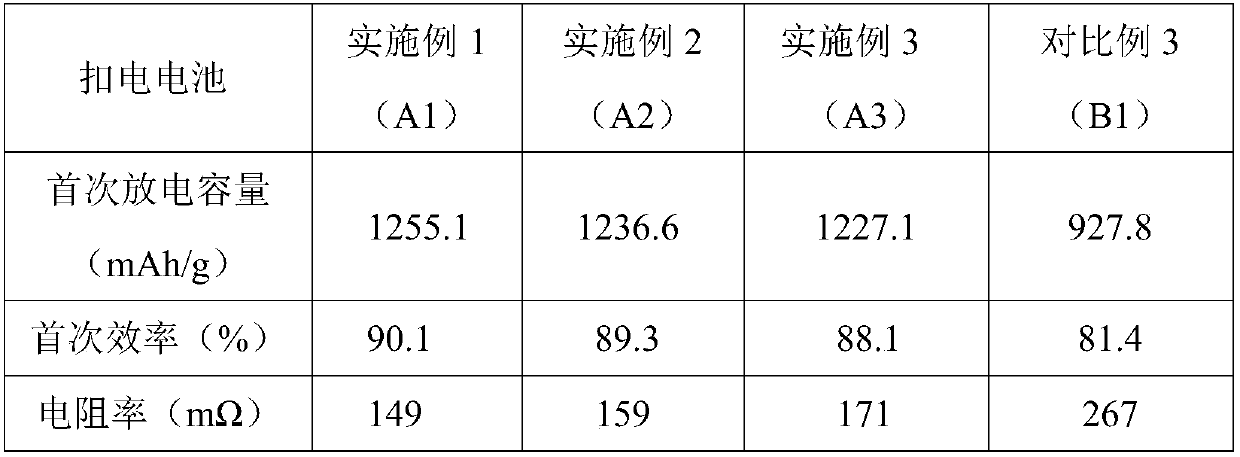

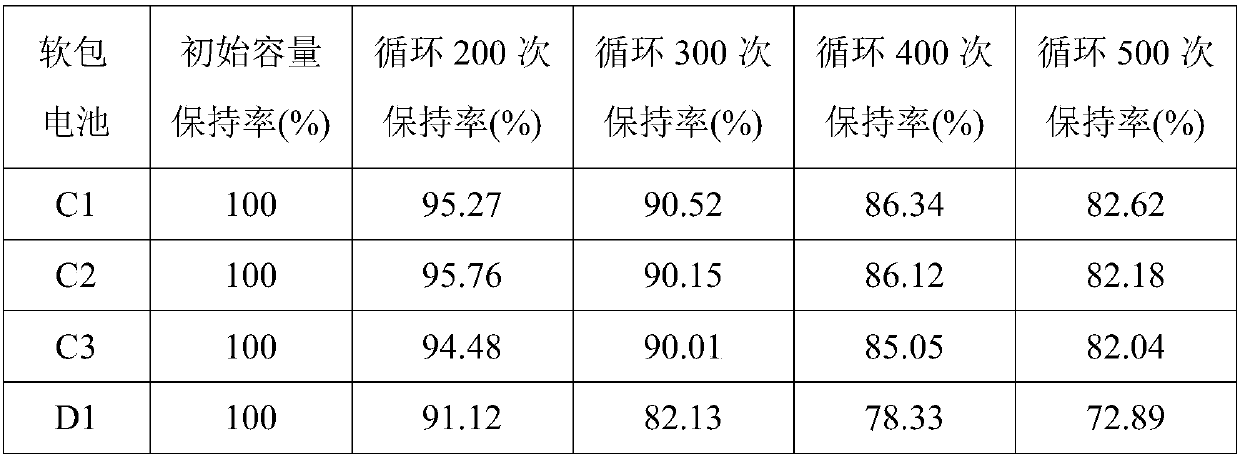

Embodiment 1

[0025] The preparation method of the silicon-based thin film composite pole piece of the present embodiment comprises the following steps:

[0026] (1) Weigh 3g of lithium bis(trimethylsilyl)amide and 0.3g of bis(tetrahydrofuryl)propane into 100g of 1-ethyl-3-methylimidazolium ionic liquid, and stir evenly to obtain an electrolyte;

[0027] (2) With graphene oxide (manufacturer: Nanjing Xianfeng Nano Material Technology Co., Ltd., model: XF0812) as the working electrode, the silicon rod as the counter electrode, and the saturated calomel electrode as the reference electrode, the electrolyte obtained in step (1) In the process, cyclic voltammetry (voltage is -2 ~ 2V, scanning speed is 5mV / s, scanning 10 cycles) is used to deposit silicon dioxide on the surface of the working electrode. After completion, it is cleaned and dried with 0.1mol / L ethylene carbonate. Obtain silica / graphene oxide composite material;

[0028] (3) Transfer the composite material to a tube furnace, first...

Embodiment 2

[0030] The preparation method of the silicon-based thin film composite pole piece of the present embodiment comprises the following steps:

[0031] (1) Weigh 0.5g of lithium hexamethyldisilazane and 0.1g of cyclopentyl ether into 100g of 1-ethyl-3-methylimidazolium ionic liquid, and stir evenly to obtain an electrolyte;

[0032] (2) With graphene oxide (manufacturer: Nanjing Xianfeng Nano Material Technology Co., Ltd., model: XF0812) as the working electrode, the silicon rod as the counter electrode, and the saturated calomel electrode as the reference electrode, the electrolyte obtained in step (1) Adopt constant voltage method (voltage is 2V, time is 30min) to deposit silicon dioxide on the working electrode surface, after finishing, adopt 0.1mol / L ethylene carbonate to clean, dry, obtain silicon dioxide / graphene oxide composite material;

[0033] (3) Transfer the composite material to a tube furnace, first pass argon inert gas to discharge the gas in the tube, then pass hyd...

Embodiment 3

[0035] The preparation method of the silicon-based thin film composite pole piece of the present embodiment comprises the following steps:

[0036] (1) Weigh 5g of lithium bis(trimethylsilyl)amide and 0.5g of ethylene glycol dimethyl ether into 100g of 1-ethyl-3-methylimidazole ionic liquid, and stir evenly to obtain an electrolyte;

[0037] (2) With graphene oxide (manufacturer: Nanjing Xianfeng Nano Material Technology Co., Ltd., model: XF0812) as the working electrode, the silicon rod as the counter electrode, and the saturated calomel electrode as the reference electrode, the electrolyte obtained in step (1) The constant current method (current density of 10mA / cm 2 , the time is 30min) to deposit silicon dioxide on the surface of the working electrode. After the completion, use 0.1mol / L ethylene carbonate to clean and dry to obtain a silicon dioxide / graphene oxide composite material;

[0038] (3) Transfer the composite material to a tube furnace, first pass argon inert ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com