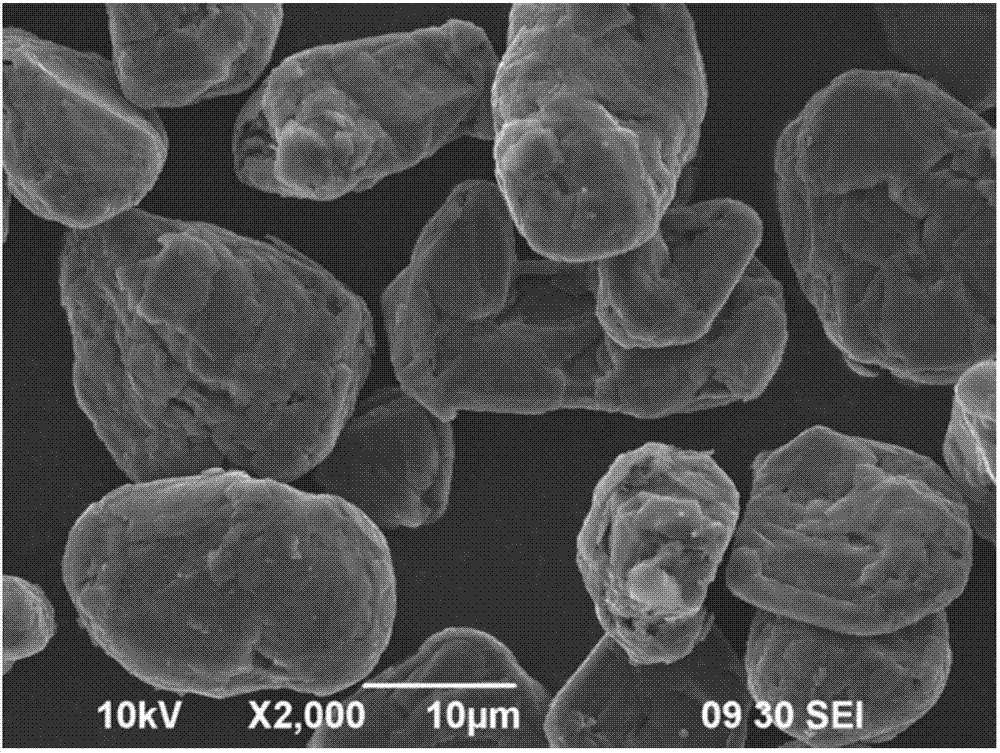

Asphalt-based nanoporous carbon material, negative material thereof, and lithium ion battery

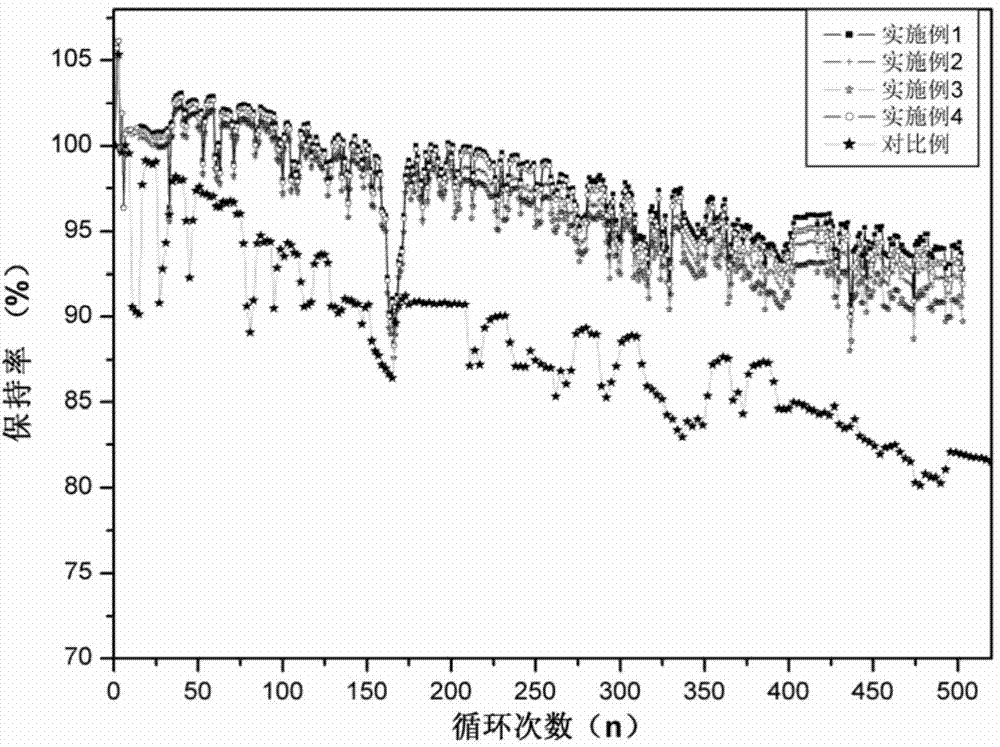

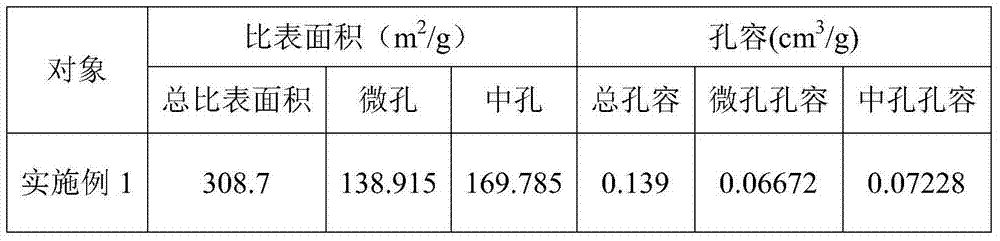

A technology of nanoporous carbon and porous carbon materials, which is applied in the field of porous carbon materials, can solve the problems of small specific surface area, poor liquid absorption performance, and limited material performance, and achieve simple synthesis conditions, strong liquid absorption and retention capabilities, and improved circulation. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The pitch-based nanoporous carbon material of this embodiment is mainly made of the following raw materials: 5 g of pitch, 20 g of anhydrous aluminum trichloride, 250 ml of anhydrous carbon tetrachloride, and 300 ml of a reaction terminator. The reaction terminator is a mixture of ethanol and water.

[0049] The pitch-based nanoporous carbon material of this embodiment is prepared by the following method:

[0050] 1) Add 5g of asphalt into 200ml of anhydrous carbon tetrachloride, stir and dissolve to obtain mixture A;

[0051] 2) the anhydrous aluminum trichloride of 20g is placed in the reaction kettle, in the anhydrous carbon tetrachloride of adding 50ml (the total consumption of anhydrous carbon tetrachloride is 250ml), after the anhydrous aluminum trichloride dissolves, Add step 1) obtained mixture A again, heat to 50 ℃ under stirring condition, reflux and carry out Friedel-Crafts reaction, after reacting for 24h, add the mixed solution of the ethanol of 300ml and ...

Embodiment 2

[0064] The pitch-based nanoporous carbon material of this embodiment is mainly made of the following raw materials: 10 g of pitch, 50 g of anhydrous aluminum trichloride, 400 ml of anhydrous carbon tetrachloride, and 500 ml of a reaction terminator. The reaction terminator is a mixture of ethanol and water.

[0065] The pitch-based nanoporous carbon material of this embodiment is prepared by the following method:

[0066] 1) Add 10 g of asphalt into 300 ml of anhydrous carbon tetrachloride, stir and dissolve to obtain mixture A;

[0067] 2) the anhydrous aluminum trichloride of 50g is placed in the reaction kettle, in the anhydrous carbon tetrachloride of adding 100ml (the total consumption of anhydrous carbon tetrachloride is 400ml), after the anhydrous aluminum trichloride dissolves, Add step 1) gained mixture A again, heat to 75 ℃ under stirring condition, reflux and carry out Friedel-Crafts reaction, after reacting for 48h, add the mixed solution of the ethanol of 500ml a...

Embodiment 3

[0079] The pitch-based nanoporous carbon material of this embodiment is mainly made of the following raw materials: 0.1 g of pitch, 3 g of anhydrous aluminum trichloride, 100 ml of anhydrous carbon tetrachloride, and 200 ml of a reaction terminator. The reaction terminator is a mixture of ethanol and water.

[0080] The pitch-based nanoporous carbon material of this embodiment is prepared by the following method:

[0081] 1) Add 0.1 g of asphalt into 6 ml of anhydrous carbon tetrachloride, stir and dissolve to obtain mixture A;

[0082] 2) 3g of anhydrous aluminum trichloride is placed in the reaction kettle, add in the anhydrous carbon tetrachloride of 94ml (the total consumption of anhydrous carbon tetrachloride is 100ml), after the anhydrous aluminum trichloride dissolves, Then add step 1) obtained mixture A, heat to 30 DEG C under stirring condition, reflux to carry out Friedel-Crafts reaction, after reacting for 72h, add the mixed solution of ethanol and double-distilled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com