Graphene-TiO2 nanotube hydrogel, preparation method, and application thereof

A titanium dioxide and graphene technology, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve the problems of low cost, high energy consumption, good effect, etc. Large specific surface area, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

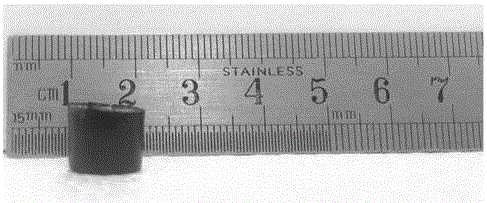

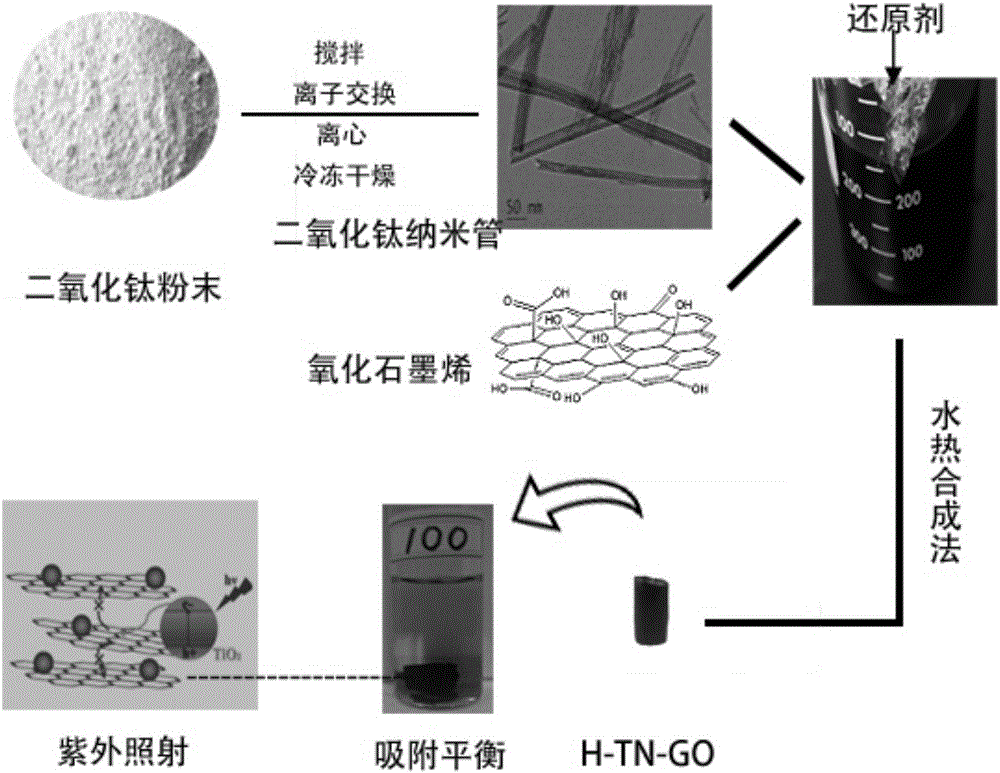

[0049] Embodiment 1 prepares graphene-titania nanotube hydrogel

[0050] (1) adding nano-powdered graphene oxide into distilled water to prepare a 2.5 mg / mL graphene oxide aqueous solution; put the aqueous solution into an ultrasonic machine for 48 hours and undergo ultrasonic treatment to fully dissolve and completely disperse;

[0051] (2) Titanium dioxide nanotubes prepared by titanium dioxide powder (P25) have a specific surface area of 129.8m 2 / g, the pore diameter is 13.6nm; titanium dioxide nanotubes have high specific surface area and have adsorption properties; add titanium dioxide nanotubes to fully dissolved graphene oxide aqueous solution, the concentration of titanium dioxide is 1mg / L; ultrasonically treat the mixture for 24 hours, and mix completely ;

[0052] (3) Configure 140g / L FeSO 4 solution, adding 1mol / L HCl to adjust the pH to 3; FeSO 4 The solution must be prepared and used immediately. In order to prevent its rapid oxidation in the air, adjust the...

Embodiment 2

[0056] Embodiment 2 prepares graphene-titania nanotube hydrogel

[0057] (1) adding nano-powdered graphene oxide into distilled water to prepare a 3 mg / mL graphene oxide aqueous solution; put the aqueous solution into an ultrasonic machine for 50 hours and undergo ultrasonic treatment to fully dissolve and disperse;

[0058] (2) Titanium dioxide nanotubes prepared by titanium dioxide powder (P25) have a specific surface area of 129.8m 2 / g, the pore diameter is 13.6nm; titanium dioxide nanotubes have high specific surface area and have adsorption properties; add titanium dioxide nanotubes to fully dissolved graphene oxide aqueous solution, the concentration of titanium dioxide is 2mg / L; ultrasonically treat the mixture for 26 hours, and mix completely ;

[0059] (3) Configure 150g / L FeSO 4 solution, adding 1mol / L HCl to adjust the pH to 3; FeSO 4 The solution must be prepared and used immediately. In order to prevent its rapid oxidation in the air, adjust the pH value of ...

Embodiment 3

[0062] Embodiment 3 prepares graphene-titania nanotube hydrogel

[0063] (1) adding nano-powdered graphene oxide into distilled water to prepare a 2 mg / mL graphene oxide aqueous solution; put the aqueous solution into an ultrasonic machine for 45 hours and undergo ultrasonic treatment to fully dissolve and completely disperse;

[0064] (2) Titanium dioxide nanotubes prepared by titanium dioxide powder (P25) have a specific surface area of 129.8m 2 / g, the pore diameter is 13.6nm; titanium dioxide nanotubes have high specific surface area and have adsorption properties; add titanium dioxide nanotubes to fully dissolved graphene oxide aqueous solution, the concentration of titanium dioxide is 1.5mg / L; ultrasonically treat the mixture for 25 hours, and mix well completely;

[0065] (3) Configure 130g / L FeSO 4 solution, adding 1mol / L HCl to adjust the pH to 3; FeSO 4 The solution must be prepared and used immediately. In order to prevent its rapid oxidation in the air, adjust...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com