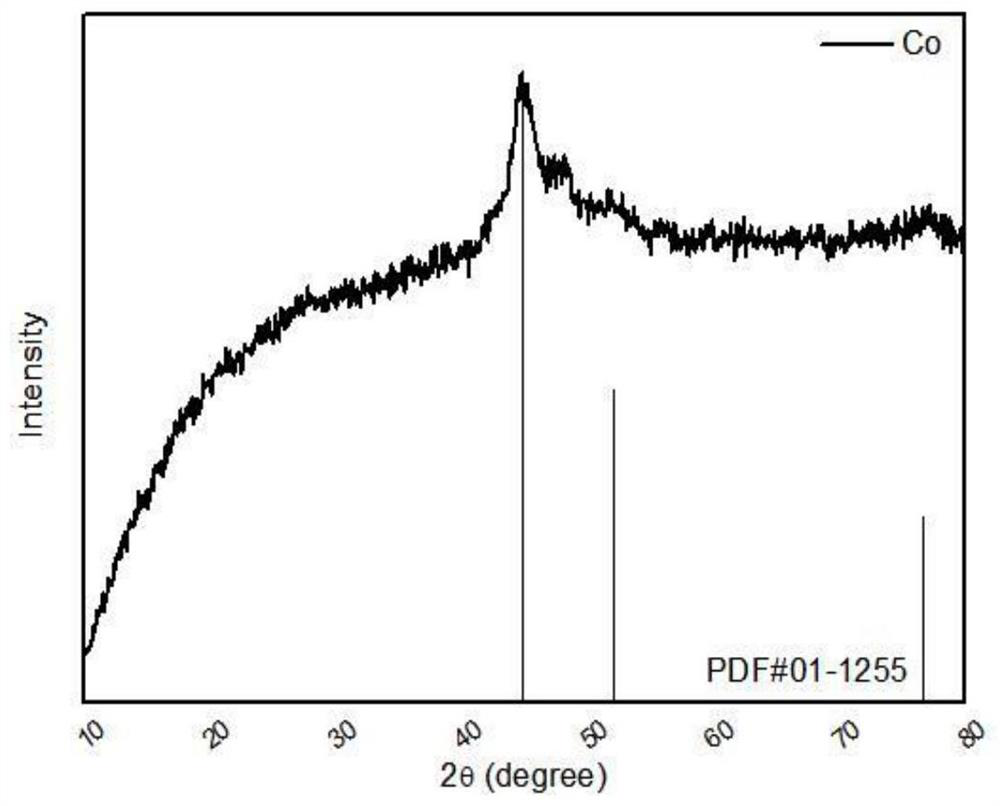

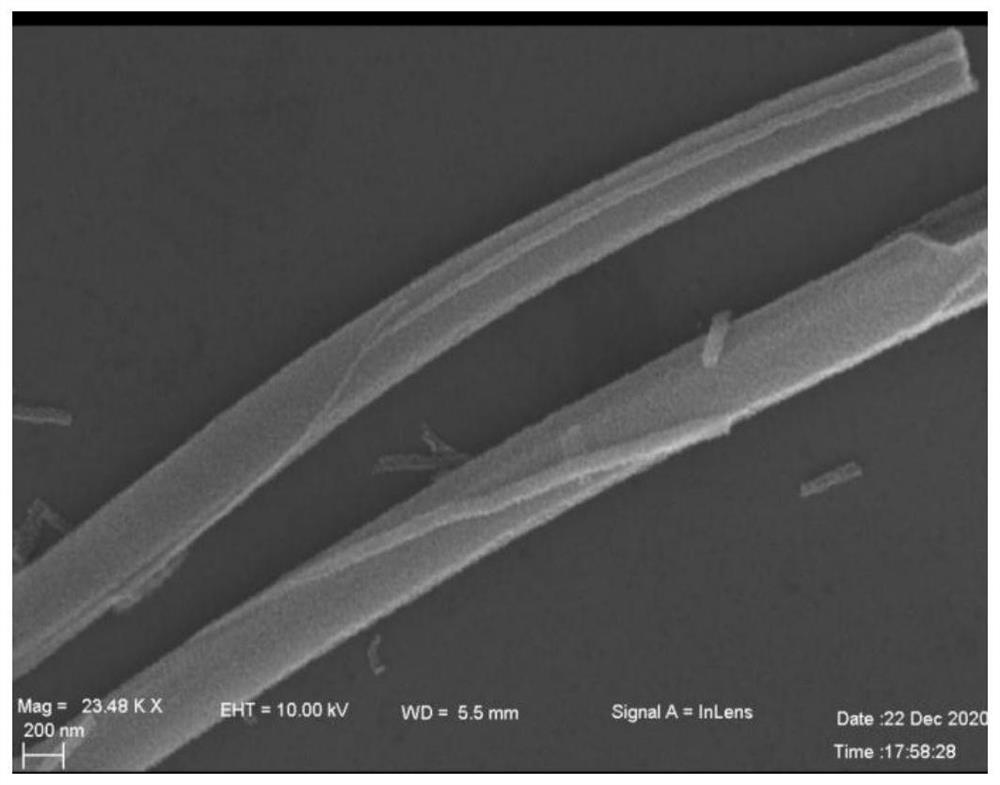

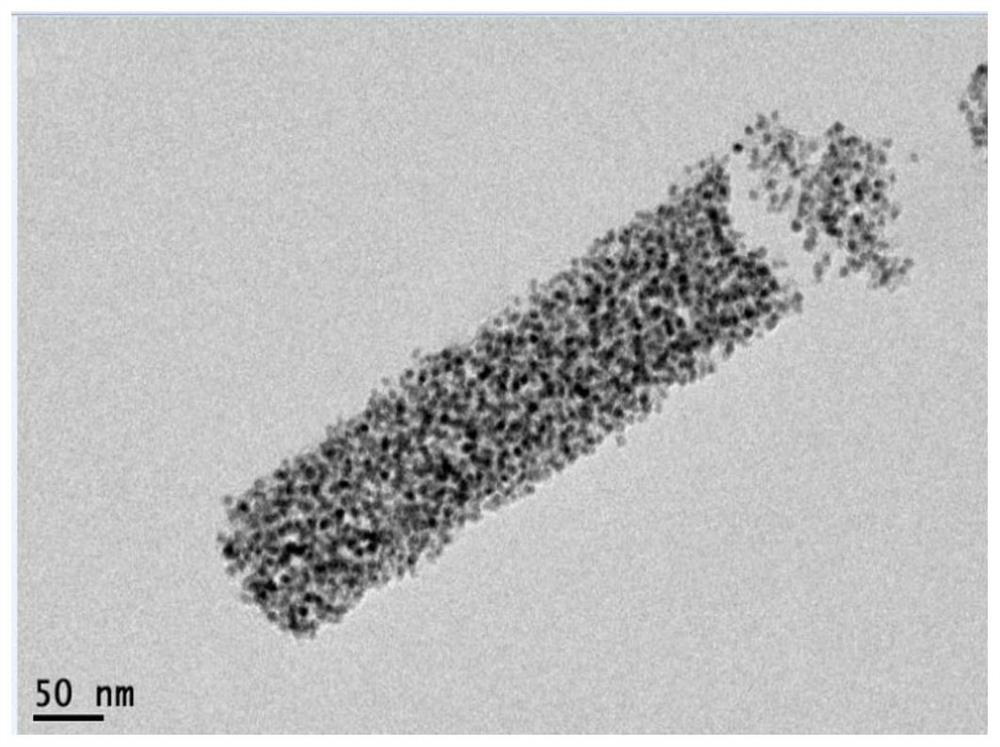

Preparation method of porous rod-like Co/C nanorod composite material

A composite material and nanorod technology, which is applied in the field of preparation of porous rod-shaped Co/C nanorod composite materials, can solve the problem of high cost of noble metal doped modified electrocatalysts, achieve excellent electrocatalytic performance, improve reaction catalytic efficiency, and high The effect of specific area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for preparing a porous rod-shaped Co / C nanorod composite material, comprising the following steps:

[0023] (1) Preparing the precursor: add 0.1911g NTA white powder to disperse in a beaker with 10mL deionized water, then add 0.20g Co(NO 3 ) 2 ·6H 2 O, NTA and Co(NO 3 ) 2 ·6H 2 The molar ratio of O is 1:1. Stir magnetically at room temperature for 10 minutes until it dissolves completely, then add 20ml of isopropanol, stir magnetically at room temperature for half an hour until uniform, move to a high-pressure reactor, put it in an oven, and react at 180°C 6 hours; the reaction product was centrifuged with a high-speed centrifuge at a speed of 4000rpm to obtain the precipitate. The precipitate was washed 3 times with water to neutrality, and then washed 3 times with absolute ethanol. The washed precipitate was placed in a vacuum oven at 60°C for 12 hours. Get precursors.

[0024] (2) Preparation of Co / C nanorods: Calcining the precursor in a tube furnace,...

Embodiment 2

[0027] A method for preparing a porous rod-shaped Co / C nanorod composite material, comprising the following steps:

[0028] (1) Preparation of the precursor: Add 0.0994g of NTA white powder to disperse in a beaker with 10mL of deionized water, then add 0.21g of Co(NO 3 ) 2 ·6H 2 O, NTA and Co(NO 3 ) 2 ·6H 2 The molar ratio of O is 1:2. Stir magnetically at room temperature for 10 minutes until it dissolves completely, then add 20ml of isopropanol, stir magnetically at room temperature for half an hour until uniform, move to a high-pressure reactor, put it in an oven, and react at 180°C 6 hours; the reaction product was centrifuged with a high-speed centrifuge at a speed of 4000rpm to obtain the precipitate. The precipitate was washed 3 times with water to neutrality, and then washed 3 times with absolute ethanol. The washed precipitate was placed in a vacuum oven at 60°C for 12 hours. get the precursor;

[0029] (2) Preparation of Co / C nanorods: Calcining the precursor i...

Embodiment 3

[0031] A method for preparing a porous rod-shaped Co / C nanorod composite material, comprising the following steps:

[0032] (1) Preparing the precursor: add 0.38g NTA white powder to disperse in a beaker with 10mL deionized water, then add 0.20g Co(NO 3 ) 2 ·6H 2 O, NTA and Co(NO 3 ) 2 ·6H 2The molar ratio of O is 2:1. Stir magnetically at room temperature for 10 minutes until it dissolves completely, then add 20ml of isopropanol, stir magnetically at room temperature for half an hour until uniform, move to a high-pressure reactor, put it in an oven, and react at 180°C 6 hours; the reaction product was centrifuged with a high-speed centrifuge at a speed of 4000rpm to obtain the precipitate. The precipitate was washed 3 times with water to neutrality, and then washed 3 times with absolute ethanol. The washed precipitate was placed in a vacuum oven at 60°C for 12 hours. get the precursor;

[0033] (2) Preparation of Co / C nanorods: Calcining the precursor in a tube furnace,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com