Cerium-titanium-doped bismuth tantalate niobate photocatalytic material and preparation method and application thereof

A photocatalytic material, bismuth niobium tantalate technology, applied in chemical instruments and methods, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., can solve the problems of low light absorption efficiency and reduced practical application value, and achieve Effects of improved light absorption, excellent photocatalytic performance, and good optical activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

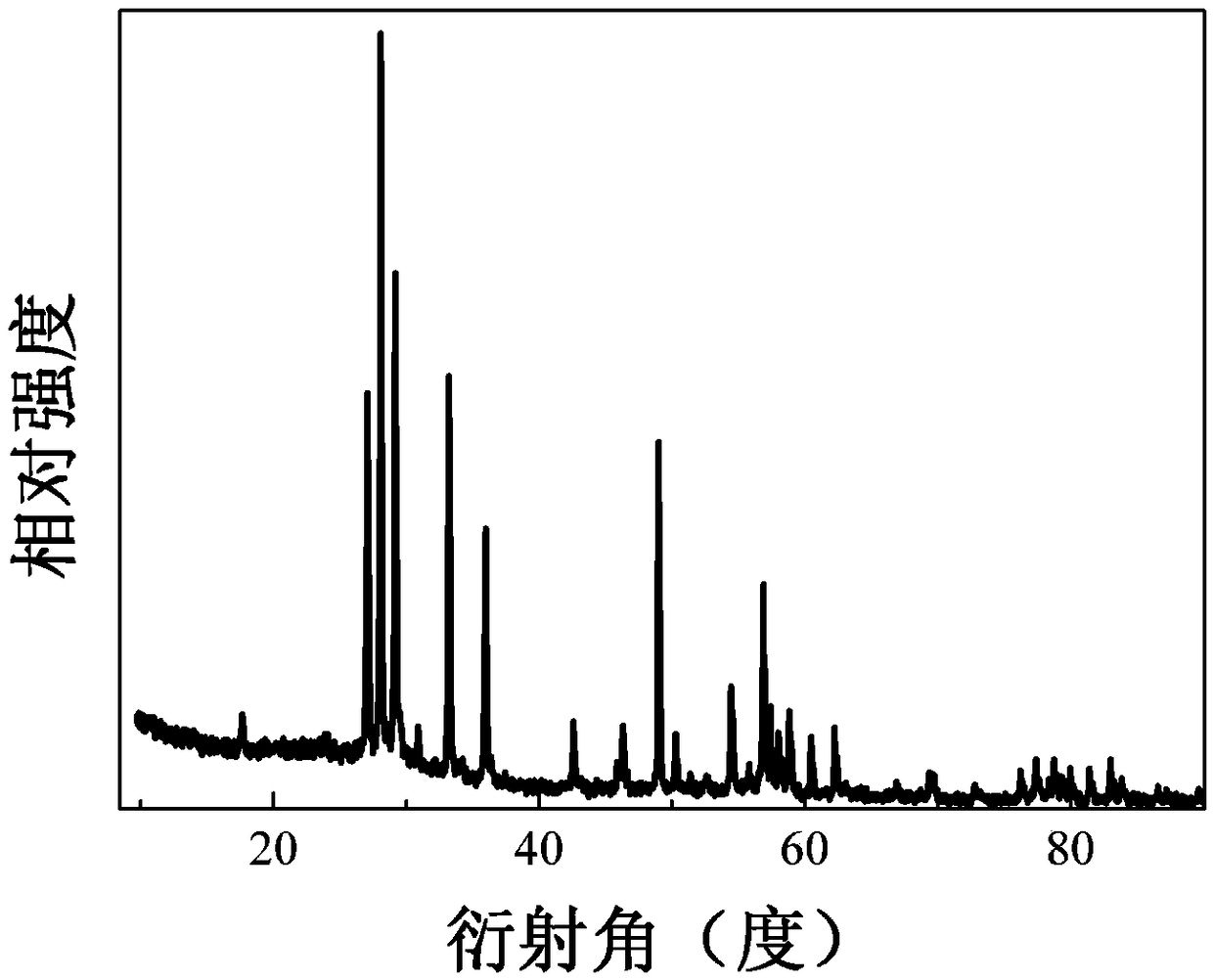

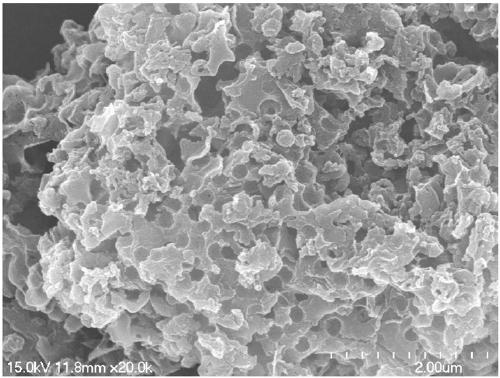

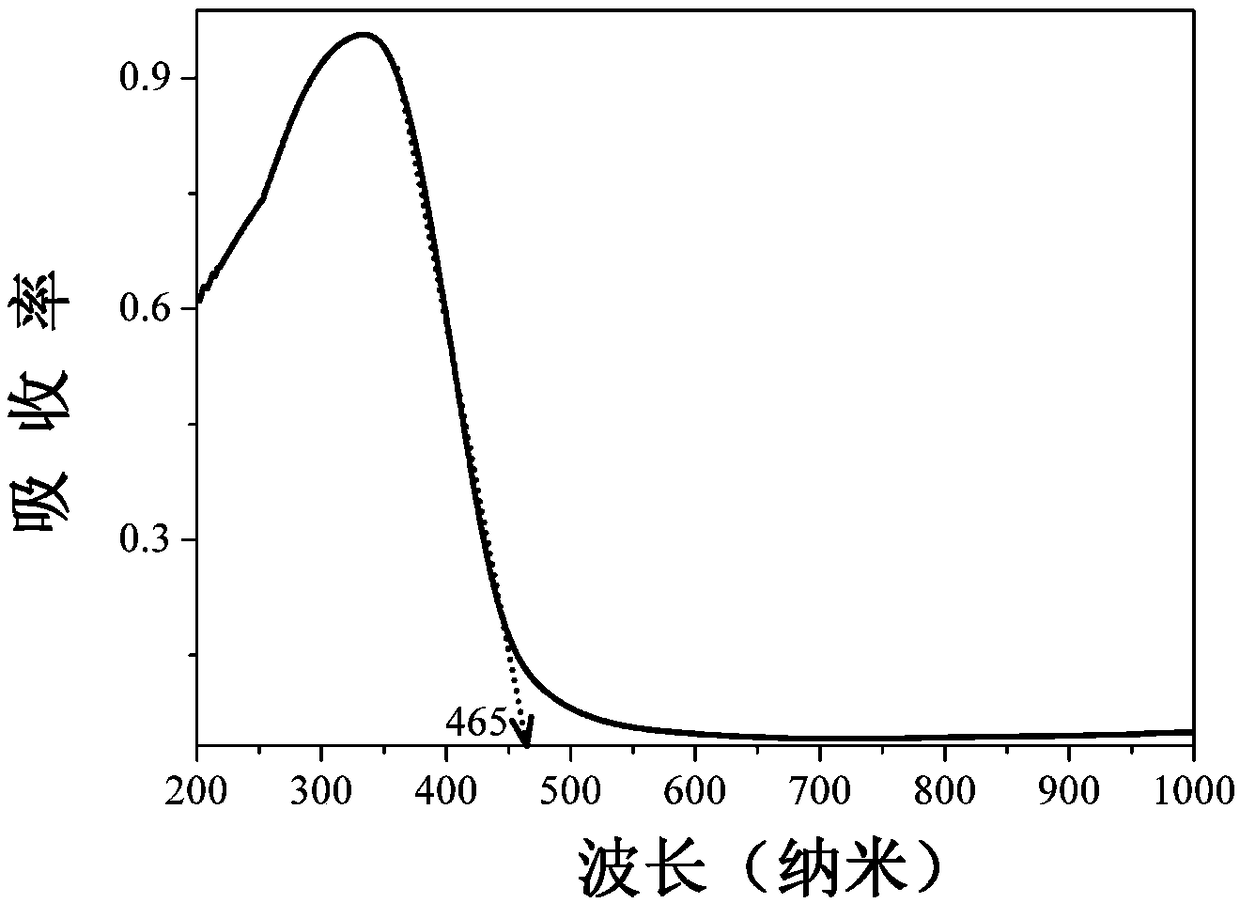

[0027] Embodiment 1: prepare Bi 7.6 Ce 0.4 Ta 7.6 Ti 0.4 Nb 10 o 57

[0028] (1) According to the general chemical formula Bi 7.6 Ce 0.4 Ta 7.6 Ti 0.4 Nb 10 o 57 The stoichiometric ratio of each element in , respectively weigh bismuth oxide Bi 2 o 3 : 8.854 g, ceria CeO 2 : 0.344 g, tantalum pentoxide Ta 2 o 5 : 6.4 g, niobium pentoxide Nb 2 o 5 : 6.625 g, titanium dioxide TiO 2 : 0.16 grams, ground and mixed uniformly to obtain a raw material mixture;

[0029] (2) The raw material mixture obtained in step (1) is placed in a muffle furnace, and the first pre-calcination is carried out under an air atmosphere, the pre-calcination temperature is 300 ° C, and the calcination time is 8 hours;

[0030] (3) Cool the mixture after the first pre-calcination in step (2) to room temperature naturally, grind and mix evenly, then place it in the muffle furnace again, and perform the second calcination in the air atmosphere, the calcination temperature is 950°C , the ca...

Embodiment 2

[0039] Embodiment 2: prepare Bi 7.44 Ce 0.56 Ta 7.44 Ti 0.56 Nb 10 o 57

[0040] (1) According to the general chemical formula Bi 7.44 Ce 0.56 Ta 7.44 Ti 0.56 Nb 10 o 57 The stoichiometric ratio of each element in , respectively weigh bismuth oxide Bi 2 o 3 : 8.667 g, ceria CeO 2 : 0.482 g, tantalum pentoxide Ta 2 o 5 : 8.221 g, niobium pentoxide Nb 2 o 5 : 6.625 g, titanium dioxide TiO 2 : 0.224 grams, ground and mixed uniformly to obtain a raw material mixture;

[0041] (2) The raw material mixture obtained in step (1) is placed in a muffle furnace, and the first pre-calcination is carried out under an air atmosphere, the pre-calcination temperature is 600 ° C, and the calcination time is 2 hours;

[0042] (3) Cool the mixture after the first pre-calcination in step (2) to room temperature naturally, grind and mix evenly, then place it in the muffle furnace again, and perform the second calcination in the air atmosphere, and the calcination temperature is ...

Embodiment 3

[0046] Embodiment 3: prepare Bi 7.76 Ce 0.24 Ta 7.76 Ti 0.24 Nb 10 o 57

[0047] (1) According to the general chemical formula Bi 7.76 Ce 0.24 Ta 7.76 Ti 0.24 Nb 10 o 57 The stoichiometric ratio of each element in the formula, respectively weighed bismuth chloride BiCl 3 : 7.333 g, ceria CeO 2 : 0.123 g, tantalum chloride Nb 2 o 5 : 8.339 g, niobium pentoxide Nb 2 o 5 : 3.975 g, Titanium Dioxide TiO 2 : 0.058 grams, ground and mixed uniformly to obtain a raw material mixture;

[0048] (2) The raw material mixture obtained in step (1) is placed in a muffle furnace, and the first pre-calcination is carried out under an air atmosphere, the pre-calcination temperature is 500 ° C, and the calcination time is 5 hours;

[0049] (3) Cool the mixture after the first pre-calcination in step (2) to room temperature naturally, grind and mix evenly, then place it in the muffle furnace again, and perform the second calcination in the air atmosphere, the calcination tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com