Patents

Literature

35results about How to "Strong liquid absorption and retention capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium ion battery graphene conductive agent and preparation method thereof

ActiveCN104505513AIncrease capacityImprove cycle lifeCell electrodesGrapheneRare-earth elementInternal resistance

The invention relates to a lithium ion battery graphene conductive agent and a preparation method thereof. The graphene conductive agent comprises the following components by mass: 25-30 parts of graphene, 10-15 parts of polyethylene glycol, 5-10 parts of monoethanolamine, 100-160 parts of a solvent, 1-5 parts of a rare earth element, and 0.5-1 part of titanium carbide. According to the invention, the graphene conductive agent utilizes the excellent conductivity of graphene to enhance the capacity of an electrode material, reduce the battery internal resistance, and improve the battery cycle life. The dosage of the graphene conductive agent only accounts for 50-60% of that of existing conductive agents during preparation of a lithium ion battery, the binder dosage is reduced by 18%, and the 2C multiplying power is improved by 6-10%, the cost is saved, and the lithium ion battery can be more competitive.

Owner:NINGBO VEKEN BATTERY

Graphine composite electric conduction agent for iron phosphate lithium battery and preparation method thereof

ActiveCN102244264AEvenly dispersedImprove stabilityCell electrodesInternal resistanceAlternating current

The invention discloses a graphine composite electric conduction agent for an iron phosphate lithium battery, and simultaneously discloses a preparation method of the electric conduction agent. The electric conduction agent provided by the invention consists of graphine, active carbon and a bonding agent in a weight ratio of 1:(0.001-0.1):(0.01-1). The preparation method comprises the following steps: 1) preparing a solution A; 2) preparing a solution B; and 3) preparing the electric conduction agent. According to the invention, the preparation method is simple, the prepared electric conduction agent has the advantages of uniform dispersion, good stability, high electron conduction capability and uniform heat conduction, and the electric conduction agent has higher liquid absorption and liquid protection capabilities when being doped into the iron phosphate lithium battery; and the electric chemical property of the iron phosphate lithium battery which is prepared by adopting the electric conduction agent provided by the invention is improved prominently, compared with the iron phosphate lithium anode material in which the composite electric conduction agent is not doped, when the prepared graphite composite electric conduction agent is doped into the 50AH iron phosphate lithium anode material, the alternating current internal resistance is reduced by 20%, and the circulating service life is improved by 15%.

Owner:JIANGSU LENENG BATTERY INC

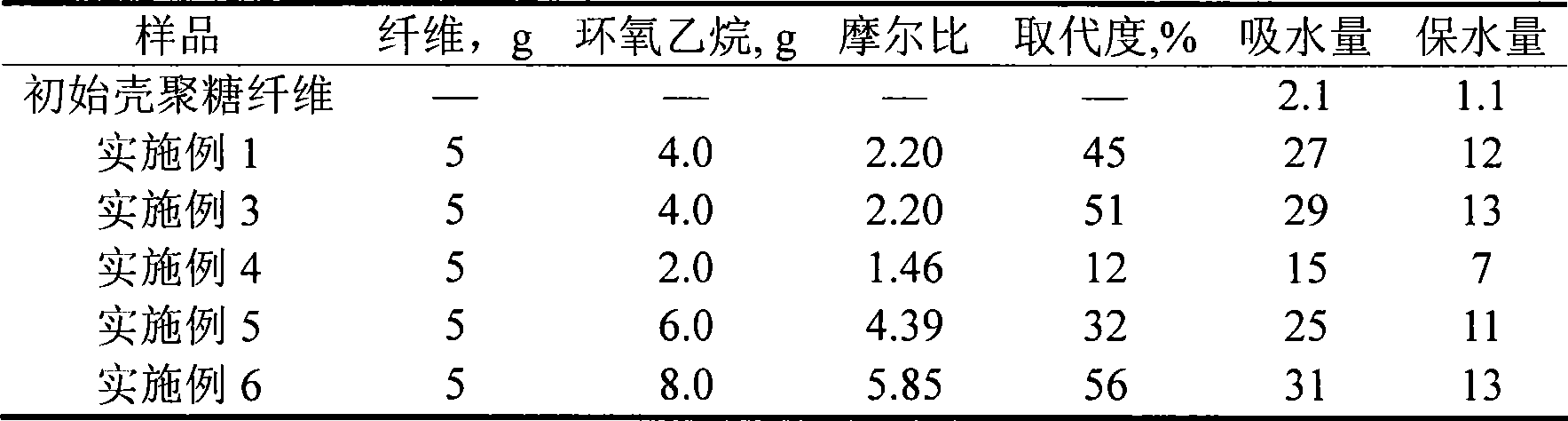

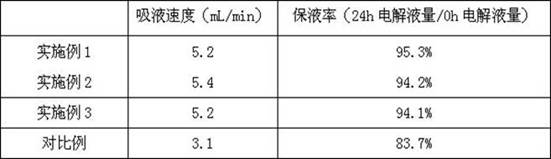

Preparation method for hydroxyethyl group chitosan fiber

InactiveCN101368328AHigh strengthReduce the number of replacementsFibre treatmentAbsorbent padsEpoxyFiber

The invention relates to a hydroxyethyl chitosan fiber preparation method, including the following steps: (1)dispersing chitosan fiber in the mixed solvent of ethanol and isopropanol, adding aqueous alkali, maintaining the temperature of the system in the range of minus 10 DEG C to 20 DEG C, dipping for 5-120min and then basifying to produce basified chitosan fiber; (2)adding isopropanol solution of epoxy ethane into the above system and rising the temperature of the system to 30-70 DEG C, then etherifying for 0.5-8h, taking out of the fiber and dispersing the fiber in ethanol aqueous, adding acetic acid solution drop by drop until the mixture becomes neutral, then washing with ethanol, dehydrating through anhydrous ethanol, and finally airing in air. In this way, partially substituted hydroxyethyl chitosan fiber can be prepared. Hydroxyethyl chitosan fiber with liquid adsorption and liquid retention capabilities can be prepared by introducing hydrophilic hydroxyethyl groups to the chain of chitosan macromolecule. The hydroxyethyl chitosan fiber has potential application value on the treatment of serous wounds; the preparation method is simple, and the substitution degree is easy to control.

Owner:DONGHUA UNIV

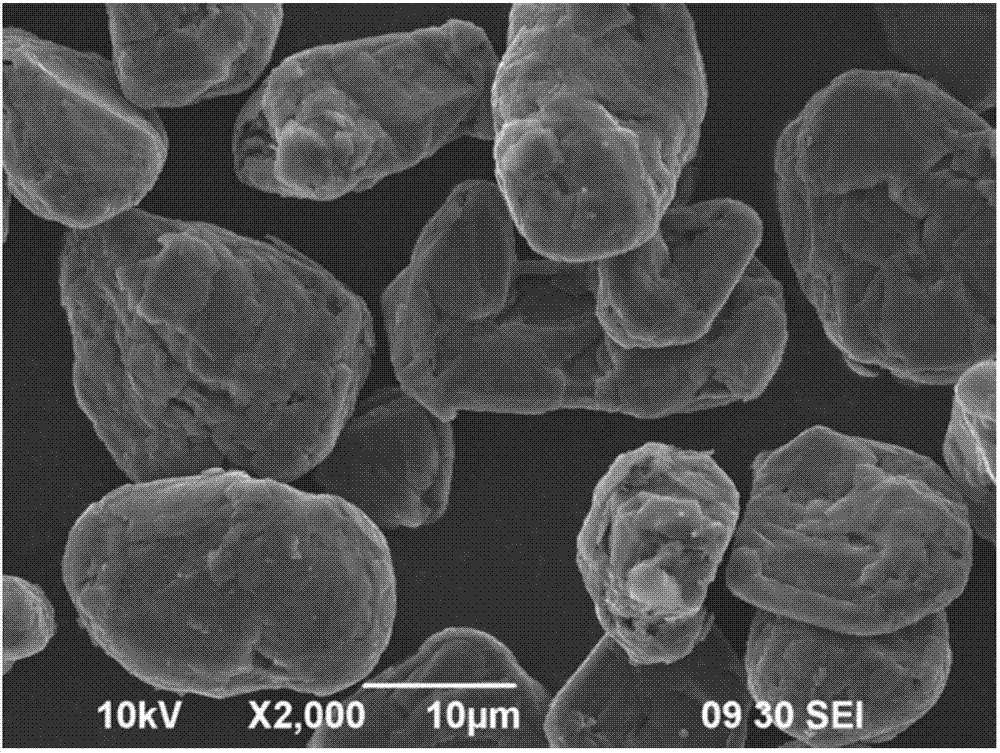

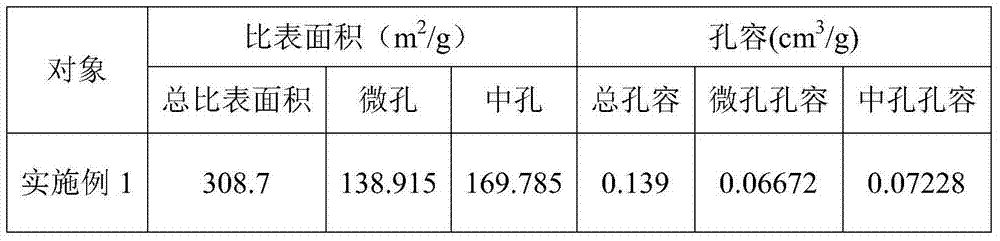

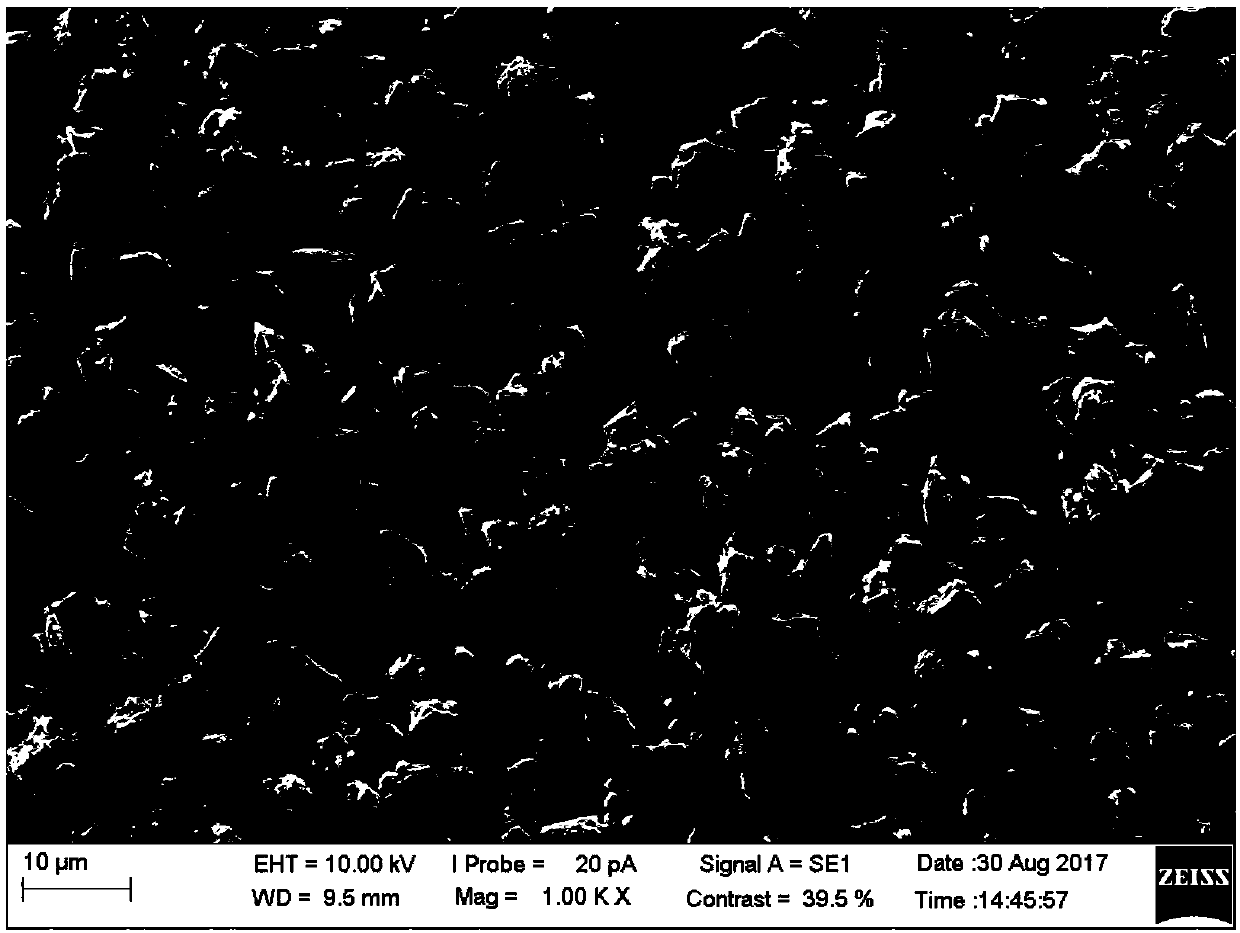

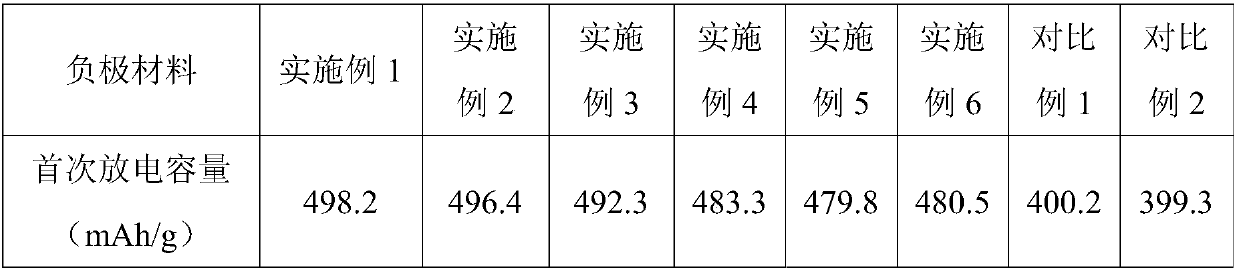

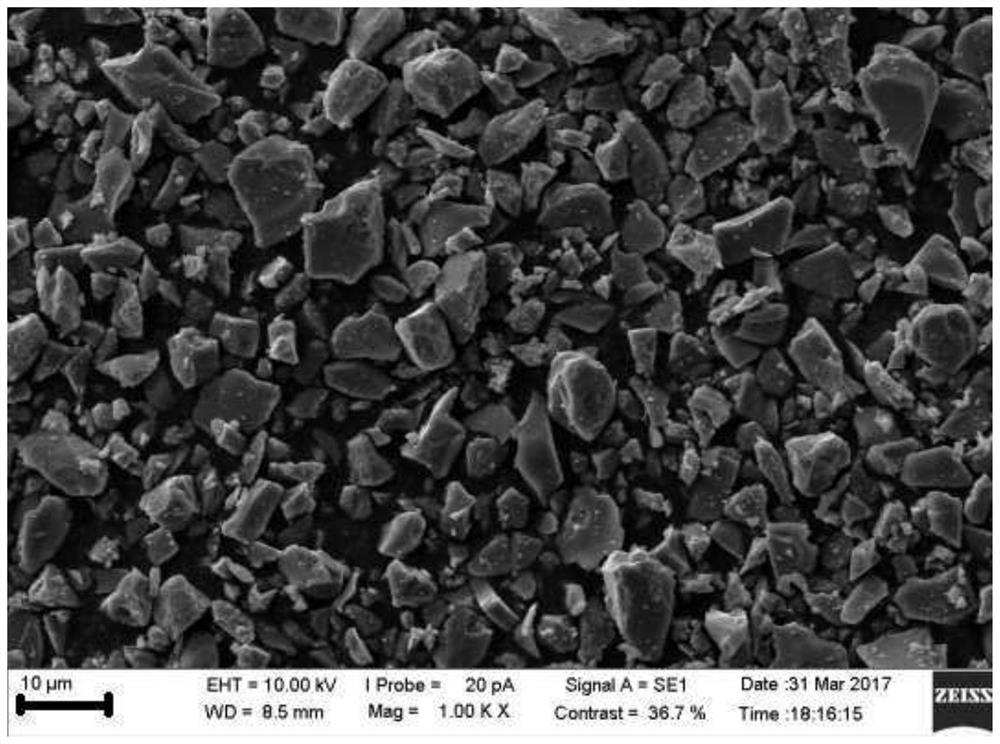

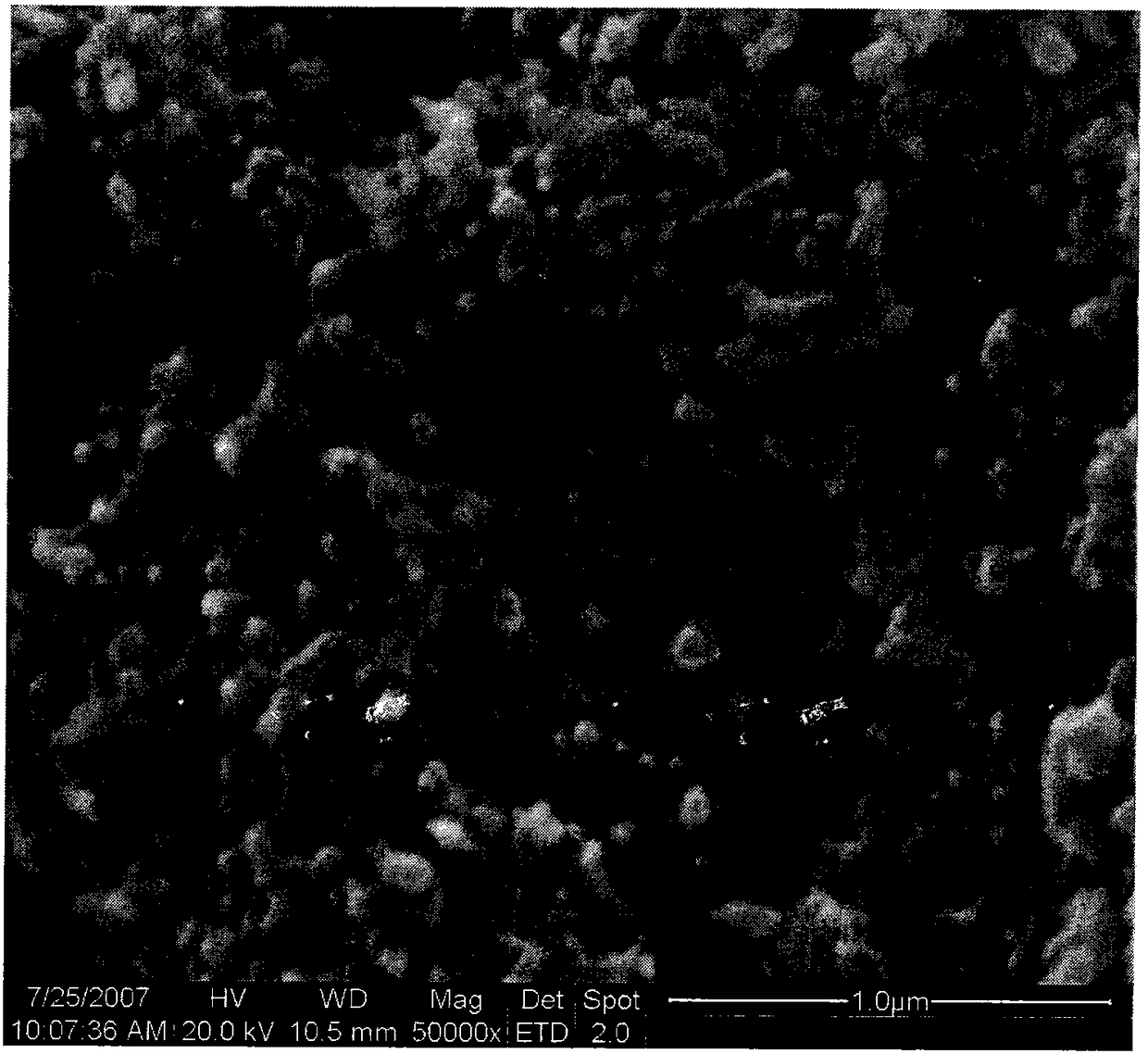

Asphalt-based nanoporous carbon material, negative material thereof, and lithium ion battery

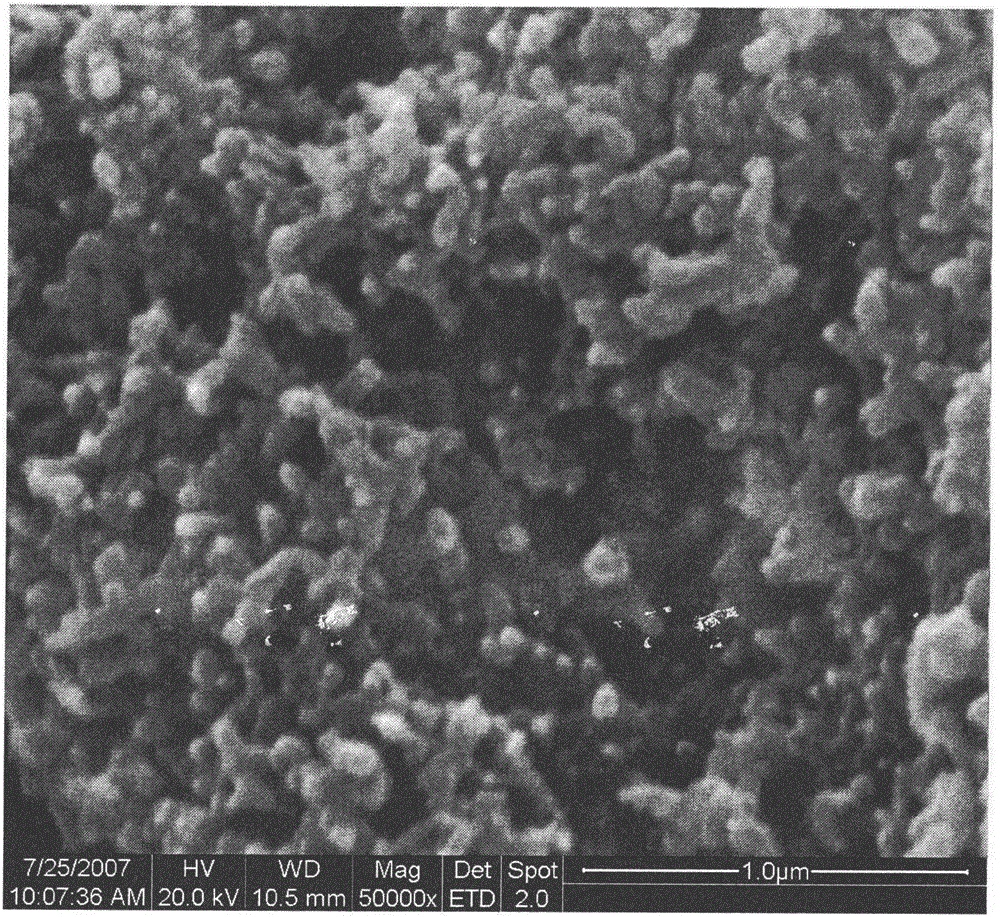

InactiveCN104300150AHas a porous structureLarge specific surface areaMaterial nanotechnologyCell electrodesNanoporous carbonSodium-ion battery

The invention discloses an asphalt-based nanoporous carbon material, a negative material thereof, and a lithium ion battery. The asphalt-based nanoporous carbon material is prepared by mainly using 0.1-10g of asphalt, 3-50g of anhydrous aluminum trichloride, 100-400ml of anhydrous carbon tetrachloride and 200-500ml of a reaction terminating agent, and the amounts of the above raw materials can be freely adjusted in proportion. The asphalt-based nanoporous carbon material is prepared by mainly using asphalt, anhydrous aluminum chloride, anhydrous carbon tetrachloride and the reaction termination agent, and asphalt and anhydrous carbon tetrachloride undergo a Friedel-Crafts crosslinking reaction through a nanometer pore forming technology, so the obtained asphalt-based carbon material has a porous structure and a high specific surface area, and the negative material prepared by using the asphalt-based nanoporous carbon material has the characteristics of strong electrolyte imbibition and retention ability, good processing performance, low price and the like, and can greatly improve the cycle performances of the lithium ion battery.

Owner:HENAN ZHONGLIAN GAOKE NEW ENERGY

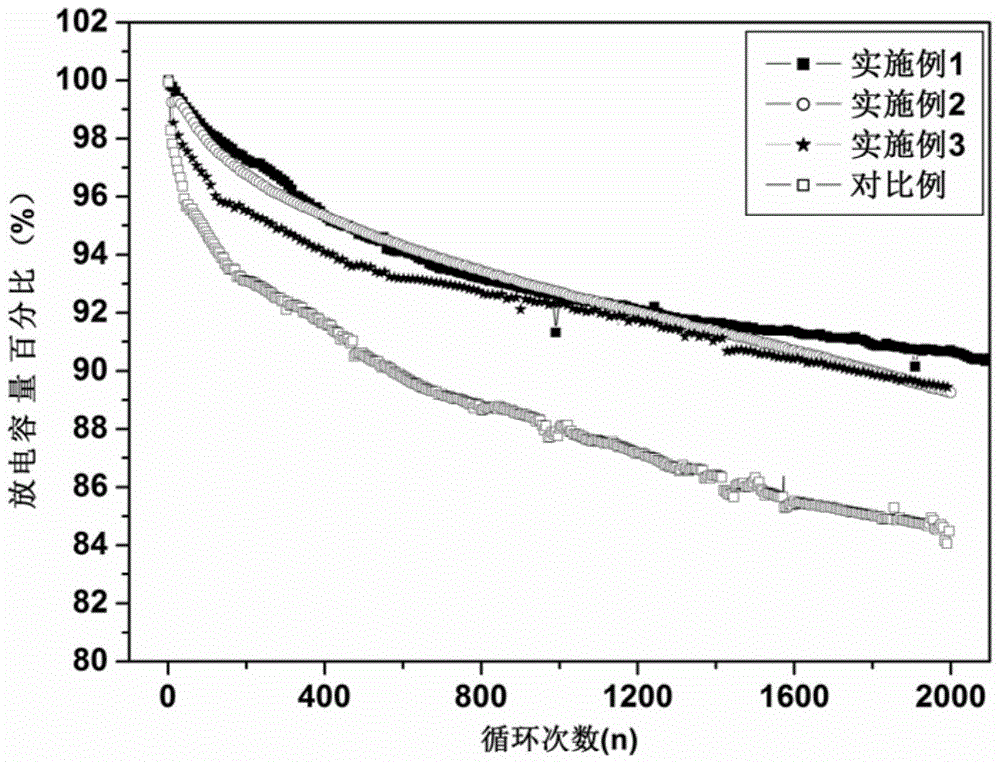

Graphene composite conductive agent and preparation method thereof

ActiveCN105932288AIncrease capacityImprove cycle lifeCell electrodesSecondary cellsEpoxyConductive polymer

The invention relates to a graphene composite conductive agent and a preparation method thereof. The graphene composite conductive agent is prepared from the following components in parts by weight: 70-100 parts of graphene, 20-45 parts of carbon nano-tubes, 30-45 parts of epoxy resin, 10-25 parts of monoethanolamine, 200-300 parts of solvent, 2-3 parts of additives, 7-10 parts of conductive polymer agent, 2-4 parts of glass beads and 3-8 parts of iridium acetylacetonate. According to the conductive agent and the method, the graphene is taken as the master component, the carbon nano-tubes are taken as the secondary component, through utilization of the excellent electric conductivity of the graphene, the capacity of an electrode material is increased, the internal resistance of a battery is reduced, and the cycle life of the battery is prolonged. The 2C rate is improved by 6-10% when a lithium ion battery is prepared, the cost is reduced, and the lithium ion battery is highly competitive.

Owner:NINGBO VEKEN BATTERY

Lithium battery, silicon composite material for same and method for preparing silicon composite material

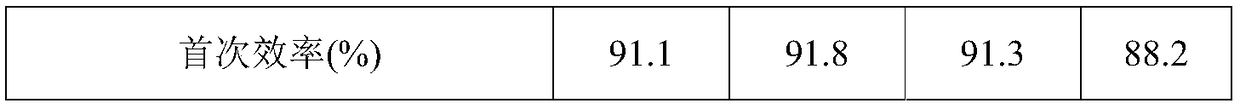

ActiveCN107834049AImprove the first charge and discharge efficiencyStrong liquid absorption and retention capacityCell electrodesSecondary cellsLithium compoundCore shell

The invention relates to a lithium battery, a silicon composite material for the same and a method for preparing the silicon composite material, and belongs to the technical field of lithium batteries. The silicon composite material for the lithium battery is provided with core-shell structures. Silicon particles are used as cores, shells comprise middle layers and outer layers, the middle layersare coated on the surfaces of the silicon particles, the outer layers are coated on the surfaces of the middle layers, the middle layers comprise non-electronic conductive high-polymer materials, theouter layers comprise inorganic lithium compounds, and the inorganic lithium compounds are a type of LiBH4, Li3N, Li2NH, LiBNH6 and Li1.8N0.4Cl0.6; a thickness ratio of the middle layers to the outerlayers is 1-5:1-5. The lithium battery, the silicon composite material and the method have the advantages that the non-electronic conductive high-polymer materials and the inorganic lithium compoundsare coated on the surfaces of the particles made of silicon materials, the quantities of lithium ions can be increased by the inorganic lithium compounds coated on the surfaces of the particles made of the silicon materials in charge and discharge procedures, and accordingly the first efficiency, the specific capacity and the cycle performances can be improved.

Owner:CALB CO LTD +1

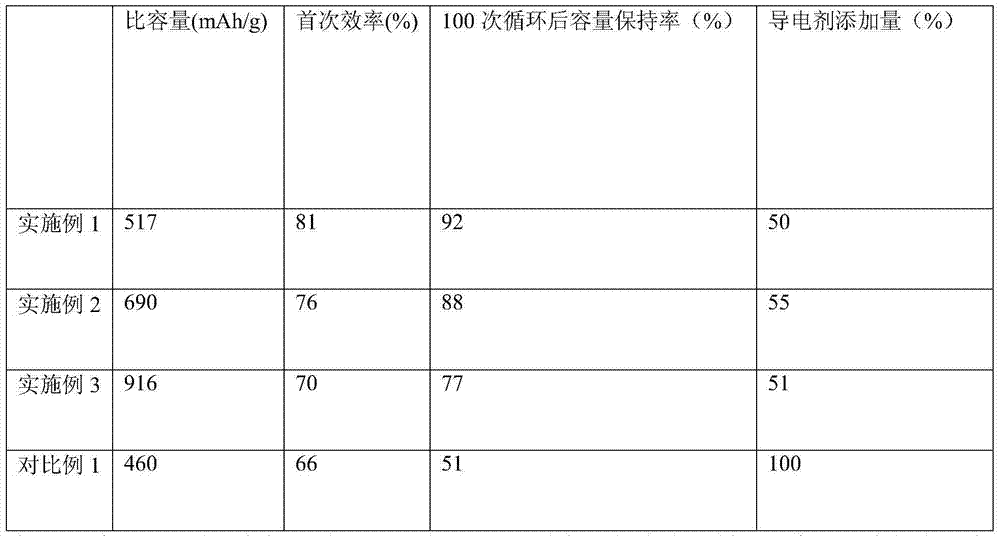

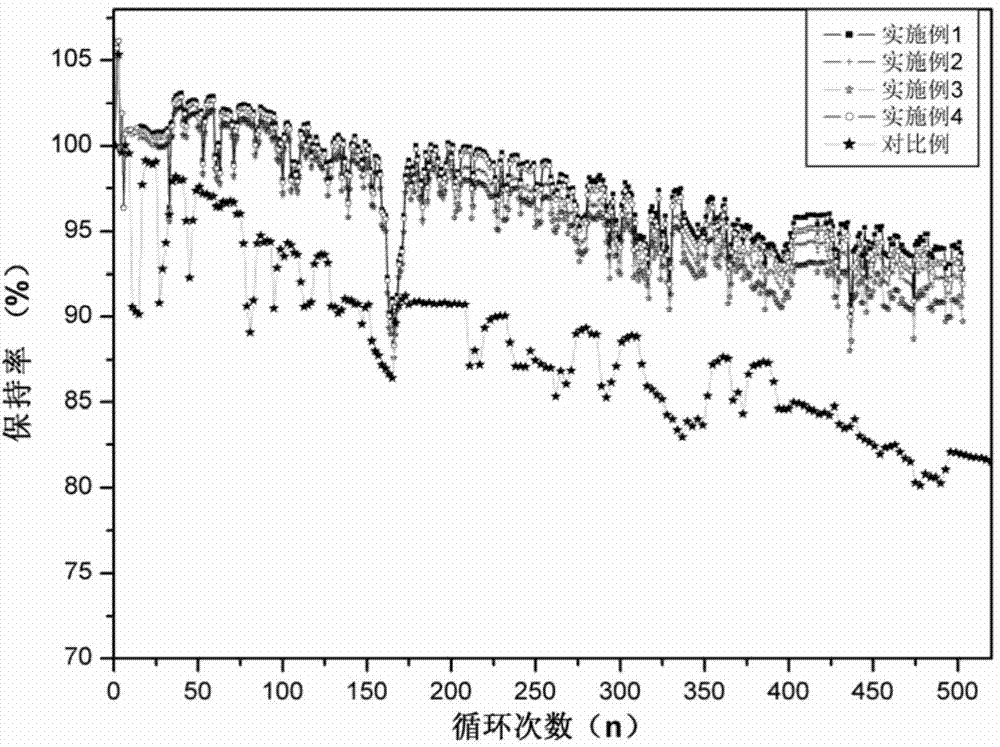

Anode material for lithium-ion power battery and preparation method of anode material

PendingCN108134087AReduce expansionImprove cycle performanceCell electrodesCarbon compositesSilver carbonate

The invention discloses an anode material for a lithium-ion power battery and a preparation method of the anode material, and relates to the field of preparation of battery materials, in particular tothe field of preparation of the anode materials of lithium batteries. The anode material is characterized by being prepared from porous silicon dioxide and coating compound asphalt, wherein porous silicon dioxide is prepared from raw materials as follows: polycrystalline silicon powder, hydrochloric acid, silver carbonate, hydrofluoric acid and hydrogen peroxide; the compound asphalt is preparedfrom materials as follows: nano calcium carbonate, asphalt, graphene, sodium hydroxide, a binder and distilled water; after porous silicon dioxide and the compound asphalt are mixed uniformly in a ratio being 5:(3-5), a mixture is carbonized, and a silicon-carbon anode material is prepared. The prepared silicon-carbon composite material has the effect of improving rate performance and safety performance while the transfer number of lithium ions is increased and stacking of the lithium ions is reduced, further has advantages of high gram volume, excellent cycle performance, high liquid absorption and retaining capability, low cost and low expansion rate, and is particularly suitable for meeting demands of high-energy-density batteries for the anode material.

Owner:内蒙古欣源石墨烯科技股份有限公司

Method for preparing high-energy-density negative pole piece and lithium ion battery comprising same

ActiveCN105591070AGood compatibilityReduce contact resistanceElectrode rolling/calenderingFinal product manufactureAbsorption capacityAluminium-ion battery

Provided is a method for preparing a high-energy-density negative pole piece and a lithium ion battery comprising the high-energy-density negative pole piece. By weight, the preparation method comprises the following steps of 1 preparation of negative pole high-viscosity slurry, 2 preparation of modified nickel foam and 3 rolling. According to the high-energy-density negative pole piece and the preparation method of the lithium ion battery of the high-energy-density negative pole piece, the contact internal resistance of electrode active matter and a current collector is effectively reduced, and the comprehensive performance of an electrode is improved. Meanwhile, the surface of the nickel foam is plated with lithium ion containing matter, and therefore the transmission rate of lithium ions in the charging and discharging process can be increased. The advantages of being high in energy density, high in liquid absorption capacity, high in adhesive power and the like are achieved, and the high-energy-density negative pole piece is especially suitable for the lithium ion batteries used in the digital field.

Owner:JIANGSU LENENG BATTERY INC

Graphine composite electric conduction agent for iron phosphate lithium battery and preparation method thereof

ActiveCN102244264BEvenly dispersedImprove stabilityCell electrodesInternal resistanceAlternating current

Owner:JIANGSU LENENG BATTERY INC

A kind of graphene conductive agent and lithium ion battery thereof

ActiveCN105932289BIncrease capacityImprove cycle lifeCell electrodesSecondary cellsConductive polymerInternal resistance

The invention relates to a graphene conductive agent. The graphene conductive agent is prepared from the following components in parts by weight: 120-150 parts of graphene, 30-45 parts of nonylphenoxypoly(ethyleneoxy)ethanol, 10-25 parts of monoethanolamine, 200-300 parts of solvent, 2-3 parts of additives, 7-10 parts of conductive polymer agent, 2-4 parts of glass beads and 3-8 parts of iridium acetylacetonate. According to the conductive agent, the graphene is taken as the master component, through utilization of the excellent electric conductivity of the graphene, the capacity of an electrode material is increased, the internal resistance of a battery is reduced, and the cycle life of the battery is prolonged. The 2C rate is improved by 6-10% when the lithium ion battery is prepared, the cost is reduced, and the lithium ion battery is highly competitive.

Owner:东莞维科新能源有限公司

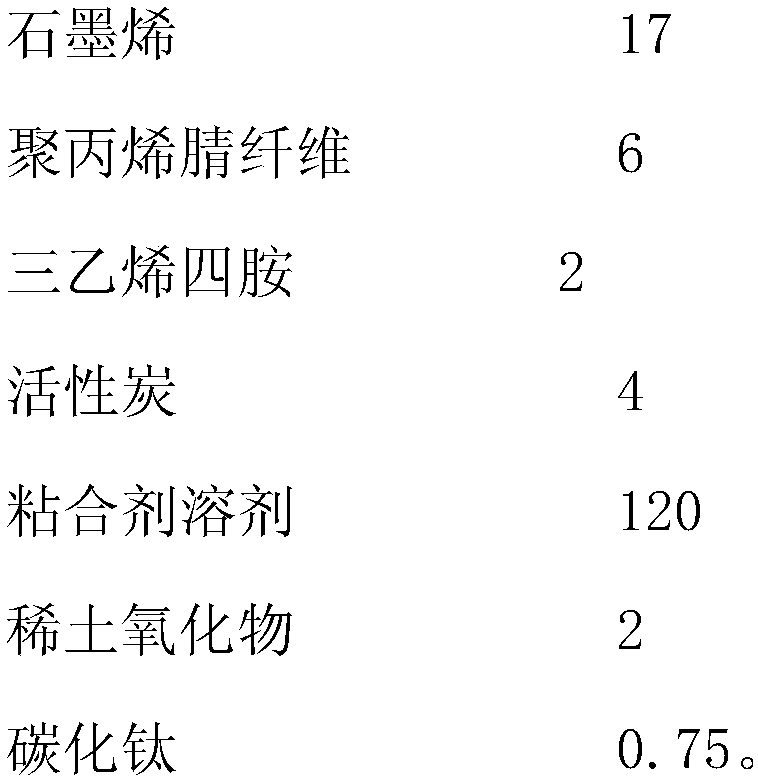

A kind of lithium ion battery graphene conductive agent and preparation method thereof

ActiveCN104505513BIncrease capacityImprove cycle lifeCell electrodesGrapheneRare-earth elementInternal resistance

The invention relates to a lithium ion battery graphene conductive agent and a preparation method thereof. The graphene conductive agent comprises the following components by mass: 25-30 parts of graphene, 10-15 parts of polyethylene glycol, 5-10 parts of monoethanolamine, 100-160 parts of a solvent, 1-5 parts of a rare earth element, and 0.5-1 part of titanium carbide. According to the invention, the graphene conductive agent utilizes the excellent conductivity of graphene to enhance the capacity of an electrode material, reduce the battery internal resistance, and improve the battery cycle life. The dosage of the graphene conductive agent only accounts for 50-60% of that of existing conductive agents during preparation of a lithium ion battery, the binder dosage is reduced by 18%, and the 2C multiplying power is improved by 6-10%, the cost is saved, and the lithium ion battery can be more competitive.

Owner:NINGBO VEKEN BATTERY

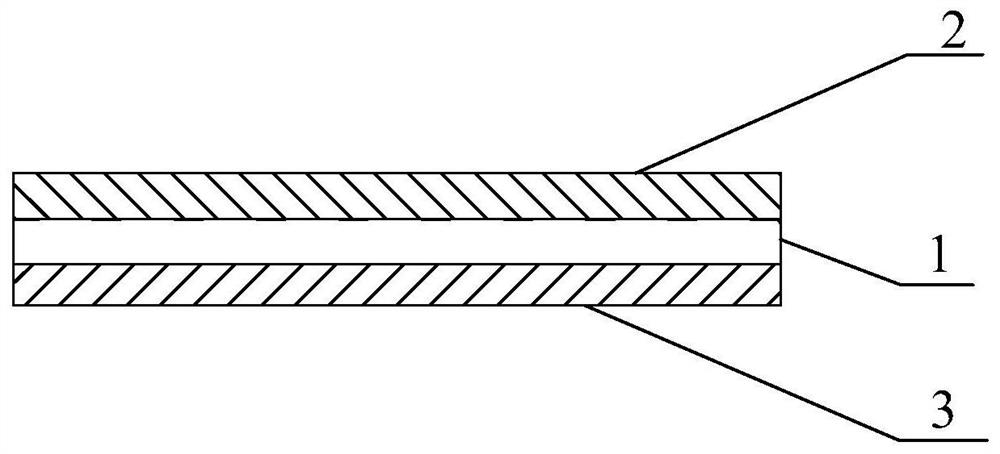

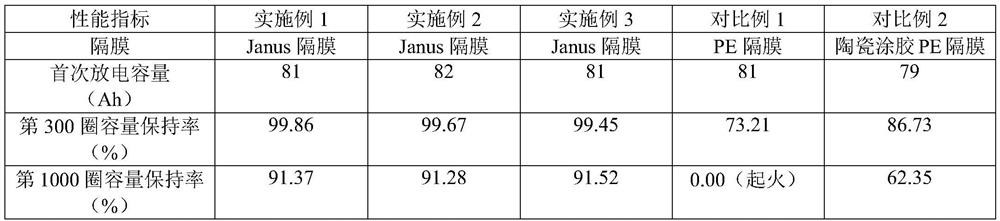

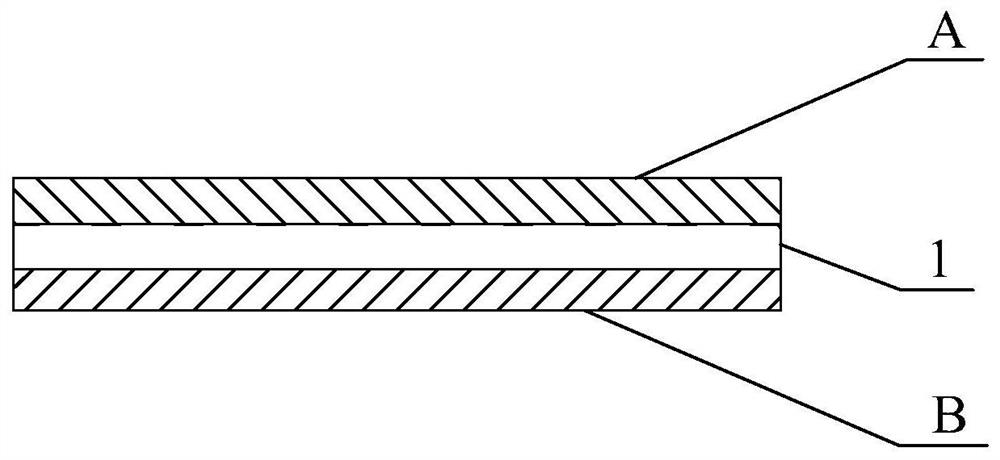

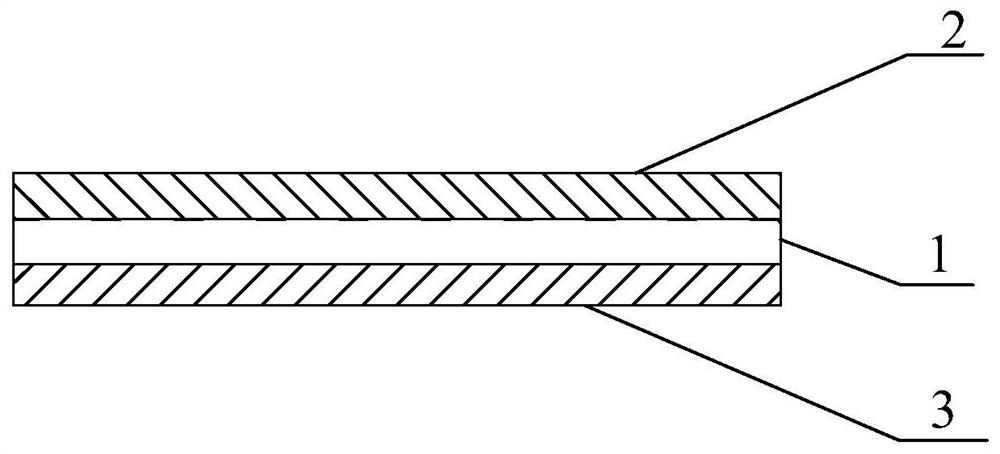

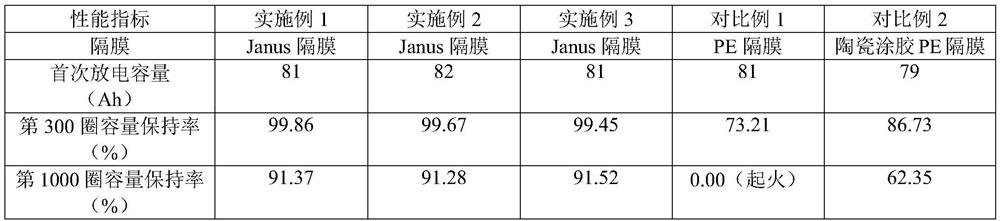

Lithium ion battery Janus diaphragm

ActiveCN112086608AReduce the risk of failureImprove securityCell component detailsPhysical chemistryEngineering

The invention relates to the technical field of lithium ion batteries and provides a lithium ion battery Janus diaphragm in order to solve problems that a traditional lithium ion battery diaphragm easily causes internal short circuit of a battery and cannot meet specific requirements of a positive plate and a negative plate. The lithium ion battery Janus diaphragm is composed of a high-temperature-resistant supporting layer, and a polar functional layer and a non-polar functional layer which are loaded on two sides of the high-temperature-resistant supporting layer. The lithium ion battery Janus diaphragm provided by the invention can promote formation of a more stable and high-quality SEI film on a surface of a negative electrode, and is beneficial to exertion of higher capacity and ratecapability of a positive electrode material, so safety and high-temperature cycle performance of the battery are improved.

Owner:WANXIANG 123 CO LTD

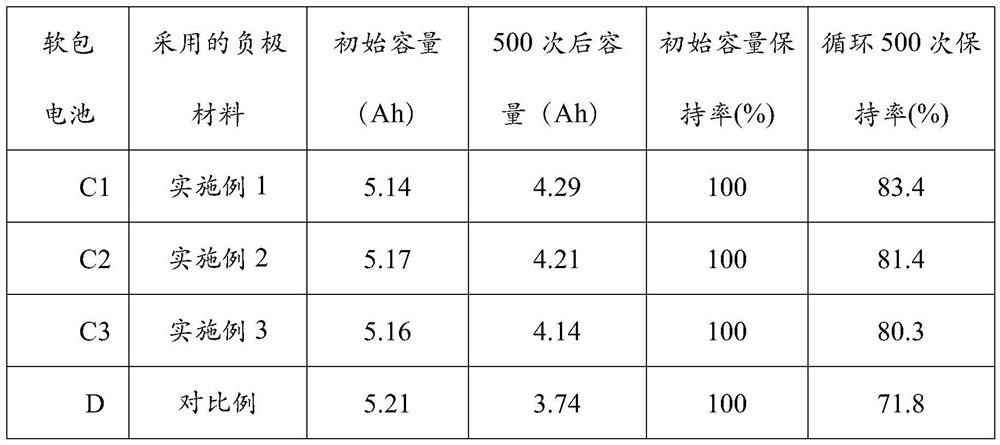

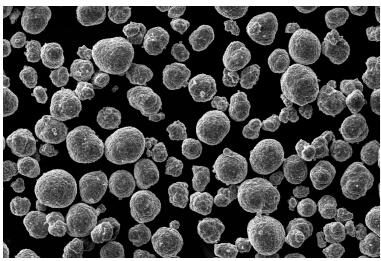

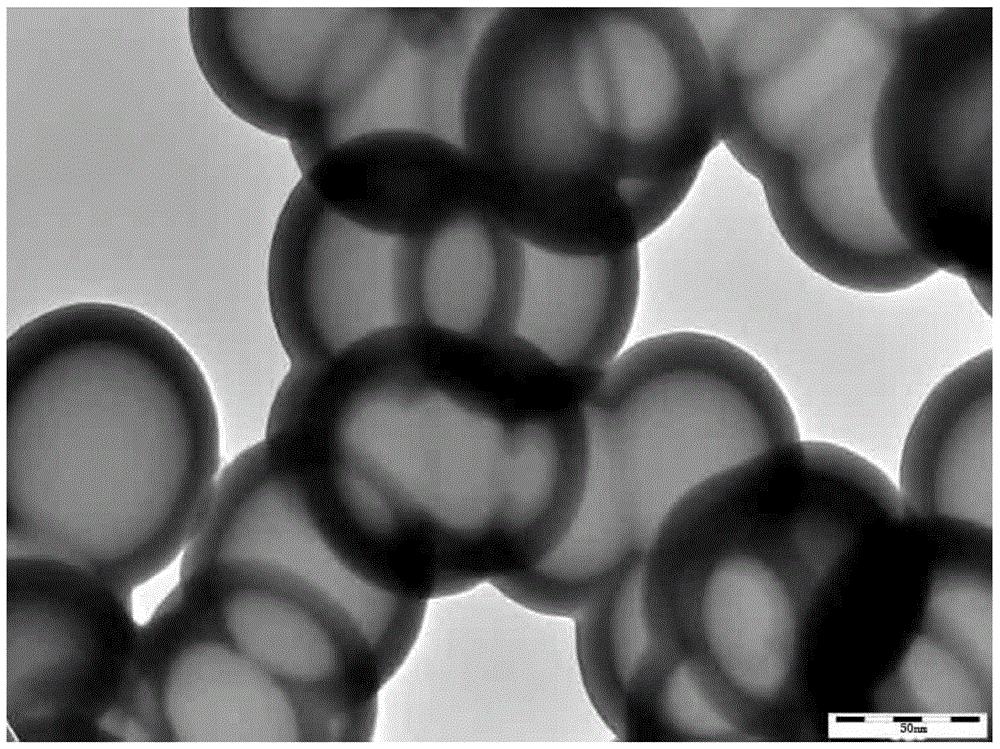

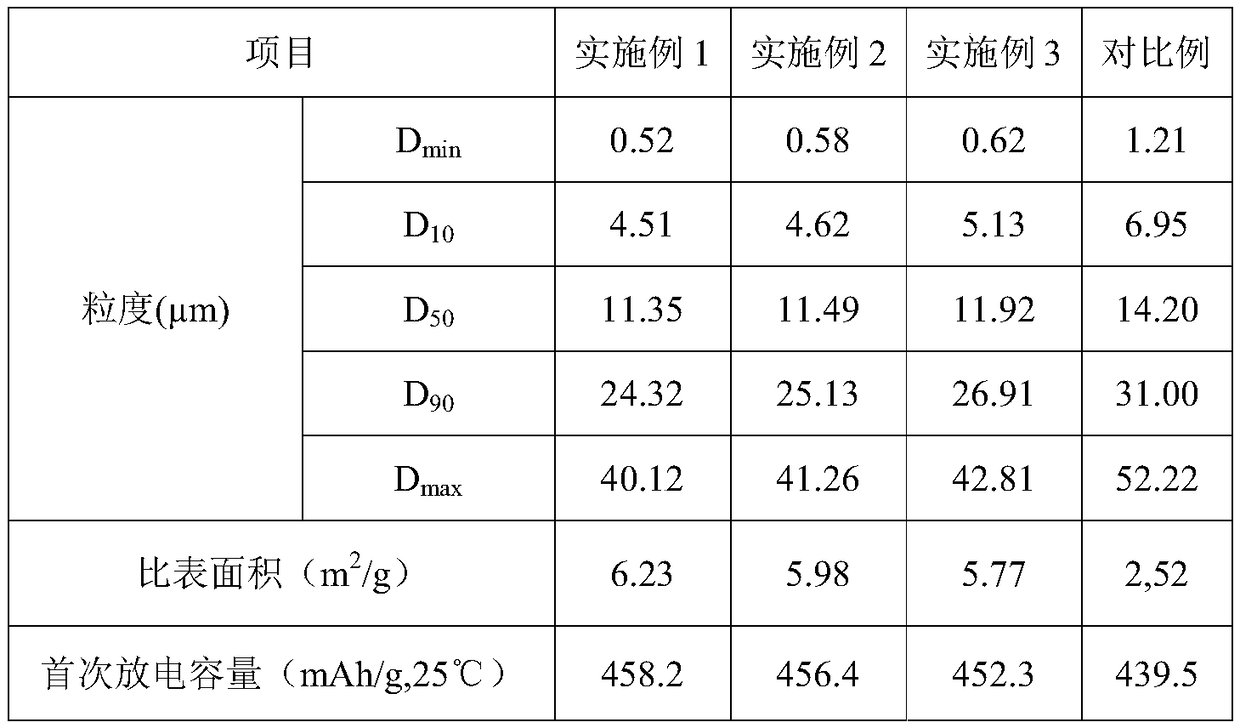

Silicon-carbon composite negative electrode material and preparation method thereof

ActiveCN107768625BIncrease transfer rateImprove transmission efficiencyMaterial nanotechnologyCell electrodesCarbon compositesNano silicon

The invention relates to a silicon-carbon composite negative electrode material. The silicon-carbon composite negative electrode material has a core-shell structure and comprises an inner core part and a shell part coated on the inner core part, wherein the inner core part is nano silicon, and the shell part is a composite structure containing a porous carbon material and a lithium salt. The invention further provides a preparation method of the silicon-carbon composite negative electrode material.

Owner:乌兰察布市大盛石墨新材料股份有限公司

Graphene conductive agent

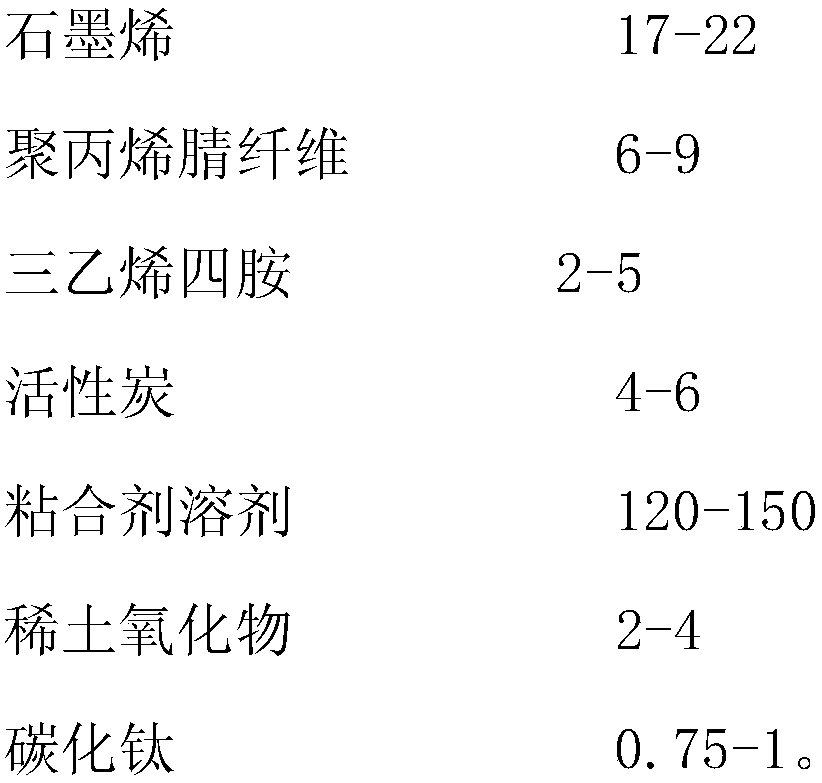

InactiveCN107808961AIncrease capacityImprove cycle lifeCell electrodesSecondary cellsFiberActivated carbon

The invention discloses a graphene conductive agent. The internal composition components of the graphene conductive agent include, by mass, 17-22 parts of graphene, 6-9 parts of polyacrylonitrile fibers, 2-5 parts of triethylenetetraamine, 4-6 parts of activated carbon, 120-150 parts of an adhesive solvent, 2-4 parts of rare earth oxide and 0.75-1 part of titanium carbide. The graphene conductiveagent using the excellent conductivity of the graphene improves the capacity of an electrode material, reduces the internal resistance of a battery, prolongs the cycle life of the battery and saves the cost, so the lithium ion battery is competitive, and has strong electron conduction ability and uniform heat conduction, and the graphene conductive agent has strong liquid absorbing and preservingability when doped into the lithium ion battery.

Owner:NANJING XUYURUI MATERIAL TECH CO LTD

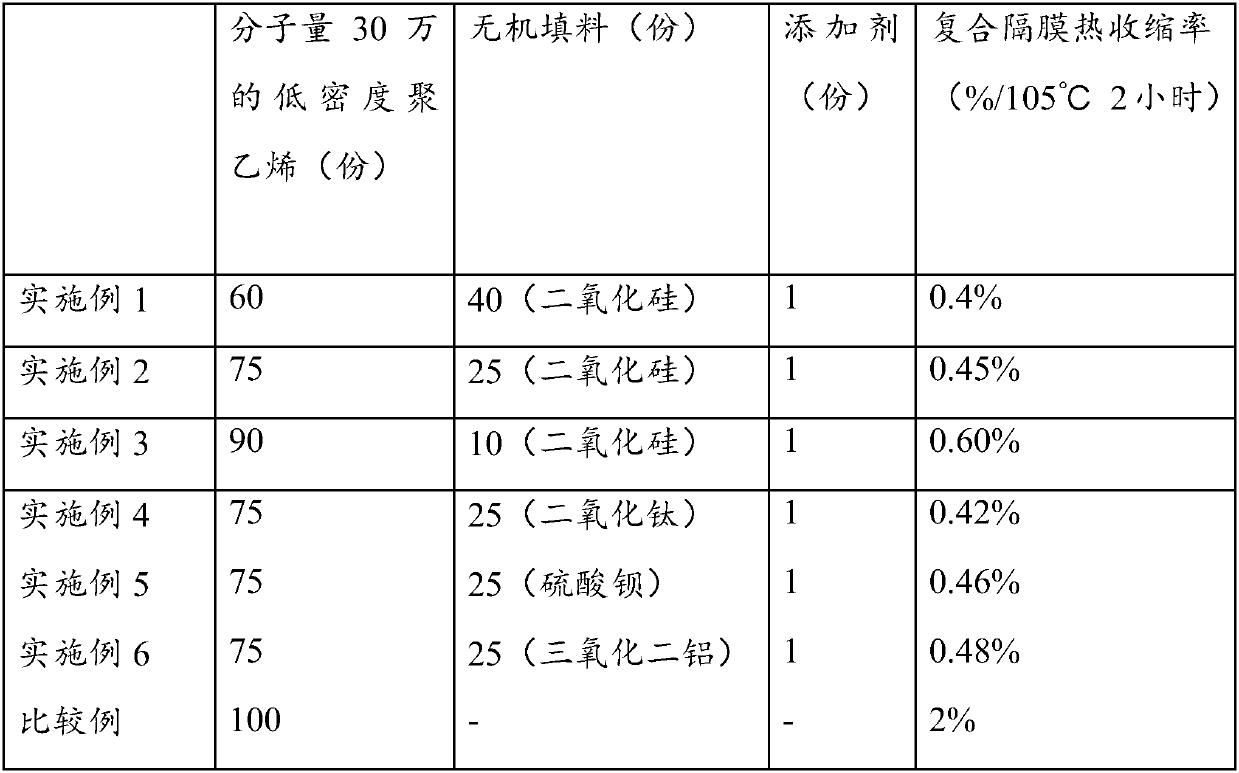

High temperature-resistant lithium ion battery composite diaphragm and preparation method thereof

InactiveCN108054327AStrong heat resistanceImprove antioxidant capacityCell component detailsLow-density polyethyleneSurface layer

The invention relates to a high temperature-resistant lithium ion battery composite diaphragm. The composite diaphragm has a skin / core / skin three-layer composite membrane structure. The skin layer includes high-density polyethylene. The core layer includes a mixture of low-density polyethylene and an inorganic filler. The composite diaphragm is prepared from raw materials of the surface layers andthe core layer through co-extrusion casting based on a dry process. The invention also relates to a preparation method of the lithium ion battery composite diaphragm based on the dry process. The lithium ion battery composite diaphragm has good heat resistance.

Owner:深圳市博盛新材料有限公司

A kind of graphene composite conductive agent and lithium ion battery thereof

ActiveCN105958074BIncrease capacityImprove cycle lifeCell electrodesSecondary cellsInternal resistanceSolvent

The invention relates to a graphene composite conductive agent and a lithium ion battery prepared from same. The graphene composite conductive agent comprises the components as follows in parts by mass: 80-120 parts of graphene, 20-45 parts of acetylene black, 30-45 parts of nonylphenol polyoxyethylene ether, 10-25 parts of monoethanolamine, 200-300 parts of solvent, 2-3 parts of auxiliaries, 7-10 parts of conductive macromolecular agent, 2-4 parts of glass beads and 3-8 parts of iridium-acetylacetonate. The graphene composite conductive agent takes graphene as the main component and takes the acetylene black as the auxiliary component; due to the excellent conductivity of graphene, the capacity of the electrode material is improved, the internal resistance of the battery is lowered, and the cycling life of the battery is prolonged; and in addition, the 2C rate of the prepared lithium ion battery is improved by 6-10%, so that the cost is saved, and the prepared lithium ion battery is more competitive.

Owner:NINGBO VEKEN BATTERY

Preparation method of graphene conductive agent

PendingCN110165216AImprove electronic conductivityIncrease capacityCell electrodesConductive polymerMass ratio

The invention relates to a conductive agent, in particular to a preparation method of a graphene conductive agent. The method comprises the following steps: (1) preparing a premix solution A; preparing a premix solution B; (3) stirring and mixing the pre-mixed solution A obtained at the step (1) and the pre-mixed solution B obtained in the step (2) according to a mass ratio of 8: 10: 2: 4, addingan auxiliary agent and a conductive polymer agent, carrying out high-pressure dispersion treatment under the pressure of 21000PSI, and then increasing the temperature to 150-200 DEG C, performing stirring for 3-6 hours, performing cooling, and grinding the mixture into particles with the particle size of 10-20 nm, and obtaining the graphene conductive agent. According to the preparation method ofthe graphene conductive agent, the excellent conductivity of graphene is utilized to increase the capacity of an electrode material, the internal resistance of a battery is reduced, and the cycle lifeof the battery is prolonged; the prepared graphene conductive agent is high in electron conduction capability and uniform in heat conduction, and has relatively high liquid absorption and retention capability when being doped into a lithium ion battery.

Owner:JINAN DEV ZONE XINGHUO SCI & TECH RES INST

A kind of preparation method of composite conductive agent used in lithium ion battery

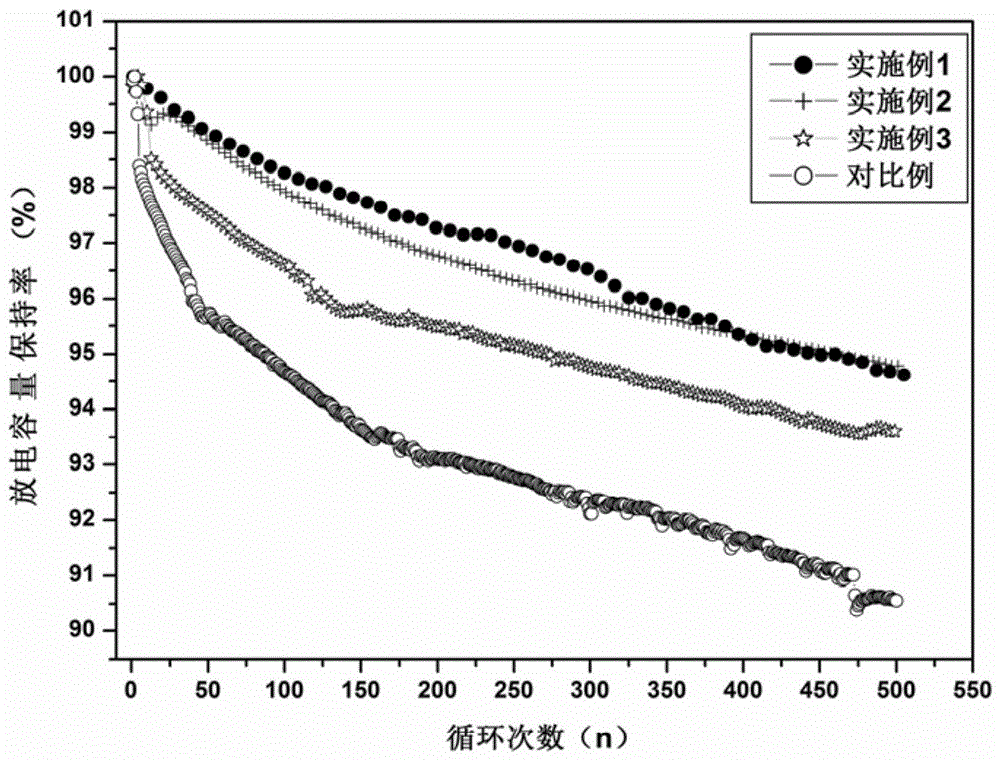

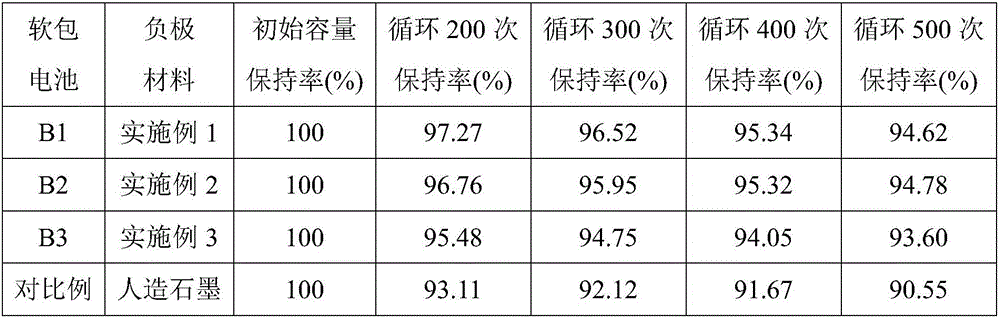

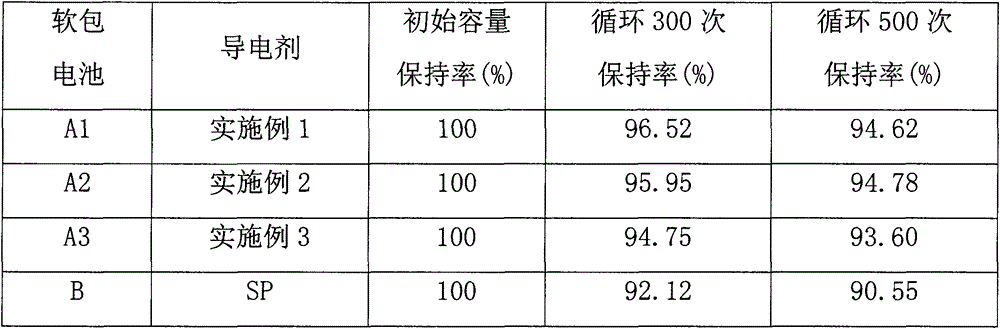

ActiveCN105932286BImprove cycle performanceImprove liquid absorption and retention capacityCell electrodesWater basedSodium-ion battery

The invention relates to a preparation method of a composite conductive agent used in lithium ion batteries. The preparation method comprises an organic composite solvent preparation process, a water-based composite solvent preparation process and a composite conductive agent preparation process. Aniline, phenylacetylene, an organic lithium compound and an organic solvent are used in the organic composite solvent preparation process, ammonium persulfate, hydrochloric acid, acidized carbon nano tubes and a water-based solvent are used in the water-based composite solvent preparation process, and an organic composite solvent and a water-based composite solvent are used in the composite conductive agent preparation process. The organic lithium compound in the composite conductive agent can use lithium ions in the organic lithium compound to reduce lithium ions caused by SEI film loss in the charging and discharging process of the lithium ion batteries, and the cycle performance of the lithium ion batteries is improved, so that the composite conductive agent has the characteristics of high conductivity, large specific surface area and the like, and the liquid suction and liquid retaining capacity of the composite conductive agent is improved.

Owner:东莞市智库新能源技术有限公司

A high-power lithium-ion battery

ActiveCN106058262BIncrease capacityImprove cycle lifeCell electrodesSecondary cellsIridiumConductive polymer

The invention relates to a high-power lithium-ion battery, which comprises a positive plate, a negative plate, a membrane and an electrolyte, wherein the lithium-ion battery comprises a graphene composite conductive agent; the high-power lithium-ion battery is evenly dispersed into a positive active material and a negative active material; and the graphene composite conductive agent is prepared from the following components in parts by mass: 120-150 parts of graphene, 20-35 parts of Super-p, 10-15 parts of carbon nanotubes, 30-45 parts of nonylphenol polyoxyethylene ether, 10-25 parts of monoethanolamine, 200-300 parts of solvents, 2-3 parts of assistants, 7-10 parts of conductive polymer agents, 2-4 parts of glass beads and 3-8 parts of acetylacetonate iridium. The graphene is taken as a main component and has excellent conductivity, so that the capacity of the electrode material is improved; the internal resistance of the battery is reduced; the cycle lifetime of the battery is prolonged; the cost is reduced; and the lithium-ion battery has higher competitiveness.

Owner:东莞维科新能源有限公司

A kind of graphene composite conductive agent and preparation method thereof

ActiveCN105932288BIncrease capacityImprove cycle lifeCell electrodesSecondary cellsEpoxyConductive polymer

Owner:NINGBO VEKEN BATTERY

A preparation method of silicon-carbon composite negative electrode material with high capacity

ActiveCN106410198BIncrease contact areaIncrease compaction densityCell electrodesSecondary cellsCarbon compositesInternal resistance

Owner:上高县荣炭科技有限公司

A kind of lithium-ion battery silicon composite negative electrode material and preparation method thereof

ActiveCN104332608BImprove performanceIncrease capacitySecondary cellsNon-aqueous electrolyte accumulator electrodesCarbon layerNano silicon

Owner:RIGHTFUL TECH

Preparation method of composite conductive agent used in lithium ion batteries

ActiveCN105932286AImprove cycle performanceImprove liquid absorption and retention capacityCell electrodesWater basedLithium compound

The invention relates to a preparation method of a composite conductive agent used in lithium ion batteries. The preparation method comprises an organic composite solvent preparation process, a water-based composite solvent preparation process and a composite conductive agent preparation process. Aniline, phenylacetylene, an organic lithium compound and an organic solvent are used in the organic composite solvent preparation process, ammonium persulfate, hydrochloric acid, acidized carbon nano tubes and a water-based solvent are used in the water-based composite solvent preparation process, and an organic composite solvent and a water-based composite solvent are used in the composite conductive agent preparation process. The organic lithium compound in the composite conductive agent can use lithium ions in the organic lithium compound to reduce lithium ions caused by SEI film loss in the charging and discharging process of the lithium ion batteries, and the cycle performance of the lithium ion batteries is improved, so that the composite conductive agent has the characteristics of high conductivity, large specific surface area and the like, and the liquid suction and liquid retaining capacity of the composite conductive agent is improved.

Owner:东莞市智库新能源技术有限公司

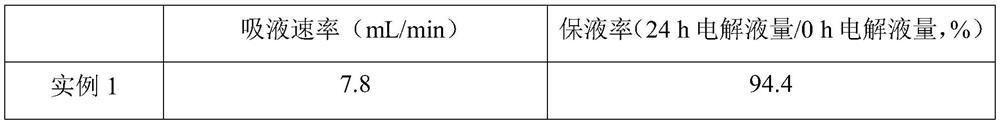

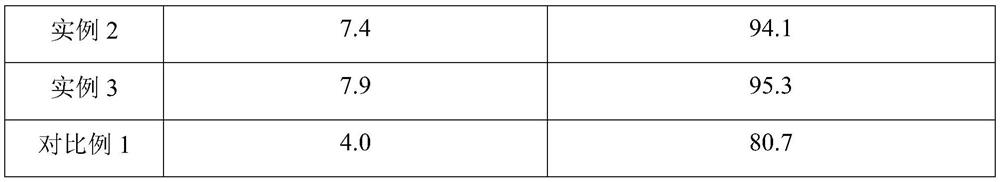

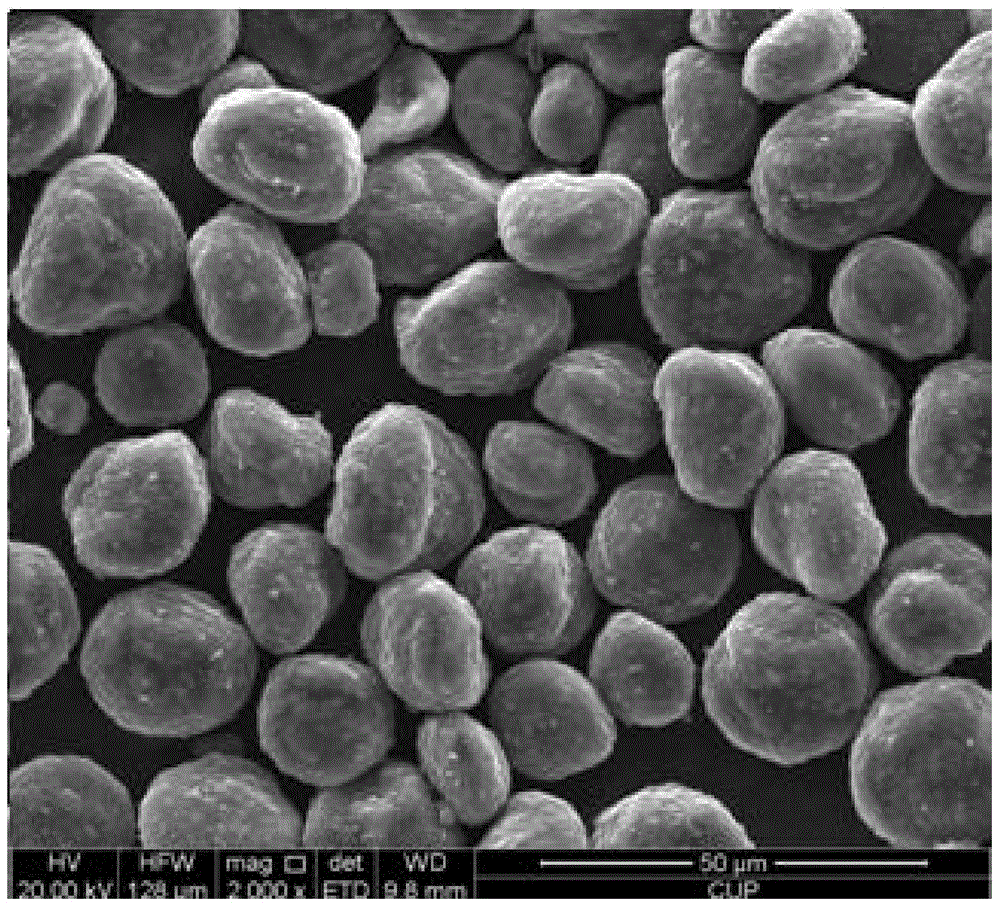

A preparation method of nanoporous lithium-rich lithium iron phosphate material

ActiveCN108923046BImprove cycle performanceLower internal resistanceCell electrodesSecondary cellsLithium-ion batteryMaterials science

The invention belongs to the field of preparation of lithium-ion battery materials, and specifically relates to a preparation method of a nanoporous lithium-rich lithium iron phosphate material. At the same time, fully mix the lithium salt, phosphorus salt, and iron source at the atomic level, add lithium amide and stir evenly, then add the above lithium powder complex, then dissolve it in the glucose solution, stir evenly, and spray dry to obtain The precursor is dissolved in tetrahydrofuran to remove the polymer template and heat-treated to obtain a porous lithium-rich lithium iron phosphate composite material. In the present invention, the prepared nanoporous lithium-rich lithium iron phosphate material utilizes the lithium ions provided by the core lithium powder to improve the transmission rate, gram capacity and liquid absorption capacity of lithium ions in the charging and discharging process, and is applied to lithium ion batteries , has the characteristics of good rate performance and excellent cycle performance.

Owner:JIANGSU LENENG BATTERY INC

Nano electrode material of energy storage lithium ion battery

InactiveCN111799435AStrong liquid absorption and retention capacityPromote circulationElectrode manufacturing processesFinal product manufactureSolution treatmentLithium carbonate

The invention discloses a nano electrode material of an energy storage lithium ion battery. The nano electrode material is prepared by the following method: 1) taking lithium carbonate as a lithium source; 2) taking tetrabutyl titanate as a titanium source; 3) adding carbon nanotubes into a mixed solution of acetic acid and nitric acid, and carrying out ultrasonic treatment to form a suspension; 4) mixing the solutions in an isopyknic manner, and continuously adding the suspension in the stirring process to form a viscous colloid; (5) standing for 12 hours in an environment with the relative humidity being lower than 40%, stirring, standing for 12 hours in an environment with the relative humidity being lower than 20%, and drying in a drying oven of 80-90 DEG C to form lumps; and 6) grinding the block into powder, sintering in a calcining furnace, cooling for solution treatment, sintering again, and cooling to room temperature to obtain the nano negative electrode material. The nano electrode material has the advantages of strong liquid absorption and retention capability, excellent cycle performance, improvement of the energy storage and utilization efficiency, and reduction of the environmental pollution.

Owner:广西华政新能源科技有限公司

A kind of preparation method of high specific energy negative pole sheet and lithium ion battery thereof

ActiveCN105591070BGood compatibilityReduce contact resistanceElectrode rolling/calenderingFinal product manufactureAluminium-ion batteryInternal resistance

A method for preparing a high specific energy negative pole piece and a lithium ion battery thereof, in parts by weight, comprising the following steps: 1) preparation of negative high-viscosity slurry; 2) preparation of modified nickel foam, and 3) pressing. The invention effectively reduces the contact internal resistance between the electrode active material and the current collector, improves the comprehensive performance of the electrode, and at the same time, the surface of the nickel foam is plated with a substance containing lithium ions, which can increase the transmission rate of lithium ions during charging and discharging. It has the advantages of high energy density, strong liquid absorption capacity, and strong adhesion, and is especially suitable for lithium-ion batteries used in the digital field.

Owner:JIANGSU LENENG BATTERY INC

A kind of lithium ion battery silicon carbon negative electrode material and preparation method thereof

ActiveCN104332632BAvoid reunionEvenly distributedMaterial nanotechnologyCell electrodesCyclic processLithium-ion battery

Owner:RIGHTFUL TECH

Integrated lithium ion battery and preparation method thereof

ActiveCN112086677BImprove adhesionGood compatibilityFinal product manufactureSecondary cellsChemical physicsElectrical battery

The present invention relates to the technical field of lithium-ion batteries. In order to solve the problems of interface relaxation and structural failure caused by volume changes in traditional lithium-ion batteries during the charge and discharge process, an integrated lithium-ion battery and a preparation method thereof are provided. The lithium ion battery is composed of a Janus separator and a positive and negative electrode sheet. The Janus separator is composed of a high-temperature resistant support layer and polar functional layers and non-polar functional layers loaded on both sides of the high-temperature resistant support layer. The polar functional layer is fixed to the negative electrode sheet, and the non-polar functional layer is fixed to the positive electrode sheet. In the present invention, the A-side of the Janus separator is designed as a polar surface, which is beneficial to forming a stable and uniform SEI film on the negative electrode surface; the B-side of the Janus separator is designed as a non-polar surface, which ensures the electrochemical performance of the positive electrode and is conducive to the development of the positive electrode material. Higher capacity and rate performance.

Owner:WANXIANG 123 CO LTD

A lithium ion battery janus separator

ActiveCN112086608BStrong liquid absorption and retention capacityImprove interface compatibilityCell component detailsElectrical batteryPhysical chemistry

Owner:WANXIANG 123 CO LTD

Preparation method of lithium ion battery composite negative electrode material, lithium ion battery composite negative electrode material and lithium ion battery

ActiveCN106099073BImprove charge and discharge performanceImprove cycle lifeCell electrodesSecondary cellsFiberCarbonization

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com