Anode material for lithium-ion power battery and preparation method of anode material

A negative electrode material and power battery technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of reducing the expansion rate of silicon materials, difficult to control the consistency, and poor cycle performance, so as to improve stability, absorb liquid and maintain liquid The effect of strong capacity and high gram capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

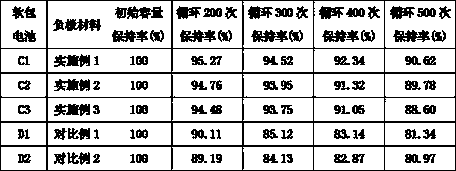

Examples

Embodiment 1

[0017] Step 1. Preparation of porous silica:

[0018] Weigh 20g of polysilicon powder with a particle size of 35 μm and put it into 200mL of hydrochloric acid with a concentration of 10% for 30 minutes, then take it out to obtain pickled nano-polysilicon powder, and then add silver carbonate with a concentration of 0.05mol / L to prepare a 500mL silver deposition solution , put the pickling nano-polysilicon powder into the deposition silver solution, deposit and soak for 2 min, then take out the polysilicon powder containing silver particles and rinse it with deionized water to obtain the polysilicon powder containing silver particles;

[0019] Prepare 500mL mixed corrosion solution with 5mol / L hydrofluoric acid and 1% hydrogen peroxide;

[0020] Put the polycrystalline silicon powder containing silver particles into the mixed etching solution. It is required that the temperature of the mixed etching solution be controlled at 80°C and the etching time be controlled at 1h. After ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com