Silicium cathode and lithium ion secondary battery containing the same, and method for preparing the same

A secondary battery, silicon anode technology, applied in secondary batteries, battery electrodes, electrode manufacturing and other directions, can solve the problems of high volume specific capacity and good cycle performance, achieve good cycle performance, small expansion rate, and ensure stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

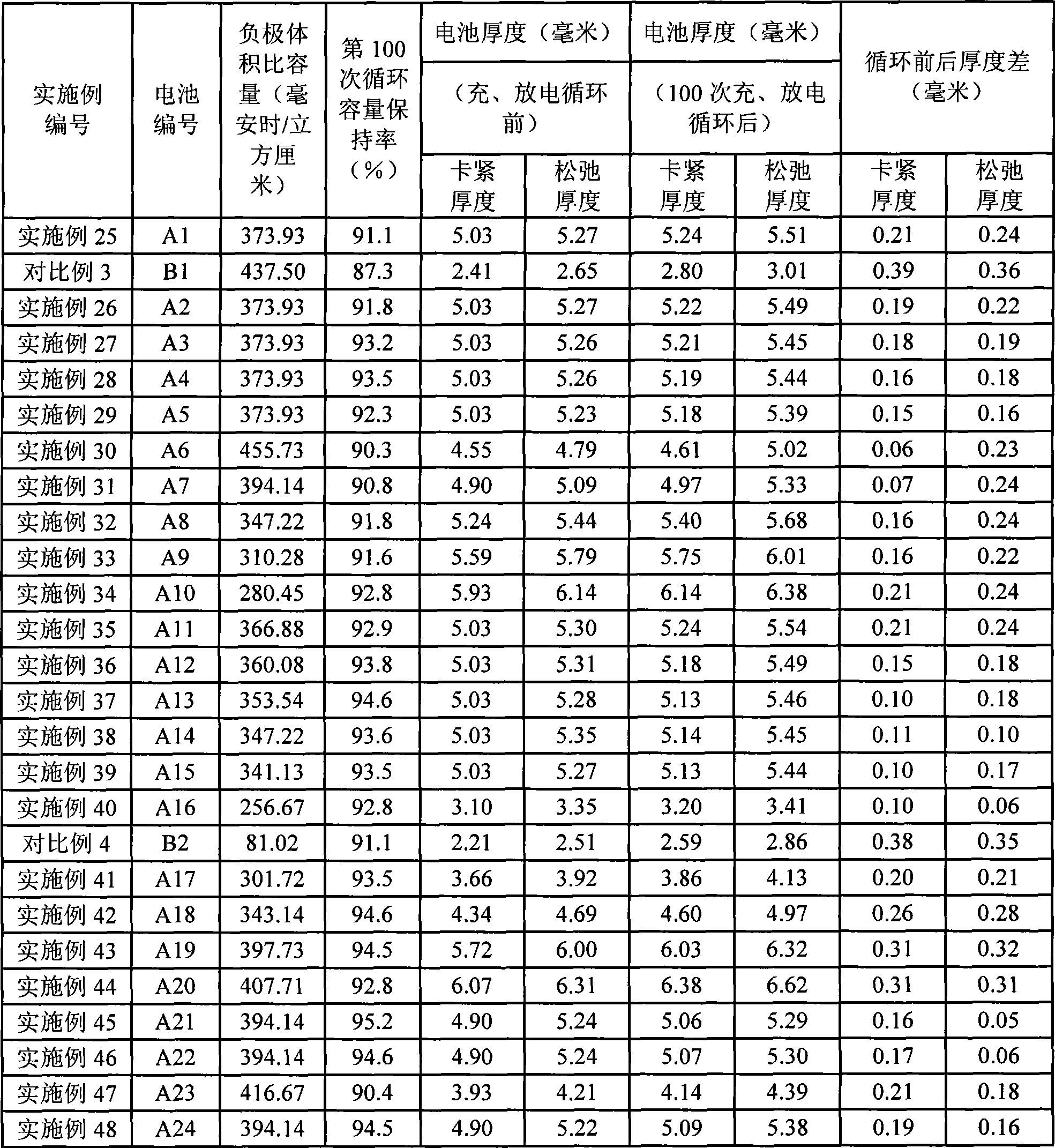

Examples

preparation example Construction

[0020] According to the preparation method of the silicon negative electrode of the present invention, the silicon negative electrode includes a conductive substrate and a material layer coated on the surface of the conductive substrate, wherein the material layer includes at least two conductive material layers and at least one silicon-based material layer , the method includes firstly attaching a conductive material layer on a conductive substrate, and then successively attaching a silicon-based material layer and a conductive material layer at intervals, so that the silicon-based material layer is located between the two conductive material layers.

[0021] The method of attaching the conductive material layer on the conductive substrate, and then attaching the silicon-based material layer and the conductive material layer sequentially at intervals can adopt various coating methods conventional in the art, such as, the method includes firstly coating the layer containing the ...

Embodiment 1

[0040] This embodiment illustrates the preparation of the lithium ion secondary battery provided by the invention

[0041] (1) Preparation of silicon negative electrode

[0042] Fully mix and stir carbon fiber, carboxymethyl cellulose, styrene-butadiene rubber and water according to the weight ratio of 10:1:1:90 to obtain a uniform slurry, and evenly coat the slurry on a 0.008mm conductive substrate copper foil On both sides, dry at 100°C to obtain a conductive material layer with a thickness of 12 microns; then silicon carbon (the weight ratio of silicon to carbon is 1:9), carboxymethyl cellulose, styrene-butadiene rubber and water are mixed according to the ratio of 100:2 : The weight ratio of 2:180 is fully mixed and stirred to obtain a uniform slurry, and the slurry is uniformly coated on the above-mentioned conductive material layer, and dried at 100°C to obtain a silicon-based material layer with a thickness of 50 microns, and finally The above-mentioned slurry containi...

Embodiment 2-5

[0051] This embodiment illustrates the preparation of the lithium ion secondary battery provided by the present invention

[0052] Prepare lithium ion secondary battery according to the method for embodiment 1, difference is, the weight ratio of carbon fiber, carboxymethyl cellulose and styrene-butadiene rubber in the conductive material layer of described silicon negative electrode is respectively 20:1:1,30: 1:1, 40:1:1, and 50:1:1. The soft-pack lithium-ion secondary batteries A2-A5 were prepared respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com