Method for preparing high-energy-density negative pole piece and lithium ion battery comprising same

A lithium-ion battery and negative pole piece technology, which is applied in the direction of electrolyte storage battery manufacturing, electrode manufacturing, battery electrodes, etc., can solve the problems of poor electrolyte compatibility, poor safety performance, and poor rate performance, and achieve good compatibility, The effect of increasing the occupancy ratio and increasing the volumetric energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

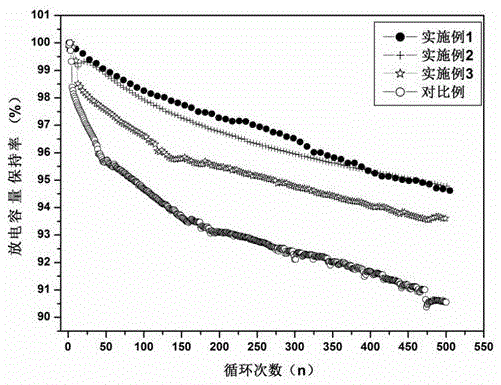

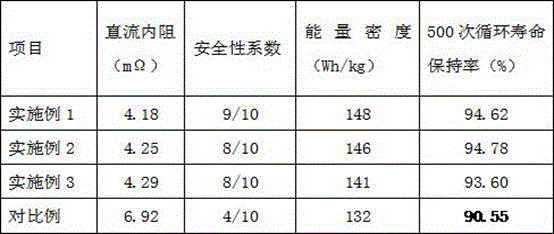

Embodiment 1

[0015] 1. Preparation of negative high-viscosity slurry: Weigh 1000g of graphite, 300g of activated carbon, and 50g of graphene and mix them uniformly in a three-dimensional mixer, then add 100g of LA133 water-based binder, and stir evenly in a high-viscosity mixer to obtain negative electrode slurry;

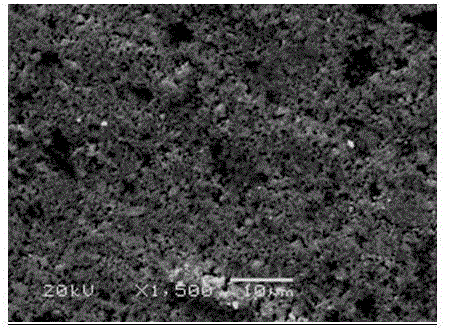

[0016] 2. Preparation of modified nickel foam: select nickel foam with a porosity of 85% as the cathode, 0.1mol / L lithium carbonate and copper chloride mixed solution (volume ratio 1:1) as the electrolyte, and a platinum electrode as the anode. Modified nickel foam is obtained by electrodepositing a layer of highly conductive and corrosion-resistant substances on the nickel foam by electrochemical method;

[0017] 3. Afterwards, the negative electrode slurry in step 1 is pressed on the modified nickel foam in step 2 by using a roller press in a static state, wherein the pressing temperature is 80°C, the pressure position is 2Mpa, and the pressing time is 5min, to prepare the neg...

Embodiment 2

[0019] 1. Preparation of negative high-viscosity slurry: Weigh 1000g of graphite, 100g of activated carbon, and 10g of graphene and mix them uniformly in a three-dimensional mixer, then add 50g of LA133 water-based binder, and stir evenly in a high-viscosity mixer to obtain negative electrode slurry;

[0020] 2. Preparation of modified nickel foam: select nickel foam with a porosity of 80% as the cathode, 0.1mol / L lithium carbonate and copper chloride mixed solution (volume ratio 1:1) as the electrolyte, and a platinum electrode as the anode. Modified nickel foam is obtained by electrodepositing a layer of highly conductive and corrosion-resistant substances on the nickel foam by electrochemical method;

[0021] 3. Afterwards, the negative electrode slurry in step 1 is pressed on the modified nickel foam in step 2 by using a roller press in a static state, wherein the pressing temperature is 50°C, the pressure position is 0.5Mpa and the pressing time is 10 minutes, and the nega...

Embodiment 3

[0023] 1. Preparation of negative high-viscosity slurry: Prepare and weigh 1000g of graphite, 500g of activated carbon, and 100g of graphene in a three-dimensional mixer, add 200g of LA133 water-based binder, and stir evenly in a high-viscosity mixer to obtain anode slurry ;

[0024] 2) Preparation of modified nickel foam: select nickel foam with a porosity of 90% as the cathode, 0.1mol / L lithium carbonate and copper chloride mixed solution (volume ratio 1:1) as the electrolyte, and a platinum electrode as the anode. Modified nickel foam is obtained by electrodepositing a layer of highly conductive and corrosion-resistant substances on the nickel foam by electrochemical method;

[0025] 3) Afterwards, the negative electrode slurry in step 1 was pressed on the modified nickel foam in step 2 by using a roller press in a static state, wherein the pressing temperature was 100°C, the pressure position was 5Mpa and the pressing time was 1min, and the negative electrode sheet was pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com