A kind of graphene conductive agent and lithium ion battery thereof

A technology of graphene and conductive agent, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as difficulty in graphene dispersion, and achieve the effects of strong electronic conductivity, increased capacity, and reduced battery internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

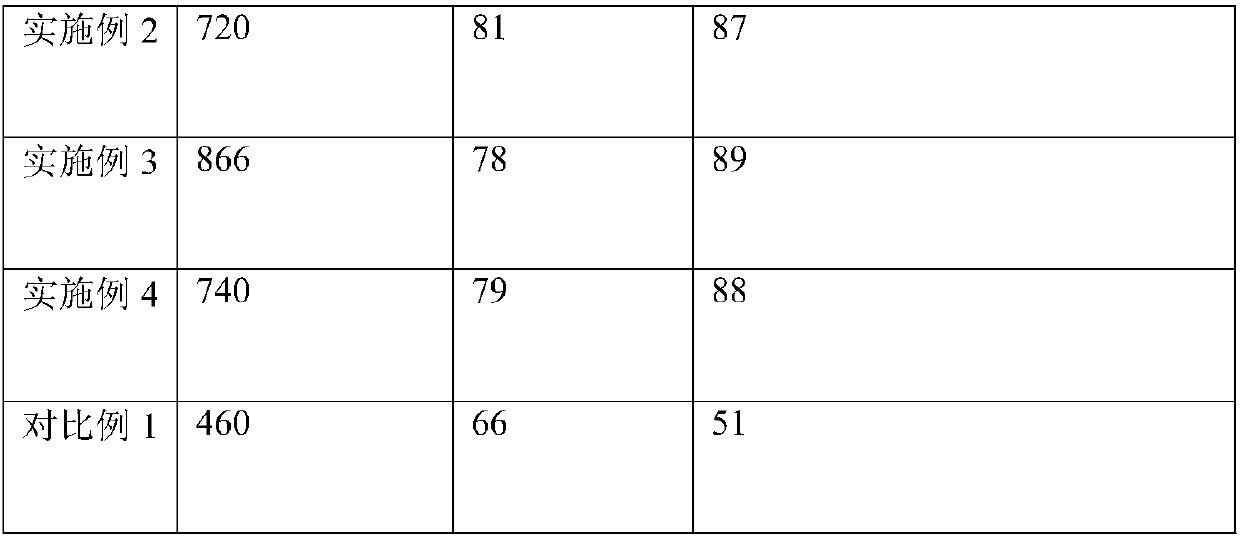

Embodiment 1

[0029] A graphene conductive agent, the mass parts of each component of the graphene conductive agent is: 120 parts of graphene, 30 parts of nonylphenol polyoxyethylene ether, 10 parts of monoethanolamine, 200 parts of solvent, 2 parts of auxiliary agent , 7 parts of conductive polymer agent, 2 parts of glass microspheres and 3 parts of iridium acetylacetonate.

[0030] The solvent is cyclohexanone.

[0031] The conductive polymer agent is polyacetylene.

[0032] The auxiliary agent is composed of the following raw materials in parts by weight: 5 parts of cellulose acetate, 10 parts of polyoxyethylene stearate, 5 parts of seaweed mud and 15 parts of silane coupling agent.

[0033] The preparation method of graphene conductive agent comprises the following steps:

[0034] 1) Add graphene to acetic acid first, raise the temperature to 90°C, stir for 3 hours, then wash and dry; mix graphene, nonylphenol polyoxyethylene ether and glass beads with half of the solvent, and ultraso...

Embodiment 2

[0038] A graphene conductive agent, the mass parts of each component of the graphene conductive agent is: 130 parts of graphene, 38 parts of nonylphenol polyoxyethylene ether, 17 parts of monoethanolamine, 260 parts of solvent, 3 parts of auxiliary agent , 8 parts of conductive polymer agent, 3 parts of glass microspheres and 5 parts of iridium acetylacetonate.

[0039] The solvent is ethanol.

[0040] The conductive polymer agent is polystyrene.

[0041] The auxiliary agent is composed of the following raw materials in parts by weight: 7 parts of cellulose acetate, 13 parts of polyoxyethylene stearate, 8 parts of seaweed mud and 18 parts of silane coupling agent.

[0042] The preparation method of graphene conductive agent comprises the following steps:

[0043] 1) Add graphene to acetic acid first, raise the temperature to 90°C, stir for 3 hours, then wash and dry; mix graphene, nonylphenol polyoxyethylene ether, glass beads and half of the solvent, and ultrasonicate at 60...

Embodiment 3

[0047] A graphene conductive agent, the mass parts of each component of the graphene conductive agent is: 150 parts of graphene, 45 parts of nonylphenol polyoxyethylene ether, 25 parts of monoethanolamine, 300 parts of solvent, 2-3 parts Additives, 10 parts of conductive polymer agent, 4 parts of glass microspheres and 8 parts of iridium acetylacetonate.

[0048] The solvent is cyclopentanone.

[0049] The conductive polymer agent is polyaniline.

[0050] The auxiliary agent is composed of the following raw materials in parts by weight: 10 parts of cellulose acetate, 15 parts of polyoxyethylene stearate, 10 parts of seaweed mud and 25 parts of silane coupling agent.

[0051] The preparation method of graphene conductive agent comprises the following steps:

[0052] 1) Add graphene to acetic acid first, raise the temperature to 90°C, stir for 3 hours, then wash and dry; mix graphene, nonylphenol polyoxyethylene ether and glass beads with half of the solvent, and ultrasonicate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com