Silicon-carbon composite negative electrode material and preparation method thereof

A technology of silicon-carbon composite and negative electrode materials, applied in nanotechnology for materials and surface science, battery electrodes, nanotechnology, etc., can solve the problems affecting the electrochemical performance, cycle performance, rate performance deviation, lithium Solve problems such as slow ion intercalation speed, achieve the effects of improving structural stability and cycle performance, improving compatibility, improving transmission rate and first-time efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

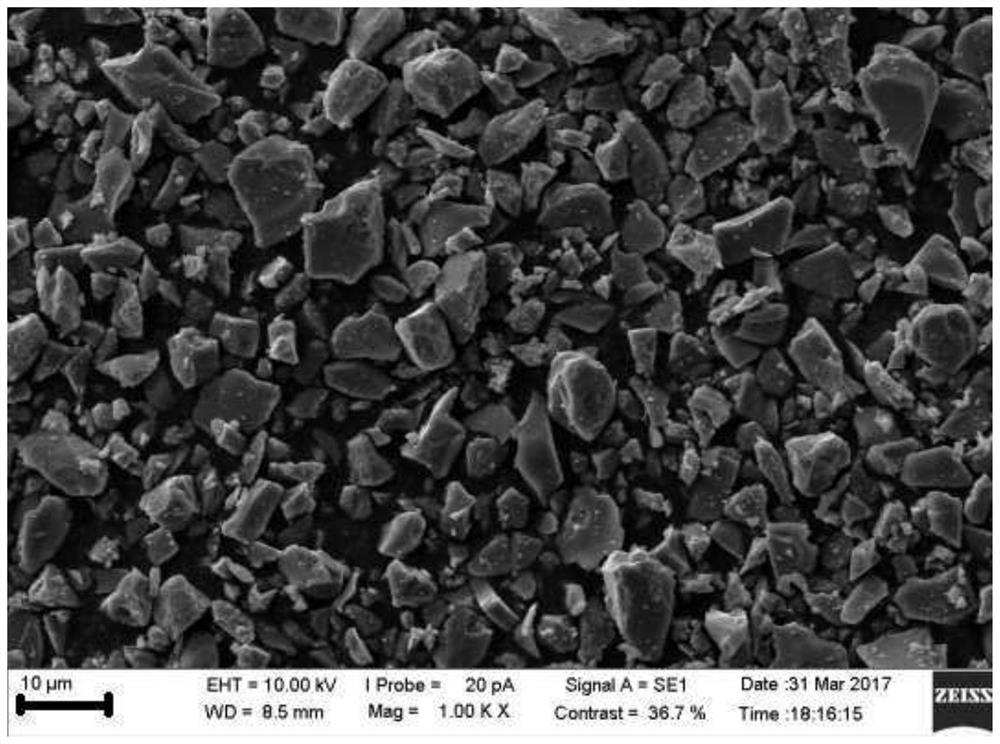

Image

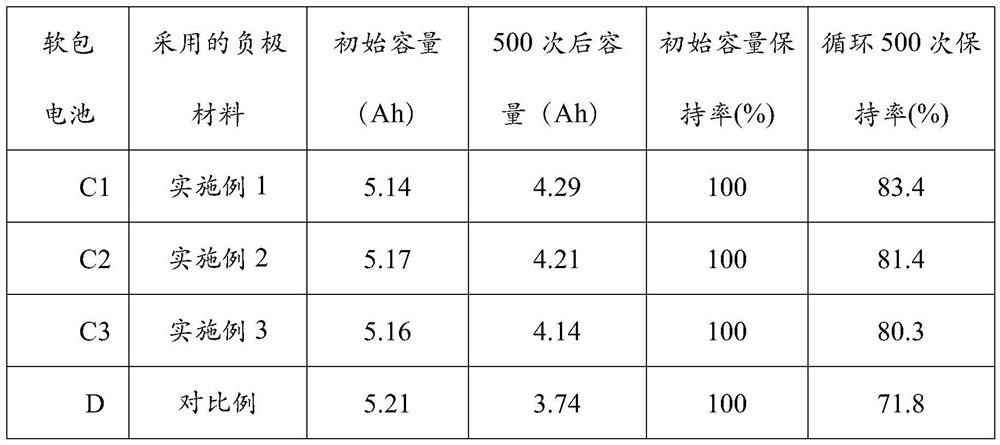

Examples

preparation example Construction

[0026] The present invention also provides a method for preparing a silicon-carbon composite negative electrode material, which includes the following steps:

[0027] S1, adding porous carbon material and additives to an organic solvent to obtain a first mixture;

[0028] S2, adding a lithium salt to the first mixture to obtain a second mixture;

[0029] S3, adding nano-silicon to the second mixture, after dispersion, adding a binder to obtain a third mixture, and spray-drying the three mixtures to obtain a silicon-carbon composite precursor; and

[0030] S4, carbonizing the silicon-carbon composite precursor to obtain a silicon-carbon composite negative electrode material.

[0031] In step S1, the organic solvent is methanol, ethanol, 1-propanol, 2-propanol, 1-butanol, 2-butanol, isobutanol, tert-butanol, 1-pentanol, 1,2 -Ethylene glycol, 1,2-propanediol, 2-methoxyethanol, 2-ethoxyethanol, acetone, 2-pentanone, 3-pentanone, 2-hexanone, 2-heptanone, 4-heptanone Ketone, diis...

Embodiment 1

[0046] 1) Add 5g of asphalt into 200mL of anhydrous carbon tetrachloride, stir and dissolve to obtain mixture A;

[0047] 2) 20g of anhydrous aluminum trichloride is placed in the reaction kettle, add 50mL of anhydrous carbon tetrachloride (the total consumption of anhydrous carbon tetrachloride is 250mL), after the anhydrous aluminum trichloride is dissolved, Then add the mixture A obtained in step 1), heat to 50°C under stirring conditions, and carry out the Friedel-Crafts reaction under reflux. After reacting for 24 hours, add 300mL of ethanol as a reaction terminator to terminate the reaction, and the mixed system obtained from the reaction is successively filtered, washed, After filtering and drying, the porous carbon material B is obtained.

[0048] 3) Weigh 20g of porous carbon-based material B and 3g of sodium fluoride and add it to 300mL of isobutanol, and disperse evenly;

[0049] 4) Add 3g of lithium metaaluminate and disperse evenly to obtain porous carbon-based m...

Embodiment 2

[0052] The preparation of the porous carbon material B is the same as that of Example 1, and will not be repeated here.

[0053] 1) Weigh 10g of porous carbon-based material B and 1g of potassium fluoride, add it to 100mL of diethyl ether organic solvent, and disperse evenly;

[0054] 2) Add 1g of lithium zirconate and disperse evenly to obtain porous carbon-based mixed liquid C';

[0055] 3) Then weigh 1g of nano-silica powder (particle size 100nm) and add it to the porous carbon-based mixed liquid C', then add 0.5g of ethylene-tetrafluoroethylene copolymer, and after high-speed dispersion and uniform dispersion, it is prepared by spray drying technology The precursor of the spherical silicon-carbon composite negative electrode material is then carbonized at 850° C. for 6 hours, pulverized and classified to obtain the silicon-carbon composite negative electrode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com