Patents

Literature

62 results about "Lithium zirconate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

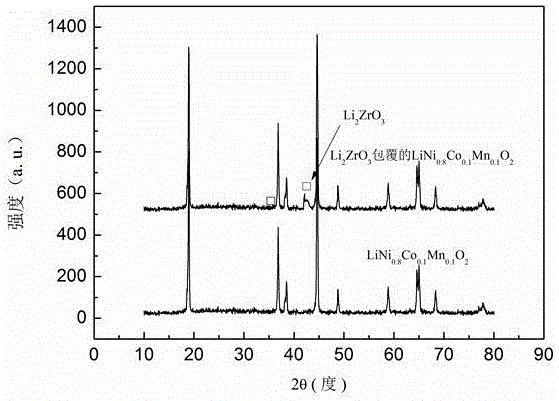

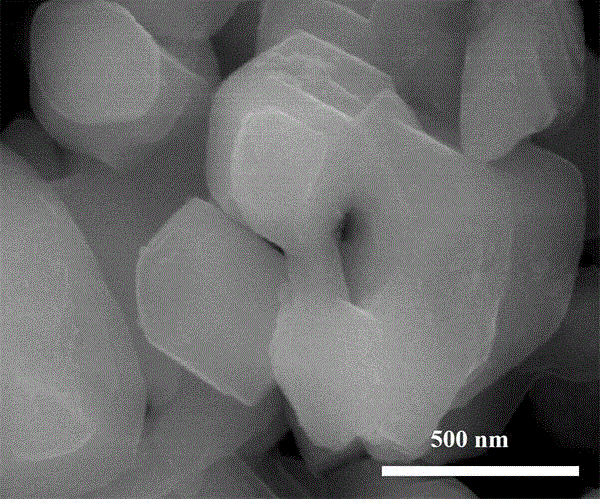

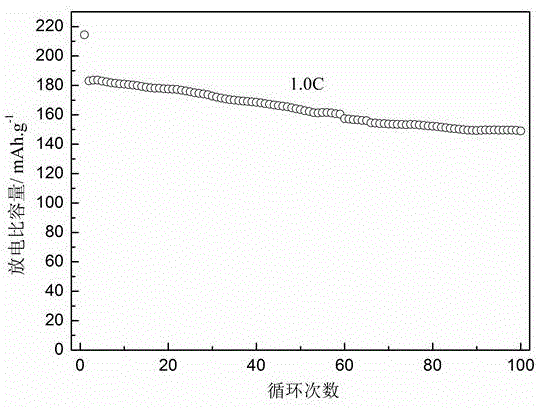

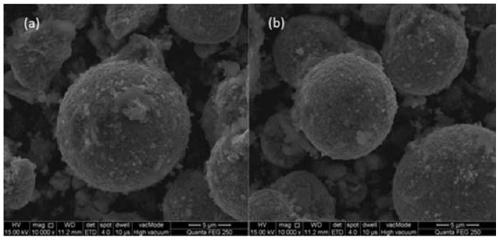

Cobalt-nickel lithium manganate composite positive electrode material with surface wrapped by lithium zirconate and preparation method

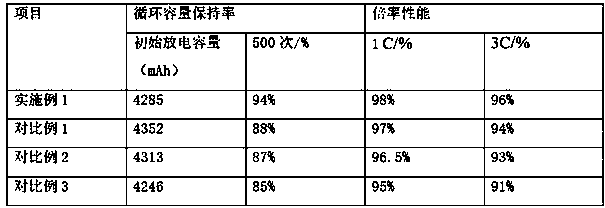

InactiveCN105140492ASimple preparation processImprove cycle performanceSecondary cellsPositive electrodesElectrical batteryManganate

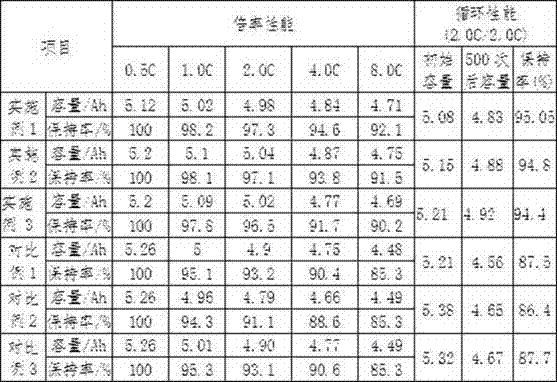

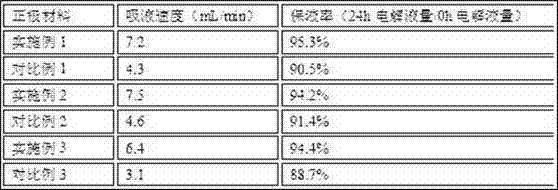

The invention discloses a cobalt-nickel lithium manganate composite positive electrode material with the surface wrapped by lithium zirconate and a preparation method. The preparation method includes the steps of firstly, preparing LiNi0.8Co0.1Mn0.1O2 through a wet chemistry method with soluble salt of nickel, cobalt and manganese and excessive lithium salt as raw materials; secondly, mixing LiNi0.8Co0.1Mn0.1O2 with zirconium nitrate, and preparing the LiNi0.8Co0.1Mn0.1O2 composite positive electrode material with the surface wrapped by Li2ZrO3 through a rheological phase method. The LiNi0.8Co0.1Mn0.1O2 composite positive electrode material with the surface wrapped by Li2ZrO3 has the advantages of being excellent in circulation performance, good in rate capability, simple and convenient in preparation process, low in cost, and the like, and is beneficial for being applied and popularized on a large scale as the positive electrode material of lithium ion batteries.

Owner:GUANGDONG TEAMGIANT NEW ENERGY TECH CORP

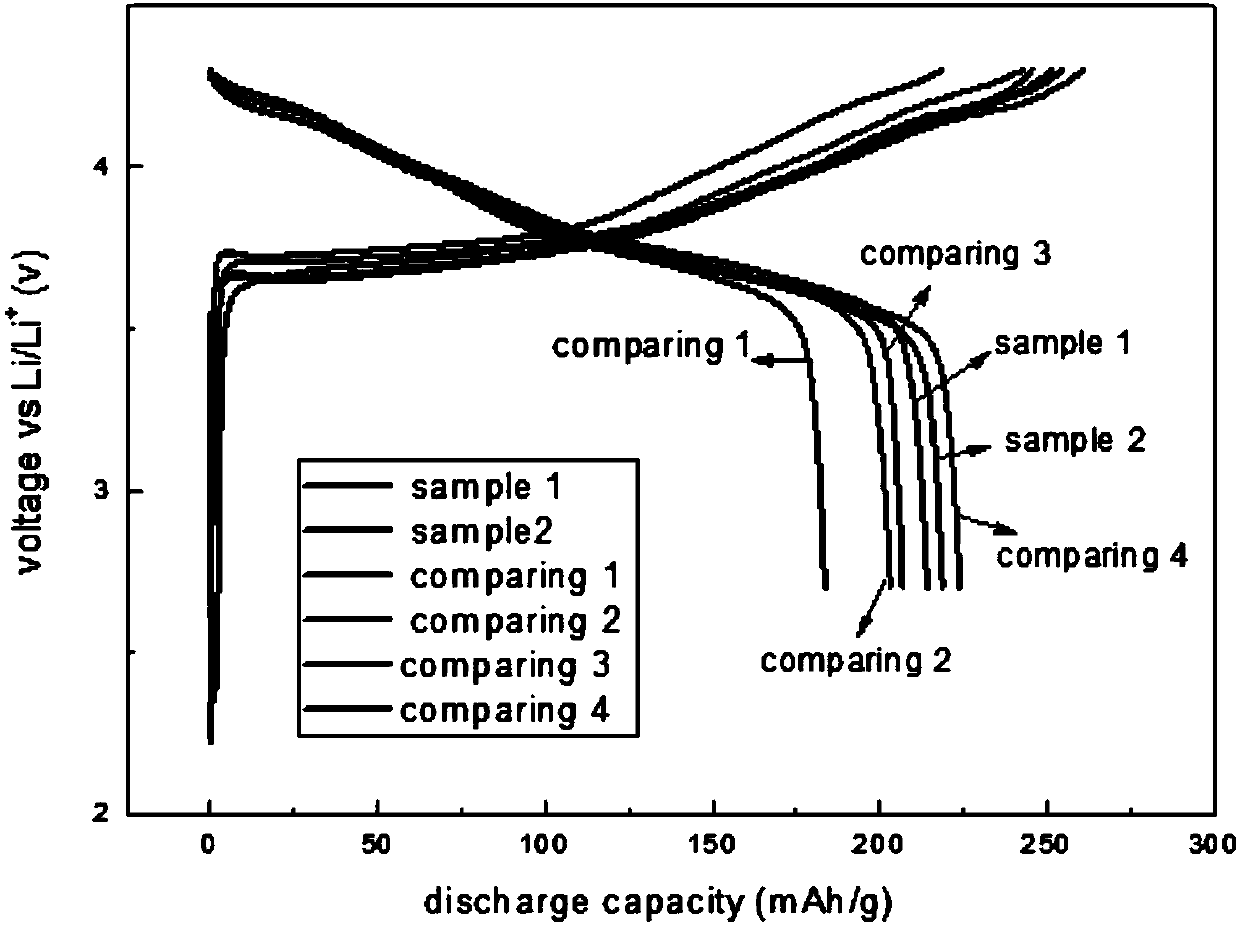

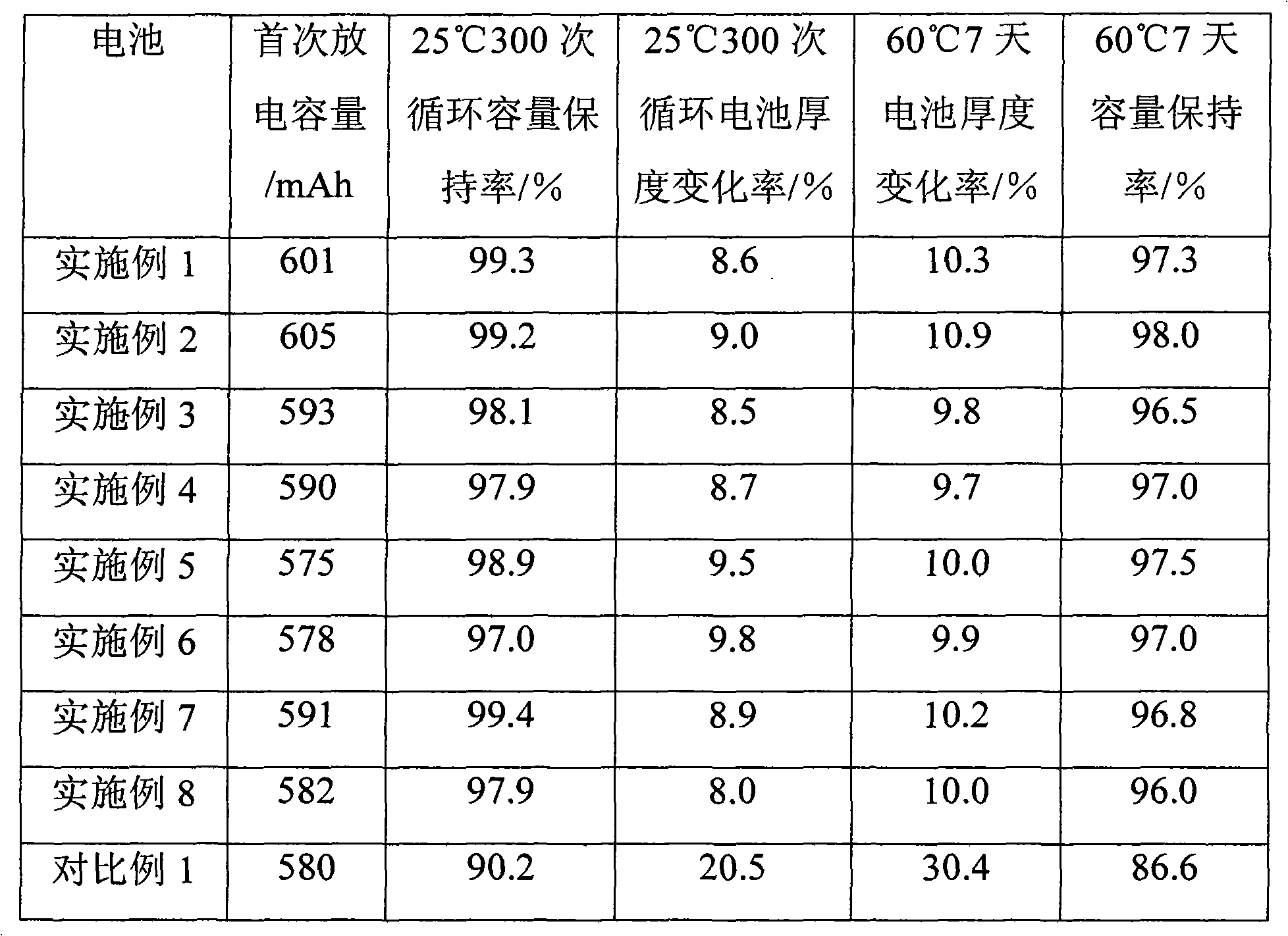

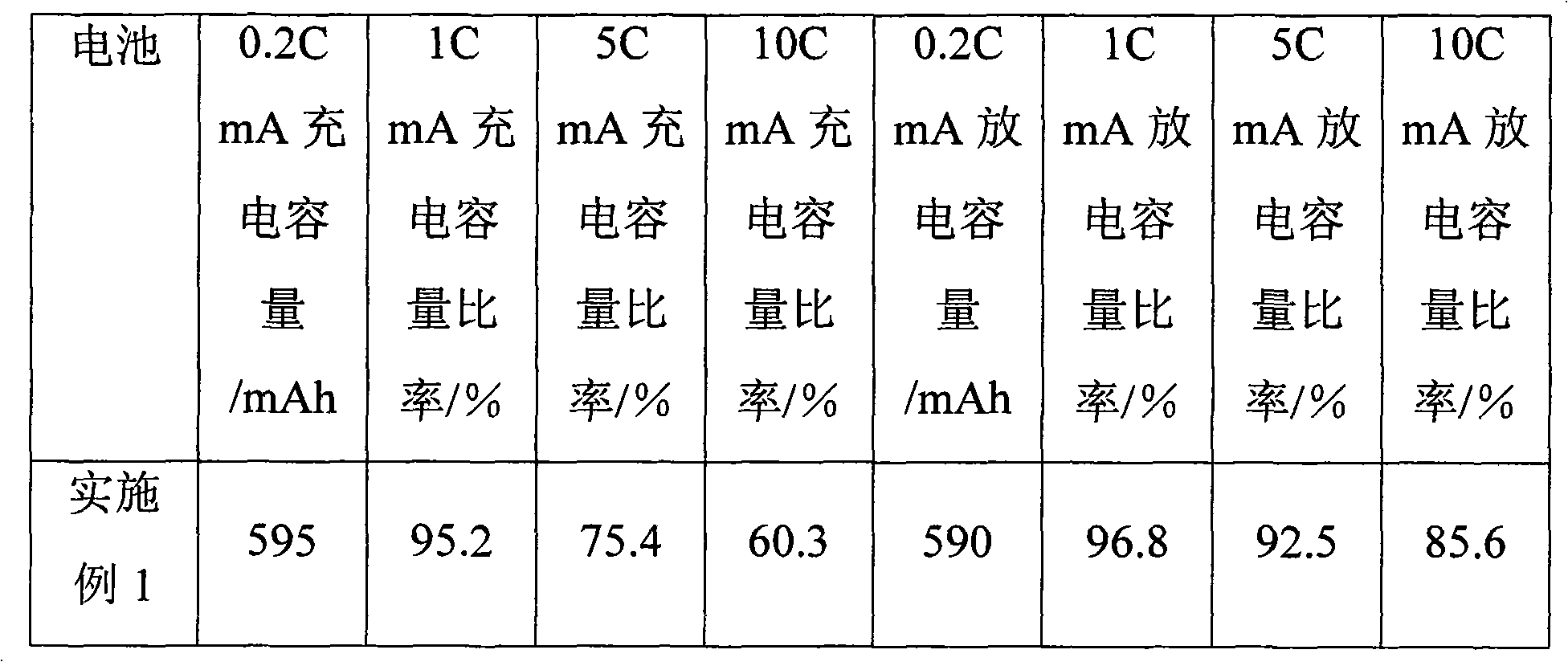

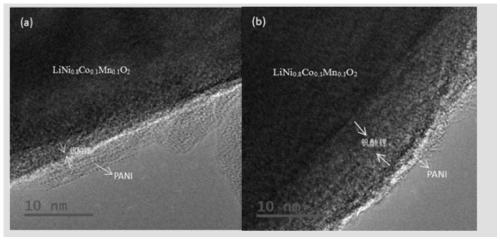

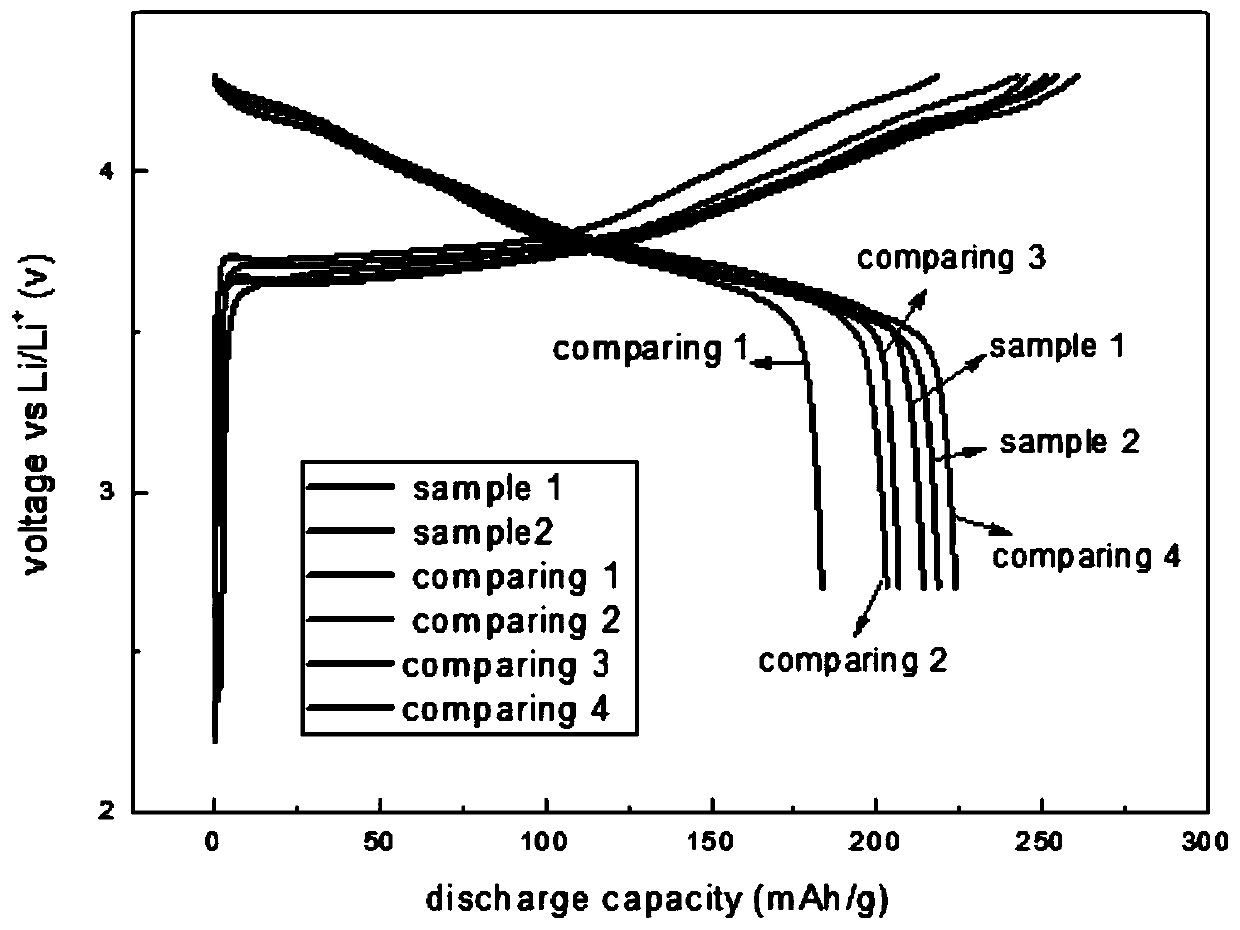

Preparation method of fast ion conductor and conducting polymer dual-modified ternary cathode material for lithium-ion battery

ActiveCN107706390AImprove cycle performanceExcellent rate performanceCell electrodesSecondary cellsElectrical conductorConductive polymer

The invention discloses a preparation method of a fast ion conductor and conducting polymer dual-modified ternary cathode material for a lithium-ion battery. According to the material, a ternary cathode material for a lithium-ion battery is taken as a core, a fast ion conductor is taken as a first coating layer, a conducting polymer is taken as a second coating layer and the fast ion conductor isany one of lithium vanadate, lithium metaaluminate and lithium zirconate. The fast ion conductor and the ternary cathode material are firstly mixed evenly and ground; the ternary cathode material is coated with the fast ion conductor by using a high-temperature solid state method; the conducting polymer and the ternary cathode material coated with the fast ion conductor are mixed evenly and milled; and the ternary cathode material coated with the fast ion conductor is coated with the conducting polymer to finally obtain the fast ion conductor and conducting polymer dual-modified ternary cathode material for the lithium-ion battery. The fast ion conductor is combined with the conducting polymer to modify the ternary cathode material, so that the ternary cathode material has excellent cycleperformance and good rate capability.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Titanium composite, preparation method thereof and application thereof

ActiveCN101901905AImprove performanceEasy to preparePigmenting treatmentAlkali titanatesLithium chlorideHigh rate

Owner:BYD CO LTD

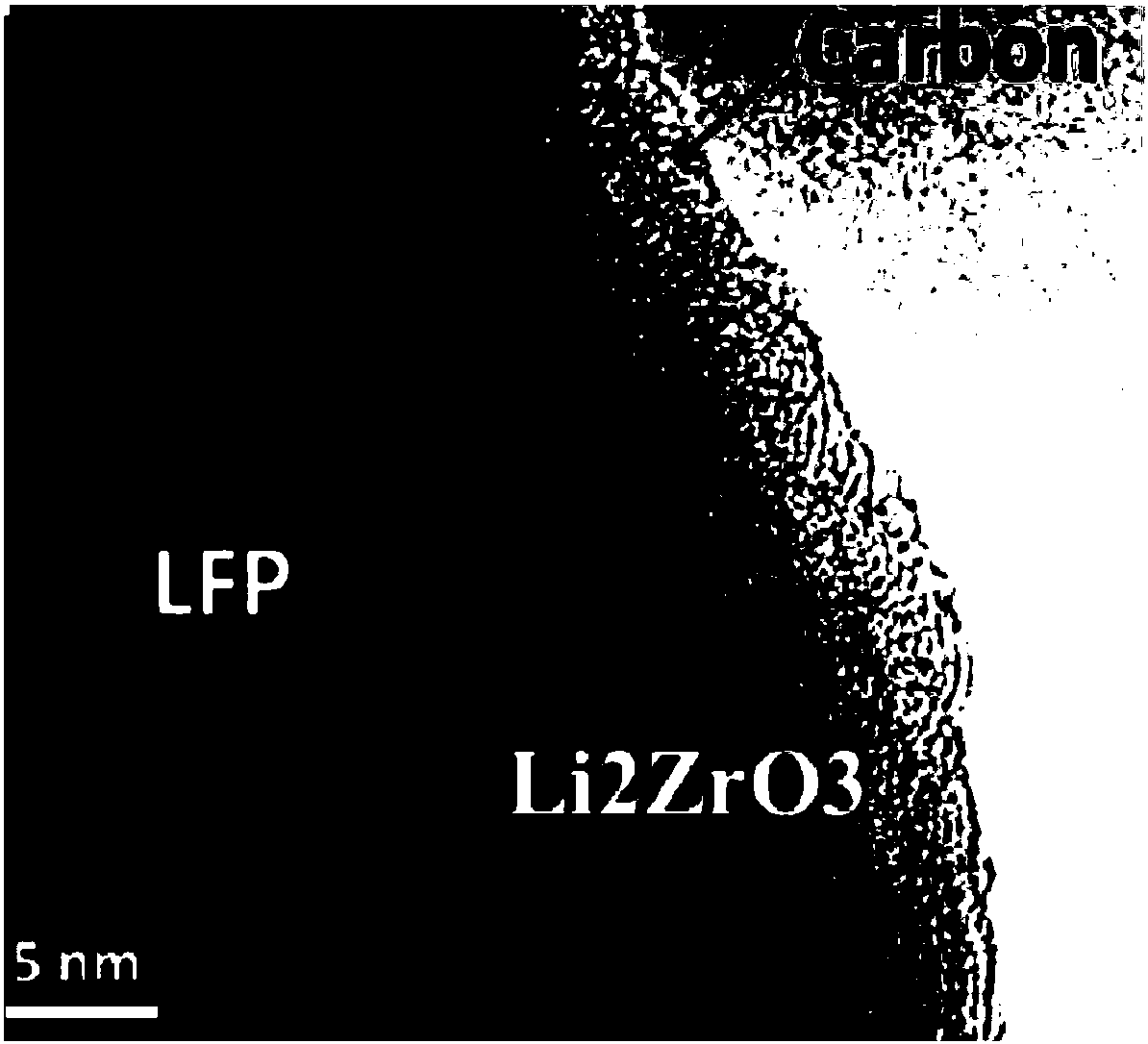

Nanometer lithium zirconate modified lithium iron phosphate composite material and preparation method thereof

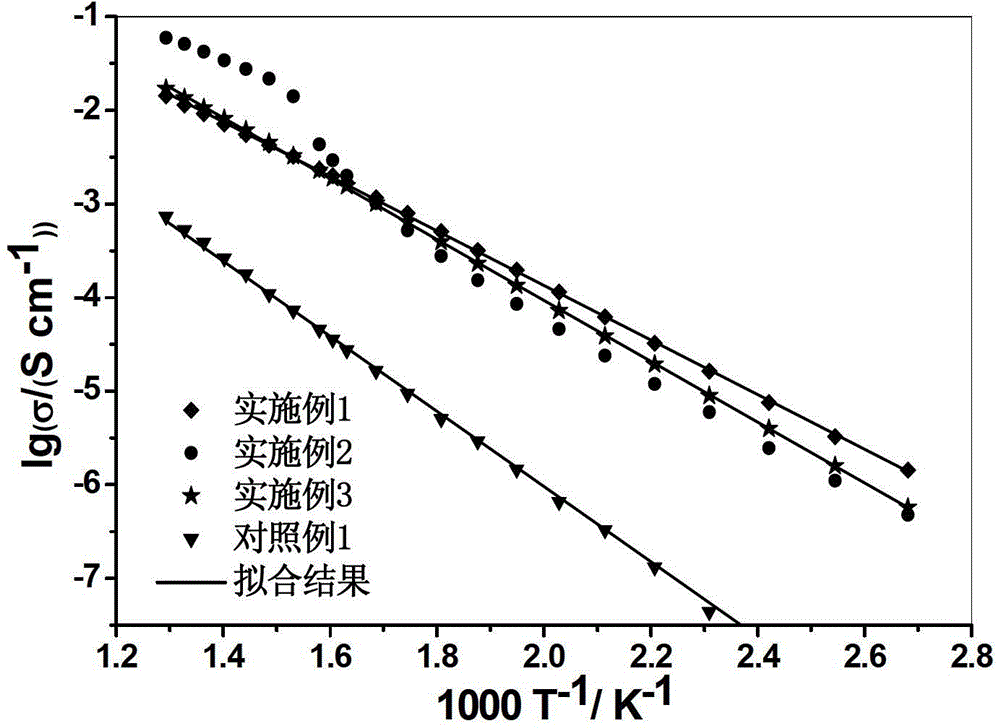

InactiveCN103400982AImprove ionic conductivityImprove cycle stabilityCell electrodesPhosphorus compoundsStructural formulaLithium zirconate

The invention discloses a nanometer lithium zirconate modified lithium iron phosphate composite material and a preparation method thereof. The structural formula of the composite material is LixFeyPO4.zLi2ZrO3 / C, and the composite material comprises lithium iron phosphate, nanometer lithium zirconate and organic matter pyrolysis carbon. The composite material is characterized by being prepared by virtue of any one of the following methods: (1) preparing a precursor mixed liquor containing nanometer lithium zirconate through a hydrothermal reaction, drying, adding an organic carbon source, mixing, and calcining at a high temperature in an inert atmosphere; (2) preparing the precursor mixed liquor through the hydrothermal reaction, drying, calcining at a low temperature in the inert atmosphere, then adding the organic carbon source and nanometer lithium zirconate, mixing, and calcining at a high temperature in the inert atmosphere. The preparation method is simple; the prepared lithium iron phosphate composite material has the advantages of high conductivity, excellent multiplying power and low temperature performance, good cycle performance and the like, and can be widely applied to field of power batteries.

Owner:YANTAI ZHUONENG BATTERY MATERIAL

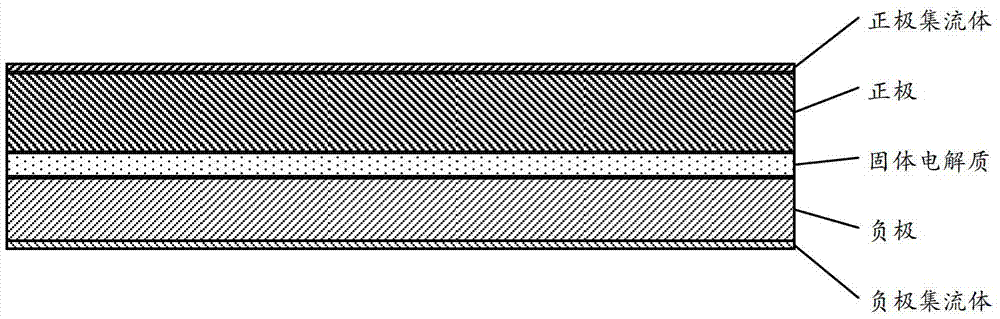

All-solid lithium-ion battery and manufacturing method thereof

The invention discloses an all-solid lithium-ion battery and a manufacturing method thereof. The all-solid lithium-ion battery comprises a positive pole material, a positive pole current collector, a solid electrolyte material, a negative pole material, a negative pole current collector and a stainless steel housing, wherein the solid electrolyte material is at least one selected from lanthanum lithium zirconate, strontium-doped lanthanum lithium zirconate, germanium-doped lanthanum lithium zirconate, aluminum-doped lanthanum lithium zirconate or silicon-doped lanthanum lithium zirconate. The manufacturing method of the battery is simple, and low in cost and energy consumption, and has a great application prospect in the future lithium-ion battery technology and market.

Owner:TSINGHUA UNIV

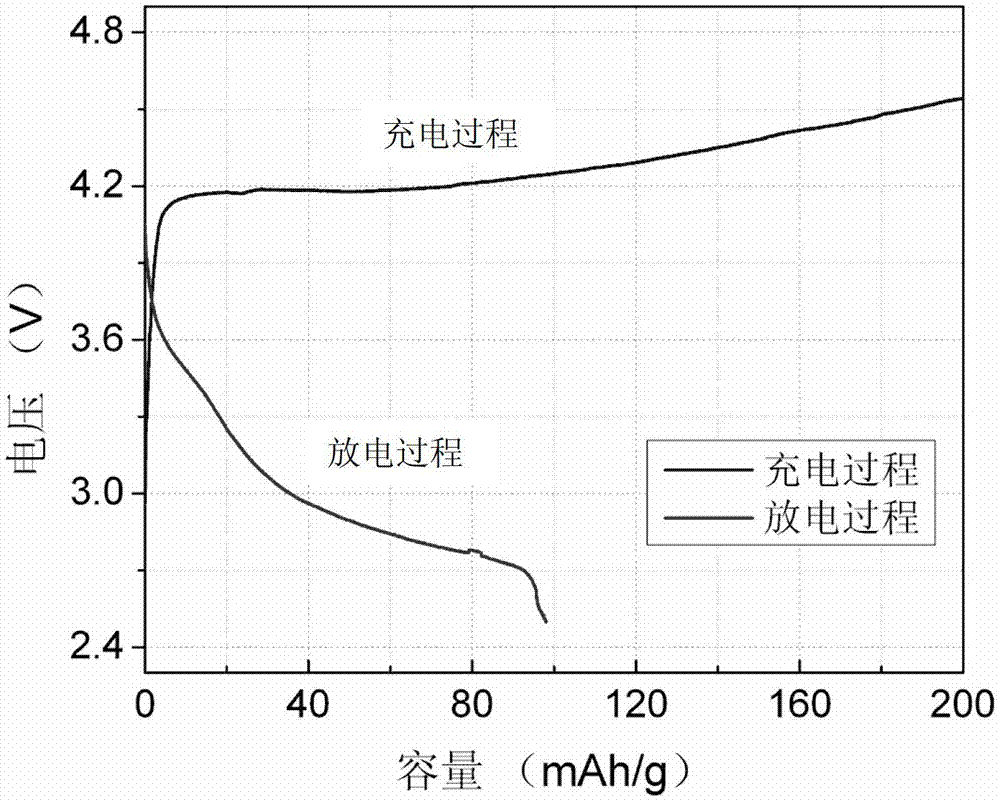

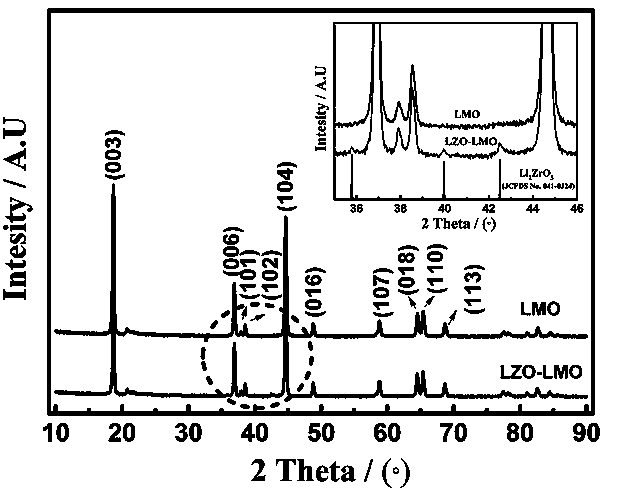

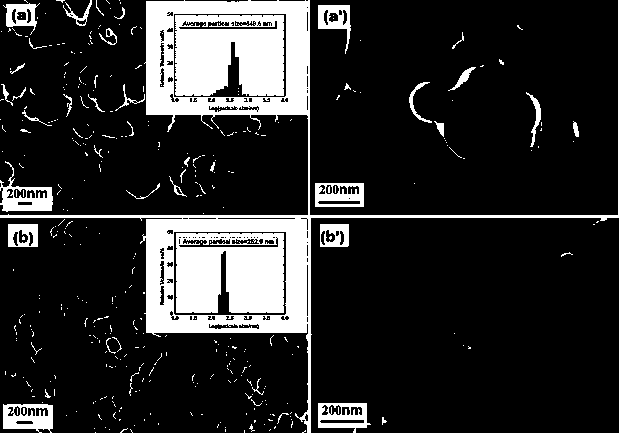

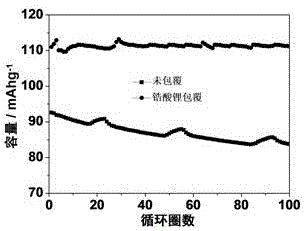

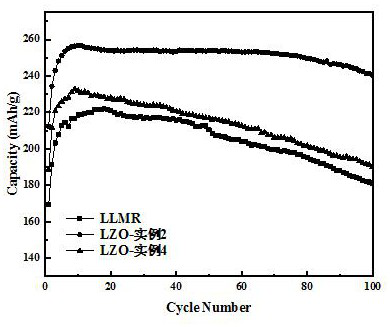

Lithium zirconate-cladded lithium-rich positive material for lithium ion battery and preparation method thereof

InactiveCN103996838AHigh rate charge and dischargeIncrease capacityCell electrodesSecondary cellsPhysical chemistryLithium zirconate

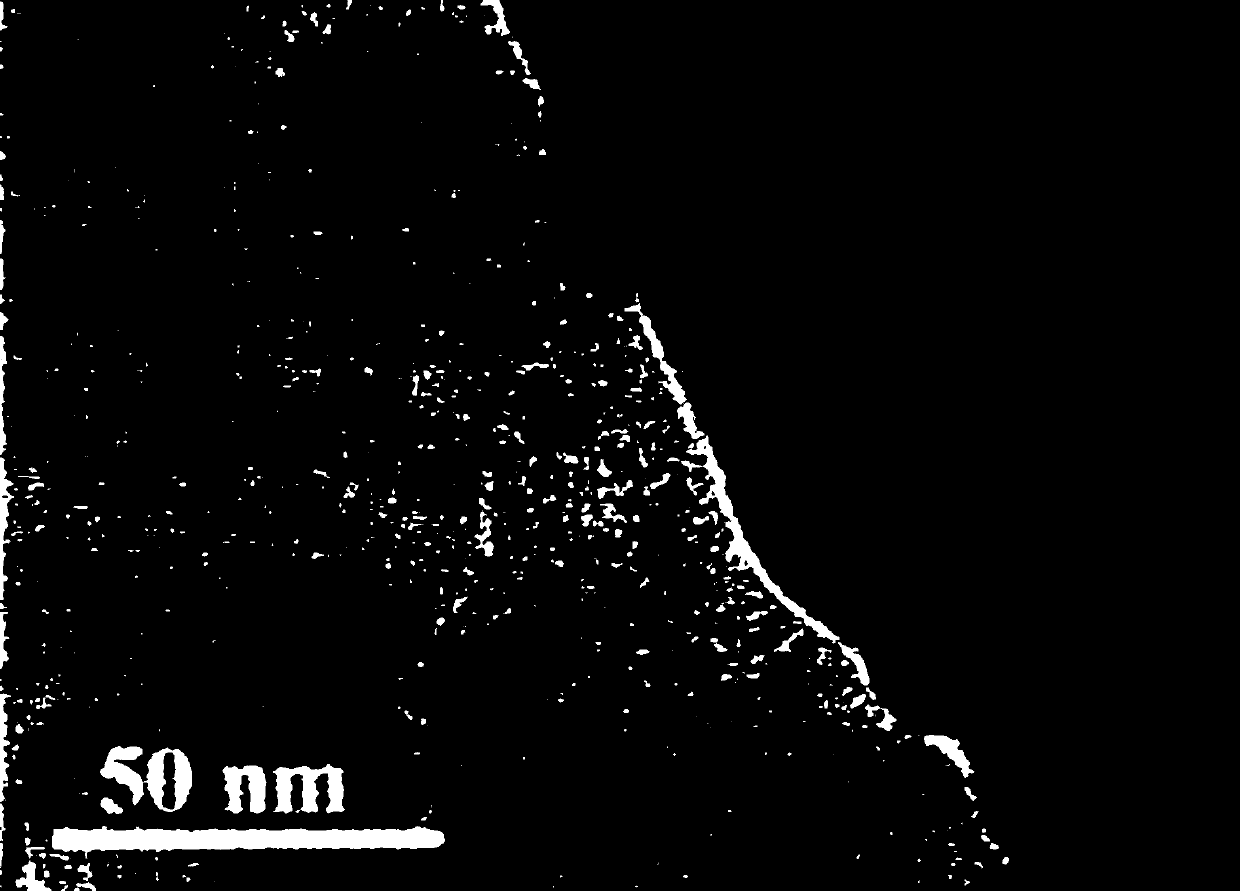

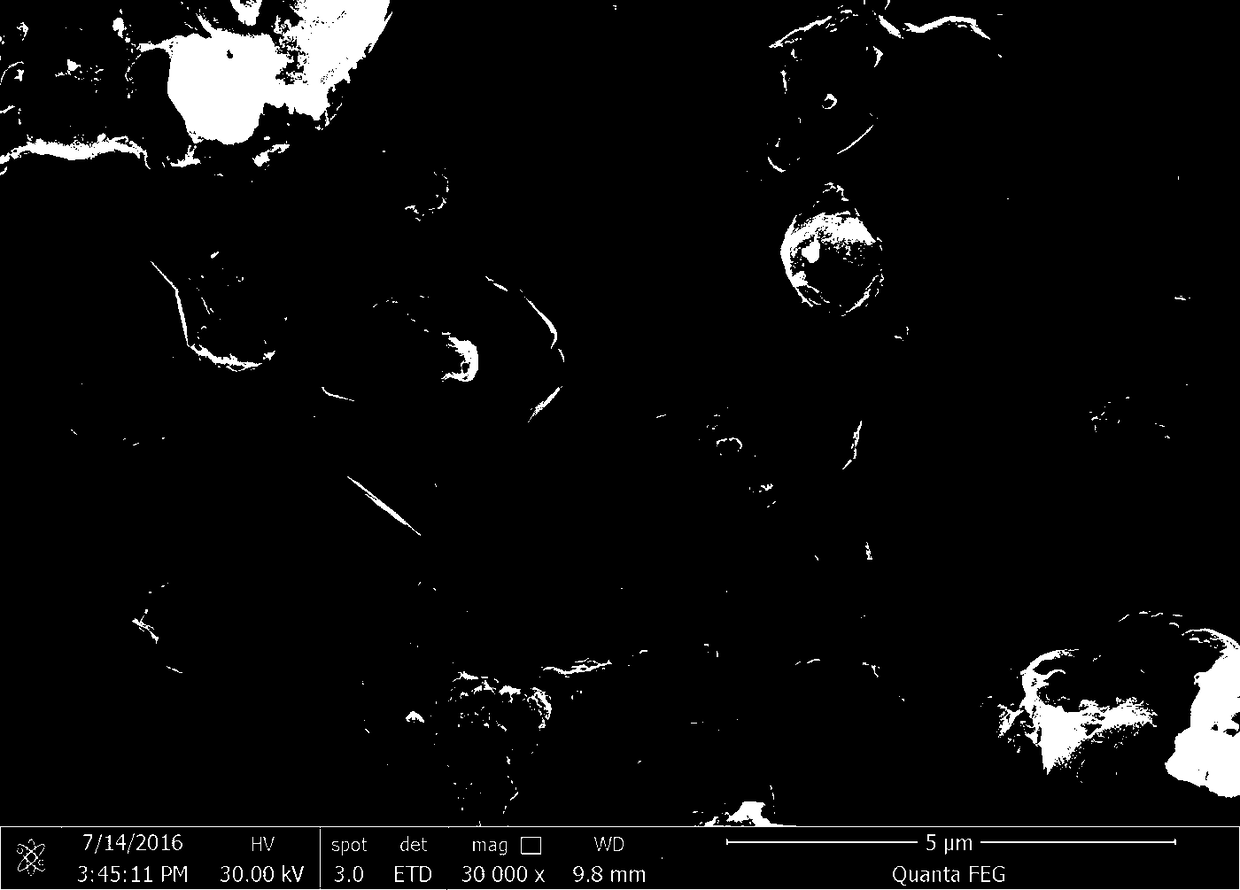

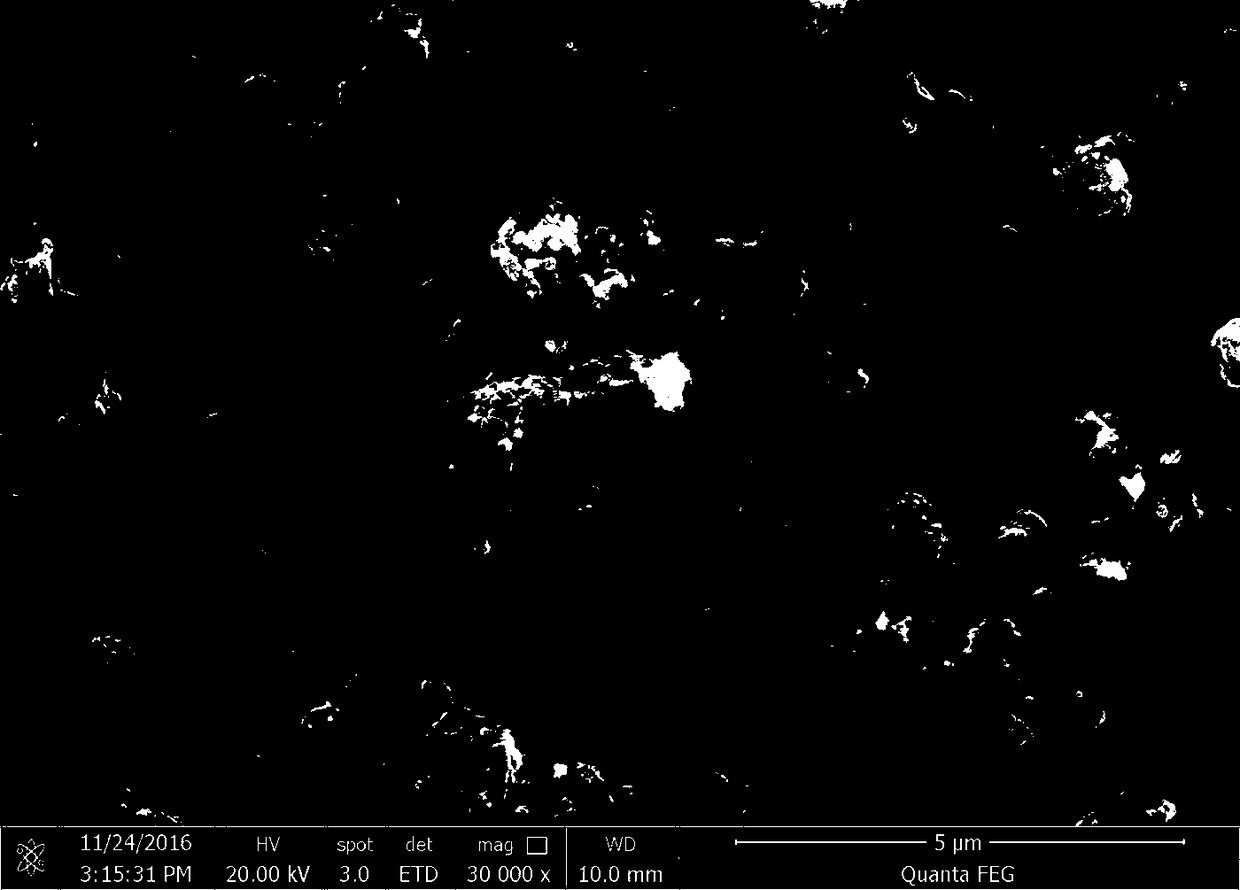

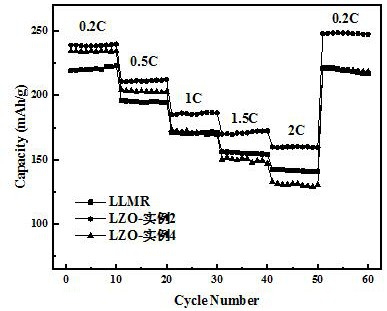

The invention discloses a lithium zirconate-cladded lithium-rich positive material for a lithium ion battery and a preparation method thereof. According to the invention, 0.4Li2MnO3.0.6LiNil / 3Co1 / 3Mn1 / 3O2 is used as a core of a composite particle, and Li2ZrO3 is used as a shell of the composite particle of the lithium-rich positive material. Thus, an LMO-LZO core-shell structure of the composite particle with the particle size being 50nm-300nm is formed, and an LMO-LZO nano-composite material is formed. LZO accounts for 1wt%-10wt% of weight of the LMO-LZO lithium-rich positive material. By the utilization of the lithium-rich positive material of a battery, higher charge-and-discharge rate, higher specific capacity, better cycle performance and lower battery production cost can be realized. The preparation method has advantages of simple preparation technology and good repeatability, provides a high-capacity long-life lithium-rich positive material for manufacturing and application of a high-rate lithium ion battery, and is suitable for industrial production.

Owner:SHANGHAI UNIV

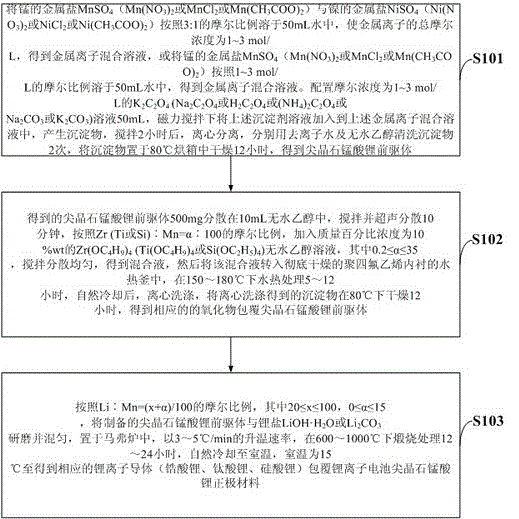

Preparation method of lithium ion conductor coated spinel lithium manganate positive electrode material

InactiveCN106299339AImproved magnification performanceImprove cycle stabilityCell electrodesHigh rateManganate

The invention discloses a preparation method of a lithium ion conductor coated spinel lithium manganate positive electrode material, which adopts two methods: coating through a hydrothermal method and coating through a direct stirring method. A lithium ion conductor (lithium zirconate, lithium titanate and lithium silicate) coating layer and a main-phase spinel lithium manganate positive electrode material are formed simultaneously in a lithiation reaction process so as to improve the bonding strength between the coating layer and the main-phase spinel lithium manganate positive electrode material, the thickness of the coating layer is uniform, the rate capability and cycling stability of the lithium ion battery are greatly improved, and particularly, the long-range cycling stability and the high rate capability are improved. According to the preparation method, the rate capability, cycling stability and high-temperature property of the spinel lithium manganate positive electrode material can be improved; the synthesis process is simple, the production efficiency is high, and the positive electrode material is suitable for large-scale production; raw materials needed by reactants are easily available and have no toxicity, and the cost is low; no special protection is needed in the production process; reaction conditions can be controlled easily; and the obtained product has the advantages of high yield, good result repeatability and the like.

Owner:UNIVERSITY OF CHINESE ACADEMY OF SCIENCES

Positive active substance for non-aqueous electrolyte secondary battery and manufacturing method of positive active substance

InactiveCN103296260ASufficient charge and discharge cycle characteristicsImprove thermal stabilityCell electrodesPhysical chemistryEngineering

The invention discloses a positive active substance for a non-aqueous electrolyte secondary battery. The positive active substance is formed by lithium-containing composite oxide powder with the chemical formula of LipNxMyOzFa, a surface layer of the powder is coated with at least one of lithium zirconate, lithium silicate and lithium titanate, N in the chemical formula is at least one element of Ni, Co and Mn, and M in the chemical formula is at least one element of transitional metal elements except for the element N, Al and alkali earth metal elements. Compared with the prior art, the positive active substance for the non-aqueous electrolyte secondary battery has an adequate charging and discharging cycling property in the real application process, and the charging-discharging cycling property or the heat stability in heating after charging is good. The positive active substance is high in practicability and wide in application range.

Owner:NANTONG RESHINE NEW MATERIAL

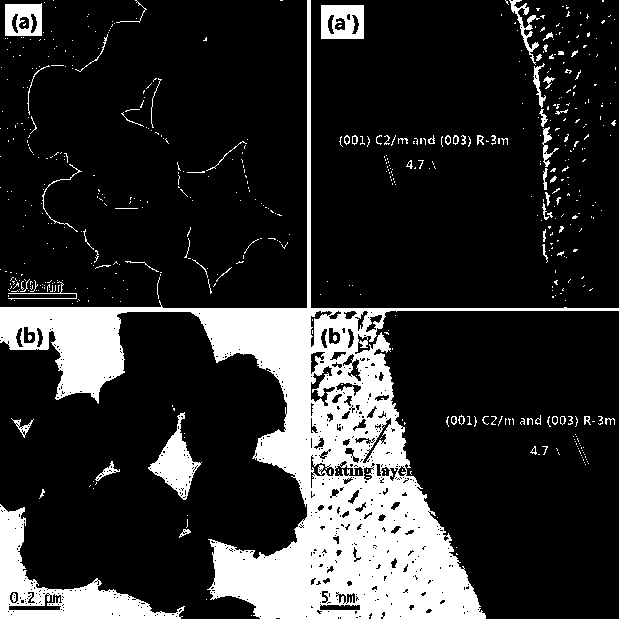

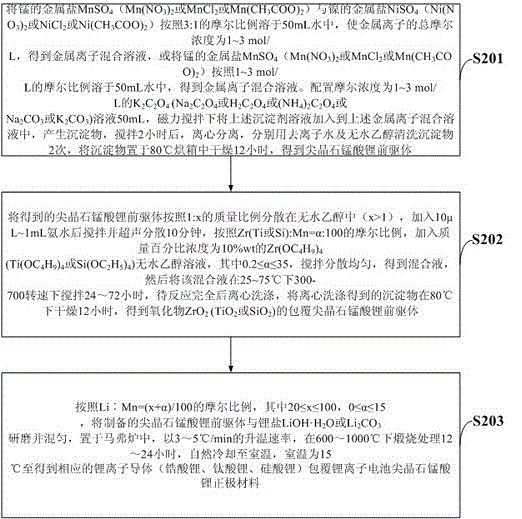

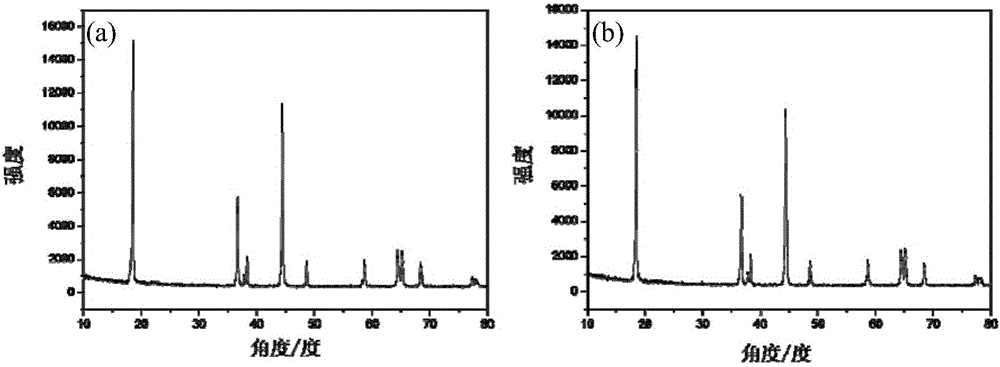

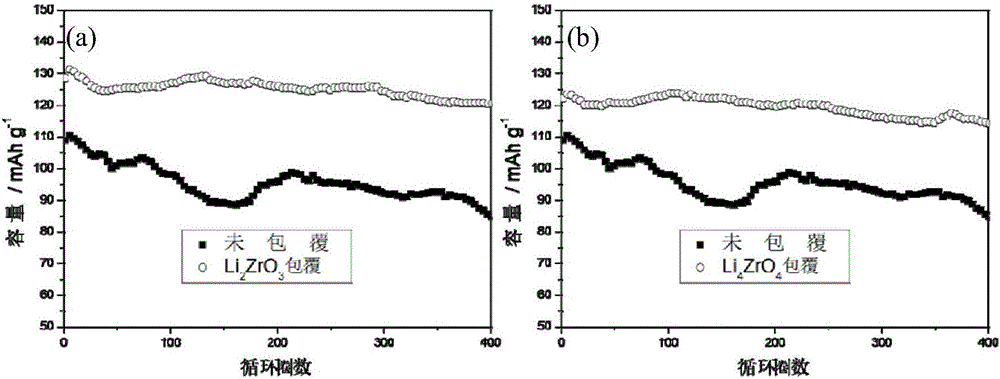

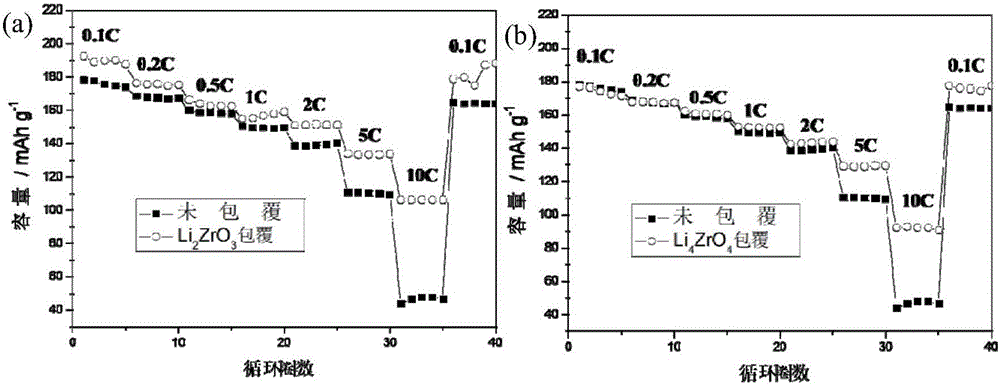

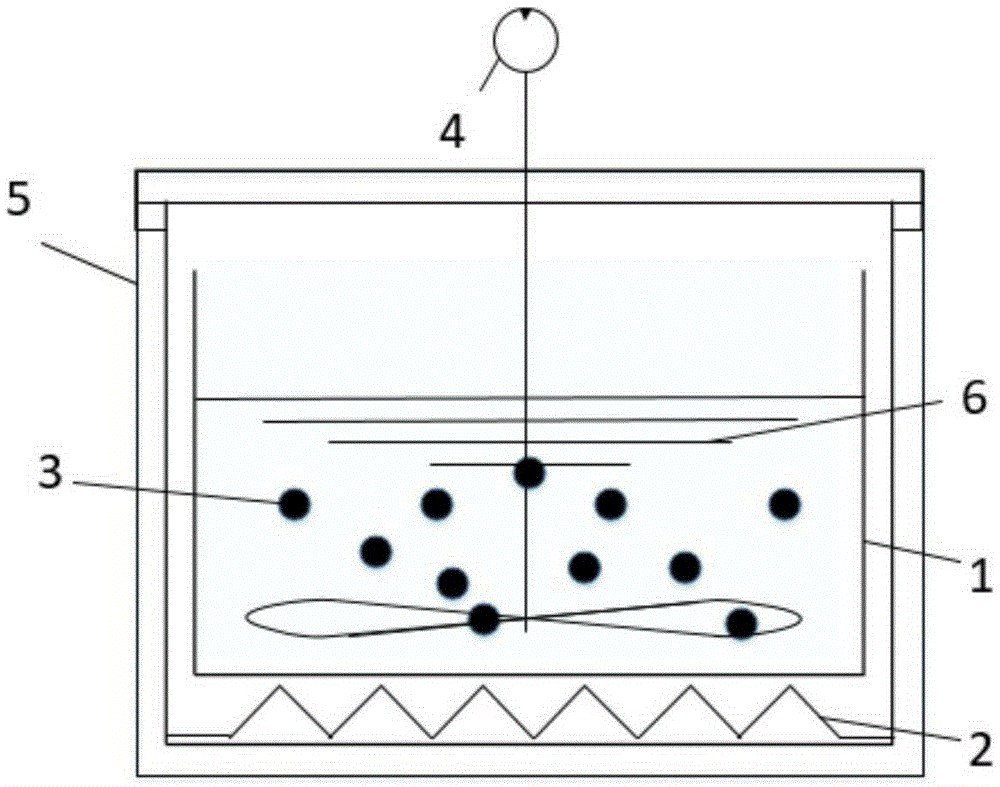

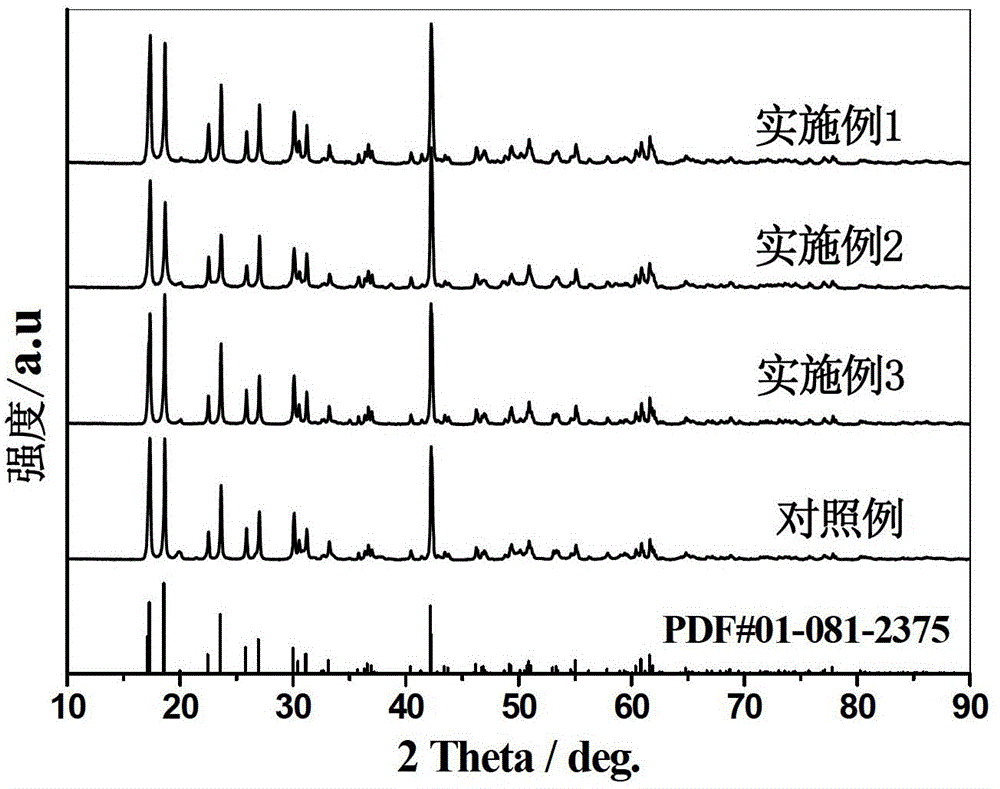

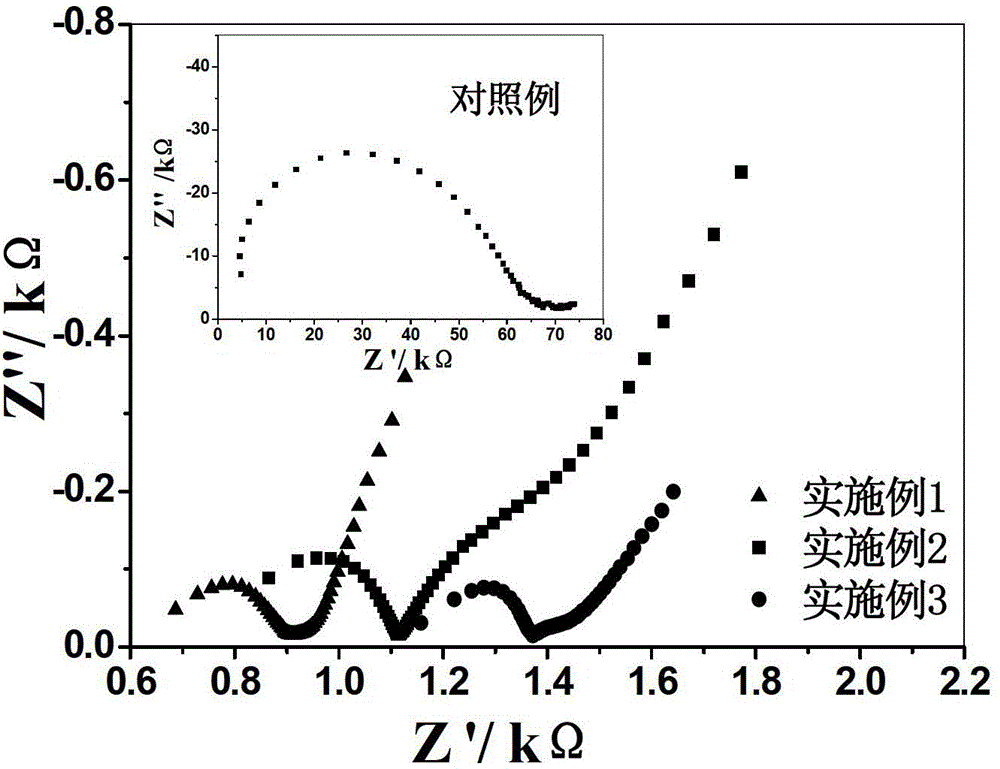

Preparation method of lithium zirconate-coated ternary layered cathode material of lithium ion battery

InactiveCN105047864AIncrease productionThe results are reproducibleCell electrodesSecondary cellsNew energyRoom temperature

The invention relates to a preparation method of a lithium zirconate-coated ternary layered cathode material of a lithium ion battery, and belongs to the technical field of new energy sources. Coating is realized by a hydrothermal method or a room-temperature stirring method; and the method specifically comprises the following three steps: preparation of an oxalate precursor, preparation of a ZrO2-coated oxalate precursor and preparation of a lithium zirconate-coated ternary layered cathode material. According to the method, the bonding strength between a coating layer Li2ZrO3 or Li4ZrO4 and a ternary cathode material of a main phase can be improved; the coating layer is uniform in thickness; and the rate capability and the cycling stability of the lithium ion battery, especially the rate capability are significantly improved. The method provided by the invention is simple in synthetic process, high in production efficiency and suitable for large-scale production, and has the advantages that the materials required by a reactant are available, nontoxic and low in cost; special protection is not needed in the production process; the reaction condition is easy to control; and the obtained product has the advantages of high yield, good result repeatability and the like.

Owner:UNIVERSITY OF CHINESE ACADEMY OF SCIENCES

Low-electric conductivity liquid-state tritium proliferation agent for fusion and preparation method thereof

ActiveCN105405471AReduce conductivityControl induced electromotive forceNuclear energy generationThermonuclear fusion reactorLithium oxideLiquid metal

The invention discloses low-electric conductivity liquid-state tritium proliferation agent for fusion and a preparation method thereof. The proliferation agent is the mixture of a liquid-state base body and dispersion particles. The conductivity is 1-106s / m. The proliferation agent comprises: by volume percentage, liquid-state proliferation agent base body 60%-99.99% and dispersion particles 0.01%-40%. The dispersion particles are prepared from silicon carbide, or aluminium oxide, or beryllia, or silica, or erbium oxide, or lithium silicate, or positive lithium silicate, or lithium titanate, or lithium oxide, or lithium aluminate, or lithium zirconate, or two of them, or more of them. The preparation method comprises steps of dispersing roasted dispersion particles into liquid state metal in a high temperature furnace with atmosphere protection via mechanical stirring. According to the invention, on the premise that performance of tritium proliferation is well ensured, electric conductivity is effectively reduced and heat conductivity is increased, thereby remarkably reducing magnetohydrodynamics pressure drop (MHD effects) of liquid-state tritium proliferation agent in high magnetic field.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

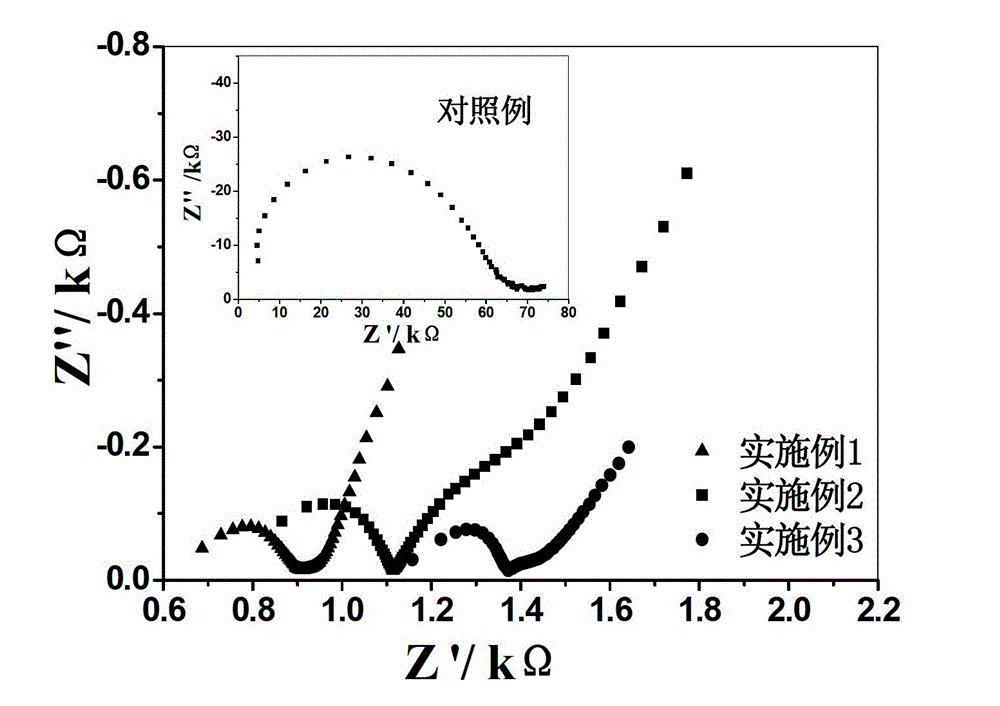

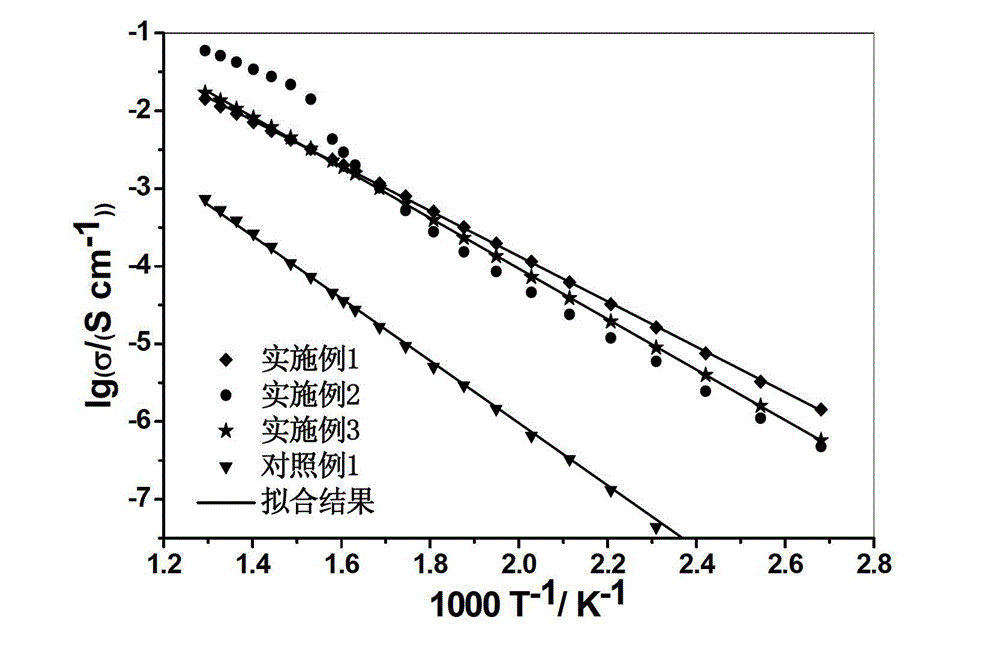

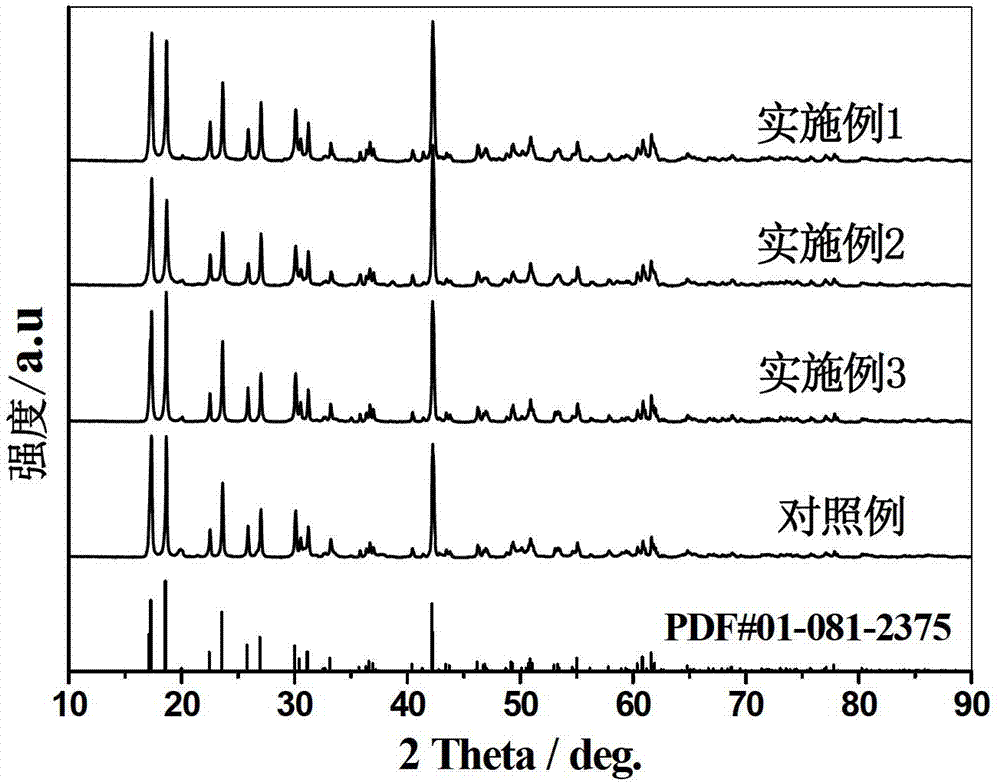

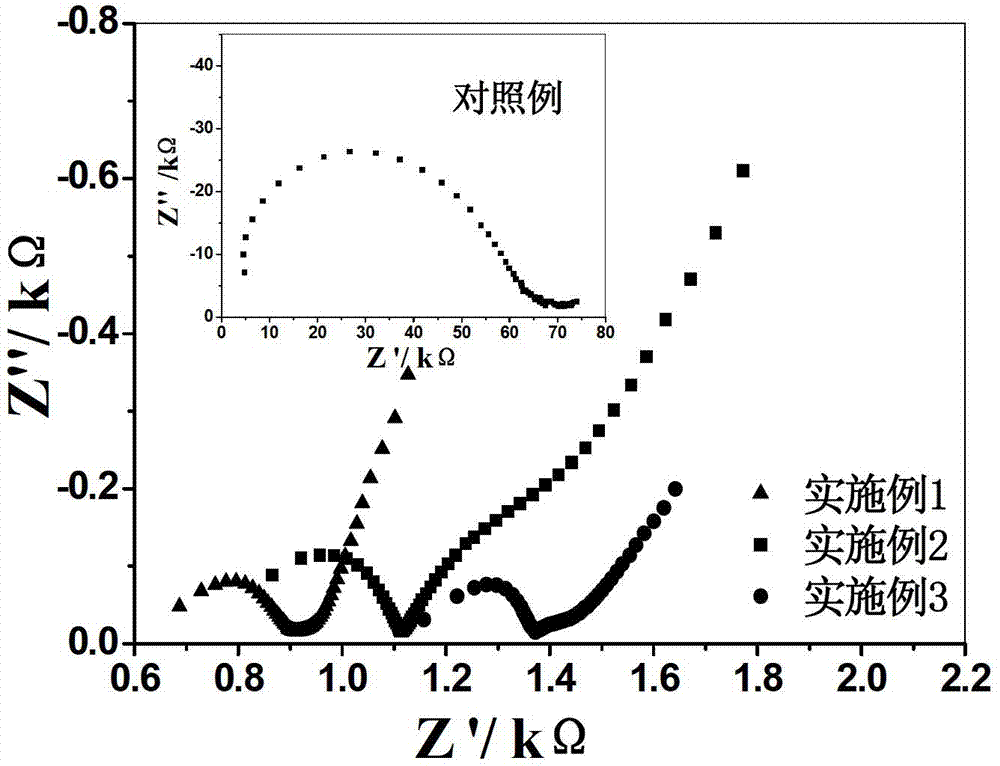

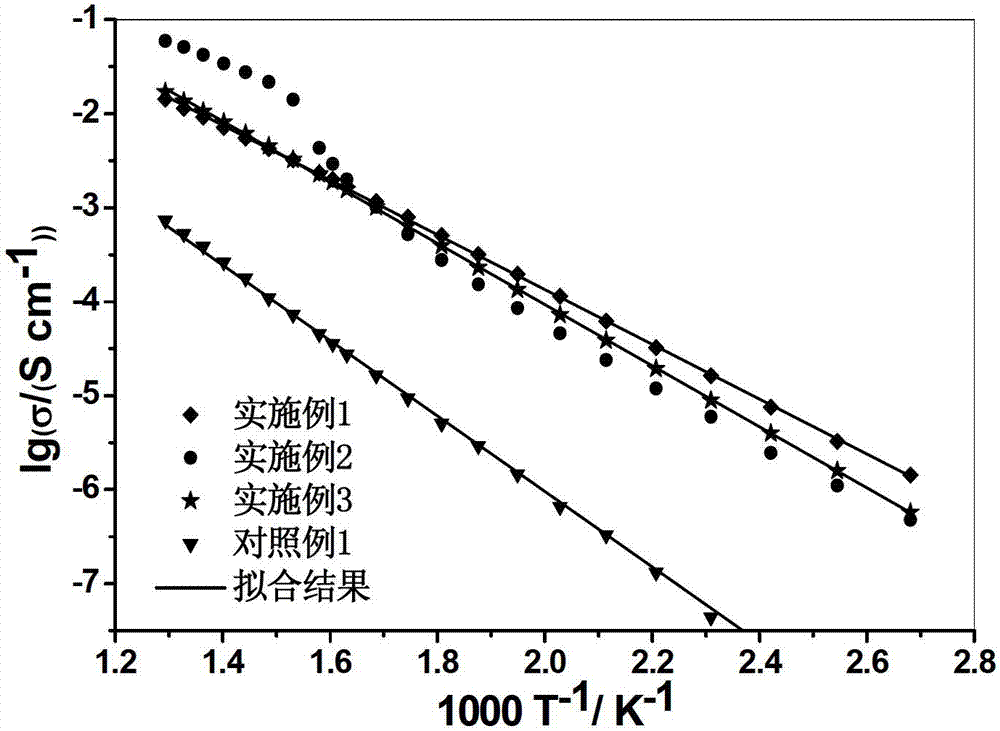

Solid electrolyte and preparation method thereof

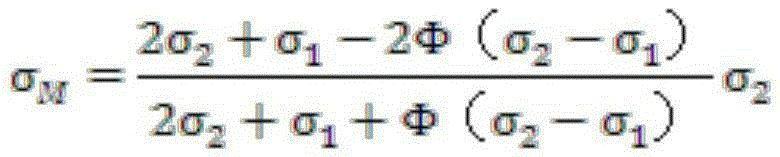

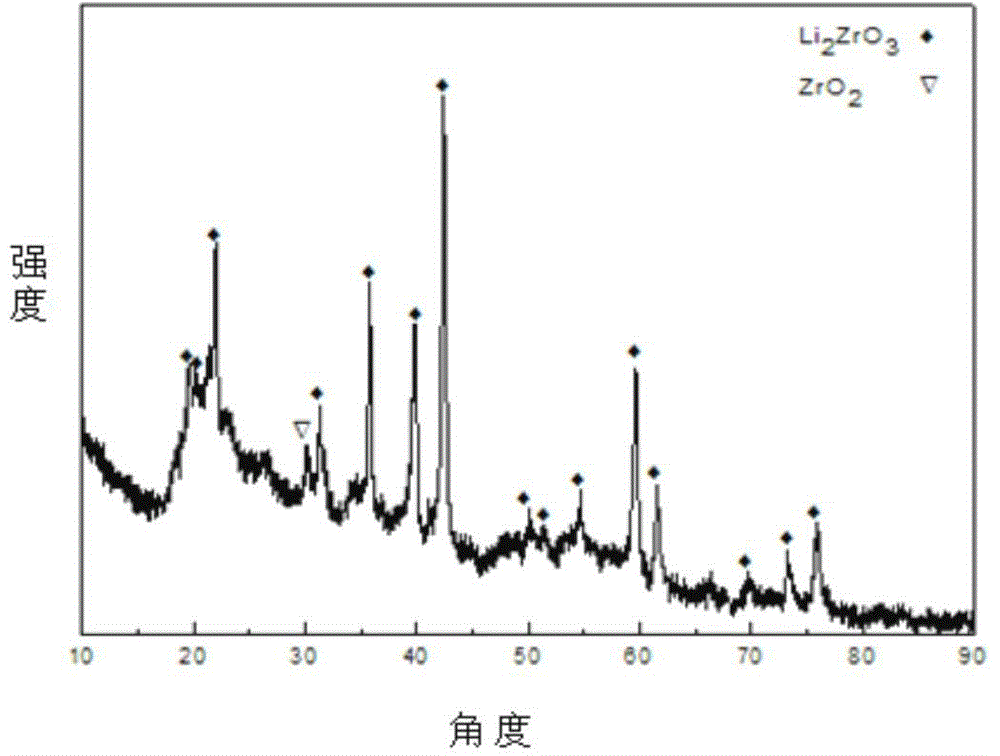

InactiveCN102916221AIncrease productionSimple processZirconium compoundsSecondary cellsLithium zirconateLithium-ion battery

The invention relates to a solid electrolyte and a preparation method thereof. The solid electrolyte is formed by monoclinic phase lithium zirconate crystal admixed with M element, and the monoclinic phase lithium zirconate crystal admixed with the M element is that M ions are admixed to lithium niobate crystal and the composition of the chemical formula is Li6+yZr2-xMxO7, wherein X is equal to 0.01-0.4, and M is a positive divalent metal element or a positive trivalent metal element; when M is the positive divalent metal element positive, and Y is equal to 2x; and when the M is the positive trivalent metal element, and y is equal to x. The method comprises steps for preparing the monoclinic phase lithium zirconate crystal admixed with the M element by adopting a high-temperature solid-phase method and dry-pressure sintering, and has the advantages of high production efficiency and high yield and purity; the safety problem of a lithium-ion battery is solved thoroughly because of no use of any liquid organic solvent; and the prepared solid electrolyte has high ionic conductivity, excellent electrochemical stability, and a very wide application prospect.

Owner:HYB BATTERY

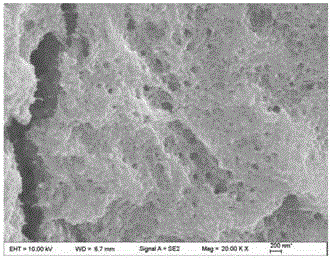

Preparation method for porous lithium zirconate block

The invention discloses a method for a porous lithium zirconate block. The method comprises the following steps sequentially: (1), dissolving inorganic zirconium salt, inorganic lithium salt, a complexing agent and a phase separation inducer in a solvent, and stirring until a transparent clear solution is obtained; (2), slowly adding a gel accelerator into the transparent clear solution, uniformly stirring, and ultrasonically processing in an ultrasonic instrument until air bubbles in the solution are removed; (3), putting a homogenous solution obtained in the step (2) into a container, sealing, and gelling at 60-90 DEG C for 5-25 minutes to obtain wet gel; (4), ageing the wet gel obtained in the step (3) at 60-90 DEG C for 4-10 hours; (5), drying the aged gel obtained in the step (4) at 20-50 DEG C for 50-100 hours, heating to 650-1,200 DEG C, and performing heat treatment for 6-12 hours to obtain the porous lithium zirconate block. The porous lithium zirconate block prepared with the method has the characteristics of common continuous porous structure and the like.

Owner:ZHEJIANG UNIV

Ternary composite with core-shell structure and preparation method therefor

InactiveCN107068999ALarge specific surface areaImprove lotion retention capacityCell electrodesSecondary cellsActivated carbonHigh rate

The invention belongs to the field of preparation of lithium ion battery materials, and particularly to a ternary composite with a core-shell structure and preparation method therefor. The composite has the core-shell structure; an inner core is a ternary material; an intermediate layer is a lithium zirconate and activated carbon composite; and an outer layer is a macromolecule polymer material. An experimental process comprises the following steps of firstly preparing a lithium zirconate and activated carbon mixed liquid; then adding the ternary material to obtain a precursor of the ternary material with the core-shell structure; and then adding into a polymer solution for coating the outer layer with the polymer and preparing the ternary composite. The prepared ternary material, depending on a characteristic of the conductivity of lithium ions in the lithium zirconate, improves the conduction velocity of a lithium ion battery; meanwhile, due to the utilization of a large specific surface area of activated carbon, the liquid-absorption ability and the liquid-retention ability of the material as well as the electric double layer effect of the material can be improved; the property of high-rate discharge of the battery can be improved; and the lithium ion battery that applies the prepared material has the characteristics of high safety performance, excellent rate performance, and the like.

Owner:江苏元景锂粉工业有限公司

High-voltage lithium ion battery electrolyte and lithium ion battery

InactiveCN110931876APrevent oxidationGuaranteed high pressure cycle performanceSecondary cellsElectrolytesElectrolytic agentPhysical chemistry

A high-voltage lithium ion battery electrolyte comprises a solvent, a lithium salt and an inorganic film-forming additive, wherein the solvent comprises (2, 2, 2-trifluoroethyl) ethyl ester which accounts for 5 to 15 percent of the weight of the solvent. The high stability of the (2, 2, 2-trifluoroethyl) ethyl ester can prevent the electrolyte from being greatly oxidized on the surface of the anode, so that the high-voltage cycle performance of the electrolyte is ensured, and meanwhile, the capacity retention ratio of the battery is ensured. The addition of the lithium fluozirconate can play arole in regulating and controlling the formation of the SEI film, so that the SEI film is more uniform, the impedance of the SEI film is reduced, and the capacity retention ratio of the battery is further improved. Meanwhile, the lithium fluozirconate can further inhibit oxygenolysis of the electrolyte under high pressure.

Owner:CENT SOUTH UNIV

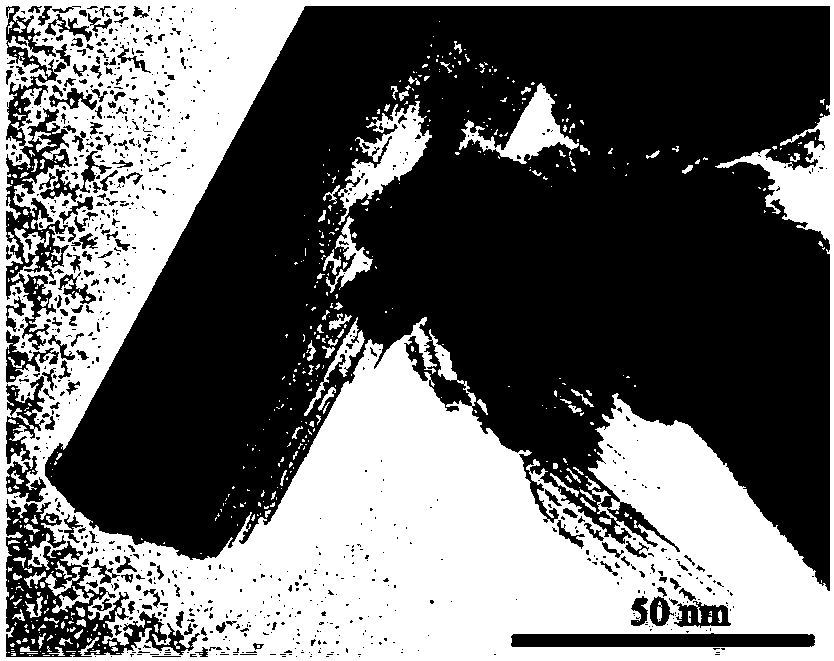

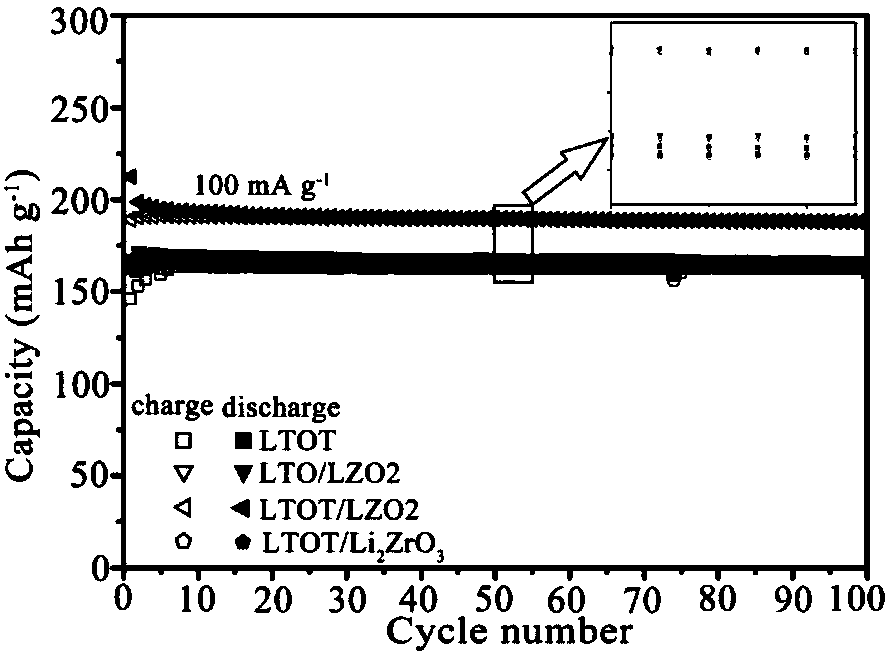

Preparation technique of composite lithium zirconate and modified biphase lithium titanate/titanium dioxide anode material

The invention provides a composite lithium zirconate and modified biphase lithium titanate / titanium dioxide anode material and a preparation method thereof. The material is prepared by the following steps: taking zirconium nitrate and lithium nitrate as the raw materials of composite lithium zirconate, performing uniform mixing with biphase lithium titanate / titanium dioxide, then performing dryingat 100-200 DEG C and performing sintering at 600-800 DEG C for 3-10 hours. The composite lithium zirconate and modified biphase lithium titanate / titanium dioxide is used as an anode material of a lithium ion battery, and the material can have excellent electronic conductivity and ionic conductivity simultaneously; the material can have excellent electrochemical properties without the need of carbon coating; The material has high coulomb efficiency, excellent multiplying power and cycle performance when quickly charged and discharged under higher current density; and the preparation method hasthe advantages of simple steps, convenient operation and high practicability.

Owner:SHANDONG UNIV

Method for manufacturing low-expansion glass-ceramics by high silicon-iron tailings

A method for manufacturing low-expansion glass-ceramics by high silicon-iron tailings comprises the step of perparing a low-expansion glass-ceramics batch which comprises the following materials in parts by weight: 40-45 parts of 80-mesh high-silicon iron tailings, 50-55 parts of 100-mesh quartz sand, 10-15 parts of 100-mesh alumina, 10-15 parts of lithium carbonate, 3-6 parts of zinc oxide, 3-6 parts of barium selenate, 2-5 parts of rare-earth cerium oxide powder, 1-4 parts of lithium zirconate, 2-5 parts of boron nitride, 3-6 parts of praseodymium chloride, 0.2-0.5 part of beryllia, 0.5-0.9 part of bismuth subcarbonate and 0.1-0.4 part of sodium antimonate. The invention aims to provide the method for manufacturing low-expansion glass-ceramics by high silicon-iron tailings, the method can reduce environmental pollution and lower manufacturing cost, and the obtained glass-ceramics is low in thermal expansion coefficient, high in thermal stability and softening temperature and very good in thermal shock resistance.

Owner:BEIJING QING MAI HUA QING HLDG GRP CO LTD

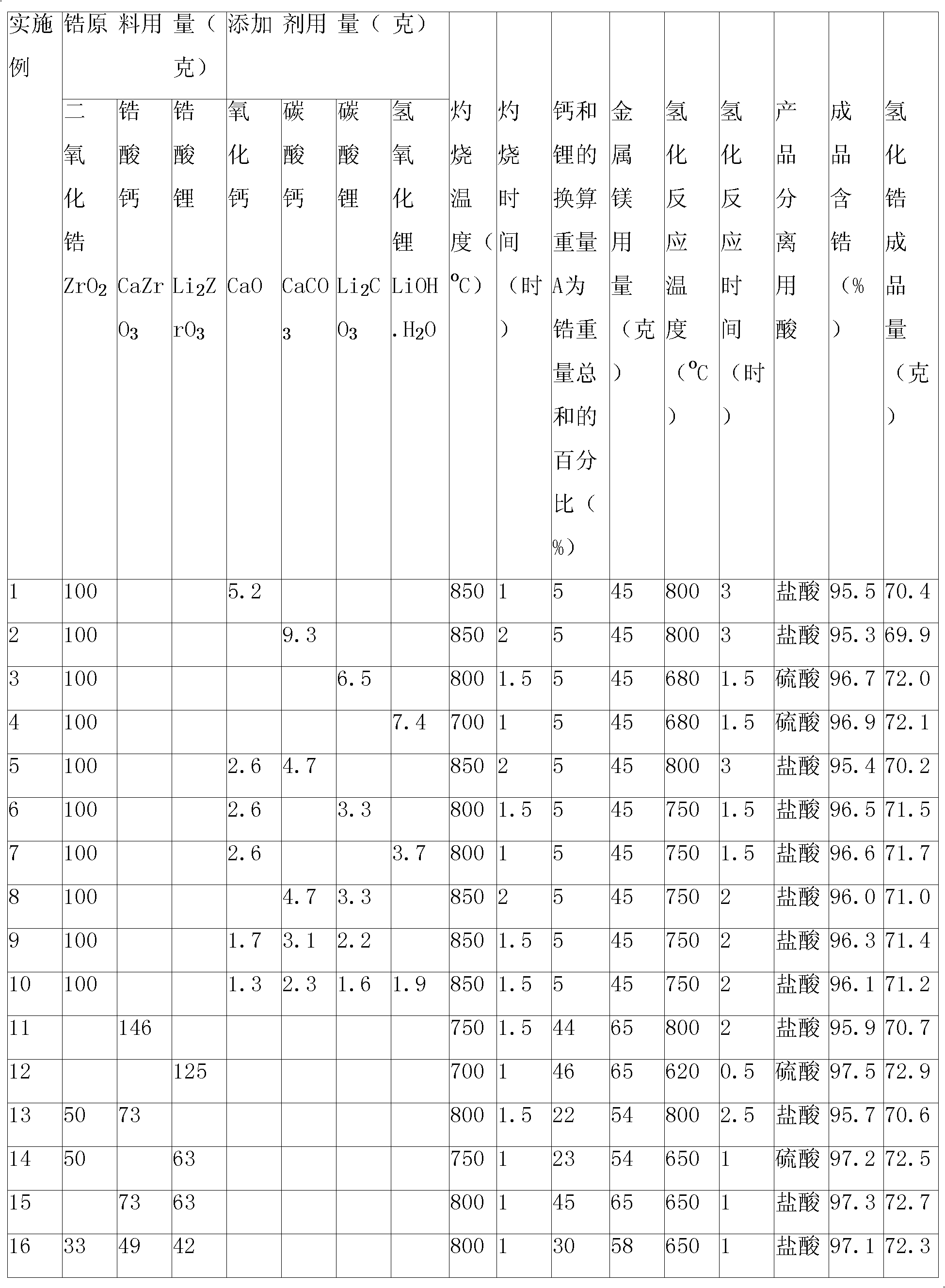

Method for preparing zirconium hydride

InactiveCN101254898ASimple processReduce energy consumptionTransition element hydridesZirconium hydrideHigh volume manufacturing

The invention discloses a method for preparing zirconium hydride, and relates to the technology field of metal smelting. The method includes mixing zirconium material containing zirconia, calcium zirconate or lithium zirconate with the magnesium metal under a calcium or lithium-contained condition; placing into a sealed container, introducing hydrogen and heating to carry out the hydrogenation to convert the zirconium in the reaction material into the zirconium hydride; and removing impurities by using acid to obtain the zirconium hydride. Compared with the prior art, the method has the advantages of greatly reduced comprehensive energy consumption, and process cost reduced by more than 20%, and is applicable for industrial production.

Owner:李健民

Preparation method for lithium zirconium oxide type adsorbent

InactiveCN104148003ARaw materials are easy to getLow costOther chemical processesDispersed particle separationSorbentLithium zirconate

The invention discloses a preparation method for a lithium zirconium oxide type adsorbent. The preparation method comprises the following steps: a lithium source and a zirconium source react in a complexing agent solution to obtain Li2ZrO3 (lithium zirconate), and after the Li2ZrO3 is mixed with carbonate, the Li2ZrO3 and the carbonate react under the temperature of 600-1000 DEG C to obtain the lithium zirconium oxide type adsorbent. The preparation method disclosed by the invention has the advantages that raw materials are easy to obtain, the cost is low, reaction conditions are mild and reaction steps are fewer. Compared with the existing adsorbent, the adsorbing effect of the adsorbent prepared by the method disclosed by the invention is better.

Owner:PURESCI ENVIRONMENTAL TECH CO LTD

Positive pole active matter for non-aqueous electrolyte secondary cell and non-aqueous electrolyte secondary cell

ActiveCN100355125CImprove load characteristicsGood low temperature characteristicsFinal product manufactureCell electrodesElectrical batteryAqueous electrolyte

Owner:NICHIA CORP

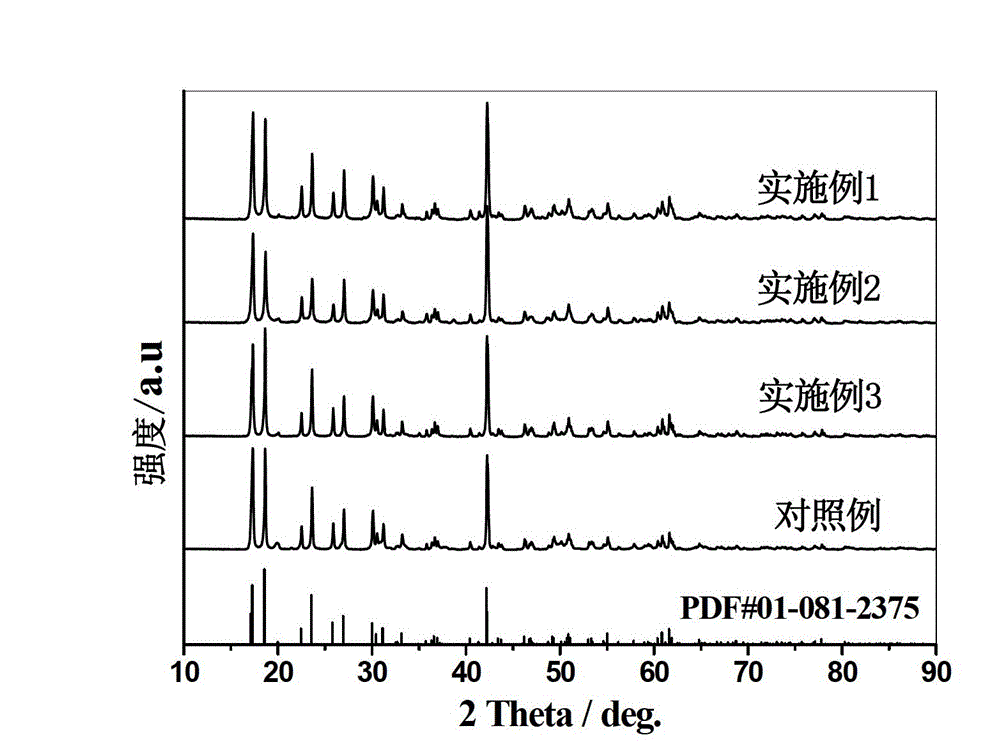

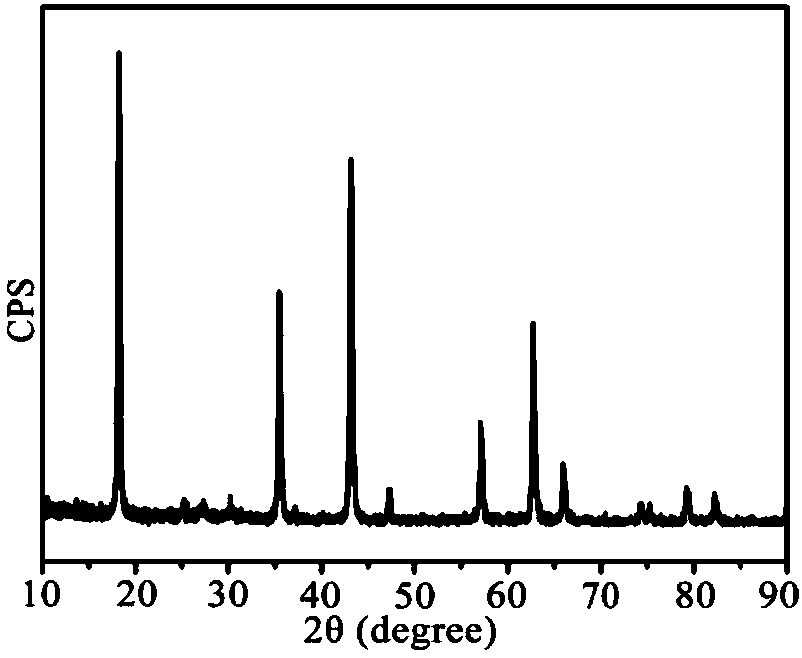

Monoclinic phase lithium zirconate crystal and preparation method and application thereof

InactiveCN102925977AIncrease productionSimple processPolycrystalline material growthFrom frozen solutionsDivalent metalLithium zirconate

The invention relates to monoclinic phase lithium zirconate crystal and a preparation method and application thereof. The monoclinic phase lithium zirconate crystal mixed with M elements is that M ions are mixed in lithium niobate crystal. The chemical formula is Li6 + yZr2 - xMxO7, wherein the x is 0.01 to 0.4, and the M is positive divalent or positive trivalent metal elements. When the M is positive divalent metal elements, the y is equal to 2x; and when the M is positive trivalent metal elements, the y is equal to x. The preparation method is a high temperature solid state method which is high production efficiency, high in product output and high in purity. The application is applied to the aspect of lithium ion battery solid electrolyte. The monoclinic phase lithium zirconate crystal is high in ionic conductivity, good in electrochemical stability, high in safety and wide in application prospect in the field of lithium ion battery.

Owner:HYB BATTERY

A preparation method of lithium-ion battery ternary cathode material double-modified by fast ion conductor and conductive polymer

ActiveCN107706390BImprove cycle performanceImproved magnification performanceCell electrodesSecondary cellsElectrical conductorConductive polymer

The invention discloses a preparation method of a fast ion conductor and conducting polymer dual-modified ternary cathode material for a lithium-ion battery. According to the material, a ternary cathode material for a lithium-ion battery is taken as a core, a fast ion conductor is taken as a first coating layer, a conducting polymer is taken as a second coating layer and the fast ion conductor isany one of lithium vanadate, lithium metaaluminate and lithium zirconate. The fast ion conductor and the ternary cathode material are firstly mixed evenly and ground; the ternary cathode material is coated with the fast ion conductor by using a high-temperature solid state method; the conducting polymer and the ternary cathode material coated with the fast ion conductor are mixed evenly and milled; and the ternary cathode material coated with the fast ion conductor is coated with the conducting polymer to finally obtain the fast ion conductor and conducting polymer dual-modified ternary cathode material for the lithium-ion battery. The fast ion conductor is combined with the conducting polymer to modify the ternary cathode material, so that the ternary cathode material has excellent cycleperformance and good rate capability.

Owner:深圳市云讯新能源科技有限公司

Solid electrolyte and preparation method thereof

InactiveCN102916221BIncrease productionSimple processZirconium compoundsSecondary cellsLithium zirconateLithium-ion battery

The invention relates to a solid electrolyte and a preparation method thereof. The solid electrolyte is formed by monoclinic phase lithium zirconate crystal admixed with M element, and the monoclinic phase lithium zirconate crystal admixed with the M element is that M ions are admixed to lithium niobate crystal and the composition of the chemical formula is Li6+yZr2-xMxO7, wherein X is equal to 0.01-0.4, and M is a positive divalent metal element or a positive trivalent metal element; when M is the positive divalent metal element positive, and Y is equal to 2x; and when the M is the positive trivalent metal element, and y is equal to x. The method comprises steps for preparing the monoclinic phase lithium zirconate crystal admixed with the M element by adopting a high-temperature solid-phase method and dry-pressure sintering, and has the advantages of high production efficiency and high yield and purity; the safety problem of a lithium-ion battery is solved thoroughly because of no use of any liquid organic solvent; and the prepared solid electrolyte has high ionic conductivity, excellent electrochemical stability, and a very wide application prospect.

Owner:HYB BATTERY

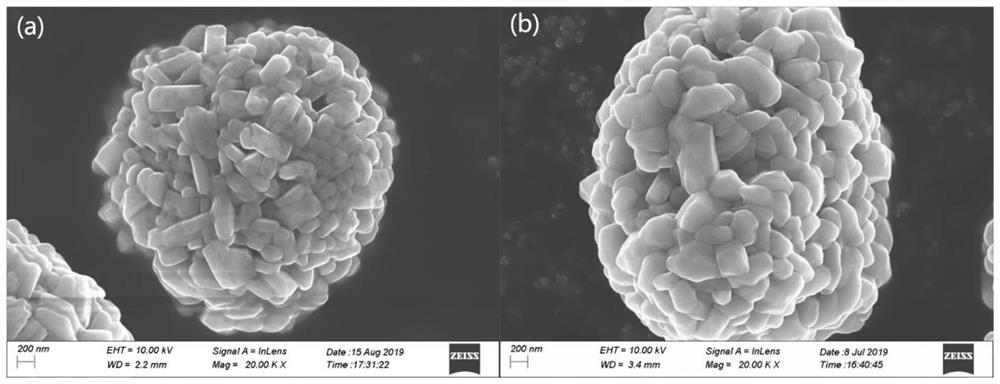

Nanometer lithium zirconate-modified lithium iron phosphate composite material and preparation method thereof

InactiveCN108448099AGood dispersionExcellent low temperature rate performanceMaterial nanotechnologyCell electrodesCarbon layerLithium hydroxide

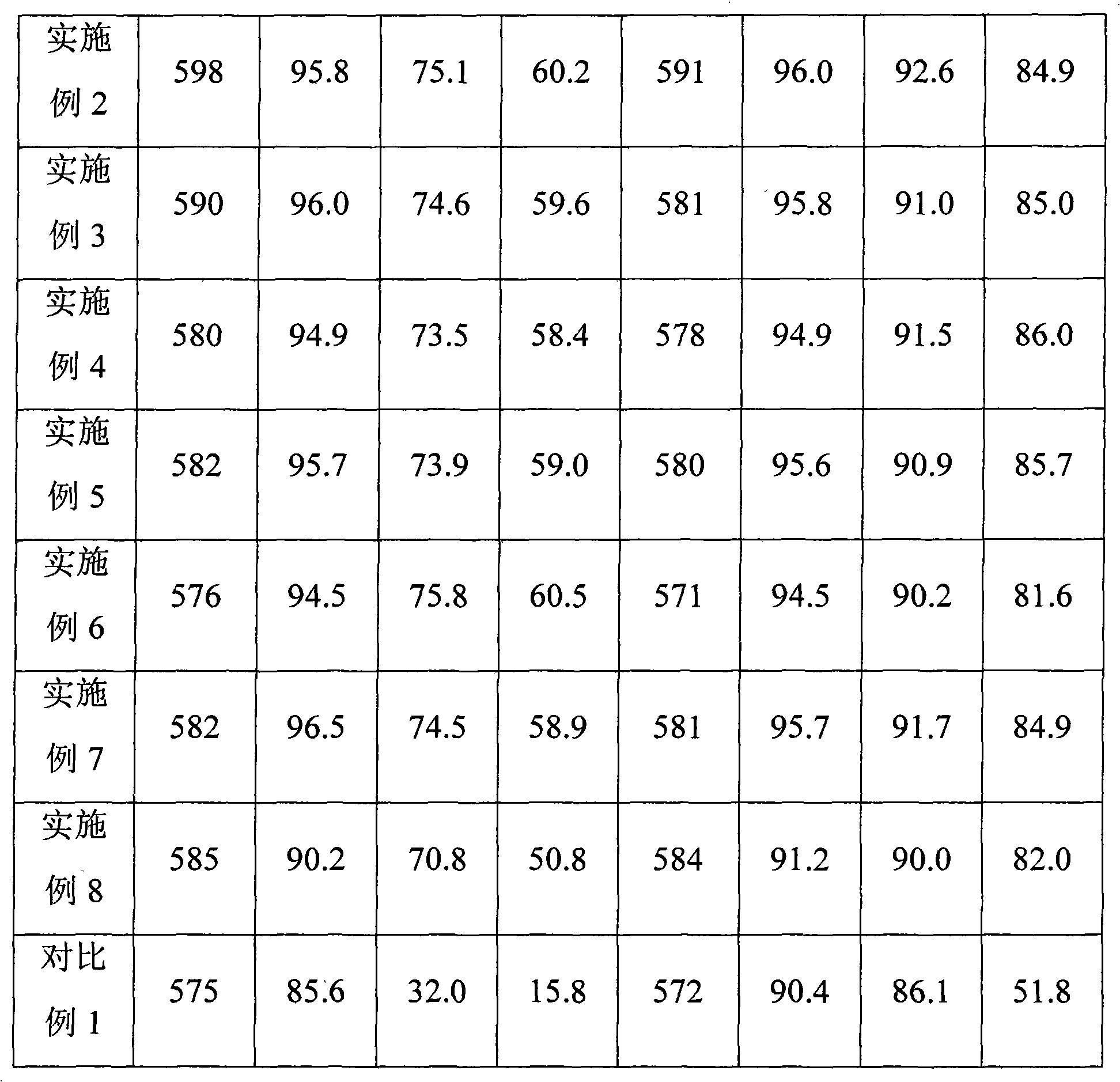

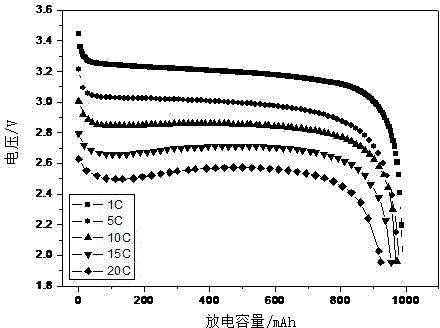

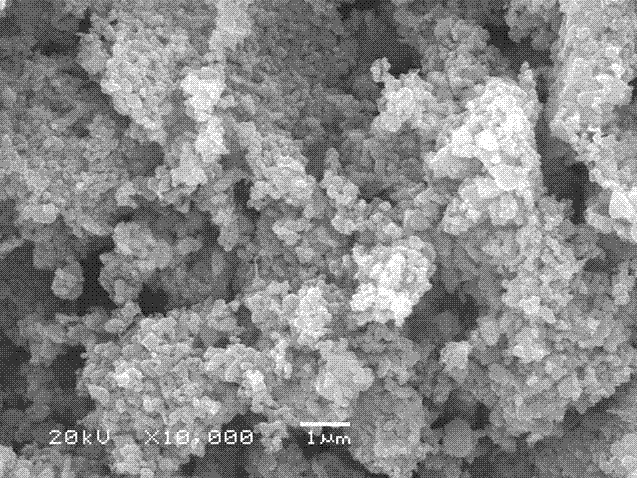

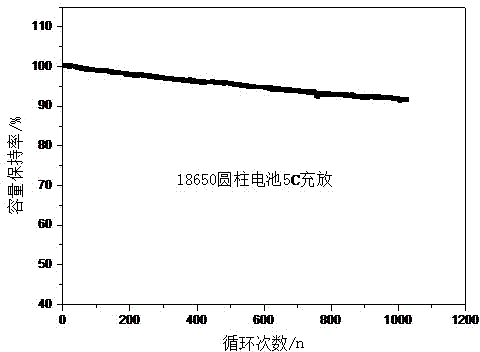

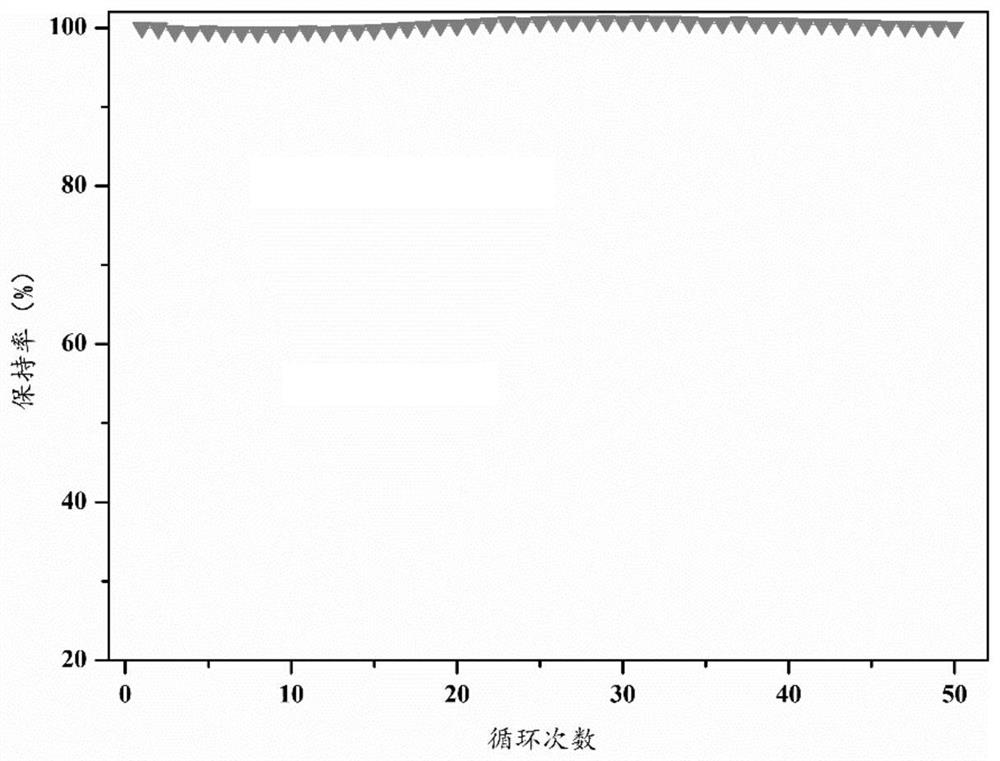

The invention provides a preparation method of a nanometer lithium zirconate-modified lithium iron phosphate composite material. The preparation method comprises the steps of (1) dissolving cocamidopropyl betaine in water to form a solution A; (2) mixing and adding lithium hydrate, ferrous sulfate and phosphoric acid to form a mixed liquid B under protection of nitrogen atmosphere; (3) adding themixed liquid B into a hydrothermal kettle, and performing reaction in advance to obtain a middle product C; (4) adding an aqueous solution containing the cocamidopropyl betaine and polyvinyl pyrrolidone into the middle product C under the nitrogen atmosphere, adding zirconium nitride and excessive amount of lithium hydrate to form a mixed liquid E; (5) performing hydrothermal reaction to obtain amiddle product F; and (6) adding sorbitan laurate into the intermediate product F, and obtaining the composite material after calcination. In the composite material, lithium iron phosphate is used asa core, a nanometer lithium zirconate layer and a carbon layer are sequentially coated from inside to outside, the discharging capacity specific value is 78% or above at -20 DEG C to 25 DEG C, and thecapacity retention ratio after circulation for 1,000 times at 5C is 94% or above.

Owner:烟台市国有资产经营有限公司

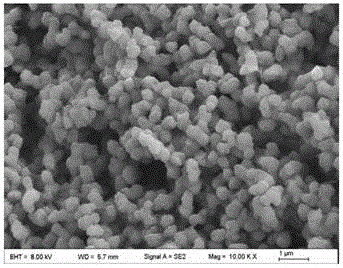

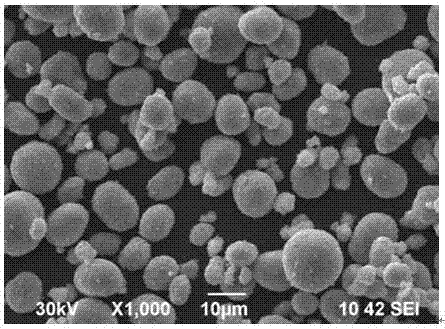

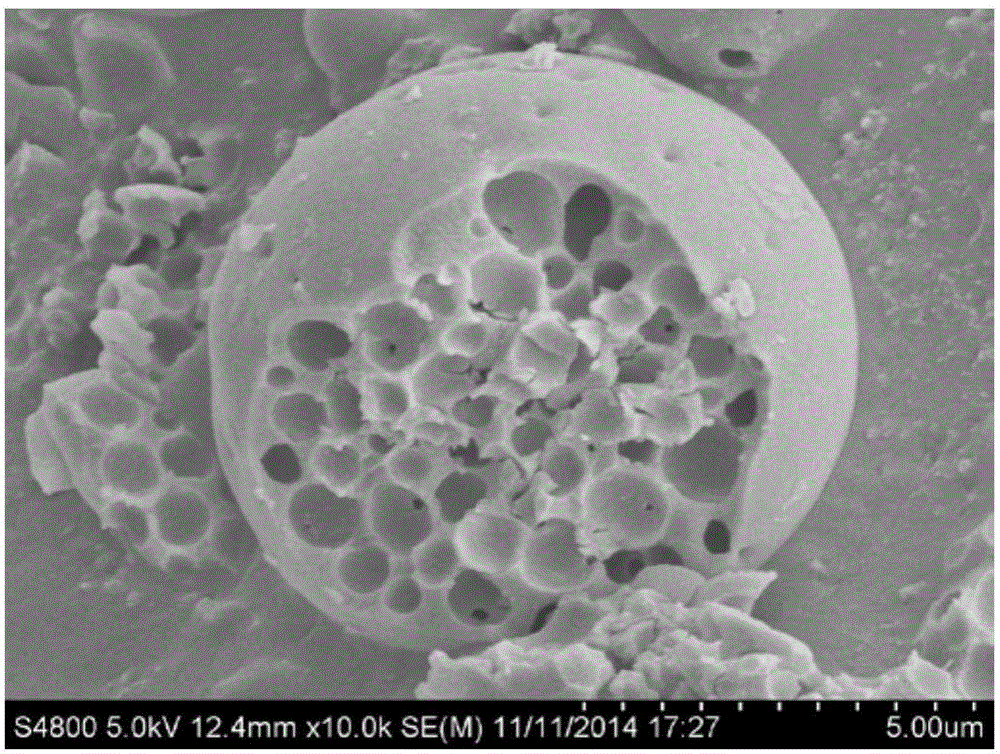

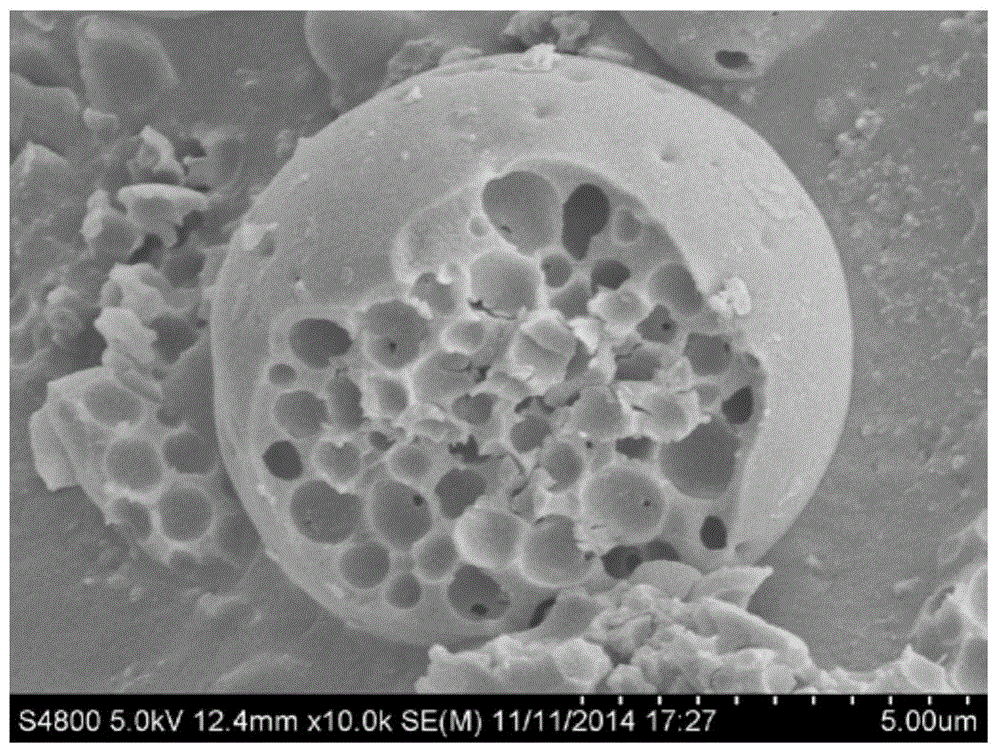

Preparation method of lithium zirconate porous microspheres

The invention discloses a preparation method of a lithium zirconate porous microsphere. The preparation method comprises the following steps: 1) dissolving an emulsifier OP-10 and a surfactant into deionized water, stirring, and obtaining an aqueous phase solution; 2) mixing a chelating agent, zirconium n-propoxide and n-octyl alcohol, stirring, obtaining an oil phase required by an emulsion method, adding span-80, a phase separation inducer and a lithium source into the oil phase, and continuously stirring until the uniform and clear solution is obtained; 3) pouring the uniform and clear solution obtained in the step 2) into the aqueous phase solution, continuously stirring and emulsifying the solution for 22-26 hours at a revolving speed of 800-1200 rpm; 4) performing vacuum filtration, washing and drying to the product obtained in the step 3), so as to obtain the powdered lithium zirconate porous microspheres. The method is relatively simple in process; the reaction conditions are relatively mild; the lithium zirconate porous microsphere with high porosity can be prepared.

Owner:ZHEJIANG UNIV

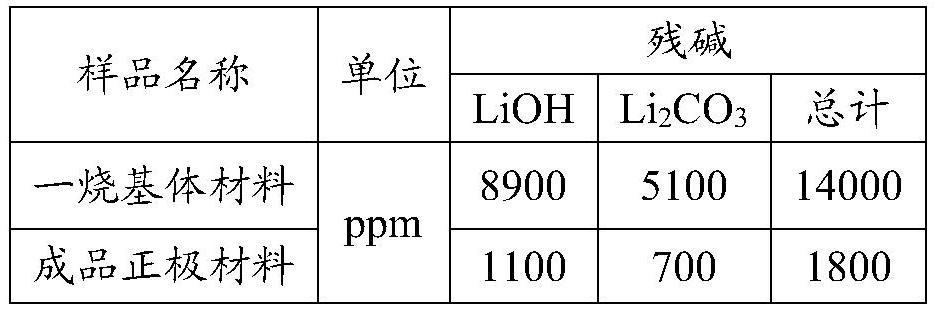

High-nickel ternary positive electrode material and preparation method thereof

The invention relates to a high-nickel ternary positive electrode material and a preparation method thereof. The high-nickel ternary positive electrode material comprises a positive electrode active material and a coating layer, and the positive electrode active material comprises a nano oxide; the nano oxide comprises any one or more of zirconium oxide, titanium oxide, tungsten oxide, molybdenum oxide, aluminum oxide and yttrium oxide; the coating layer comprises lithium zirconate, lithium titanate and lithium cobalt oxide. According to the ternary positive electrode material and the preparation method thereof provided by the invention, residual alkali on the surface of the high-nickel positive electrode material is reduced, the electronic conductivity of the material is increased, and gas production and cycle stability in the cycle process of the positive electrode material are improved.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

Preparation method of lithium zirconate porous microsphere

The invention discloses a preparation method of a lithium zirconate porous microsphere. The preparation method comprises the following steps: 1) dissolving an emulsifier OP-10 and a surfactant into deionized water, stirring, and obtaining an aqueous phase solution; 2) mixing a chelating agent, zirconium n-propoxide and n-octyl alcohol, stirring, obtaining an oil phase required by an emulsion method, adding span-80, a phase separation inducer and a lithium source into the oil phase, and continuously stirring until the uniform and clear solution is obtained; 3) pouring the uniform and clear solution obtained in the step 2) into the aqueous phase solution, continuously stirring and emulsifying the solution for 22-26 hours at a revolving speed of 800-1200 rpm; 4) performing vacuum filtration, washing and drying to the product obtained in the step 3), so as to obtain the powdered lithium zirconate porous microspheres. The method is relatively simple in process; the reaction conditions are relatively mild; the lithium zirconate porous microsphere with high porosity can be prepared.

Owner:ZHEJIANG UNIV

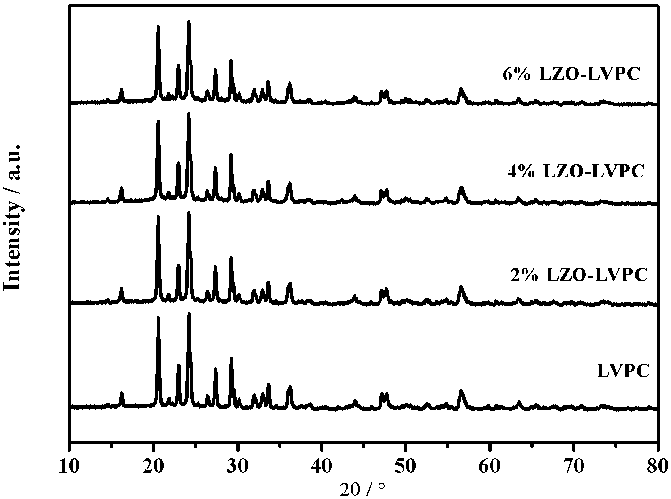

Lithium zirconate-lithium vanadium phosphate composite electrode material and preparation method and application thereof

ActiveCN108539180AImprove stabilityImprove cycle performanceSecondary cellsPositive electrodesComposite electrodeLithium carbonate

The invention provides lithium zirconate-lithium vanadium phosphate composite electrode material, comprising lithium vanadium phosphate, and elemental carbon and lithium zirconate which sequentially coat the surface of the lithium vanadium phosphate; coating of the elemental carbon and lithium zirconate helps effectively increase the specific capacity of the material and improve its cycle performance. In addition, the invention also provides a preparation method and application of the lithium zirconate-lithium vanadium phosphate composite electrode material; the preparation method is simple and easily operable, is suitable for the preparation of electrode materials evenly coated with elemental carbon and lithium carbonate, and has a promising application prospect.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Method for preparing zirconium hydride

InactiveCN101254898BSimple processReduce energy consumptionTransition element hydridesZirconium hydrideHigh volume manufacturing

The invention discloses a method for preparing zirconium hydride, and relates to the technology field of metal smelting. The method includes mixing zirconium material containing zirconia, calcium zirconate or lithium zirconate with the magnesium metal under a calcium or lithium-contained condition; placing into a sealed container, introducing hydrogen and heating to carry out the hydrogenation toconvert the zirconium in the reaction material into the zirconium hydride; and removing impurities by using acid to obtain the zirconium hydride. Compared with the prior art, the method has the advantages of greatly reduced comprehensive energy consumption, and process cost reduced by more than 20%, and is applicable for industrial production.

Owner:李健民

Preparation method of lithium ion conductor coated lithium-rich manganese-based positive electrode material

InactiveCN112607790AImprove electrochemical performanceInhibit side effectsZirconium compoundsSecondary cellsElectrical conductorManganese

The invention discloses a preparation method of a lithium ion conductor coated lithium-rich manganese-based positive electrode material, which comprises the following steps: dispersing a carbonate precursor and lithium carbonate in absolute ethyl alcohol according to a molar ratio of 1:1.02-1.5, uniformly stirring and mixing, drying to obtain powder, putting the obtained powder into a muffle furnace, and carrying out heat preservation twice to obtain the lithium-rich manganese-based positive electrode material; dissolving zirconium oxynitrate and lithium nitrate in 40-80mL of absolute ethyl alcohol, adding urea, stirring until complete dissolution, adding the lithium-rich manganese-based positive electrode material, continuously stirring until uniform, sealing the obtained mixed solution in polytetrafluoroethylene, heating to 120-150 DEG C in a drying oven, keeping for 15-20 hours, cooling to room temperature, performing vacuum filtration, washing, and drying at 80 DEG C for 12 hours, collecting the material powder, putting into a muffle furnace, heating to 500 DEG C, keeping the temperature for 3-6 hours, and cooling to room temperature along with the furnace to obtain the lithium zirconate coated lithium-rich manganese positive electrode material.

Owner:TIANJIN NORMAL UNIVERSITY

High-temperature adsorption filtering agent capable of absorbing carbon dioxide and preparation method therefor

InactiveCN104826392AEffective absorptionExtended service lifeOther chemical processesFiltration separationPorosityFiber

The present invention discloses a high-temperature adsorption filtering agent capable of absorbing carbon dioxide. The high-temperature adsorption filtering agent capable of absorbing carbon dioxide is characterized by being prepared from the following raw materials in parts by weight: 63-70 parts of barite, 7-11 parts of hydrotalcite, 10-20 parts of coal gangues, 7-9 parts of seaweed carbon fibers, 5-9 parts of nanotitanium dioxide, 1.4-3.5 parts of lithium zirconate, 1-3 parts of manganous nitrate, 2-4 parts of sodium chlorite, 0.8-1.5 parts of cyclopropylboronic acid, 3-5 parts of coal tar, 6-8 parts of a polytetrafluoroethylene emulsion solution and an appropriate amount of water. According to the high-temperature adsorption filtering agent capable of absorbing carbon dioxide, by taking barite as a raw material which is matched with hydrotalcite, coal gangues, lithium zirconate and the like, nanotitanium dioxide is loaded on the surface of the barite through physical and chemical modification methods to decompose organic pollutants into carbon dioxide and oxygen, so that harmful substances adsorbed onto the barite are reduced, and the service life of the adsorption filtering agent is prolonged. The prepared adsorption filtering agent is coarse and hard in surface, large in specific surface area, high in porosity, good in adsorption and filtration capacity and low in cost, and moreover, carbon dioxide can be efficiently absorbed, so that the discharge rate of carbon dioxide is reduced.

Owner:BENGBU DEMO FILTRATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com