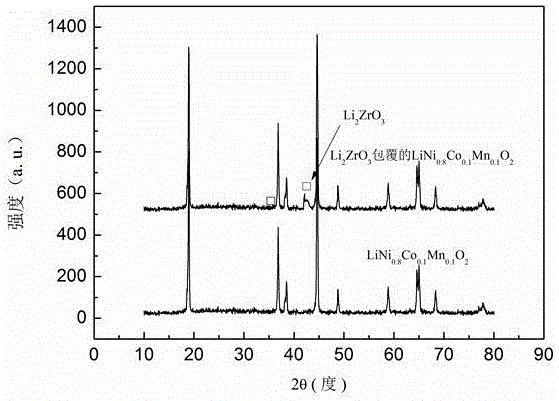

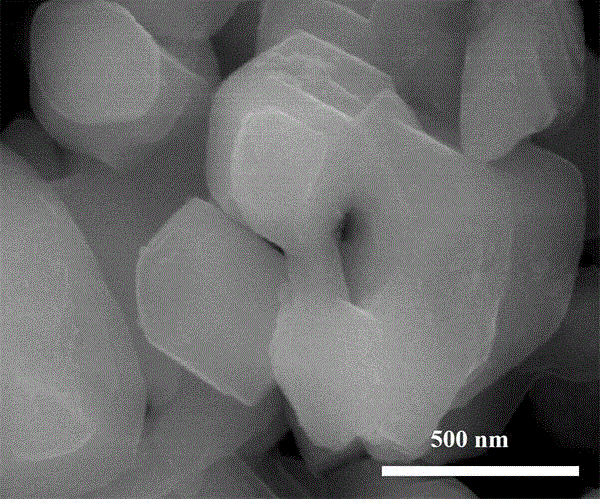

Cobalt-nickel lithium manganate composite positive electrode material with surface wrapped by lithium zirconate and preparation method

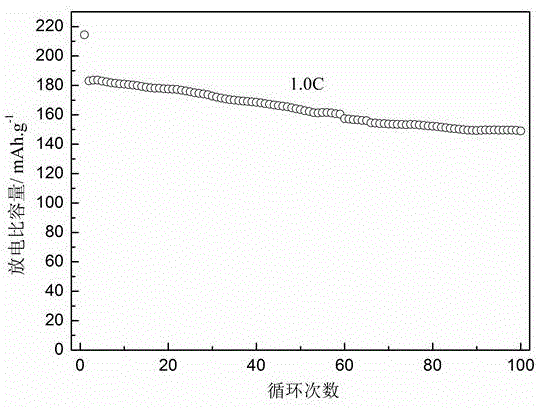

A composite positive electrode material, nickel-cobalt lithium manganese oxide technology, applied in positive electrodes, battery electrodes, active material electrodes, etc., can solve the problems of poor rate performance and cycle performance, and achieve simple process, low cost, and excellent cycle performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A surface-coated Li 2 ZrO 3 LiNi 0.8 co 0.1 mn 0.1 o 2 The preparation method of composite cathode material, its specific steps are as follows:

[0039] (1) Weigh 5.97g of nickel acetate tetrahydrate, 0.75g of cobalt acetate tetrahydrate, and 0.74g of manganese acetate tetrahydrate into 100ml of secondary deionized water, stir well to form a stable suspension A with a concentration of 74.6g / L;

[0040] (2) Weigh 1.24g of lithium acetate and dissolve it in 100ml of secondary deionized water, stir well to form a stable solution B with a concentration of 12.4g / L;

[0041] (3) Add solution B in step (2) dropwise to suspension A in step (1) at a rate of 30ml / min, stir at room temperature for 2h, then place the mixed solution at 90°C and heat 8h, keep stirring during the heating process, and finally heat at 120°C to remove moisture to obtain a dry precursor;

[0042] (4) Grinding the precursor obtained in step (3) in a dry environment for 15 minutes to obtain a dry pre...

Embodiment 2

[0053] A surface-coated Li 2 ZrO 3 LiNi 0.8 co 0.1 mn 0.1 o 2 The preparation method of composite cathode material, its specific steps are as follows:

[0054] (1) Weigh 9.95g of nickel acetate tetrahydrate, 1.25g of cobalt acetate tetrahydrate, and 1.23g of manganese acetate tetrahydrate into 100ml of secondary deionized water, stir well to form a stable suspension A with a concentration of 134.2g / L;

[0055] (2) Weigh 2.10g of lithium acetate and dissolve it in 100ml of secondary deionized water, stir well to form a stable solution B with a concentration of 21.0g / L;

[0056] (3) Add solution B in step (2) dropwise to suspension A in step (1) at a rate of 25ml / min, stir at room temperature for 4 hours, then place the mixed solution at 80°C and heat 10h, keep stirring during the heating process, and finally heat at 120°C to remove moisture to obtain a dry precursor;

[0057] (4) Grinding the precursor obtained in step (3) in a dry environment for 20 minutes to obtain a ...

Embodiment 3

[0063] A surface-coated Li 2 ZrO 3 LiNi 0.8 co 0.1 mn 0.1 o 2 The preparation method of composite cathode material, its specific steps are as follows:

[0064] (1) Weigh 7.96g of nickel acetate tetrahydrate, 1.00g of cobalt acetate tetrahydrate, and 0.99g of manganese acetate tetrahydrate into 100ml of secondary deionized water, stir well to form a stable suspension A with a concentration of 99.5g / L;

[0065] (2) Weigh 1.70g of lithium nitrate and dissolve it in 100ml of secondary deionized water, stir well to form a stable solution B with a concentration of 17.0g / L;

[0066] (3) Add solution B in step (2) dropwise to suspension A in step (1) at a rate of 30ml / min, stir at room temperature for 3h, then place the mixed solution at 70°C and heat 12h, keep stirring during the heating process, and finally heat at 110°C to remove moisture to obtain a dry precursor;

[0067] (4) Grinding the precursor obtained in step (3) in a dry environment for 15 minutes to obtain a dry pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com