High-nickel ternary positive electrode material and preparation method thereof

A technology of positive electrode material and positive electrode active material, which is applied in the field of low surface residual alkali and high nickel positive electrode material and its preparation, and can solve the problems of battery flatulence, coating difficulty, structure collapse and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

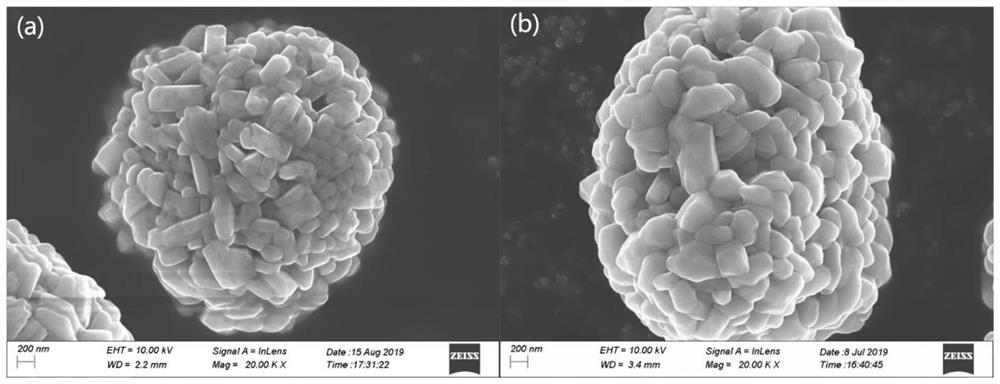

Image

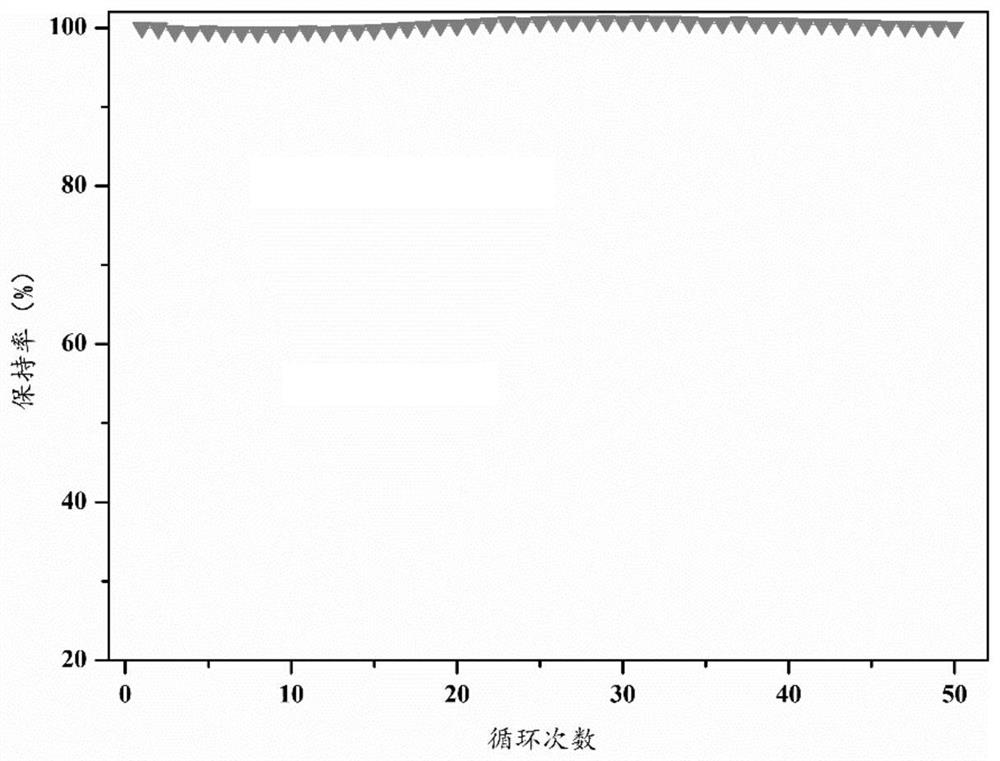

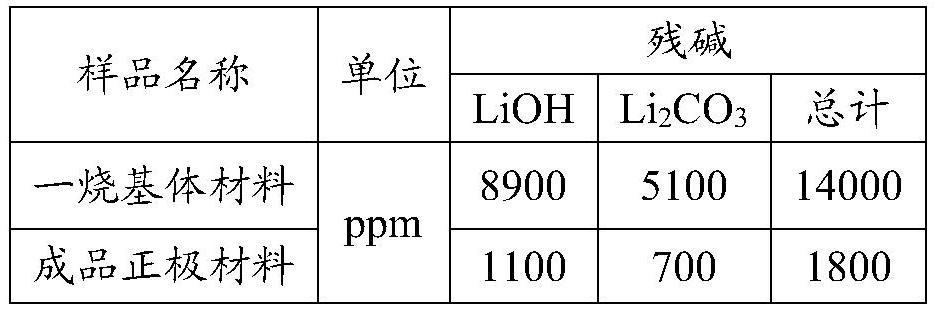

Examples

Embodiment 1

[0048] In this embodiment, the synthesis method of the low surface residual alkali and high nickel positive electrode material is as follows:

[0049] S1. Weigh the precursor, lithium hydroxide and nano-oxide for mixing stage

[0050] The hydroxide precursor Ni 0.83 co 0.11 mn 0.06 (OH) 2 (x≥0.8, x+y+z=1) and lithium hydroxide are added to the high-speed mixer according to the molar ratio of the sum of the moles of nickel, cobalt, manganese and lithium element at 1:1.05, and then add nickel, cobalt, manganese and three Nano-zirconia with a total mass of 2000ppm of the three metals and nano-yttrium oxide with a total mass of 2000ppm of the three metals of nickel, cobalt and manganese are uniformly mixed in a high-speed mixer. Mixing conditions: rotating speed 2000rpm, mixing materials for 20 minutes, to obtain a uniform primary mixture.

[0051] The average particle diameter of the nano oxide raw material is 100nm to 500nm;

[0052] S2. Primary sintering stage of precurso...

Embodiment 2

[0061] The difference between this embodiment and embodiment 1 is that the molar ratio of the lithium element to the total amount of nickel, cobalt and manganese elements in step S1 is 1.0, and other conditions and parameters are exactly the same as in embodiment 1.

Embodiment 3

[0063] The difference between this example and Example 1 is that the molar ratio of the lithium element to the total amount of nickel, cobalt, and manganese elements in step S1 is 1.1:1, and other conditions and parameters are exactly the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com