Lithium zirconate-lithium vanadium phosphate composite electrode material and preparation method and application thereof

A lithium vanadium phosphate and composite electrode technology, applied in the direction of positive electrode, battery electrode, active material electrode, etc., can solve the problems of unsuitable large-scale production, low lithium ion diffusion, affecting rate performance, etc., to achieve easy control and improve specific capacity. , the effect of improving quality and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

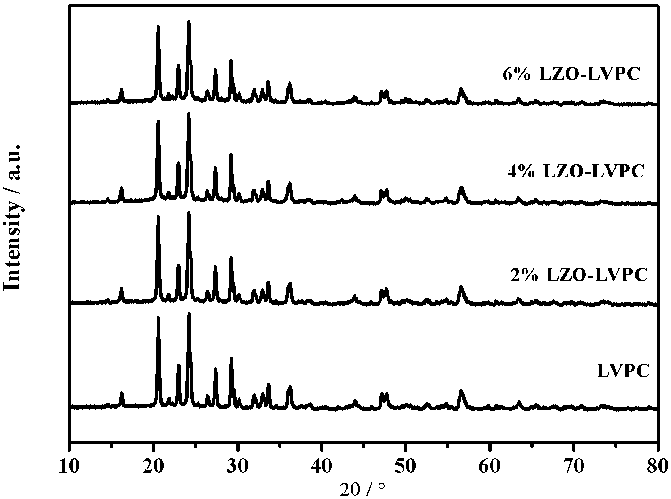

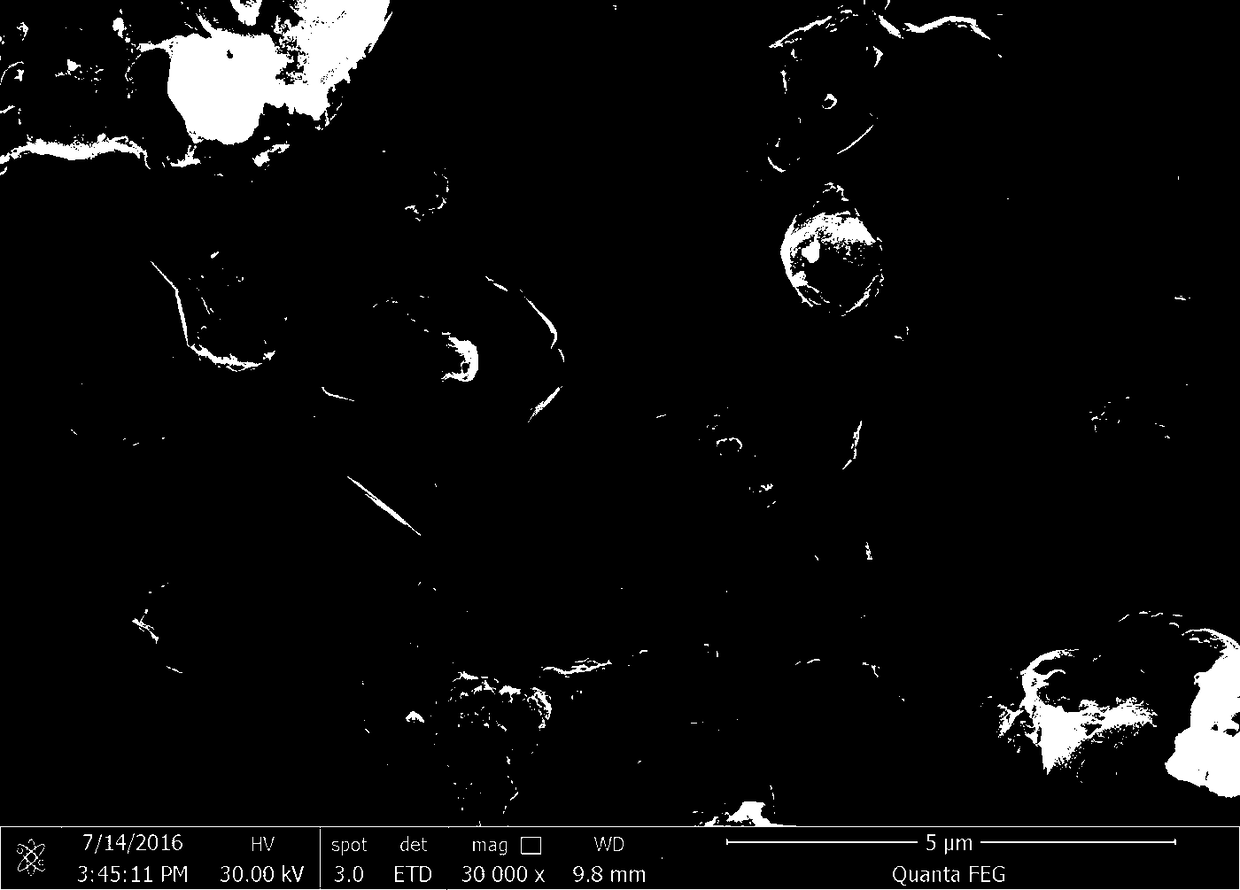

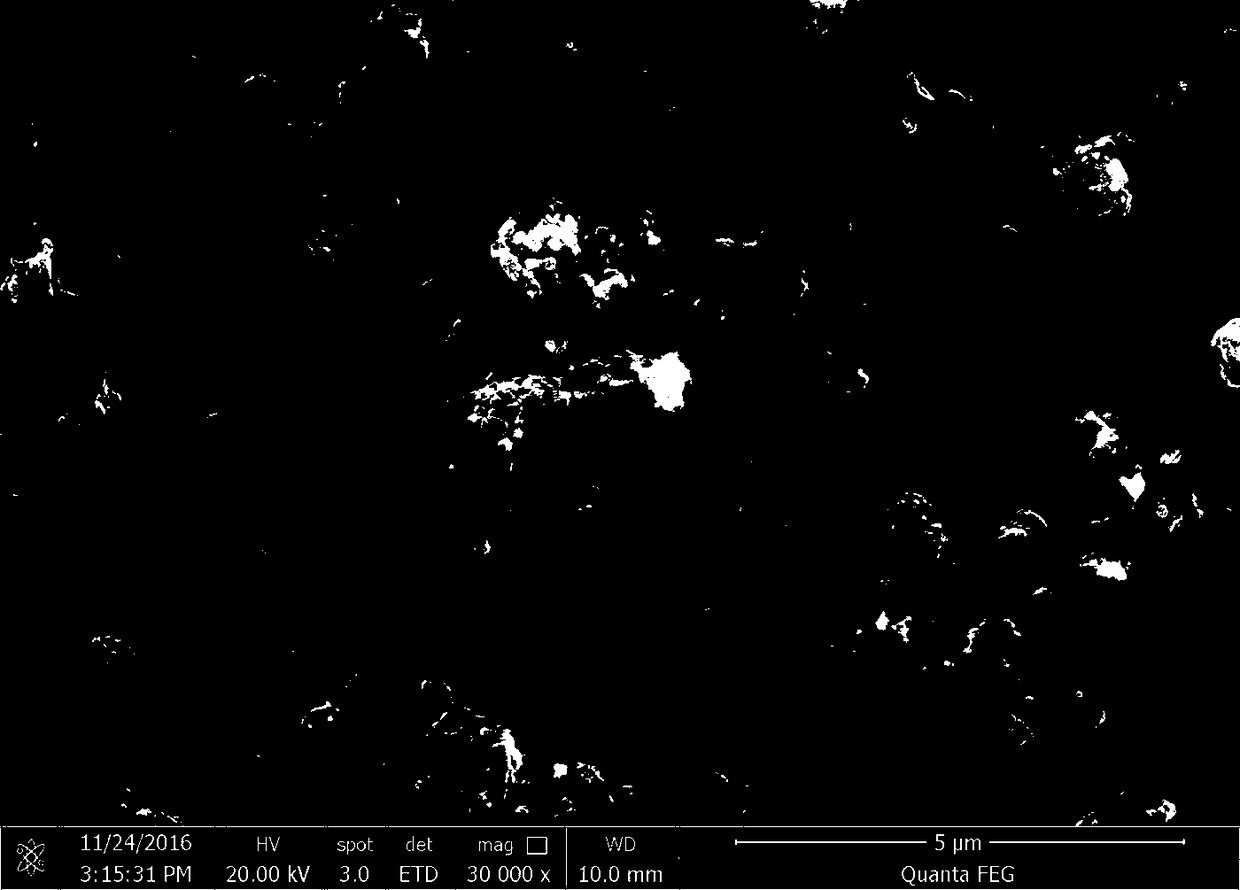

[0038] This embodiment provides a lithium zirconate-lithium vanadium phosphate composite electrode material, which includes lithium vanadium phosphate, carbon simple substance and lithium zirconate coated on the surface of the lithium vanadium phosphate in sequence.

[0039] This embodiment also provides a preparation method of the lithium zirconate-lithium vanadium phosphate composite electrode material, which includes the following steps:

[0040] Lithium vanadium phosphate precursor is prepared according to the molar ratio of lithium element, vanadium element, carbon element, phosphorus element is 3.1:2:12:3, lithium hydroxide, vanadium pentoxide, tartaric acid and phosphoric acid are ground together and mixed evenly , to obtain a mixed raw material; dropwise deionized water was added to the mixed raw material and mixed evenly to obtain a solid-liquid rheological body; the solid-liquid rheological body was kept at 70-90° C. for 5 hours, taken out, ℃ drying for 10 hours to o...

Embodiment 2

[0046] This embodiment provides a lithium zirconate-lithium vanadium phosphate composite electrode material, which includes lithium vanadium phosphate, carbon simple substance and lithium zirconate coated on the surface of the lithium vanadium phosphate in sequence.

[0047] This embodiment also provides a preparation method of the lithium zirconate-lithium vanadium phosphate composite electrode material, which includes the following steps:

[0048] The lithium vanadium phosphate precursor is prepared according to the molar ratio of lithium element, vanadium element, carbon element, and phosphorus element at a ratio of 3.1:2:12:3, and lithium carbonate, ammonium metavanadate, citric acid, and ammonium dihydrogen phosphate are co-ground , and mix uniformly to obtain a mixed raw material; add deionized water dropwise to the mixed raw material and mix evenly to obtain a solid-liquid rheological body; keep the solid-liquid rheological body at 70-90°C for 8 hours, take it out, and ...

Embodiment 3

[0054] This embodiment provides a lithium zirconate-lithium vanadium phosphate composite electrode material, which includes lithium vanadium phosphate, carbon simple substance and lithium zirconate coated on the surface of the lithium vanadium phosphate in sequence.

[0055] This embodiment also provides a preparation method of the lithium zirconate-lithium vanadium phosphate composite electrode material, which includes the following steps:

[0056] Lithium vanadium phosphate precursor is prepared according to the molar ratio of lithium element, vanadium element, carbon element, phosphorus element is 3.1:2:12:3, lithium carbonate, vanadium pentoxide, salicylic acid and phosphoric acid are ground together, mixed homogeneously, to obtain the mixed raw material; dropwise add deionized water to the mixed raw material and mix evenly to obtain the solid-liquid rheological variant; keep the solid-liquid rheological variant at 70-90°C for 6 hours, take it out, and heat it at 90-90°C D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com