Preparation method of lithium zirconate porous microsphere

A technology of porous microspheres and lithium zirconate, applied in the field of porous materials, can solve problems such as difficult to meet the requirements of adsorption materials and performance, and achieve the effect of high temperature reaction conditions, simple equipment requirements, and simple processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

[0036] Embodiment 1-1, the preparation method of lithium zirconate porous microspheres, comprises the following steps:

[0037] 1) Dissolve 0.5g of emulsifier OP-10 and 1g of Tween80 in 30g of deionized water to obtain the water phase required by the emulsion method, and continue stirring for 1 hour at a speed of 1000r / min in a high-speed disperser to obtain an aqueous phase solution;

[0038] 2), 2.0g of acetylacetone, 8.4g of zirconium n-propoxide (0.026mol) and 10g of n-octanol were mixed, and stirred at a speed of 500r / min at room temperature for 1h, as the oil phase required by the emulsion method; thereafter, to the obtained oil Add 0.5 g of Span 80, 0.5 g of polyacrylamide and 13.6 g (0.052 mol) of lithium methoxide into the phase, and continue stirring (500 r / min) at room temperature for about 1 hour to obtain a homogeneous and clear solution.

[0039] (3) According to step 2) the obtained uniform clear solution and step 1) gained water phase solution are 1:10 mass rat...

Embodiment 1-2

[0042] Embodiment 1-2, changing the amount of polyacrylamide from 0.5 g to 1.0 g; the rest are the same as in embodiment 1-1.

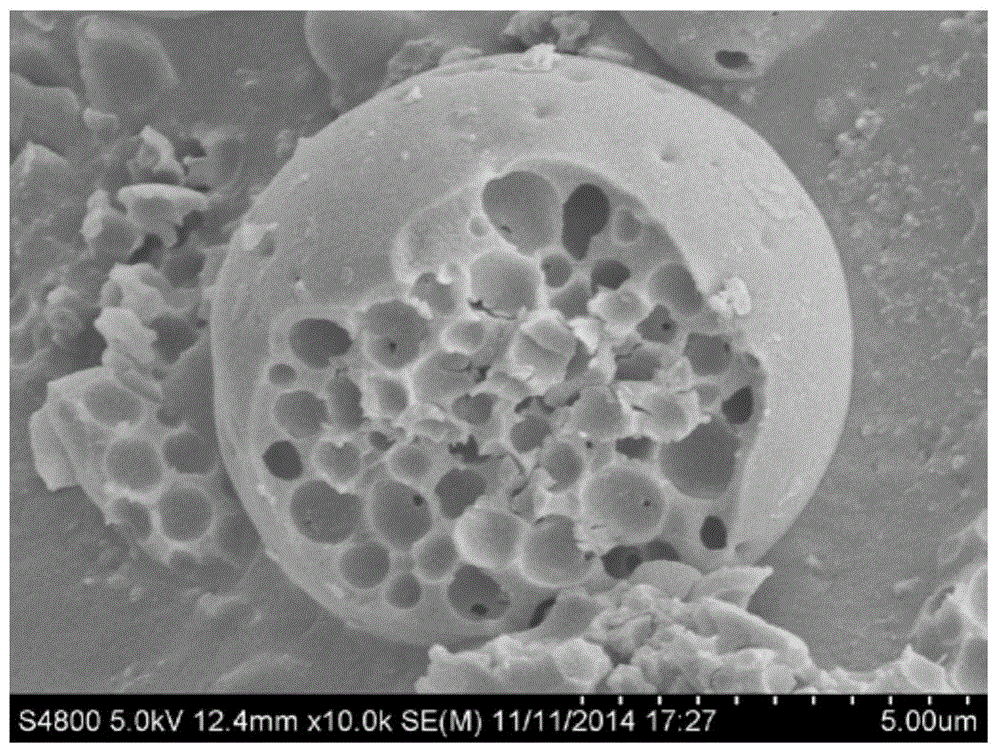

[0043]The SEM and particle size distribution tests of lithium zirconate porous microspheres show that the porous microspheres all have a smooth surface structure with a size of 20-40 μm. ~2.1 μm.

Embodiment 1-3

[0044] Embodiment 1-3, the amount of polyacrylamide is changed from 0.5g to 1.5g, and the rest are the same as embodiment 1-1.

[0045] The SEM and particle size distribution tests of lithium zirconate porous microspheres show that the porous microspheres have a smooth surface structure with a size of 20-40 μm, and the interior of the microspheres is a structure of interconnected and closed pores, and the closed pores have a diameter of 1.0 μm. ~2.5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com