Method for preparing zirconium hydride

A technology of zirconium hydride and zirconium oxide, applied in the direction of transition element hydride, can solve the problems of difficulty, high cost, high price, etc., and achieve the effects of reduced processing cost, reduced comprehensive energy consumption, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Below in conjunction with specific embodiment, the present invention is described in further detail:

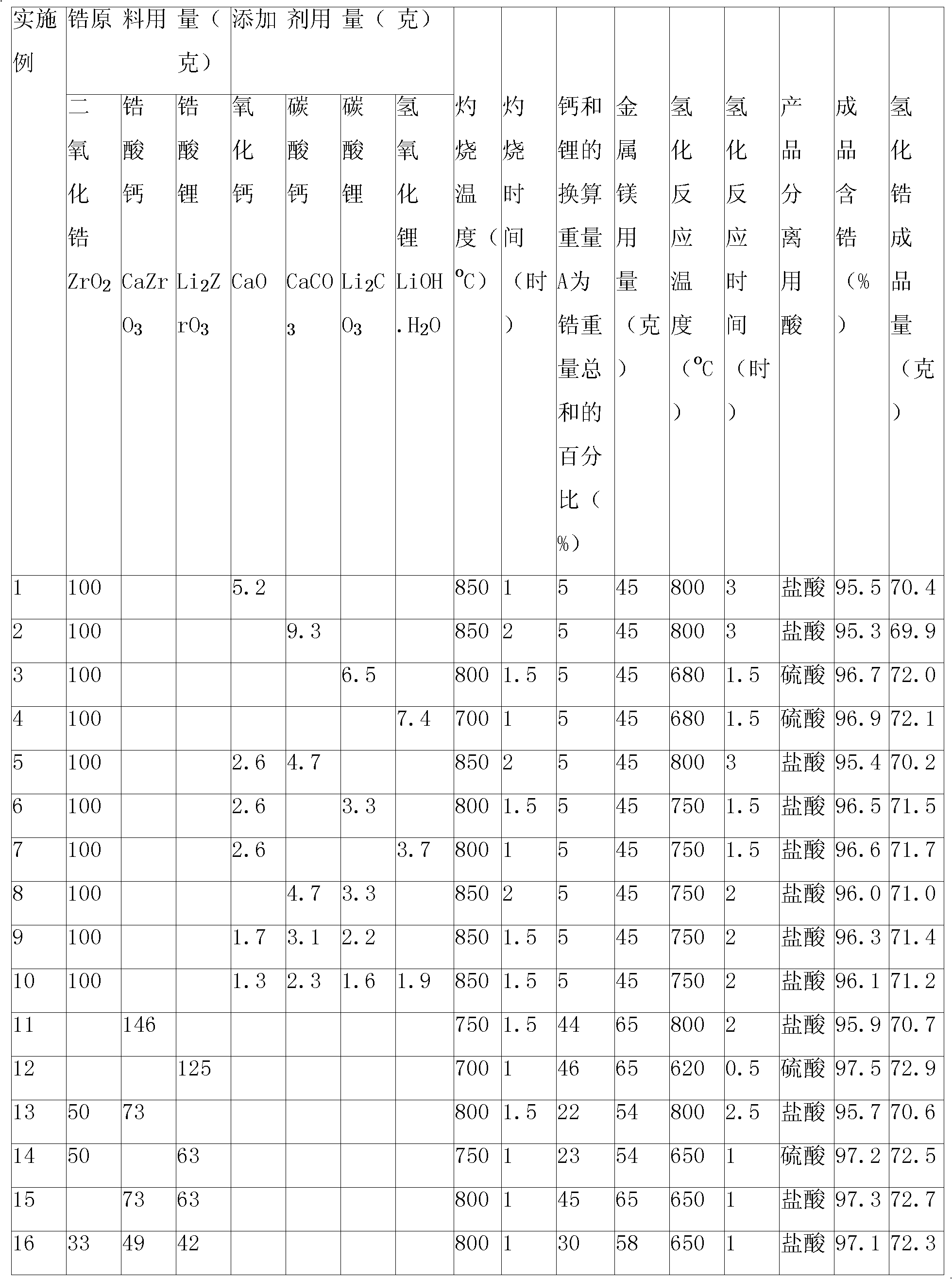

[0009] 16 examples of the preparation method of zirconium hydride:

[0010] 1. Determine the type and amount of zirconium raw materials according to the convenience of raw materials and equipment conditions.

[0011] 2. Select additives. According to the selection of different additives, the conversion weight A of calcium and lithium in the hydrogenation reaction is more than 5% of the sum of the zirconium weights. The amount of each substance used as the additive is selected, and the conversion weight A=B+3C, wherein B is the weight sum of calcium in the hydrogenation reaction material, and C is the weight sum of lithium in the hydrogenation reaction material.

[0012] 3. The amount of metal magnesium is determined by converting the oxygen in the reaction material into magnesium oxide and the excess is 10%.

[0013] 4. The selected zirconium raw material (in the emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com