Nanometer lithium zirconate modified lithium iron phosphate composite material and preparation method thereof

A technology of lithium iron phosphate and composite materials, applied in the direction of phosphorus compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of lithium iron phosphate hindering the application and development, low temperature and poor rate performance, and no continuity, etc. Excellent electrical conductivity and cycle stability, high rate and low temperature performance, and the effect of improving electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

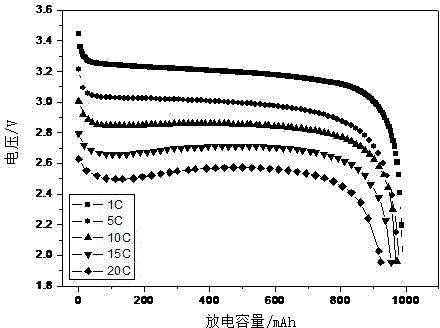

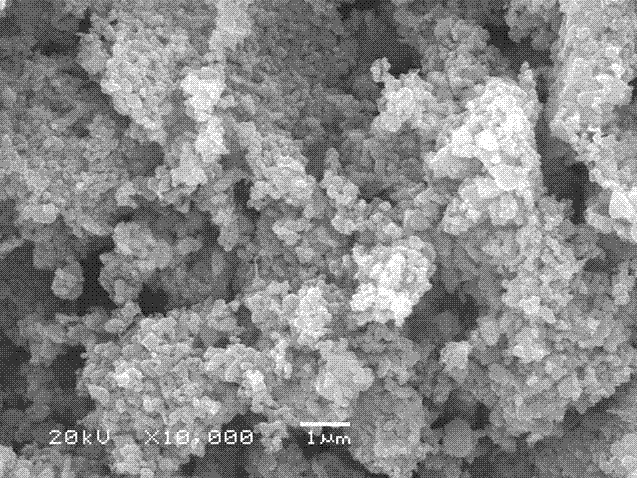

[0031] Weigh 42.38 g of lithium hydroxide (monohydrate), 176.29 g of ferrous oxalate (dihydrate), 122.50 g of 80% phosphoric acid, and 1.53 g of nano-lithium zirconate, and add them to a reaction kettle with 2L of deionized water, stir Mix for 1.5 hours, then add 1.60g of citric acid, adjust the pH to 6.8 with 20% ammonia water, the filling degree is 60%, close the reaction kettle and stir vigorously, adjust the temperature to 90°C for 4 hours, then raise the temperature to 180°C for 7 hours , and then cooled to room temperature. The reaction product was evaporated to dryness at 70°C, then dried at 110°C for 2.5 hours, and 15.82g of microcrystalline cellulose was added, mixed in a high-speed mixer for 40 minutes, and then heated to 700°C at a heating rate of 10°C / min. ℃, in a nitrogen atmosphere for 6 hours, after crushing and sieving, the composition is Li 1.01 Fe 0.98 PO 4 0.01 Li 2 ZrO 3 / C lithium iron phosphate composite material, the carbon content is 2.5% as tested...

Embodiment 2

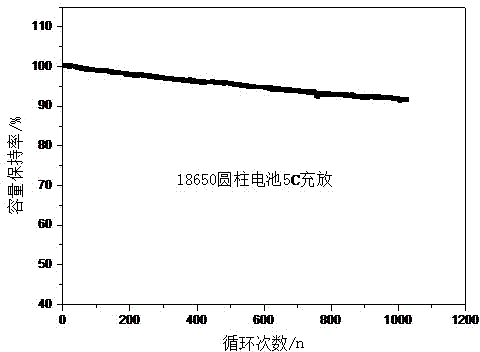

[0035] Weigh 59.39 g of lithium acetate, 156.54 g of ferrous acetate, 115.02 g of ammonium dihydrogen phosphate and 15.31 g of nano-lithium zirconate, and add them to a reaction kettle with 2.5 L of deionized water, stir and mix for 1.5 hours, then add poly Ethylene glycol 0.33g, adjust the pH=6 with 20% ammonia water, the filling degree is 50%, close the reaction kettle and stir vigorously, adjust the temperature to 50°C for 3 hours, then raise the temperature to 140°C for 5 hours, then cool to room temperature . The reaction product was evaporated to dryness at 90°C, then dried at 100°C for 2 hours, added 50.04 g of glucose, mixed in a high-speed mixer for 30 minutes, and then heated to 650°C at a rate of 10°C / min. Insulated under air atmosphere for 12 hours, after pulverization and sieving, the composition of Li 0.9 Fe 0.9 PO 4 0.1 Li 2 ZrO 3 / C lithium iron phosphate composite material, the carbon content is 5.5% as tested by the carbon sulfur analyzer.

[0036] Acco...

Embodiment 3

[0038] Weigh 40.64 g of lithium carbonate, 269.44 g of ferric citrate, 132.06 g of diammonium hydrogen phosphate and 3.06 g of nano-lithium zirconate, and add them to a reaction kettle with 3.5 L of deionized water, stir and mix for 2 hours, then add laurel Acid 6.68g, use 20% ammonia water to adjust pH=9, filling degree is 70%, close the reaction kettle and continue to stir, adjust the temperature to 100°C for 3 hours, then raise the temperature to 200°C for 8 hours, then cool to room temperature. Evaporate the reaction product to dryness at 80°C, then dry it at 110°C for 2.5 hours, add 8.35g of methylcellulose, mix it in a high-speed mixer for 1 hour, and then raise the temperature to 800°C at a heating rate of 10°C / min , kept under an argon atmosphere for 12 hours, after crushing and sieving, the composition of Li 1.1 Fe 1.1 PO 4 0.02Li 2 ZrO 3 / C lithium iron phosphate composite material, the carbon content is 1.5% as tested by the carbon sulfur analyzer.

[0039] Acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com