High-voltage lithium ion battery electrolyte and lithium ion battery

A lithium-ion battery and electrolyte technology, applied in the field of lithium-ion batteries, can solve the problems of thick SEI film, poor cycle performance, and little attention to solvents, etc., to inhibit oxidation and decomposition, uniform SEI film, and ensure high-voltage cycle performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

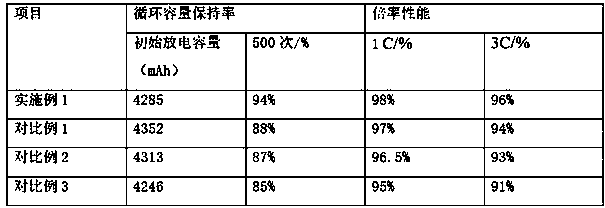

Examples

Embodiment 1

[0032] Ethylene carbonate, methyl vinyl carbonate, (2,2,2-trifluoroethyl) ethyl ester and methyl ethyl ketone are configured into a multi-component blend solvent at a mass ratio of 4:3:1:1, and then added to the above Lithium salt (lithium hexafluorocarbonate) and inorganic film-forming additive (lithium fluorozirconate) are added to the multi-component blending solvent to prepare high-voltage lithium-ion battery electrolyte 1, wherein the amount of lithium hexafluorocarbonate is 1.5mol / L, the amount of the inorganic film-forming additive accounts for 5% of the total mass of the electrolyte.

[0033] A lithium-ion battery 1 was prepared using the above-mentioned high-voltage-resistant lithium-ion battery electrolyte 1 by a conventional method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com